Abstract

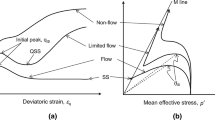

State parameter defined using void ratio, e, and the steady-state line has been shown to be effective in predicting the undrained behaviour of sand. However, steady-state line for sand with fines is dependent on fines content. To overcome this problem, the concept of equivalent granular void ratio, e*, has been well investigated. However, the conversion from e to e* has been essentially a back-analysis process. A methodology for converting e to e* without the need of a back-analysis process was first presented. The concept of equivalent granular state parameter, ψ*, defined in terms of e*, and equivalent granular steady-state line was then developed. An extensive experimental study was conducted to investigate whether ψ* can capture the effects of fines content, and thus can be used to correlate undrained behaviour of sand–fines mixtures without the need of separately considering the effects of fines content. This study suggested that the effective stress path and deviatoric stress–strain responses in undrained shearing can be correlated with the ψ* value at the start of undrained shearing irrespective of fines content.

Similar content being viewed by others

Abbreviations

- b :

-

Active fraction of fines in force structure

- d :

-

Small particle diameter

- d 50 :

-

Fines particle diameter at 50% finer

- D :

-

Large particle diameter

- D 10 :

-

Sand particle diameter at 10% finer

- dε v :

-

Volumetric strain increment

- dε 1 :

-

Axial strain increment

- e :

-

Void ratio

- e 300 :

-

Void ratio on SSL at p′ of 300 kPa

- e g :

-

Intergranular void ratio

- e* :

-

Equivalent granular void ratio

- e SS :

-

Void ratio at steady state

- \(e^{*}_{\text{SS}}\) :

-

Equivalent granular void ratio at steady state

- ε q :

-

Deviatoric strain

- η IS :

-

Instability stress ratio

- ψ :

-

State parameter

- ψ(0):

-

Initial state parameter

- ψ* :

-

Equivalent granular state parameter

- ψ*(0):

-

Initial equivalent granular state parameter

- f c :

-

Fines content in decimal

- f thre :

-

Threshold fines content in decimal

- μ, n b :

-

Fitting constants in Eq. 3

- α, β :

-

Fitting constants in Eq. 5

- p′:

-

Mean effective stress, p′ = \( ({\sigma^{\prime}_{1}} - 2{\sigma^{\prime}_{3}})/3\)

- \(p^{\prime}_{SS}\) :

-

Mean effective stress at steady state

- q :

-

Deviatoric stress, \(q=({\sigma^{\prime}_{1}} - {\sigma^{\prime}_{3}})\)

- q IS :

-

Deviatoric stress at the onset of instability

- q 15, q 25 :

-

Deviatoric stress at 15 and 25% deviator strain, respectively

- r :

-

Particle size ratio, r = (1/χ) = d 50 /D 10

- χ :

-

Particle size ratio, χ = D 10 /d 50

References

Been K, Jefferies MG (1985) A state parameter for sands. Géotechnique 35(2):99–112

Bobei D (2004) Static liquefaction of sand with a small amount of fines. In: Department of Civil Engineering. University of New South Wales at Australian Defence Force Academy, PhD thesis, Canberra

Bobei DC, Lo SR (2005) Reverse behaviour and critical state of sand with small amount of fines. In: The proceedings of the 16th international conference on soil mechanics and geotechnical engineering (16ICSMGE). Millpress Science Publishers, Japan, pp 475–478

Bobei DC, Lo SR, Wanatowski D, Gnanendran CT, Rahman MM (2009) A modified state parameter for characterizing static liquefaction of sand with fines. Can Geotech J 46(3):281–295. doi:10.1139/T08-122

Chu J, Leong WK (2002) Effect of fines on instability behaviour of loose sand. Géotechnique 52(10):751–755

Chu J, Wanatowski D (2008) Instability conditions of loose sand in plane strain. J Geotech Geoenviron Eng 134(1):136–142. doi:10.1061/(ASCE)1090-0241(2008)134:1(136)

Huang Y-T, Huang A-B, Kuo Y-C, Tsai M-D (2004) A laboratory study on the undrained strength of silty sand from Central Western Taiwan. Soil Dyn Earthquake Eng 24:733–743

Lo SR, Chu J, Lee IK (1989) A technique for reducing membrane penetration and bedding errors. Geotech Test J 12(4):311–316

Lo SR, Rahman MM, Bobei DC (2010) Limited flow behaviour of sand with fines under monotonic and cyclic loading. Geomech Geoeng 5(1):15–25. doi:10.1080/17486020903452709

McGeary RK (1961) Mechanical packing of spherical particles. J Am Ceram Soc 44(10):513–522

Murthy TG, Loukidis D, Carraro JAH, Prezzi M, Salgado R (2007) Undrained monotonic response of clean and silty sands. Géotechnique 57(3):273–288

Ni Q, Tan TS, Dasari GR, Hight DW (2004) Contribution of fines to the compressive strength of mixed soils. Géotechnique 54(9):561–569

Pitman TD, Robertson PK, Sego DC (1994) Influence of fines on the collapse of loose sands. Can Geotech J 31(5):728–739

Polito CP (1999) The effects of non-plastic and plastic fines on the liquefaction of sandy soils. PhD thesis in Civil Engineering, The Virginia Polytechnic Institute and State University, Blacksburg, USA

Polito CP, Martin JR (2001) Effects of nonplastic fines on the liquefaction resistance of solids. J Geotech Geoenviron Eng 127(5):408–415

Prakasha KS, Chandrasekaran VS (2005) Behavior of marine sand-clay mixtures under static and cyclic triaxial shear. J Geotech Geoenviron Eng 131(2):213–222

Rahman MM (2009) Modelling the influence of fines on liquefaction behaviour. In: Department of Civil Engineering, University of New South Wales at Australian Defence Force Academy, PhD thesis, Canberra. http://handle.unsw.edu.au/1959.4/43920. Accessed 12 Sept 2011

Rahman MM, Lo SR (2007) On intergranular void ratio of loose sand with small amount of fines. In: 16th South East Asian geotechnical conference. Kuala Lumpur, Malaysia, pp 255–260

Rahman MM, Lo SR (2007) Equivalent granular void ratio and state parameters for loose clean sand with small amount of fines. In: 10th Australia New Zealand conference on geomechanics: common ground. Brisbane, Australia, pp 674–679

Rahman MM, Lo SR (2008) The prediction of equivalent granular steady state line of loose sand with fines. Geomech Geoeng 3(3):179–190. doi:10.1080/17486020802206867

Rahman MM, Lo SR (2011) Instability behaviour of sandy soils. In: Proc., Geo-Frontiers 2011: Advances in Geotechnical Engineering, GSP 211, ASCE, 3587–3597. doi:10.1061/41165(397)367

Rahman MM, Lo SR, Gnanendran CT (2008) On equivalent granular void ratio and steady state behaviour of loose sand with fines. Can Geotech J 45(10):1439–1455. doi:10.1139/T08-064

Rahman MM, Lo SR, Gnanendran CT (2009) Reply to discussion by Wanatowski, D. and Chu, J. On equivalent granular void ratio and steady state behaviour of loose sand with fines. Can Geotech J 46(4):483–486. doi:10.1139/T09-025

Thevanayagam S (1998) Effect of fines and confining stress on undrained shear strength of silty sands. J Geotech Geoenviron Eng 124(6):479–491

Thevanayagam S (2003) Role of intergranular contacts on mechanisms causing liquefaction and slope failures in silty sands. Final Report. USGS Award No. 01HQGR0032 and 99HQGR0021. http://erp-web.er.usgs.gov/reports/abstract/2001/pt/01hqgr0032-report.pdf Accessed 26 April 2006

Thevanayagam S, Martin GR (2002) Liquefaction in silty soils-screening and remediation issues. Soil Dyn Earthquake Eng 22(9-12):1035–1042

Thevanayagam S, Mohan S (2000) Intergranular state variables and stress-strain behaviour of silty sands. Géotechnique 50(1):1–23

Thevanayagam S, Fiorillo M, Laing L (2000) Effect of non-plastic fines on undrained cyclic strength of silty sands. In: ASCE Geotechnical Special Publication, pp 77–91

Thevanayagam S, Shenthan T, Mohan S, Liang J (2002) Undrained fragility of clean sands, silty sands, and sandy silts. J Geotech Geoenviron Eng 128(10):849–859

Wang Z-L, Dafalias YF, Li X-S, Makdisi FI (2002) State pressure index for modelling sand behaviour. J Geotech Geoenviron Eng 128(6):511–519

Yamamuro JA, Lade PV (1997) Static liquefaction of very loose sands. Can Geotech J 34(6):901–917

Yang J (2002) Non-uniqueness of flow liquefaction line for loose sand. Géotechnique 52(10):757–760

Yang SL, Sandven R, Grande L (2006) Steady-state lines of sand-silt mixtures. Can Geotech J 43(11):1213–1219

Yang SL, Lacasse S, Sandven RF (2006) Determination of the transitional fines content of mixtures of sand and non-plastic fines. Geotech Test J 29(2):102–107

Yang SL, Sandven R, Grande L (2006) Instability of sand-silt mixtures. Soil dynamics and earthquake engineering-11th international conference on soil dynamics and earthquake engineering (ICSDEE): part II, 26(2–4):183–190

Zlatovic S, Ishihara K (1995) On the influence of nonplastic fines on residual strength. In: Proceedings of IS-TOKY0’95/the first international conference on earthquake geotechnical engineering, Tokyo, 14–16 November 1995. A.A. Balkema, Rotterdam, pp 239–244

Acknowledgments

The first author was supported by the Endeavour International Postgraduate Research Scholarship (EIPRS) and UNSW Global Scholarship while conducting his PhD research on “Modelling the liquefaction behaviour for sand with fines” at University of New South Wales at Australian Defence Force Academy, Canberra, Australia. The third author is supported by UCPRS scholarship for his PhD study at University of New South Wales at Australian Defence Force Academy, Canberra, Australia.

Author information

Authors and Affiliations

Corresponding author

Appendix 1

Appendix 1

Instability (flow and limited flow) is equivalent to dq < 0 with shearing. q = ηp′ leads to:

Based on elasto-plastic idealization, undrained shearing implies:

where superscripts “e” and “p” denote elastic and plastic components, respectively. A contractant response means with shearing, \( d\varepsilon_{v}^{p} > 0 \) and therefore \( d\varepsilon_{v}^{e} < 0 \). This in turn implies dp′ < 0 (based on elasticity consideration) which guarantees the first term of Eq. 9 being negative. As the second term remains positive, dq < 0 (instability) cannot be guaranteed.

Rights and permissions

About this article

Cite this article

Rahman, M.M., Lo, S.R. & Baki, M.A.L. Equivalent granular state parameter and undrained behaviour of sand–fines mixtures. Acta Geotech. 6, 183–194 (2011). https://doi.org/10.1007/s11440-011-0145-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11440-011-0145-4