Abstract

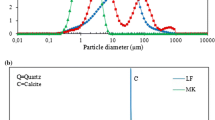

The phosphorus slag (PS) can be used as a supplementary cementitious material due to its potential hydrating activity. However, its usage has been limited by its adverse effects, including prolonged setting and lowered early-stage strength. In this study, we achieved ultrafine granulation of PS using wetmilling (reducing d50 to as low as 2.02 μm) in order to increase its activity, and examined the physico-chemical properties of the resulting materials, including particle-size distribution, slurry pH, zeta potential, and activity index, as well as how their replacement level and granularity affect the setting time and mechanical performance of PS-cement mixture systems. The results suggested that as the granularity increases, there are significant boosts in the uniformity of particle sizes, slurry pH, and activity index, and the effects on cement paste, including setting times, and early- and late-stage strengths, are significantly mitigated. When d50=2.02 μm, the slurry becomes strongly alkaline (pH=12.16) compared to the initial d50=20.75 μm (pH=9.49), and the activity is increased by 73%; when used at 40% replacement, the PS-cement mixture system can reach a 28 d compressive strength of 93.2 MPa, 36% higher than that of the pure cement control group.

Similar content being viewed by others

References

Sun D, Zhou T, Wang A, et al. Research Status and Analysis of Cement-based Materials Mixed with Phosphorus Slag[J]. Materials Review, 2014, 28, (13): 96–100(in Chinese)

Li D, Shen J, Mao L, et al. The Influence of Admixtures on the Properties of Phosphorous Slag Cement[J]. Cem. Concr. Res., 2000, 30, (7): 1169–1173

Li D, Shen J, Chen L, et al. The Influence of Fast-setting/Early-strength Agent on High Phosphorous Slag Content Cement[J]. Cem. Concr. Res., 2001, 31, (1): 19–24

Li D, Chen L, Xu Z, et al. A Blended Cement Containing Blast Furnace Slag and Phosphorous Slag[J]. J. Wuhan Univ. Technol.-Mater. Sci. Ed., 2002, 17, (2): 62–65

Gao P, Lu X, Yang C, et al. Microstructure and Pore Structure of Concrete Mixed with Superfine Phosphorous Slag and Superplasticizer[J]. Constr. Build. Mater., 2008, 22, (5): 837–840

Chen X, Zeng L, Fang K. Anti-crack Performance of Phosphorus Slag Concrete[J]. Wuhan Univers. J. Nat. Sci., 2009, 14(1): 80–86

Cheng L, Sheng G, Pi Y, et al. Effect of Retardation Mechanism of Phosphorous Slag on Portland Cement[J]. Bull. Chin. Ceram. Soc., 2005, 24, (4): 40–44(in Chinese)

Zhang Z, Wang Q, Yang J. Hydration Mechanisms of Composite Binders Containing Phosphorus Slag at Different Temperatures[J]. Constr. Build. Mater., 2017, 147: 720–732

Peng Y, Zhang J, Liu J, et al. Properties and Microstructure of Reactive Powder Concrete Having a High Content of Phosphorous Slag Powder and Silica Fume[J]. Constr. Build. Mater., 2015, 101: 482–487

Allahverdi A, Mahinroosta M. Mechanical Activation of Chemically Activated High Phosphorous Slag Content Cement[J]. Powder Technol., 2013, 245: 182–188

Allahverdi A, Pilehvar S, Mahinroosta M. Influence of Curing Conditions on the Mechanical and Physical Properties of Chemically-activated Phosphorous Slag Cement[J]. Powder Technol., 2016, 288: 132–139

Allahverdi A, Abadi MMBR, Anwar Hossain KM, et al. Resistance of Chemically-activated High Phosphorous Slag Content Cement Against Freeze–thaw Cycles[J]. Cold Reg. Sci. Technol., 2014, 103: 107–114

Collins FG, Sanjayan JG. Workability and Mechanical Properties of Alkali Activated Slag Concrete[J]. Cem. Concr. Res., 1999, 29, (3): 455–458

Lee WKW, van Deventer JSJ. The Effects of Inorganic Salt Contamination on the Strength and Durability of Geopolymers[J]. Colloid. Surface A, 2002, 211, (2): 115–126

Palacios M, Puertas F. Effect of Shrinkage-reducing Admixtures on the Properties of Alkali-activated Slag Mortars and Pastes[J]. Cem. Concr. Res., 2007, 37, (5): 691–702

Allahverdi A, Mahinroosta M. A Model for Prediction of Compressive Strength of Chemically Activated High Phosphorous Slag Content Cement[J]. Int. J. Civ. Eng., 2014, 12(4): 481–487

Kotake N, Kuboki M, Kiya S, et al. Influence of Dry and Wet Grinding Conditions on Fineness and Shape of Particle Size Distribution of Product in a Ball Mill[J]. Adv. Powder Technol., 2011, 22, (1): 86–92

Nakach M, Authelin JR, Chamayou A, et al. Comparison of Various Milling Technologies for Grinding Pharmaceutical Powders[J]. Int. J. Miner. Process., 2004, 74: S173–S181

Liu D, Fang K, Shi Y. Efeects of Phosphorous Slag on Hydration Properties and Pore Structure of Cement Paste[J]. J. Chin. Ceram. Soc., 2007, 35, (1): 109–113(in Chinese)

Chen X, Fang K, Yang H, et al. Hydration Kinetics of Phosphorus Slag-cement Paste[J]. J. Wuhan Univ. Technol.-Mater. Sci. Ed., 2011, 26, (1): 142–146

Derjaguin B, Landau L. Theory of the Stability of Strongly Charged Lyophobic Sols and of the Adhesion of Strongly Charged Particles in Solutions of Electrolytes[J]. Prog. Surface Sci., 1993, 43, (1): 30–59

Verwey EJW, Overbeek JTG. Theory of the Stability of Lyophobic Colloids[J]. J. Colloid Sci., 1955, 10(2): 224–225

Yoshioka K, Tazawa E, Kawai K, et al. Adsorption Characteristics of Superplasticizers on Cement Component Minerals[J]. Cem. Concr. Res., 2002, 32, (10): 1507–1513

Yukselen-Aksoy Y, Kaya A. Zeta Potential of Kaolinite in the Presence of Alkali, Alkaline Earth and Hydrolyzable Metal Ions[J]. Water Air Soil Poll., 2003, 145, (1): 155–168

Yukselen-Aksoy Y, Kaya A. A Study of Factors Affecting on the Zeta Potential of Kaolinite and Quartz Powder[J]. Environ. Earth Sci., 2011, 62, (4): 697–705

Kaya A, Yukselen-Aksoy Y. Zeta Potential of Clay Minerals and Quartz Contaminated by Heavy Metals[J]. Can. Geotech. J., 2005, 42, (5): 1280–1289

Wang S, Zhao Z. Hydration Features of New Phosphorous Slag Cement[J]. J. Chin. Ceram. Soc., 1990, (4): 379–384 (in Chinese)

Author information

Authors and Affiliations

Corresponding author

Additional information

Funded by National Natural Science Foundation of China (No. 51372076), the Technology Innovation Major Project of Hubei Province (No.2017ACA178), the Science and Technology Support Program of Hubei Province (No. 2015BCA244)

Rights and permissions

About this article

Cite this article

He, X., Ye, Q., Yang, J. et al. Physico-chemical Characteristics of Wet-milled Ultrafine-granulated Phosphorus Slag as a Supplementary Cementitious Material. J. Wuhan Univ. Technol.-Mat. Sci. Edit. 33, 625–633 (2018). https://doi.org/10.1007/s11595-018-1870-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11595-018-1870-4