Abstract

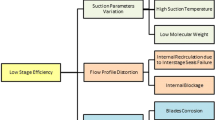

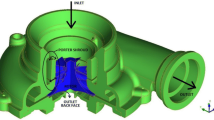

Very high flow coefficient centrifugal compressor stages are mostly applied as the first stages of multistage compressors. The performance of this type of stages is critical to the entire centrifugal compressors, but surprisingly little related information is available in the open literature. A centrifugal compressor with high inlet flow coefficient of 0.2, presenting a narrow operating range and unstable running situation even at design speed during the test, is investigated here. To reveal flow details in this centrifugal compressor, numerical simulations have been carried out and indicate that excessive impeller flow diffusion results in the poor performance of this centrifugal compressor. With the same inlet flow coefficient, six redesign cases coming from an in-house one-dimensional analysis program are proposed together with impeller trimming and equal flow area design method for corresponding vaneless diffuser. Performance comparison among these redesign centrifugal compressors is presented and the most suitable one is recommended for test in the future. In addition, three redesign cases with lower inlet flow coefficient developed by means of flow trimming are shown in the end to satisfy potential application areas. Finally, the results in this study can provide valuable reference information for multistage centrifugal compressor design.

Similar content being viewed by others

References

Sato T, Oh J M, Engeda A. Experimental and numerical investigation of the flow in a vaneless diffuser of a centrifugal compressor stage. Part 1: Experimental investigation. Proc Inst Mech Eng C-J Mech Eng Sci, 2005, 219: 1053–1059

Sorokes J M. Selecting a centrifugal compressor. Chem Eng Prog, 2013, 6: 44–51

Dalbert P, Ribi B, Kmeci T, et al. Radial compressor design for industrial compressor. Proc Inst Mech Eng C-J Mech Eng Sci, 1999, 213: 71–83

Tsang L M. A theoretical account of impeller trimming of the centrifugal pump. Proc Inst Mech Eng C-J Mech Eng Sci, 1992, 206: 213–214

Mario S, Hrvoje K, Igor S. Improving centrifugal pump efficiency by impeller trimming. Desalination, 2009, 249: 654–659

Yang S S, Kong F Y, Jiang W M, et al. Effects of impeller trimming influencing pump as turbine. Comput Fluids, 2012, 67: 72–78

Engeda A. Effect of impeller exit width trimming on compressor performance. In: Proceedings of the 8th International Symposium on Experimental and Computational Aerothermodynamics of Internal Flows. Lyon, France, July 2007. ISAIF 8-00135

Xu C, Amano R S. Empirical design considerations for industrial centrifugal compressors. Int J Rotat Mach, 2012, 2012: 184061

Rodgers C. Centrifugal compressor blade trimming for a range of flows. In: Proceedings of ASME Turbo Expo 2001, New Orleans, Louisiana, June 2001. 2001-GT-0316

Ji X N, Liu Y G, Zhu Z F, et al. Numerical simulation of impeller trimming for centrifugal compressor. Vehicle Eng, 2012, 2: 26–29

Moroz L. Centrifugal compressor design and rerating in turbochargers. Technical Paper. SoftInWay, Inc. Burlington, MA, USA, 2010

David T, Zhang D H, Cave M. Frictional effects on a base and a flow-trimmed impeller of a low specific speed industrial compressor. In: ASME Turbo Expo 2006: Power for Land, Sea and Air, Barcelona, Spain, May 8–11, 2006. GT 2006-90998

Schumann L F, Clark D A. Effect of area ratio on the performance of a 5.5:1 pressure ratio centrifugal impeller. ASME J Turbomach, 1987, 109: 10–19

Shibata T, Nishida H, Kobayashi H, et al. Effect of impeller blade loading on compressor stage performance in a high specific speed range. ASME J Turbomach, 2012, 134: 041012

Wang Y S, Tong Z T, Lin F, et al. Stall improvement mechanism of vaneless diffuser flow path control in a centrifugal compressor. J Aerospace Power, 2012, 27: 2106–2112

Wang Y S, Wang K, Tong Z T, et al. Design and performance evaluation of a very flow coefficient centrifugal compressor. Int J Rotat Turbomach, 2013, 2013: 293486

Japikse D. Centrifugal Compressor Design and Performance. Vermont, USA: Concepts ETI Inc., 1996

Aungier R H. Centrifugal Compressor: A Strategy for Aerodynamic Design and Analysis. New York: ASME Press, 2000

Shibata T, Nishida H, Kobayashi H, et al. Performance improvement of a centrifugal compressor stage by increasing degree of reaction and optimizing blade loading of a 3D impeller. ASME J Turbomach, 2011, 133: 041012

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Wang, Y., Wang, K., Lin, F. et al. Performance analysis and improvement of a high flow coefficient centrifugal compressor. Sci. China Technol. Sci. 57, 1647–1657 (2014). https://doi.org/10.1007/s11431-014-5557-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11431-014-5557-6