Abstract

The assessment and control of ground movements during the installation of large diameter deeply-buried (LDDB) caissons are critically important to maintain the stability of surrounding infrastructures. However, for twin LDDB caissons which have been installed worldwide, no well-documented guidelines for assessing the induced ground movements are available due to the complexities of caisson–soil interaction. To this end, considering the mechanical boundaries of caissons and mechanized installation process, this paper presents a simple kinematic mechanical model balancing both computational cost and accuracy, which can be easily incorporated in commercial finite-element (FE) programs. Based on a project of twin LDDB caissons alternately installed employing a newly developed installation technology in wet ground with stiff clays in Zhenjiang, China, a three-dimensional (3D) numerical model is developed to capture the ground movements in terms of surface settlements and radial displacements induced by the installation of twin LDDB caissons. Moreover, hardening soil model with small-strain stiffness (HSSmall model) conceptually capable of capturing the nonlinear soil stiffness from very small to large strain levels is used to simulate undrained ground. The validations against field observations, empirical predictions and centrifuge test data are carried out to demonstrate the accuracy and validity of the developed FE model. Subsequently, the comparisons of ground movements numerically obtained in three frequently used installation schemes (i.e., synchronous, asynchronous and alternating installation) are conducted for installation sequence optimization of twin caissons. It is found that synchronous installation is the optimal scheme for limiting ground movements. Parametric studies considering the effects of horizontal spacing between twin caissons, staged penetration depth, inner diameter, controllable soil-plugging height, frictional coefficient between caisson–soil interface, as well as cutting edge gradient are thus performed in synchronous installation scheme. Based on an artificial data set generated through FE calculation, the multivariate adaptive regression splines (MARS) model capable of accurately capturing the nonlinear relationships between a set of input variables and output variables in multi-dimensions is used to analyze the sensitivity of caisson design parameters. Finally, the MARS mathematical equations for predicting the maximum surface settlement and radial displacement used in preliminary caisson design are proposed.

Similar content being viewed by others

Abbreviations

- \(A_{1}\) :

-

Contact area of leading edge and base soils

- \(A_{2}\) :

-

Contact area of shaft lining and surrounding soils

- \(D_{{{\text{in}}}}\) :

-

Inner and external diameter of open caisson

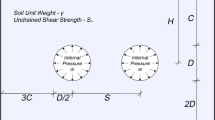

- H :

-

Shaft depth (total penetration depth)

- \(h_{{\mathrm{p}}}\) :

-

Staged penetration depth

- \(h_{{\mathrm{s}}}\) :

-

Controllable soil-plugging height

- \(n\) :

-

Cutting edge gradient

- \(S\) :

-

Horizontal spacing between twin caissons

- γ :

-

Unit weight

- ω :

-

Water content

- \(\omega_{{\text{L}}}\) :

-

Liquid limit

- \(\omega_{{\text{P}}}\) :

-

Plastic limit

- \(c_{{\text{u}}}\) :

-

Cohesion

- \(S_{{\text{u}}}\) :

-

Undrained shear strength

- \(\phi_{{\text{u}}}\) :

-

Friction angle

- e :

-

Void ratio

- \(E_{0.1{-}0.2}\) :

-

Constrained modulus

- \(K_{{\text{h}}} ,K_{{\text{v}}}\) :

-

Horizontal and vertical permeability coefficients

- \(N_{63.5}\) :

-

SPT below counts

- \(q_{{\text{c}}}\) :

-

Cone resistance of CPT

- \(f_{{\text{s}}}\) :

-

Sleeve resistance of CPT

- \(W\) :

-

Self-weight of caisson shaft

- \(Q\) :

-

End bearing on cutting edge

- \(q_{{\text{u}}}\) :

-

Unit end bearing on cutting edge

- \(F\) :

-

Total penetration resistance

- \(f_{{\text{s}}}\) :

-

Unit skin friction

- \(J\) :

-

Total jacking force

- \(j\) :

-

Jacking force provided by a jack

- \(U\) :

-

Total buoyancy

- \(N_{\gamma } ,N_{q} ,\,{\text{and}}\,N_{{\text{c}}}\) :

-

Bearing capacity factors related to unit weight, surcharge and cohesion

- \(G\) :

-

Shear modulus

- \(G_{0}\) :

-

Maximum shear modulus at a very small strain

- \(\varepsilon\) :

-

Shear strain

- \(\varepsilon_{0}\) :

-

Maximum shear strain

- \(\tau_{\max }\) :

-

Maximum shear stress at failure

- \(G_{0}^{{{\text{ref}}}}\) :

-

Reference shear modulus at very small strains

- \(\gamma_{0.7}\) :

-

Shear strain at which \(G/G_{0} = 0.7\)

- \(c^{\prime}\) :

-

Effective cohesion

- \(\phi^{\prime}\) :

-

Effective frictional angle

- \(E_{0}\) :

-

Young's modulus

- \(E_{50}^{\prime{\text{ref}}}\) :

-

Reference secant stiffness in standard drained triaxial test

- \(E_{{\text{oed}}}^{\prime{\text{ref}}}\) :

-

Reference tangent stiffness for primary oedometer loading

- \(E_{{\text{ur}}}^{\prime{\text{ref}}}\) :

-

Reference unloading/reloading stiffness at engineering strains

- \(\nu_{{\text{ur}}}\) :

-

Poisson ratio

- \(m\) :

-

Power for the stress-level dependency of stiffness

- \(p^{{\text{ref}}}\) :

-

Reference stress for stiffness

- \(R_{{\text{f}}}\) :

-

Failure ratio

- \(\gamma^{\prime}\) :

-

Effective unit weight

- \(K_{0}^{{\text{nc}}}\) :

-

\(K_{0}\) value for normal consolidation

- \(u\) :

-

Frictional coefficient of caisson–soil interfaces

- \(\delta_{{\text{r}}}\) :

-

Radial displacements of surrounding soils

- \(\delta_{{\text{v}}}\) :

-

Ground surface settlement

- \(z\) :

-

Buried depth of soils

- \(x\) :

-

Radial distance to caisson shaft

- \(\delta_{r,\max } ,\delta_{v,\max }\) :

-

Maximum radial displacement and surface settlement

- \(f(x)\) :

-

Optimal equation in MARS model

- \(\beta_{0}\) :

-

Constant in MARS mathematical equation

- \(M\) :

-

Number of basic functions

- \(\lambda_{m}\) :

-

mth basic function

- \(\beta_{m}\) :

-

Coefficient of \(\lambda_{m}\)

References

Abaqus (2017) Abaqus 2017 documentation, SIMULA, Dassault Systemès

Abdrabbo F, Gaaver K (2012) Challenges and uncertainties relating to open caissons. DFI J J Deep Found Inst 6(1):21–32

Abdrabbo FM, Gaaver KE (2012) Applications of the observational method in deep foundations. Alex Eng J 51(4):269–279

Allenby D, Kilburn D (2015) Overview of underpinning and caisson shaft-sinking techniques. Proc ICE Geotech Eng 168(1):3–15

Allenby D, Waley G, Kilburn D (2009) Examples of open caisson sinking in Scotland. Proc ICE Geotech Eng 162(1):59–70

Belous NP (1968) Deformation of soils and settlement of reference points at the zone where a caisson is sunk. Soil Mech Found Eng 5(5):359–361

Benz T (2006) Small-strain stiffness of soils and its numerical consequences. University of Stuttgart, Stuttgart

Brinkgreve RBJ, Broere W, Waterman D (2017) PLAXIS version 2017 Manual. The Netherlands

Burland JB (1989) Ninth Laurits Bjerrum memorial lecture: “small is beautiful”—the stiffness of soils at small strains. Can Geotech J 26(4):499–516

Calvello M, Finno RJ (2004) Selecting parameters to optimize in model calibration by inverse analysis. Comput Geotech 31(5):410–424

Chen F, Miao G, Lai F (2020) Base instability triggered by hydraulic uplift of pit-in-pit braced excavations in soft clay overlying a confined aquifer. KSCE J Civ Eng 24(6):1717–1730

Fargnoli V, Boldini D, Amorosi A (2015) Twin tunnel excavation in coarse grained soils: observations and numerical back-predictions under free field conditions and in presence of a surface structure. Tunn Undergr Sp Tech 49:454–469

Faustin NE, Elshafie MZEB, Mair RJ (2018) Case studies of circular shaft construction in London. Proc ICE Geotech Eng 171(5):391–404

Fischer GR, Gerszewski WL, Barchok FJ, Yavarow MK (2004) Deep caisson sinking in soft soils, grand forks, north dakota. In: 5th international conference on case histories in geotechnical engineering. Missouri University of Science and Technology, New York

Georgiannou VN, Serafis A, Pavlopoulou E-M (2017) Analysis of a vertical segmental shaft using 2D & 3D finite element codes. Int J Geomate 13(36):138–146

Grabe J, Heins E (2016) Coupled deformation–seepage analysis of dynamic capacity tests on open-ended piles in saturated sand. Acta Geotech 12(1):1–13

Hamann T, Gang Q, Grabe J (2015) Application of a coupled Eulerian–Lagrangian approach on pile installation problems under partially drained conditions. Comput Geotech 63:279–290

Hardin BO, Drnevich VP (1972) Shear modulus and damping in soils: design equations and curves. Geotech Spec Publ 98(118):667–692

Ho CE (2002) Settlement performance of large diameter friction caissons in bouldery clay. In: Deep found 2002: int perspect theory, des, constr perform., pp 525–541

Hoffman J, Roboski J, Finno RJ (2004) Ground movements caused by caisson installation at the Lurie Excavation project. In: Geotech Eng Transport Proj, California, United States. ASCE, pp 1280–1289

Irini D-M, Daniel D, Ngoc-Anh Do, Pierpaolo O (2014) Three-dimensional numerical simulation of a mechanized twin tunnels in soft ground. Tunn Undergr Sp Tech 42:40–51

Jamsawang P, Jamnam S, Jongpradist P, Tanseng P, Horpibulsuk S (2017) Numerical analysis of lateral movements and strut forces in deep cement mixing walls with top-down construction in soft clay. Comput Geotech 88:174–181

Jardine RJ (1986) Studies of the influence of non linear stress–strain characteristics in soil–structure interaction. Géotechnique 36(3):377–396

Jiang B-N, Ma J-L, Chu J-L (2019) The Influence of soil surrounding the caisson cutting edge to excavation and sinking. In: IACGE 2018: geotech seism research pract sustainability, Chongqing, China, vol 435–448. ASCE, New York

Jiang B-N, Wang M-T, Chen T, Zhang L-L, Ma J-L (2019) Experimental study on the migration regularity of sand outside a large, deep-water, open caisson during sinking. Ocean Eng 193:106601

Ko J, Jeong S, Lee JK (2016) Large deformation FE analysis of driven steel pipe piles with soil plugging. Comput Geotech 71:82–97

Kung GT-C, Ou C-Y, Juang CH (2009) Modeling small-strain behavior of Taipei clays for finite element analysis of braced excavations. Comput Geotech 36(1–2):304–319

Lai F, Liu S, Deng Y, Sun Y (2020) Mechanical behaviors and geo-environmental effects due to the installation of giant deep-buried open caissons: state of the art. J Basic Sci Eng 28(3):1–16

Lai F, Liu S, Deng Y, Sun Y, Wu K, Liu H (2020) Numerical investigations of the installation process of giant deep-buried circular open caissons in undrained clay. Comput Geotech 118:103322

Le BT, Goodey RJ, Divall S (2019) Subsurface ground movements due to circular shaft construction. Soils Found 59(5):1160–1171

Likitlersuang S, Surarak C, Wanatowski D, Oh E, Balasubramaniam A (2013) Finite element analysis of a deep excavation: a case study from the Bangkok MRT. Soils Found 53(5):756–773

Lim A, Hsieh PG, Ou CY (2016) Evaluation of buttress wall shapes to limit movements induced by deep excavation. Comput Geotech 78:155–170

Lim A, Ou C-Y, Hsieh P-G (2018) Investigation of the integrated retaining system to limit deformations induced by deep excavation. Acta Geotech 13(4):973–999

Lim YX, Tan SA, Phoon K-K (2018) Application of press-replace method to simulate undrained cone penetration. Int J Geomech 18(7):04018066

Mohurd (2011) Code for design of building foundation. China Architecture & Building Press, Beijing

Morrison P, McNamara A, Roberts T (2004) Design and construction of a deep shaft for Crossrail. Proc ICE Geotech Eng 157(4):173–182

Muramatsu M, Abe Y (1996) Considerations in shaft excavation and peripheral ground deformation. In: Geotech aspects undergr constr soft ground, pp 173–178

New BM (2017) Settlements due to shaft construction. In: Tunn Tunn Int, pp 16–17

New BM, Bowers KH (1994) Ground movement model validation at the Heathrow Express trial tunnel. Springer, US

Newman T, Wong H-Y (2011) Sinking a jacked caisson within the London Basin geological sequence for the Thames Water Ring Main extension. Q J Eng Geol Hydroge 44(2):221–232

Nonveiller E (1987) Open caissons for deep foundations. J Geotech Eng 113(5):424–439

Osman AS, Bolton MD (2006) Ground movement predictions for braced excavations in undrained clay. J Geotech Geoenviron Eng 132(4):465–477

Peng F-L, Wang H-L, Tan Y, Xu Z-L, Li Y-L (2011) Field measurements and finite-element method simulation of a tunnel shaft constructed by pneumatic caisson method in Shanghai soft ground. J Geotech Geoenviron Eng 137(5):516–524

Phutthananon C, Jongpradist P, Yensri P, Jamsawang P (2018) Dependence of ultimate bearing capacity and failure behavior of T-shaped deep cement mixing piles on enlarged cap shape and pile strength. Comput Geotech 97:27–41

Plaxis (2017) Plaxis 3D user’s manual. Plaxis bv, Delft

Royston R (2018) Investigation of soil–structure interaction for large diameter caissons. University of Oxford, Oxford

Royston R, Sheil B, Byrne W (2020) Monitoring the construction of a large-diameter caisson in sand. Proc ICE Geotech Eng 2020:1–17

Schwamb T (2014) Performance monitoring and numerical modelling of a deep circular excavation. University of Cambridge, Cambridge

Schwamb T, Elshafie MZEB, Soga K, Mair RJ (2016) Considerations for monitoring of deep circular excavations. Proc ICE Geotech Eng 169(GE6):1–17

Schwamb T, Soga K (2015) Numerical modelling of a deep circular excavation at Abbey Mills in London. Géotechnique 65(7):604–619

Soomro M, Ng C, Liu K, Memon N (2017) Pile responses to side-by-side twin tunnelling in stiff clay: effects of different tunnel depths relative to pile. Comput Geotech 84:101–116

Sun Y, Shen S, Xu Z, Xia X (2014) Prediction of lateral displacement of soil behind the reaction wall caused by pipe jacking operation. Tunn Undergr Sp Tech 40:210–217

Sun Y, Su J, Xia X, Xu Z (2015) Numerical analysis of soil deformation behind the reaction wall of an open caisson induced by horizontal parallel pipe-jacking construction. Can Geotech J 52(12):1–9

Sun Y, Su J-b, Xia X-h, Xu Z-l (2015) Numerical analysis of soil deformation behind the reaction wall of an open caisson induced by horizontal parallel pipe-jacking construction. Can Geotech J 52(12):2008–2016

Terzaghi K (1943) Theoretical soil mechanics. Wiley, New York

Terzaghi K, Peck RB (1967) Soil mechanics in engineering practice. Wiley, New York

Tho KK, Leung CF, Chow YK, Swaddiwudhipong S (2013) Eulerian finite element simulation of spudcan–pile interaction. Can Geotech J 50(6):595–608

Voottipruex P, Jamsawang P, Sukontasukkul P, Jongpradist P, Chindaprasirt P (2019) Performances of SDCM and DCM walls under deep excavation in soft clay: field tests and 3D simulations. Soils Found 59:1728–1739

Wang D, Bienen B, Nazem M, Tian Y, Zheng J, Pucker T, Randolph MF (2015) Large deformation finite element analyses in geotechnical engineering. Comput Geotech 65:104–114

Wang HL, Peng FL, Tan Y (2011) Site monitoring and development of real-time monitoring program for new pneumatic caisson construction. In: Geo-Front Congr 2011: Adv Geotech Eng, pp 182–191

Wharmby N, Kiernan B, Duffy L, Puller D (2011) Stormwater tank construction at Blackpool. In: Proceedings of the conference on underground construction, pp 1–12

Wong R, Kaiser P (1988) Behaviour of vertical shafts: reevaluation of model test results and evaluation of field measurements. Can Geotech J 25(2):338–352

Yao Q, Yang X, Li H (2014) Construction technology of open caisson for oversize surge shaft in drift gravel stratum. Electr J Geotech Eng 19:5725–5738

Zakhem A-M, Naggar HE (2019) Effect of the constitutive material model employed on predictions of the behaviour of earth pressure balance (EPB) shield-driven tunnels. Transp Geotech 21:100264

Zhang W (2019) MARS applications in geotechnical engineering systems. Springer, Beijing

Zhang N, Arroyo M, Ciantia MO, Gens A, Butlanska J (2019) Standard penetration testing in a virtual calibration chamber. Comput Geotech 111(3):277–289

Zhang WG, Goh ATC (2013) Multivariate adaptive regression splines for analysis of geotechnical engineering systems. Comput Geotech 48:82–95

Zhang W, Goh ATC (2015) Nonlinear structural modeling using multivariate adaptive regression splines. Comput Concr 16(4):569–585

Zhang W, Goh ATC, Xuan F (2015) A simple prediction model for wall deflection caused by braced excavation in clays. Comput Geotech 63:67–72

Zhang W, Zhang Y, Goh ATC (2017) Multivariate adaptive regression splines for inverse analysis of soil and wall properties in braced excavation. Tunn Undergr Sp Tech 64:24–33

Zhang W, Zhang R, Goh ATC (2018) MARS inverse analysis of soil and wall properties for braced excavations in clays. Geomech Eng 16(6):577–588

Zhao G, Meng S, Guan C, Yang Y (2019) Test study on the stress and deformation behaviors of a shaft supported by a prefabricated prestressed structure. Appl Sci 9(4):629

Zheng G, Yang X, Zhou H, Du Y, Sun J (2018) A simplified prediction method for evaluating tunnel displacement induced by laterally adjacent excavations. Comput Geotech 95:119–128

Zheng G, Yang P, Zhou H, Zeng C, Yanf X, He X, Yu X (2019) Evaluation of the earthquake induced uplift displacement of tunnels using multivariate adaptive regression splines. Comput Geotech 113:103099

Acknowledgements

This study is supported from the National Key R&D Program of China (Grant No. 2016YFC0800201), National Natural Science Foundation of China (Grant No. 41972269), Fundamental Research Funds for the Central Universities of China (Grant No. 2242019), Postgraduate Research and Practice Innovation Program of Jiangsu Province (Grant No. KYCX20_0118) and Scientific Research Foundation of Graduate School of Southeast University (Grant No. YBPY2041). The authors are grateful to Mr. Yingwu Xu (Engineer of Shanghai Foundation Engineering Group Co., Ltd.) for his help in providing the construction information regarding Dagang waterworks project.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Lai, F., Zhang, N., Liu, S. et al. Ground movements induced by installation of twin large diameter deeply-buried caissons: 3D numerical modeling. Acta Geotech. 16, 2933–2961 (2021). https://doi.org/10.1007/s11440-021-01165-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11440-021-01165-1