Abstract

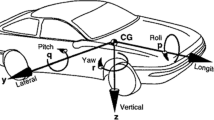

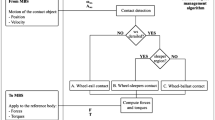

In allusion to fatigue life of a tracked vehicle torsion bar, a virtual prototype model of the tracked vehicle suspension system including a flexible torsion bar was built based on dynamic simulation software—ADAMS. Node force and stress results of the torsion bar from last step simulation were acquired; taking into account the material characteristics and influential factors, fatigue life of the flexible body of the torsion bar was predicted. Engineering results can be acquired through the contrast of the result of virtual test and statistical fatigue.

Similar content being viewed by others

References

Craig R R, Bampton M C C. Coupling of substructures for dynamics analyses. AIAA Journal, 1968, 6(7): 1 313–1 319

Mechanical Dynamics. INC “ADAMS Tracked Vehicle Toolkit. Version 12.0-Documentation, April 30th”, 2002

Yao Weixing. Configuration Fatigue Life Analysis. Beijing: National Defence Industry Press, 2003, 18–42 (in Chinese)

Wang Yancai. Design and Manufacture of Vehicle Torsion Bar Spring. Beijing: National Defence Industry Press, 1996, 196–227 (in Chinese)

Author information

Authors and Affiliations

Corresponding author

Additional information

__________

Translated from Journal of Academy of Armored Force Engineering, 2006, 20(1): 44–47 [译自: 装甲兵工程学院学报]

Rights and permissions

About this article

Cite this article

Wang, H., Rui, Q. & He, X. The prediction technology study of fatigue life for key parts of a tracked vehicle’s suspension system. Front. Mech. Eng. China 2, 68–71 (2007). https://doi.org/10.1007/s11465-007-0011-0

Issue Date:

DOI: https://doi.org/10.1007/s11465-007-0011-0