Abstract

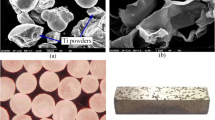

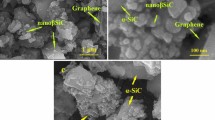

Reduced graphene oxide (rGO) enhanced B4C ceramics was prepared by SPS sintering, the enhancement effect of rGO on the microstructure and mechanical properties of composites was studied through experiments and numerical simulation. The results show that the composite with 2wt% rGO has the best comprehensive mechanical properties. Compared with pure boron carbide, vickers hardness and bending strength are increased by 4.8% and 21.96%, respectively. The fracture toughness is improved by 25.71%. The microstructure observation shows that the improvement of mechanical properties is mainly attributed to the pull-out and bridge mechanism of rGO and the crack deflection. Based on the cohesive force finite element method, the dynamic crack growth process of composites was simulated. The energy dissipation of B4C/rGO multiphase ceramics during crack propagation was calculated and compared with that of pure boron carbide ceramics. The results show that the fracture energy dissipation can be effectively increased by adding graphene.

Similar content being viewed by others

References

Levin L, Frage N, Dariel MP. A Novel Approach for the Preparation of B4C-based Ceramics[J]. International Journal of Refractory Metals & Hard Materials, 2000, 18(2–3): 131–135

Roy TK, Subramanian C, Suri AK. Pressureless Sintering of Boron Carbide[J]. Ceramics International, 2006, 32(3): 227–233

Suri AK, Subramanian C, Sonber JK, et al. Synthesis and Consolidation of Boron Carbide: A Review[J]. International Materials Reviews, 2010, 55(1): 4–40

Lee WE, Gilbert M, Murphy ST, et al, Opportunities for Advanced Ceramics and Composites in the Nuclear Sector[J]. Am. Ceram. Soc., 2013, 58(96): 2 005–2 030

Jung CH, Kim C. Sintering and Characterization of Al2O3-B4C Composites[J]. Journal of Materials Science, 1991, 26(18): 5 037–5 040

Kobayashi T, Yoshida K, Yano T. Fabrication of Carbon Nanotube Reinforced Boron Carbide Composite by Hot-pressing Following Extrusion Molding[J]. Key Engineering Materials, 2014, 616: 27–31

Geim AK, Novoselov KS. The Rise of Graphene[J]. Nature Materials, 2007, 6(22): 52–65

Balandin, Alexander A. Thermal Properties of Graphene and Nanostructured Carbon Materials[J]. Nature Materials, 2011, 10(8): 569

Porwal H, Grasso S, Reece MJ. Review of Graphene-ceramic Matrix Composites[J]. Advances in Applied Ceramics, 2015, 112(8): 443–454

Yun C, Feng YB, Qiu T, et al. Mechanical, Electrical, and Thermal Properties of Graphene Nanosheet/Aluminum Nitride Composites[J]. Ceramics International, 2015, 41(7): 8 643–8 649

Ahmad I, Islam M, Abdo HS, et al. Toughening Mechanisms and Mechanical Properties of Graphene Nanosheet-reinforced Alumina[J]. Materials & Design, 2015, 88(25): 1 234–1 243

Tan Y, Zhang H, Peng S. Electrically Conductive Graphene Nanoplatelet/Boron Carbide Composites with High Hardness and Toughness[J]. Scripta Materialia, 2016, 114: 98–102

Richard, Sedlák, Alexandra, et al. Boron Carbide/Graphene Platelet Ceramics with Improved Fracture Toughness and Electrical Conductivity[J]. Journal of the European Ceramic Society, 2017, 37(12): 3 773–3 780

Rajath A, Ch MTSR, Vasanthakumar K, et al. In-situ Synthesis and Densification of Boron Carbide and Boron Carbide-graphene Nanoplatelet Composite by Reactive Spark Plasma Sintering[J]. Ceramics International, 2018, 44(17): 522–550

Kovalíková A, Sedlák R, Rutkowski P, et al. Mechanical Properties of Boron Carbide+Graphene Platelet Composites[J]. Ceramics International, 2015, 42(1): 2 094–2 098

Tan Y, Zhang H, Peng S. Electrically Conductive Graphene Nanoplatelet/Boron Carbide Composites with High Hardness and Toughness[J]. Scripta Materialia, 2016, 114(2016): 98–102

Zya B, Jya B, Mca B, et al. Mechanical Property and Ballistic Resistance of Graphene Platelets/B4C Ceramic Armor Prepared by Spark Plasma Sintering — ScienceDirect[J]. Ceramics International, 2019, 45(17): 23 781–23 787

Sheinerman AG, Morozov NF, Gutkin MY. Effect of Grain Boundary Sliding on Fracture Toughness of Ceramic/Graphene Composites[J]. Mechanics of Materials, 2019, 137: 103–126

Fonseca GM, Barros FB, Oliveira T, et al. 2-D Crack Propagation Analysis Using Stable Generalized Finite Element Method with Global-local Enrichments[J]. Engineering Analysis with Boundary Elements, 2020, 118(2020): 70–83

Zhang Y, Xiao G, Xu C, et al. Cohesive Element Model for Fracture Behavior Analysis of Al2O3/Graphene Composite Ceramic Tool Material[J]. Crystals, 2019, 9(12): 669

Zhou T, Huang C, Liu H, et al. Crack Propagation Simulation in Microstructure of Ceramic Tool Materials[J]. Computational Materials Science, 2012, 54: 150–156

Dong L, Yang J, Chhowalla M, et al. Synthesis and Reduction of Large Sized Graphene Oxide Sheets[J]. Chemical Society Reviews, 2017, 46(2017): 1 021–1 039

Mencik J. Strength and Fracture of Glass and Ceramics[M]. Elsevier, 1992

Zavattieri E. A Grain Level Model for the Study of Failure Initiation and Evolution in Polycrystalline Brittle Materials. Part I: Theory and Numerical Implementation[J]. Mechanics of Materials, 2003, 52(544): 855–865

Zhang P, Ma L, Fan F, et al. Fracture Toughness of Graphene[J]. Nature Communications, 2014, 5(3728): 9–10

Aw A, Qh A, Cl A, et al. Enhanced Toughness and Strength of Boron Carbide Ceramics with Reduced Graphene Oxide Fabricated by Hot Pressing-Science Direct[J]. Ceramics International, 2020, 46(17): 26 511–26 520

Benedetti I, Aliabadi M H. A Three-dimensional Cohesive-frictional Grain-boundary Micromechanical Model for Intergranular Degradation and Failure in Polycrystalline Materials[J]. Computer Methods in Applied Mechanics and Engineering, 2013, 265(9): 36–62

Alexandr A, Dolbin V. The Effect of the Thermal Reduction Temperature on the Structure and Sorption Capacity of Reduced Graphene Oxide Materials[J]. Applied Surface Science, 2016, 361(JAN.15): 213–220

Aw A, Qh A, Cl A, et al. Microstructure and Mechanical Properties of Boron Carbide/Graphene Nanoplatelets Composites Fabricated by Hot Pressing[J]. Ceramics International, 2020, 46(6): 7879–7887

Failla S, Melandri C, Zoli L. Hard and Easy Sinterable B4C-TiB2 Based Composites Doped with WC[J]. Journal of the European Ceramic Society, 2018, 955(2219): 1 830–1 849

Richard, Sedlák, Alexandra, et al. Effect of Graphene Platelets on Tribological Properties of Boron Carbide Ceramic Composites[J]. International Journal of Refractory Metals & Hard Materials, 2017, 588(852): 152–180

Yavas B, Sahin F, Yucel O, et al. Effect of Particle Size, Heating Rate and CNT Addition on Densification, Microstructure and Mechanical Properties of B4C Ceramics[J]. Ceramics International, 2015, 41(7): 8 936–8 944

Funding

Funded by the National Natural Science Foundation of China (52002299)

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Liao, X., Gao, L., Wang, X. et al. Mechanical Properties of Boron Carbide/Reduced-graphene-oxide Composites Ceramics. J. Wuhan Univ. Technol.-Mat. Sci. Edit. 37, 1087–1095 (2022). https://doi.org/10.1007/s11595-022-2638-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11595-022-2638-4