Abstract

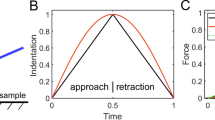

In this study, we theoretically investigate the dynamic indentation for measuring the loss (damping) factor of a linear viscoelastic material from its indentation response. A rigid indenter with arbitrary tip profile is assumed to indent into a viscoelastic substrate with arbitrary shape. We perform a theoretical analysis and identify the conditions under which the loss factor of the material can be determined from the phase angle between the applied harmonic indentation load and the corresponding harmonic displacement, a directly measurable quantity in a dynamic indentation test. To validate the conclusion drawn from our theoretical analysis, a series of numerical experiments are performed, including the spherical indentation of a soft layer with irregular surface morphology bonded to a rigid substrate, a conical indenter with tip defects indenting into a half-spherical particle, and the indentation of porous materials. This study may facilitate the use of the dynamic indentation technique to evaluate the damping properties of linear viscoelastic materials, including some advanced polymers and biological soft tissues.

Similar content being viewed by others

References

Suhr J, Koratkar N, Keblinski P, et al. Viscoelasticity in carbon nanotube composites. Nat Mater, 2005, 4: 134–137

Levental I, Georges P C, Janmey P A. Soft biological materials and their impact on cell function. Soft Matter, 2007, 3: 299–206

Lee B, Han L, Frank E H, et al. Dynamic mechanical properties of the tissue-engineered matrix associated with individual chondrocytes. J Biomech, 2010, 43: 469–476

Shimizu S, Yanagimoto T, Sakai M. Pyramidal indentation load-depth curve of viscoelastic materials. J Mater Res, 1999, 14: 4075–4086

Fischer-Cripps A C. Nanoindentation. New York: Springer, 2002

Lu H, Wang B, Ma J, et al. Measurement of creep compliance of solid polymers by nanoindentation. Mech Time-Depend Mater, 2003, 7: 189–207

Cheng Y T, Cheng C M. Scaling, dimensional analysis, and indentation measurements. Mater Sci Eng R, 2004, 44: 91–149

Ngan A H W, Wang H T, Tang B, et al. Correcting power-law viscoelastic effects in elastic modulus measurement using depth-sensing indentation. Int J Solids Struct, 2005, 42: 1831–1846

Ebenstein D M, Pruitt L A. Nanoindentation of biological materials. Nano Today, 2006, 1: 26–33

Vandamme M, Ulm F J. Viscoelastic solutions for conical indentation. Int J Solids Struct, 2006, 43: 3142–3165

Constantinides G, Kalcioglu Z L, McFarland M, et al. Probing mechanical properties of fully hydrated gels and biological tissues. J Biomech, 2008, 41: 3285–3289

Cheng Y T, Yang F Q. Obtaining shear relaxation modulus and creep compliance of linear viscoelastic materials from instrumented indentation using axisymmetric indenters of power-law profiles. J Mater Res, 2009, 24: 3013–3017

Oyen M L, Cook R F J. Load-displacement behavior during sharp indentation of viscous-elastic-plastic materials. J Mater Res, 2003, 18: 139–150

Oyen M L. Spherical indentation creep following ramp loading. J Mater Res, 2005, 20: 2094–2100

Oyen M L. Sensitivity of polymer nanoindentation creep measurements to experimental variables. Acta Mater, 2007, 55: 3633–3639

Cao Y P, Ma D C, Raabe D. The use of flat punch indentation to determine the viscoelastic properties in the time and frequency domains of a soft layer bonded to a rigid substrate. Acta Biomater, 2009, 5: 240–248

Nashif A D, Jones D I G, Henderson J P. Vibration Damping. New York: Wiley, 1985

Corsaro R D, Sperling L H. Sound and Vibration Damping with Polymers. Washington DC: American Chemical Society, 1990

Cao Y P, Ji X Y, Feng X Q. Geometry independence of the normalized relaxation functions of viscoelastic materials in indentation. Phil Mag, 2010, 90: 1639–1655

Lucas B N, Oliver W C, Swindeman J E. The dynamics of frequency-specific, depth-sensing indentation testing. In: Moody N R, Gerberich W W, Burnham N, et al., eds. Materials-Research-Society Symposium on Fundamentals of Nanoindentation and Nanotribology. San Francisco: Materials Research Society, 1998. 522: 3–14

Loubet J L, Oliver W C, Lucas B N. Measurement of the loss tangent of low-density polyethylene with a nanoindentation technique. J Mater Res, 2000, 15: 1195–1198

Fischer-Cripps A C. Multiple-frequency dynamic nanoindentation testing. J Mater Res, 2004, 19: 2981–2988

Cheng Y T, Ni W Y, Cheng C M. Nonlinear analysis of oscillatory indentation in elastic and viscoelastic solids. Phys Rev Lett, 2006, 97: 075506

Huang G, Wang B, Lu H. Measurements of viscoelastic functions of polymers in the frequency-domain using nanoindentation. Mech Time-Depend Mater, 2004, 8: 345–364

Herbert E G, Oliver W C, Pharr G M. Nanoindentation and the dynamic characterization of viscoelastic solids. J Phys D-Appl Phys, 2008, 41: 074021

Herbert E G, Oliver W C, Lumsdaine A, et al. Measuring the constitutive behavior of viscoelastic solids in the time and frequency domain using flat punch nanoindentation. J Mater Res, 2009, 24: 626–637

Christensen R M. Theory of viscoelasticity: An introduction. New York: Academic Press, 1982

Cao Y P. Determination of the creep exponent of a power-law creep solid using indentation tests. Mech Time-Depend Mater, 2007, 11: 159–172

ABAQUS User’s Manual, Version 6.5.1. Providence: Hibbit, Karlsson & Sorenson, 2006

Huang G, Lu H B. Measurement of Young’s relaxation modulus using nanoindentation. Mech Time-Depend Mater, 2006, 10: 229–243

Tan E P S, Lim C T. Mechanical characterization of nanofibers—A review. Compos Sci Technol, 2006, 66: 1102–1111

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Cao, Y., Ji, X. & Feng, X. On determination of the damping factor of linear viscoelastic materials using dynamic indentation: a theoretical study. Sci. China Phys. Mech. Astron. 54, 598–605 (2011). https://doi.org/10.1007/s11433-011-4279-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11433-011-4279-z