Abstract

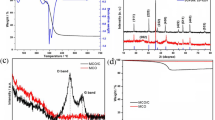

Carbon nanostructures (CNS) with high electrical conductivity and unique branched structure of carbon nanotubes combined with NiO nanofibers (NFs) were used as anode for lithium-ion batteries. CNS works as a framework substrate for the anodic conversion reaction of nickel oxide (NiO). Electrochemical performance and behavior of CNS/NiO anodes is compared with the conventional carbon (C)/NiO anodes. CNS/NiO NF-based anode retains high specific capacity under different current densities compared to C/NiO anode. Moreover, specific capacity as high as 450 mAh/g for CNS/NiO NF anode is observed compared to only 90 mAh/g for C/NiO NFs using a current density of 500 mA/g after 500 cycles. This improved performance is attributed to the highly conductive network of CNS leading to efficient charge transfer. The high porosity, electrical conductivity as well as the branched and networked nature of CNS reveal to be of critical importance to allow the electrochemical conversion reactions.

Similar content being viewed by others

References

Van Schalkwijk W, Scrosati B (2002) Advances in lithium-ion batteries. Springer

Etacheri V, Marom R, Elazari R, Salitra G, Aurbach D (2011) Challenges in the development of advanced Li-ion batteries: a review. Energy Envniron Sci 4(9):3243–3262

Whittingham MS (2004) Lithium batteries and cathode materials. Chem Rev 104(10):4271–4302

Zhang W-J (2011) A review of the electrochemical performance of alloy anodes for lithium-ion batteries. J Power Sources 196(1):13–24

Pistoia G (1994) Lithium batteries: new materials, developments, and perspectives, vol 5. Elsevier Science Ltd

Yamaura J, Ozaki Y, Morita A, Ohta A (1993) High voltage, rechargeable lithium batteries using newly-developed carbon for negative electrode material. J Power Sources 43(1):233–239

Nazri G-A, Pistoia G (2008) Lithium batteries: science and technology. Springer Science & Business

Johnson C, Vaughey J, Thackeray M, Sarakonsri T, Hackney S, Fransson L, Edström K, Thomas JO (2000) Electrochemistry and in-situ X-ray diffraction of InSb in lithium batteries. Electrochem Commun 2(8):595–600

Fransson LM, Vaughey J, Benedek R, Edström K, Thomas JO, Thackeray M (2001) Phase transitions in lithiated Cu2Sb anodes for lithium batteries: an in situ X-ray diffraction study. Electrochem Commun 3(7):317–323

Goodenough JB, Park K-S (2013) The Li-ion rechargeable battery: a perspective. J Am Chem Soc 135(4):1167–1176

Song M-K, Park S, Alamgir FM, Cho J, Liu M (2011) Nanostructured electrodes for lithium-ion and lithium-air batteries: the latest developments, challenges, and perspectives. Mater Sci Eng R Rep 72(11):203–252

de las Casas C, Li W (2012) A review of application of carbon nanotubes for lithium ion battery anode material. J Power Sources 208:74–85

Wu Z-S, Ren W, Xu L, Li F, Cheng H-M (2011) Doped graphene sheets as anode materials with superhigh rate and large capacity for lithium ion batteries. ACS Nano 5(7):5463–5471

Lalia BS, Shah T, Hashaikeh R (2015) Microbundles of carbon nanostructures as binder free highly conductive matrix for LiFePO4 battery cathode. J Power Sources 278 (0):314-319. doi:10.1016/j.jpowsour.2014.12.079

Liang C, Gao M, Pan H, Liu Y, Yan M (2013) Lithium alloys and metal oxides as high-capacity anode materials for lithium-ion batteries. J Alloys Compd 575:246–256

Poizot P, Laruelle S, Grugeon S, Dupont L, Tarascon J (2000) Nano-sized transition-metal oxides as negative-electrode materials for lithium-ion batteries. Nature 407(6803):496–499

Wu HB, Chen JS, Hng HH, Lou XWD (2012) Nanostructured metal oxide-based materials as advanced anodes for lithium-ion batteries. Nanoscale 4(8):2526–2542

Li H, Li D, Zhou H One‐dimensional nanostructured metal oxides for lithium ion batteries. One-dimensional nanostructures: principles and applications:295-320

Needham SA, Wang G, Liu HK (2006) Synthesis of NiO nanotubes for use as negative electrodes in lithium ion batteries. J Power Sources 159(1):254–257

Cohen-Hyams T, Bhargava Y, Thorne S, Wilcox J, Devine T (2008) Synthesis of NiO nanowiress for use in lithium batteries. ECS Trans 11(31):1–7

Su D, Kim HS, Kim WS, Wang G (2012) Mesoporous nickel oxide nanowires: hydrothermal synthesis, characterisation and applications for lithium‐ion batteries and supercapacitors with superior performance. Chem Eur J 18(26):8224–8229

Aravindan V, Suresh Kumar P, Sundaramurthy J, Ling WC, Ramakrishna S, Madhavi S (2013) Electrospun NiO nanofibers as high performance anode material for Li-ion batteries. J Power Sources 227:284–290

Sigmund W, Yuh J, Park H, Maneeratana V, Pyrgiotakis G, Daga A, Taylor J, Nino JC (2006) Processing and structure relationships in electrospinning of ceramic fiber systems. J Am Ceram Soc 89(2):395–407

Khalil A, Hashaikeh R (2014) Electrospinning of nickel oxide nanofibers: process parameters and morphology control. Mater Charact 49:3052–3065

Shah TK, Malecki HC, Basantkumar RR, Liu H, Fleischer CA, Sedlak JJ, Patel JM, Burgess WP, Goldfinger JM (2013) Carbon nanostructures and methods of making the same. Google Patents

Varghese B, Reddy M, Yanwu Z, Lit CS, Hoong TC, Subba Rao G, Chowdari B, Wee ATS, Lim CT, Sow C-H (2008) Fabrication of NiO nanowall electrodes for high performance lithium ion battery. Chem Mater 20(10):3360–3367

Zhang C, Tu J, Yuan Y, Huang X, Chen X, Mao F (2007) Electrochemical performances of Ni-coated ZnO as an anode material for lithium-ion batteries. J Electrochem Soc 154(2):A65–A69

Brodd RJ (2012) Batteries for sustainability: selected entries from the encyclopedia of sustainability science and technology. Springer Science & Business Media

Huang X, Tu J, Zhang C, Xiang J (2007) Net-structured NiO–C nanocomposite as Li-intercalation electrode material. Electrochem Commun 9(5):1180–1184

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Lalia, B.S., Khalil, A., Shah, T. et al. Flexible carbon nanostructures with electrospun nickel oxide as a lithium-ion battery anode. Ionics 21, 2755–2762 (2015). https://doi.org/10.1007/s11581-015-1482-3

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11581-015-1482-3