Abstract

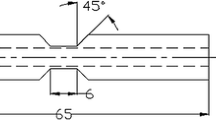

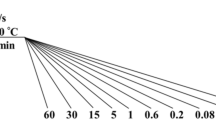

We investigated phase transition and precipitation of ultra-high strength steel (UHSS) in a new “short process” with controlled rolling and controlled cooling. Thermal expansion test combined with metallographic observation was used to research the continuous cooling transformation (CCT) curve. Moreover, the microstructural transformation and precipitation law was revealed by morphological observation and alloying elements by electron probe micro-analyzer (EPMA). Transmission electron microscopy (TEM) was utilized to analyze the composition and grain orientation of microstructure. The study showed that the measured critical transformation temperatures of Ac1 and Ac3 were 746 and 868 °C, respectively. The CCT curve indicated that the undercooled austenite was transformed into proeutectoid ferrite and bainite with HV 520 in a broad range of cooling rate of 1 °C•s−1. When subjected to a cooling rate of 1 °C•s−1, the undercooled austenite was divided into small-sized blocks by formed martensite. With further increase of cooling rate, micro-hardness increased dramatically, the microstructure of specimen was mainly lathe bainite(LB), granular bainite(GB), lath martensite (LM) and residual austenite. By diffraction test analysis, it was identified that there was K-S orientation relationship between martensite and austenite for {110}α//{111}γ, {111}α//{101}γ. EPMA clearly showed that carbon diffused adequately due to staying for a long time at high temperature with a lower cooling rate of 2 °C•s−1. Phase transition drive force was lower and the residual austenite existed in the block form of Martensite austenite island (M-A). With the increase of cooling rate to 10 °C•s−1, the block residual austenite reduced, the carbon content of residual austenite increased and α phase around the residual austenite formed into a low carbon bainite form.

Similar content being viewed by others

References

Garrison W. Ultrahigh-strength Steels for Aerospace Applications[J]. JOM, 1990, 42(5): 20–24

Magnee A, Drapier J, Coutsouradis D, et al. Cobalt-containing High-Strength Steels[M]. Brussels: Gentre d’information du cobalt, 1974

Dabkowski DS, Konkol PJ, Porter LF, et al. Nickel, Cobalt, Chromium Steel[P]. US Patent 3,502,462, 1970

Zhi-Hong W, Kuang-Nian H, Hua L, et al. Development Progress and Process Analysis of Ultra High-strength Plate[J]. Steel Rolling, 2012, 29(3): 43–45

Speich G, Dabkowski D, Porter L. Strength and Toughness of Fe-10Ni Alloys Containing C, Cr, Mo, and Co[J]. Metallurgical Transactions, 1973, 4(1): 303–315

Chang L, Bhadeshia H. Carbon Content of Austenite in Isothermally Transformed 300M Steel[J]. Materials Science and Engineering: A, 1994, 184(1): 17–19

Yang G, Sun X, Li Z, et al. Effects of Vanadium on the Microstructure and Mechanical Properties of a High Strength Low Alloy Martensite Steel[J]. Materials & Design, 2013, 50: 102–107

Garrison WM. High-strength Steel Slloy Used as Structural Component for Aircraft, Comprises Specified Amount of Iron, Carbon, Chromium, Molybdenum, Tungsten, Vanadium, Nickel and Cobalt, and Has Specified Fracture Toughness and Charpy Impact Energy[P]. WO2012058404-A1; US2013228253-A1; WO2012058404-A1 03 May 2012 C22C-038/00 201232

Balogh A, Török I, Gáspár M, et al. Present State and Future of Advanced High Strength Steels[J]. Journal of Production Processes and Systems, 2012, 6(1): 79–90

Caballero F G, Santofimia M J, Garcia-Mateo C, et al. Theoretical Design and Advanced Microstructure in Super High Strength Steels[J]. Materials & Design, 2009, 30(6): 2077–2083

Baik SC, Kim S, Jin Y S, et al. Effects of Alloying Elements on Mechanical Properties and Phase Transformation of Cold Rolled TRIP Steel Sheets[J]. ISIJ International, 2001, 41(3): 290–297

Mejía I, Salas-Reyes A, Bedolla-Jacuinde A, et al. Effect of Nb and Mo on the Hot Ductility Behavior of a High-manganese Austenitic Fe-21Mn-1. 3 Al-1. 5 Si-0. 5 C TWIP Steel[J]. Materials Science and Engineering: A, 2014, 616: 229–239

Hashimoto S, Ikeda S, Sugimoto K-I, et al. Effects of Nb and Mo Addition to 0. 2% C-1. 5% Si-1. 5% Mn Steel on Mechanical Properties of Hot Rolled TRIP-aided Steel Sheets[J]. ISIJ International, 2004, 44(9): 1590–1598

Zargaran A, Kim H, Kwak J, et al. Effects of Nb and C Additions on the Microstructure and Tensile Properties of Lightweight Ferritic Fe-8Al-5Mn Alloy[J]. Scripta Materialia, 2014, 89: 37–40

Cahoon J, Broughton W, Kutzak A. The Determination of Yield Strength from Hardness Measurements[J]. Metallurgical Transactions, 1971, 2(7): 1979–1983

Andrews K. Empirical Formulae for the Calculation of Some Transformation Temperatures[J]. J. Iron Steel Inst., 1965, 203(7): 721–727

Grange R, Stewart H. The Temperature Range of Martensite Formation[J]. Trans. AIME, 1946, 167: 467–501

Payson P, Savage C H. Martensite Reactions in Alloy Steels[J]. Trans. ASM, 1944, 33: 261–280

Steven W, Haynes A. The Temperature of Formation of Martensite and Bainite in Low-alloy Steels[J]. Journal of the Iron and Steel Institute, 1956, 183(8): 349–359

Zuyue X, Shijie L. Bainite Transition and Bainite[M]. Beijing: Science Press, 1991

Porter D A, Easterling K E, Sherif M. Phase Transformations in Metals and Alloys[M]. Brussels: CRC Press, 2009

Wei W L C Q Y, Aidi W H L. Microstructure and Mechanical Properties of 1500 Mpa Grade Ultra-high Strength Low Alloy Steel[J]. Acta Metall Sin, 2010, 46(6): 687–694

Babu S, Bhadeshia H. Mechanism of the Transition from Bainite to Acicular Ferrite[J]. Materials Transactions, JIM, 1991, 32(8): 679–688

Flower H, Lindley T. Electron Backscattering Diffraction Study of Acicular Ferrite, Bainite, and Martensite Steel Microstructures[J]. Materials Science and Technology, 2000, 16(1): 26–40

Thompson S W, Colvin D J, Krauss G. Austenite Decomposition During Continuous Cooling of an HSLA-80 Plate Steel[J]. Metallurgical and Materials Transactions a-Physical Metallurgy and Materials Science, 1996, 27(6): 1557–1571

Gregg J, Bhadeshia H. Solid-state Nucleation of Acicular Ferrite on Minerals Added to Molten Steel[J]. Acta Materialia, 1997, 45(2): 739–748

Author information

Authors and Affiliations

Corresponding author

Additional information

Funded by the Scientific and Technological Research Program of Chongqing Municipal Education Commission (No. KJ1501324), the General Project of Chongqing Frontier and Applied Basic Research Project (No. cstc2015jcyjA90005) and the Research Foundation of Chongqing University of Science and Technology (Nos. CK2013Z16 & CK2014Z20)

Rights and permissions

About this article

Cite this article

Chen, Y., Zhao, Y., Zhou, X. et al. Microstructural transformation and precipitation of an ultra-high strength steel under continuous cooling. J. Wuhan Univ. Technol.-Mat. Sci. Edit. 31, 387–392 (2016). https://doi.org/10.1007/s11595-016-1380-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11595-016-1380-1