Abstract

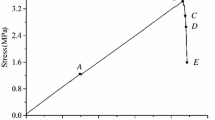

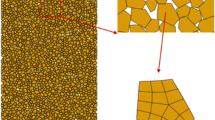

Brinell indentation tests were performed on Montney siltstone, and the results were compared with discrete element indentation simulations that use the micro-parameters calibrated using compression test data from the same siltstone samples. The simulated proppant indentation into the rock surface can be 15% less than the laboratory measurements. A lower effective particle–particle modulus and thus a lower Young’s modulus are needed in discrete element models for proper simulation of indentation. An equation to find the appropriate value of Young’s modulus for indentation simulation is proposed using Brinell indentation tests including 198 laboratory tests and 32 discrete element simulations. This equation can improve the prediction of Young’s modulus and thus the particle–particle effective modulus for indentation simulations to match the measured force–indentation depth curve in the laboratory. Using the improved micro-parameters, a parametric analysis of the influence of rock Young’s modulus and proppant particle size on proppant embedment was performed. An equation to estimate Brinell hardness as a function of Young’s modulus and closure stress was derived. A practical procedure was developed to predict proppant embedment from the estimated hardness. The predictions agree with the laboratory measurements in a case study on the Montney Formation.

Similar content being viewed by others

References

Alramahi B, Sundberg MI (2012) Proppant embedment and conductivity of hydraulic fractures in shales. In: 46th US rock mechanics/geomechanics symposium, Chicago, USA

André D, Jebahi M, Iordanoff I et al (2013) Using the discrete element method to simulate brittle fracture in the indentation of a silica glass with a blunt indenter. Comput Method Appl M 265:136–147

ASTM D4543-08e1 (2008) Standard practices for preparing rock core as cylindrical test specimens and verifying conformance to dimensional and shape tolerances. ASTM International, West Conshohocken

ASTM E10-17 (2017) Standard test method for Brinell hardness of metallic materials. ASTM International, West Conshohocken

ASTM E2546-15 (2015) Standard practice for instrumented indentation testing. ASTM International, West Conshohocken

British Columbia Oil and Gas Commission (2013) https://files.bcogc.ca/. Accessed 18 June 2018

Chen C, Martysevich V, O’Connell P et al (2015) Temporal evolution of the geometrical and transport properties of a fracture/proppant system under increasing effective stress. SPE J 20(3):527–535

Chen D, Ye Z, Pan Z et al (2017) A permeability model for the hydraulic fracture filled with proppant packs under combined effect of compaction and embedment. J Petrol Sci Eng 149:428–435

Corapcioglu H, Miskimins J, Prasad M et al (2014) Fracturing fluid effects on young’s modulus and embedment in the Niobrara formation. In: SPE annual technical conference and exhibition, Amsterdam, the Netherlands. https://doi.org/10.2118/170835-MS

Cui A, Brezovski R (2013) Laboratory permeability measurements of unconventional reservoirs: useless or full of information? A Montney example from the western Canadian sedimentary basin. In: Unconventional resources conference, Brisbane, Australia. https://doi.org/10.2118/167047-MS

Cui A, Glover K, Wust RAJ (2014) Elastic and plastic mechanical properties of liquids-rich unconventional shales and their implications for hydraulic fracturing and proppant embedment: a case study of the Nordegg Member in Alberta, Canada. In: 48th US rock mechanics/geomechanics symposium, Minneapolis, USA

Cundall PA, Strack ODL (1979) A discrete numerical model for granular assemblies. Géotechnique 29(1):47–65

Deng S, Li H, Ma G et al (2014) Simulation of shale–proppant interaction in hydraulic fracturing by the discrete element method. Int J Rock Mech Min Sci 70:219–228

Duan K, Kwok CY, Tham LG (2015) Micromechanical analysis of the failure process of brittle rock. Int J Numer Anal Methods 39(6):618–634

Gensterblum Y, Ghanizadeh A, Cuss RJ et al (2015) Gas transport and storage capacity in shale gas reservoirs—a review. Part A: transport processes. J Unconv Oil Gas Resour 12:87–122

Ghanizadeh A, Clarkson CR, Aquino S et al (2015) Petrophysical and geomechanical characteristics of Canadian tight oil and liquid-rich gas reservoirs: II. Geomechanical property estimation. Fuel 153:682–691

Huang H, Detournay E (2013) Discrete element modeling of tool–rock interaction II: rock indentation. Int J Numer Anal Methods 37(13):1930–1947

Itasca Consulting Group, Inc. (2014) PFC3D user manual (5.0)

Jebahi M, André D, Dau F et al (2013) Simulation of Vickers indentation of silica glass. J Non Cryst Solids 378:15–24

Kazerani T (2013) Effect of micromechanical parameters of microstructure on compressive and tensile failure process of rock. Int J Rock Mech Min Sci 64:44–55

Kumar V, Sondergeld CH, Rai CS (2012) Nano to macro mechanical characterization of shale. In: SPE annual technical conference and exhibition, San Antonio, USA. https://doi.org/10.2118/159804-MS

Lacy LL, Rickards AR, Bilden DM (1998) Fracture width and embedment testing in soft reservoir sandstone. SPE Drill Completion 13(1):25–29

Mattson ED, Huang H, Li X et al (2014) 2D discrete element modeling and experimental results of proppant embedment into fracture rock walls. In: 1st international conference on discrete fracture network engineering, Vancouver, Canada

Montgomery D (2001) Design and analysis of experiments. Wiley, New York

Mueller M, Amro M (2015) indentation hardness for improved proppant embedment prediction in shale formations. In: SPE European formation damage conference and exhibition, Budapest, Hungary. https://doi.org/10.2118/174227-MS

Neto LB, Kotousov A (2013) Residual opening of hydraulic fractures filled with compressible proppant. Int J Rock Mech Min Sci 61:223–230

Neto LB, Khanna A, Kotousov A (2015) Conductivity and performance of hydraulic fractures partially filled with compressible proppant packs. Int J Rock Mech Min Sci 74:1–9

Potyondy DO, Cundall PA (2004) A bonded-particle model for rock. Int J Rock Mech Min Sci 41:1329–1364

Rivers M, Zhu D, Hill AD (2012) Proppant fracture conductivity with high proppant loading and high closure stress. In: SPE hydraulic fracturing technology conference, The Woodlands, USA. https://doi.org/10.2118/151972-MS

Shell Canada Energy (2013) Integrated tight rock analysis of SCL Blueberry b-93-1/94-B-09

Tang Y, Ranjith PG, Perera MSA (2018) Major factors influencing proppant behaviour and proppant-associated damage mechanisms during hydraulic fracturing. Acta Geotech 13:757–780

Tang Y, Ranjinth PG, Perera M et al (2018) Influences of proppant concentration and fracturing fluids on proppant-embedment behavior for inhomogeneous rock medium: an experimental and numerical study. SPE Prod Oper SPE-189984-PA. https://doi.org/10.2118/189984-PA

Yang Z, Wang L, Zhang G et al (2016) Micromechanical characterization of fluid-shale interactions via nanoindentation. In: SPE Asia pacific hydraulic fracturing conference, Beijing, China. https://doi.org/10.2118/181833-MS

Yoon J (2007) Application of experimental design and optimization to PFC model calibration in uniaxial compression simulation. Int J Rock Mech Min Sci 44(6):871–889

Zeng K, Chiu C (2001) An analysis of load–penetration curves from instrumented indentation. Acta Mater 49(17):3539–3551

Zhang F, Huang H, Vajdova V (2011) Discrete element modeling of sphere indentation in rocks. In: 45th US rock mechanics/geomechanics symposium, San Francisco, USA

Zhang J, Ouyang L, Zhu D et al (2015) Experimental and numerical studies of reduced fracture conductivity due to proppant embedment in the shale reservoir. J Petrol Sci Eng 130:37–45

Zhang F, Zhu H, Zhou H et al (2017) Discrete-element-method/computational-fluid-dynamics coupling simulation of proppant embedment and fracture conductivity after hydraulic fracturing. SPE J 22(2):632–644

Zheng W, Tannant DD (2018) Grain breakage criteria for discrete element models of sand crushing under one-dimensional compression. Comput Geotech 95:231–239

Zheng W, Tannant DD (2019) Influence of proppant fragmentation on fracture conductivity—insights from three-dimensional discrete element modeling. J Petrol Sci Eng 177:1010–1023

Zheng W, Silva SC, Tannant DD (2018) Crushing characteristics of four different proppants and implications for fracture conductivity. J Nat Gas Sci Eng 53:125–138

Acknowledgements

The Particle Flow Code was provided by Itasca through an educational partnership. This work was support by grants from the Key Program of National Natural Science Foundation of China (41630643), China Postdoctoral Science Foundation (2018M642952) and Postdoctoral International Exchange Program, British Columbia Oil and Gas Commission, and Mitacs. Trican Geological Solutions (now AGAT Laboratories) contributed to the laboratory measurement work.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

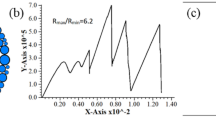

Appendix: micro-parameters analysis of bonded siltstone models

Rights and permissions

About this article

Cite this article

Zheng, W., Tannant, D.D., Cui, X. et al. Improved discrete element modeling for proppant embedment into rock surfaces. Acta Geotech. 15, 347–364 (2020). https://doi.org/10.1007/s11440-019-00819-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11440-019-00819-5