Abstract

It is well known that the effect of air entrainment for cavitation damage controls is related not only to the air discharge into aerator devices but also the flow regime of the cavity below them. On the basis of the hydraulic characteristics of the flow, the aerator devices were for the first time classified. The theoretical considerations were performed about the jet length and cavity flow regime with the influencing factors. Comparing with the behavior of the flow through the aerator of discharge tunnels, the flow regimes of the cavity below spillway aerators were experimentally investigated, and the empirical expressions were presented to identify the conversions of the cavity flow regimes, including fully filled cavity, partially filled cavity, and net air cavity. Some issues of the design of the aerator devices were suggested in the present work.

Similar content being viewed by others

References

Novak P, Moffat A I B, Nalluri C, et al. Hydraulic Structures. London and New York: Spon Press, 2001

Quintela A C. Flow aeration to prevent cavitation erosion. Water Power Dam Constr, 1980, 32(1): 17–22

IWHR (China Institute of Water Resources and Hydropower Research), Fengjiashan Reservoir Project Headquarters, Shanxi Province Institute of Water Resources and Electric Power Investigation and Design, et al. Prototype investigations of air entrainment to pre vent cavitation damage for spillway of the Fengjiashan reservoir (in Chinese). Shanxi Water Resources and Hydropower, 1996, 68(1): 50–51

Peterka A J. The effect of entrained air on cavitation pitting. In: Proceedings of the 5th IAHR Congress. Minneapolis, IAHR, 1953. 507–518

Falvey H T. Cavitation in Chutes and Spillway. Denver: Bureau of Reclamation, 1990

Chen W X, Xie S Z, Liu Z P, et al. Aeration device on lateral walls for the discharge tunnel with inclined inlet (in Chinese). Hydropower, 2005, 31(4): 31–34

Wu J H, Ruan S P. Cavity length below chute aerators. Sci China Ser E-Tech Sci, 2008, 51(2): 170–178

Pinto N L de S, Neidert S H, Ota J J. Aeration at high velocity flows. Water Power Dam Constr, 1982, 34(2): 34–38

Pinto N L de S, Neidert S H. Evaluating entrained air flow through aerators. Water Power Dam Constr, 1983, 35(8): 40–42

Mohaghegh A. Hydraulics of bottom cavity downstream of discharge tunnel service gate. Doctoral Dissertation. Nanjing: Hohai University, 2009

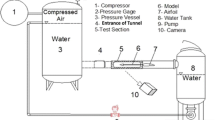

Wu W W, Wu J H, Ruan S P. Study of the geometries of aerators for flat-bottomed discharge tunnels (in Chinese). Chin J Hydrodyn, 2007, 22(4): 397–402

Qi L J, Liao H S, Li G J, et al. Numerical simulation on backwater downstream of aerators in spillway with low Froude number flow (in Chinese). J Hydrau Eng, 2007, 38(7): 819–825

Shi Q S, Pan S B, Shao Y Y, et al. Experimental investigation of flow aeration to prevent cavitation erosion by a deflector (in Chinese). J Hydrau Eng, 1983, 14(3): 1–13

Chanson H. Predicting the filling of ventilated cavities behind spillway aerators. J Hydrau Res, 1995, 33(3): 361–372

Mohagheg A, Wu J H. Hydraulics of discharge tunnel service gate: the flow regimes. In: Proceedings of the 9th International Conference of Hydrodynamics, Shanghai, China, 2010. 726–732

Wu J H, Ma F, Dai H C. Influence of filling water on air concentration. J Hydrodyn, 2011, 23(5): 601–606

Ma F, Wu J H. Flow regime below aerators for discharge tunnel. J Hydrodyn, 2012, 24(6): 378–382

Wu J H, Fu Z F, Wang J Q, et al. Experimental investigation of air entrainment to prevent cavitation damage for the spillway of the Jiangpinghe hydropower station (in Chinese). Hohai University, Report No. 2010817216, 2010

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Wu, J., Ma, F. Cavity flow regime for spillway aerators. Sci. China Technol. Sci. 56, 818–823 (2013). https://doi.org/10.1007/s11431-013-5145-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11431-013-5145-1