Abstract

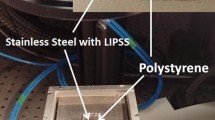

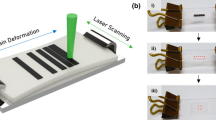

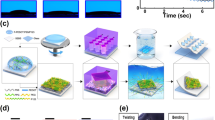

A general, rapid and solvent-free approach is proposed to fabricate nanostructured polymer surfaces by coupling ultrasonic vibration and anodized aluminum oxide templating. With our approach, hollow nanorods or nanofibers with controlled diameter and length are prepared on polymer surfaces. The whole fabrication process is completed in ∼30 s and equally applicable to polymers of different crystalline structures. The wettability of the as-fabricated polymer surfaces (being hydrophilic, hydrophobic, highly hydrophobic or even superhydrophobic) is readily regulated by adjusting the welding time from 0 s to a maximum of 10 s. Our approach can be a promising industrial basis for manufacturing functional nanomaterials in the fields of electronics, optics, sensors, biology, medicine, coating, or fluidic technologies.

Similar content being viewed by others

References

Lee W, Jin M K, Yoo W C, et al. Nanostructuring of a polymeric substrate with well-defined nanometer-scale topography and tailored surface wettability. Langmuir, 2004, 20: 7665–7669

Lee Y W, Park S H, Kim K B, et al. Fabrication of hierarchical structures on a polymer surface to mimic natural superhydrophobic surfaces. Adv Mater, 2007, 19: 2330–2335

Xu Y Y, Zhang F, Feng X L. Patterning of conjugated polymers for organic optoelectronic devices. Small, 2011, 7: 1338–1360

Guo Z G, Liu W M, Su B L. Superhydrophobic surfaces: From natural to biomimetic to functional. J Colloid Inter Sci, 2011, 353: 335–355

Del Campo A, Arzt E. Fabrication approaches for generating complex micro- and nanopatterns on polymeric surfaces. Chem Rev, 2008, 108: 911–945

Widawski G, Rawiso M, Francois B. Self-organized honeycomb morphology of star-polymer polystyrene films. Nature, 1994, 369: 387–389

Zhang J, Yu X, Yang P, et al. Microphase separation of block copolymer thin films. Macromol Rapid Commun, 2010, 31: 591–608

Steinhart M, Wendorff J H, Greiner A, et al. Polymer nanotubes by wetting of ordered porous templates. Science, 2002, 296: 1997

Zhu S J, Li Y F, Zhang J H, et al. Biomimetic polyimide nanotube arrays with slippery or sticky superhydrophobicity. J Colloid Interface Sci, 2010, 344: 541–546

Ito H. Chemical amplification resists for microlithography. Adv Polym Sci, 2005, 172: 37–245

Krebs F C. Fabrication and processing of polymer solar cells: A review of printing and coating techniques. Sol Energy Mater Sol Cells, 2009, 93: 394–412

Zhang Y L, Chen Q D, Xia H, et al. Designable 3D nanofabrication by femtosecond laser direct writing. Nano Today, 2010, 5: 435–448

Steinhart M, Wendorff J H, Wehrspohn R B. Nanotubes à la carte: Wetting of porous templates. ChemPhysChem, 2003, 4: 1171–1176

Sun Y M, Steinhart M, Zschech D, et al. Diameter-dependence of the morphology of PS-b-PMMA nanorods confined within ordered porous alumina templates. Macromol Rapid Commun, 2005, 26: 369–375

Zhang M F, Dobriyal P, Chen J T, et al. Wetting transition in cylindrical alumina nanopores with polymer melts. Nano Lett, 2006, 6: 1075–1079

Cannon J P, Beardena S D, Goldb S A. Effect of wetting solvent on poly(3-hexylthiophene) (P3HT) nanotubles fabricated via template wetting. Synth Met, 2010, 160: 2623–2627

Tian W, Yung K L, Xu Y, et al. Beta-cyclodextrin and its hyperbranched polymers-induced micro/nanopatterns and tunable wettability on polymer surfaces. Nanoscale, 2011, 3: 5147–5155

Belova V, Gorin D A, Shchukin D G, et al. Selective ultrasonic cavitation on patterned hydrophobic surfaces. Angew Chem Int Ed, 2010, 49: 7129–7133

Cao B Y, Li Y W, Kong J, et al. High thermal conductivity of polyethylene nanowire arrays fabricated by an improved nanoporous template wetting technique. Polymer, 2011, 52: 1711–1715

Tao L S, Desai T A. Aligned arrays of biodegradable poly(ɛ-capro-lactone) nanowires and nanofibers by template synthesis. Nano Lett, 2007, 7: 1463–1468

Yun H, Kim W S, Kim K H, et al. Highly enhanced interfacial adhesion properties of steel-polymer composites by dot-shaped surface patterning. J Appl Phys, 2011, 109: 074302

Girifalco L A, Hodak M, Lee R S. Carbon nanotubes, buckyballs, ropes, and a universal graphitic potential. Phys Rev B, 2000, 62: 13104

Li J, Cassell A, Delzeit L, et al. Novel three-dimensional electrodes: Electrochemical properties of carbon nanotube ensembles. J Phys Chem B, 2002, 106: 9299–9305

Liu H, Li S H, Zhai J, et al. Self-assembly of large-scale micropatterns on aligned carbon nanotube films. Angew Chem Int Ed, 2004, 43: 1146–1149

Liu S J, Dung Y T. Hot embossing precise structure onto plastic plates by ultrasonic vibration. Polym Eng Sci, 2005, 45: 915–925

Mekaru H, Nakamura O, Maruyama O, et al. Development of precision transfer technology of atmospheric hot embossing by ultrasonic vibration. Microsyst Tech, 2007, 13: 385–391

Lin C H, Chen R S. Ultrasonic nanoimprint lithography: A new approach to nanopatterning. J Microlith Microfab Microsyst, 2006, 5: 011003

Lee C H, Jung P G, Lee S M, et al. Replication of polyethylene nano-micro hierarchical structures using ultrasonic forming. J Micromech Microeng, 2010, 20: 035018

Li S C, Lu L N. Melt rheological properties of reactive compatibilized HDPE/PET blends. J Appl Polym Sci, 2008, 108: 3559–3564

Wu Z, Petzold A, Henze T, et al. Temperature and molecular weight dependent hierarchical equilibrium structures in semiconducting poly(3-hexylthiophene). Macromolecules, 2010, 43: 4646–4653

Lee D J, Kim H M, Song Y S, et al. Water droplet bouncing and superhydrophobicity induced by multiscale hierarchical nanostructure. ACS Nano, 2012, 6: 7656–7664

Marmur A. Wetting on hydrophobic rough surfaces: To be heterogeneous or not to be? Langmuir, 2003, 19: 8343–8348

Baek S J, Park J B, Lee W J, et al. A facile method to prepare regioregular poly(3-hexylthiophene) nanorod arrays using anodic aluminium oxide templates and capillary force. New J Chem, 2009, 33: 986–990

Byun J, Kim Y, Jeon G, et al. Ultrahigh density array of free-standing poly(3-hexylthiophene) nanotubes on conducting substrates via solution wetting. Macromolecules, 2011, 44: 8558–8562

Wang J H, Min G Q, Song Z T, et al. Solvent-infiltration imprint lithography: A novel method to prepare large area poly(3-hexylthiophene) micro/nano-patterns. J Mater Chem, 2012, 22: 21154–21158

References

Zhang Z B, Luo Y, Wang X D, et al. A low temperature ultrasonic bonding method for PMMA microfluidic chips. Microsyst Tech, 2010, 16: 533–541

Liu S J, Dung Y T. Hot embossing precise structure onto plastic plates by ultrasonic vibration. Polym Eng Sci, 2005, 45: 915–925

Author information

Authors and Affiliations

Corresponding authors

Electronic supplementary material

Rights and permissions

About this article

Cite this article

Tian, W., Huang, L., Wang, D. et al. A general, rapid and solvent-free approach to fabricating nanostructured polymer surfaces. Sci. China Technol. Sci. 57, 2328–2333 (2014). https://doi.org/10.1007/s11431-014-5647-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11431-014-5647-5