Abstract

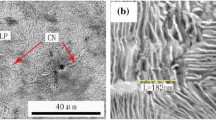

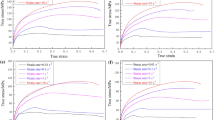

In order to study the high temperature flow behaviour of the V modified 2.25Cr-1Mo steel plate to guide the industrial rolling practice, the hot compression tests were carried out at the temperatures from 900 °C to 1150 °C and the strain rates from 0.01 s−1 to 1 s−1 on Thermecmastor-Z equipment. Based on the experimental data of the hot compression tests, a kind of Arrhenius-type constitutive equation was developed. The equation can accurately show the relationship between the flow stress and the deformation temperature, the strain and the strain rate. The measured true stress-true strain curves exhibit two kinds of flow stress curves. Moreover, the forming mechanisms of these two types curves were explained by softening, wok hardening theory as well as metallographic and hardness experimental results. The accuracy of the developed Arrheniustype constitutive equation was identified by three kinds of statistic parameters and also by comparison of the measured and predicted data. The reasonable value of the three types of statistic parameters and the good agreement between the experimental and predicted data can confirm the validity of the developed Arrheniustype constitutive equation for V modified 2.25Cr-1Mo heat resistant steel plate.

Similar content being viewed by others

References

Bhadeshi H K D H. Design of Ferritic Creep-Resistant Steels[J]. ISIJ Int., 2001, 41(6): 626–640

Jiang Z H, Wang P, Li D Z, et al. The Evolution of Microstructure and Mechanical Properties of 2.25Cr-1Mo-0.25V Steel with Different Initial Microstructures during Tempering[J]. Mater. Sci. Eng. A, 2017, 699: 165–175

Janovec J, Vyrostkova A. Effect of Tempering on Development of Carbide Particles in 2.7Cr-0.6Mo-0.3V Steel[J]. J. Mater. Sci., 1992, 27(24): 6 564–6 572

Fu R D, Wang T S, Zhou W H, et al. Characterization of Precipitates in a 2.25Cr-1Mo-0.25V Steel for Large-Scale Cast-Forged Products[J]. Materials Characterization, 2007, 58(10): 968–973

Klueh R L, Swindeman R W. The Microstructure and Mechanical Properties of a Modified 2.25Cr-lMo Steel[J]. Metallurgical and Materials Transactions A, 1986, 17A(6): 1 027–1 034

Zhang Yongtao, Zhao Sixin, Liang Jiamiao, et al. Rietveld Quantitative Analysis of Carbides Precipitation in Normalized-Tempered 2.25Cr- 1Mo-0.25V Steel[J]. J. Wuhan Univ. Technol.-Mat. Sci. Ed., 2009, 24(6): 922–926

Cheruvu N S. Degradation of Mechanical Properties of Cr-Mo-V and 2.25Cr-1Mo Steel Components after Long-Term Service at Elevated Temperatures[J]. Metallurgical and Materials Transactions A, 1989, 20(1): 87–97

Zhang Y, Miao L, Wang X, et al. Evolution Behavior of Carbides in 2.25Cr-1Mo-0.25V Steel[J]. Mater. Trans., 2009, 50(11): 2 507–2 511

Zhang Y T, Han H B, Miao L D, et al. Quantitative Carbide Analysis Using the Rietveld Method for 2.25Cr-1Mo-0.25V Steel[J]. Mater. Charact., 2009, 60(9): 953–956

Zhang Jingli, Fu Ruidong, Zhang Wenhui, et al. Hot Deforming Behaviors and Microstructures of 2.25Cr-1Mo-0.25V Steels[J]. Journal of Plasticity Engineering, 2010, 17(3): 44–49

Pu Enxiang, Zheng Wenjie, Song Zhigang, et al. Optimization of Hot Workability in Superaustenitic Stainless Steel 654SMO[J]. Journal of Iron and Steel Research, International, 2014, 21(10): 975–982

Shi Zhaoxia, Yan Xiaofeng, Duan Chunhua, et al. Hot Deformation Behavior of GH4945 Superalloy Using Constitutive Equation and Processing Map[J]. Journal of Iron and Steel Research, International, 2017, 24(6): 625–633

Yan J, Pan Q L, Li B, et al. Research on the Hot Deformation Behavior of Al-6.2 Zn-0.70 Mg-0.3 Mn-0.17 Zr Alloy Using Processing Map[J]. J. Alloy. Compd.. 2015, 632: 549–557

Imbert C A C, McQUeen H J. Dynamic Recrystallization of A2 and M2 Tool Steels[J]. Material Science & Engineering A, 2001, 313(1-2): 104–116

Johnson G R, Cook W H. Constitutive Model and Data for Metals Subjected to Large Strains, High Strain Rates and High Temperatures[C]. Proceedings of the Seventh International Symposium on Ballistic, 1983

Li Yunfei, Zeng Xiangguo. Dynamic Tensile Behavior and Constitutive Modeling of TC21 Titanium Alloy[J]. Journal of Wuhan University of Technology-Mater. Sci. Ed., 2019, 34(3): 707–716

Park S S, Garmestani H, Bae G T, et al. Constitutive Analysis on the Superplastic Deformation of Warm-Rolled 6013 Al Alloy[J]. Material Science and Engineering A, 2006, 435–436: 687–692

Sellars C M, McTegar W J. On the Mechanism of Hot Deformation[J]. Acta Metall., 1966, 14(9): 1 136–1 141

Wang S, Hou L G, Luo J R, et al. Characterization of Hot Workability in AA 7050 Aluminum Alloy Using Activation Energy and 3-D Processing Map[J]. J. Mater. Process. Technol., 2015, 225: 110–121

He An, Xie Ganlin, Zhang Hailong, et al. A Comparative Study on Johnson-Cook, Modified Johnson-Cook and Arrhenius-Type Constitutive Models to Predict the High Temperature Flow Stress in 20CrMo Alloy Steel[J]. Materails and Design, 2013, 52: 677–685

Akira Y, Jun Y. A Novel Approach to Determine the Kinetics for Dynamic Recrystallization by Using the Flow Curve[J]. Journal of Materials Processing Technology, 2004, 151: 33–38.

Liang Gaofei, Lin Changqing, Fang Yuan. Flow Stress and Critical Dynamic Recrystallization Behavior of Cu-Fe16Mn0. 6C High Manganese TWIP Steel[J]. Steel Research International, 2012, 83(4): 328–333

Jonas J J, Sellars C M, McGTagart W J. Strength and Structure under Hot-Working Conditions[J]. Int. Metall. Rev.. 1969, 14(1): 1–24

Zener C, Hollomon H. Effect of Strain Rate upon Plastic Flow of Steel[J]. J. Appl. Phys., 1944, 15(1): 22–32

Phniraj M P, Lahiri A K. The Applicability of Neural Network Model to Predict Flow Stress for Carbon Steels[J]. J. Mtater. Process. Technol., 2003, 141(2): 219–227

Author information

Authors and Affiliations

Corresponding author

Additional information

Funded by the New Product Research Program (No.X18ECQ0A00) of Baoshan Iron & Steel Co. Ltd

Rights and permissions

About this article

Cite this article

Liu, Z., Liu, C., Ding, J. et al. Characterization and Modelling of High Temperature Flow Behaviour of V Modified 2.25Cr-1Mo Heat Resistant Steel Plate. J. Wuhan Univ. Technol.-Mat. Sci. Edit. 35, 192–199 (2020). https://doi.org/10.1007/s11595-020-2243-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11595-020-2243-3