Abstract

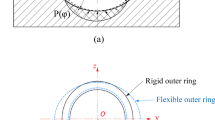

Roundness and surface waviness are main manufacturing errors on the components of single row angular contact ball bearings (ACBBs). An analytical study for vibrations of the ACBBs with coupling errors including the roundness and waviness can be useful for the vibration control of the rotating machinery. However, most previous works only focused on the single error modelling method. In this paper, an improved time dependent displacement excitation (TDDE) model is proposed to consider the coupling errors including the roundness and waviness on the inner and outer races of an ACBB. The TDDE model for the roundness and waviness is established by using a combination of several sinusoidal functions. A dynamic model in the previous study is improved to consider the influences of coupling errors including the roundness and waviness. The Hertzian contact theory and Dowson’s method are adopted to calculate the bearing contact stiffness. The time- and frequency-domain vibrations for the experimental and simulation results are compared to show some model validation. The influences of roundness orders and waviness amplitudes on the vibrations of the ACBB are analysed. The obtained results show that the coupling errors including the roundness and waviness have some influence on the time-domain impulse waveform and frequency-domain spectrum characteristics of the bearing accelerations. The differences of the vibrations between the coupling errors and sing error are from 4% to 42%. This paper can provide a useful guidance for the accurate diagnosis of surface imperfections in the ACBBs.

Similar content being viewed by others

References

Littmann W E. The mechanism of contact fatigue. NASA Spec Publ, 1970, 237: 309

Liu J, Shao Y, Lim T C. Vibration analysis of ball bearings with a localized defect applying piecewise response function. Mechanism Machine Theor, 2012, 56: 156–169

Liu J, Shao Y. An improved analytical model for a lubricated roller bearing including a localized defect with different edge shapes. J Vib Control, 2018, 24: 3894–3907

Liu J, Shao Y. Dynamic modeling for rigid rotor bearing systems with a localized defect considering additional deformations at the sharp edges. J Sound Vib, 2017, 398: 84–102

Liu J, Xu Z, Zhou L, et al. A statistical feature investigation of the spalling propagation assessment for a ball bearing. Mechanism Machine Theor, 2019, 131: 336–350

Liu J, Shao Y. Overview of dynamic modelling and analysis of rolling element bearings with localized and distributed faults. Nonlinear Dyn, 2018, 93: 1765–1798

Cao H, Niu L, Xi S, et al. Mechanical model development of rolling bearing-rotor systems: A review. Mech Syst Signal Processing, 2018, 102: 37–58

Cao H, Li Y, Chen X. A dynamic modelling method of a rotor-roller bearing-housing system with a localized fault including the additional excitation zone. J Sound Vib, 2020, 469: 115144

Liu J. A dynamic modelling method of a rotor-roller bearing-housing system with a localized fault including the additional excitation zone. J Sound Vib, 2020, 469: 115144

Liu J, Tang C, Wu H, et al. An analytical calculation method of the load distribution and stiffness of an angular contact ball bearing. Mechanism Machine Theor, 2019, 142: 103597

Tallian T E, Gustafsson O G. Progress in rolling bearing vibration research and control. A S L E Trans, 1965, 8: 195–207

Yhland E M. Paper 29: Waviness measurement-an instrument for quality control in rolling bearing industry. Proc Institution Mech Engineers Conf Proc, 1967, 182: 438–445

Wardle F P. Vibration forces produced by waviness of the rolling surfaces of thrust loaded ball bearings Part 1: Theory. Proc Inst Mech Engineers Part C-J Mech Eng Sci, 1988, 202: 305–312

Choudhury A, Tandon N. A theoretical model to predict vibration response of rolling bearings to distributed defects under radial load. J Vib Acoust, 1998, 120: 214–220

Aktürk N. The effect of waviness on vibrations associated witli ball bearings. J Tribol, 1999, 121: 667–677

Harsha S P, Sandeep K, Prakash R. Non-linear dynamic behaviors of rolling element bearings due to surface waviness. J Sound Vib, 2004, 272: 557–580

Yhland E. A linear theory of vibrations caused by ball bearings with form errors operating at moderate speed. J Tribol, 1992, 114: 348–359

Jang G, Jeong S W. Vibration analysis of a rotating system due to the effect of ball bearing waviness. J Sound Vib, 2004, 269: 709–726

Bai C Q, Xu Q Y. Dynamic model of ball bearings with internal clearance and waviness. J Sound Vib, 2006, 294: 23–48

Wang L Q, Li C, Dezhi Z, et al. Nonlinear dynamics behaviors of a rotor roller bearing system with radial clearances and waviness considered. Chin J Aeronaut, 2008, 21: 86–96

Kankar P K, Sharma S C, Harsha S P. Nonlinear vibration signature analysis of a high speed rotor bearing system due to race imperfection. J Comput Nonlinear Dyn, 2012, 7: 011014

Liu J, Shao Y. Vibration modelling of nonuniform surface waviness in a lubricated roller bearing. J Vib Control, 2017, 23: 1115–1132

Liu J, Wu H, Shao Y M. A comparative study of surface waviness models for predicting vibrations of a ball bearing. Sci China Tech Sci, 2017, 60: 1841–1852

Liu J, Yan Z, Shao Y. An investigation for the friction torque of a needle roller bearing with the roundness error. Mech Machine Theor, 2018, 121: 259–272

Jang G H, Jeong S W. Nonlinear excitation model of ball bearing waviness in a rigid rotor supported by two or more ball bearings considering five degrees of freedom. J Tribol, 2002, 124: 82–90

Harris T A, Kotzalas M N. Rolling Bearing Analysis-Essential Concepts of Bearing Technology. 5th ed. New York: Taylor and Francis, 2007

Hamrock B J, Dowson D. Isothermal elastohydrodynamic lubrication of point contacts: part III—Fully flooded results. J Lubr Tech, 1977, 99: 264–275

Savalia R, Kumar Ghosh M, Kumar Pandey R. Vibration analysis of lubricated angular contact ball bearing of rigid rotor considering waviness of ball and races. Tribol Online, 2008, 3: 322–327

Babu C K, Tandon N, Pandey R K. Vibration modeling of a rigid rotor supported on the lubricated angular contact ball bearings considering six degrees of freedom and waviness on balls and races. J Vib Acoust, 2012, 134: 011006

Welch P. The use of fast Fourier transform for the estimation of power spectra: A method based on time averaging over short, modified periodograms. IEEE Trans Audio Electroacoust, 1967, 15: 70–73

Author information

Authors and Affiliations

Corresponding author

Additional information

This work was supported by the National Natural Science Foundation of China (Grant Nos. 51605051, 51975068), and Chongqing Research Program of Basic Research and Frontier Technology (Grant No. cstc2017jcyjAX0202).

Rights and permissions

About this article

Cite this article

Liu, J., Pang, R., Xu, Y. et al. Vibration analysis of a single row angular contact ball bearing with the coupling errors including the surface roundness and waviness. Sci. China Technol. Sci. 63, 943–952 (2020). https://doi.org/10.1007/s11431-019-1493-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11431-019-1493-7