Abstract

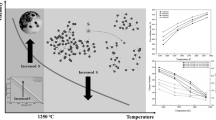

Based on the concept of melt residual bonds, a calculating model quantitatively describing the evolution of the residual bond structure of titanium melt at the melting point or in a certain range above the melting point was established; i.e., both the size dS and the bond number n of the residual bond structure decrease monotonously with the increase of temperature. By mathematical deduction, a linear relationship between the residual bond structure size d S and the dynamic viscosity η of Titanium melt was revealed, i.e., η= 0.876 + 0.471·d S, which is of great significance to the investigation of the relationship between the melt microstructure and the macroscopic properties of metals with high melting temperature.

Similar content being viewed by others

References

Moiseyev V V. Titanium Alloy Russian Aircraft and Aerospace Applications. New York: CRC Press, 2006

Mi G B, Li P J, He L J, et al. EET research on melt structural information of magnesium Alloy. Rare Metal Mater Eng, 2010, 39(11): 1881–1887

Mi G B, Li P J, He L J. Structure and property of metal melt I. The number of residual bonds after solid-liquid phase changes. Sci China-Phys Mech Astron, 2010, 53(9): 1571–1577

Mi G B, Li P J, He L J. Structure and property of metal melt II. Evolution of atomic clusters in the not high temperature range above liquidus. Sci China-Phys Mech Astron, 2010, 53(10): 1823–1830

Khrushchev B I. Nature of the bond and change in the structure of metals during melting. Strukturnoi Khimii, 1971, 12(6): 958–963

Данилов В И. Строение и кристаллиэация жидкости: Иэбранные статьи. Киев: АН УССР, 1956: 2–4

Бухаренко В В, Чень С Щ, Иляинский А Г, и др. Рентгеновское исследование структуры жидких сплавов системы индий-галлий. Металлофиэика, 1991, 19(10): 92

Лящко А С, Полтавцев У Г. Рентгенографическое исследование жидкого галлия в щироком интервале температуре. Украинский Фиэический журнал, 1968, 13(9): 1579–1583

Кпименков Е А, Гельб П В, Баум Б А, и др. О структуре ближнего порядка в жидком желеэе, кобальте и никеле. Докл. АН СССР, 1976, 230(1): 71–73

Ерщов Г С, Бычнов У Б. Высокопрочные алюминиевые сплавы на основе вторичного сырья. Москва: Металлургия, 1979: 5–60

Каэимиров В П, Роик А С, Самсонников А В, и др. Характер упорядочения атомов в расплаве и поверхностные свойства систем с интерметаллическими соединениями. Сверхтвердые материалы, 2009, 4: 40–54

Rao B K, Jena P. Evolution of the electronic structure and properties of neutral and charged aluminum clusters: A comprehensive analysis. J Chem Phys, 1999, 111(5): 1890–1904

Arnold G L, Anbar A D, Barling J, et al. Formation of Al13I: Evidence for the superhalogen character of Al13. Science, 2004, 304: 84–87

Chacko S, Deshpande M, Kanhere D G. Structural and electronic properties of aluminium-based binary clusters. Phys Rev B, 2001, 64: 155409

Medel V M, Reveles J U, Khanna S N, et al. Hund’s rule in superatoms with transition metal impurities. PNAS Early Ed, 2011: 1–5

Woodward W H, Eyet N, Shuman N S, et al. Aluminum Cluster anion reactivity with singlet oxygen: Evidence of Al9-stability. J Phys Chem C, 2011, 115: 9903–9908

Milligan J, Heard D W, Brochu M. Formation of nanostructured weldments in the Al-Si system using electrospark welding. Appl Surf Sci, 2010, 256: 4009–4016

Granqvist C G, Buhrman R A. Ultrafine metal particles. J Appl Phys, 1976, 47(5): 2200–2219

Zhang R L. Empirical Electron Theory of Solids and Molecules (in Chinese). Changchun: Jilin Science and Technology Press, 1993. 66–67

Dean J A. Lange’s Handbook of Chemistry. 15th ed. New York: McGraw-Hill, 1999. 6.124–6.142

Iida T, Rodarick I L. The Properties of Liquid Metal. Oxford: Clavendon Press, 1993. 148–153

Paradis P F, Ishikawa T, Yoda S. Non-contact measurements of surface tension and viscosity of niobium, zirconium, and titanium using an electrostatic levitation furnace. Int J Thermophys, 2002, 23(3): 825–842

Ъвидковский Е Г, Горяга Г И. Метод иэмерения вяэкости металлических расплавов: влияние примеси на вяэкость. Вестн. МГУ, 1953, 9: 63

Sklyarchuk V, Plevachuk Y, Yakymovych A, et al. Structure sensitive properties of liquid Al-Si alloys. Int J Thermophys, 2009, 30: 1400–1410

Mi G B, Li P J, Okhapkin A V, et al. Relationship between liquid structure and property (i). Kinematic viscosity of Mg melt and its relationship with the microstructure (in Chinese). Acta Phys Sin, 2011, 60(4): 046601

Mi G B, Li P J, Okhapkin A V, et al. Relationship between liquid structure and property (ii). Kinematic viscosity of Mg-9Al melt and its relationship with the microstructure (in Chinese). Acta Phys Sin, 2011, 60(5): 056601

Mi G B, Li P J, Popel P S, et al. Structure and property of metal melt III. Relationship between kinematic viscosity and size of atomic clusters. Sci China-Phys Mech Astron, 2010, 53(11): 2054–2058

Qi J G. Research on Electric Pulse Treatment and Liquid Structure of Aluminum Melt (in Chinese). Beijing: University of Science and Technology Beijing, 2006. 39–55

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Mi, G., Cao, J., Huang, X. et al. Structure and property of metal melt IV—Evolution of titanium melt residual bond structure and its effect on dynamic viscosity. Sci. China Phys. Mech. Astron. 55, 1371–1375 (2012). https://doi.org/10.1007/s11433-012-4804-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11433-012-4804-8