Abstract

This article describes the efforts that led to the development of surface-loaded preforms that may be used to significantly improve the compression-after-impact strength of high-temperature composites and correspondingly to dramatically reduce the area of damage because of impact. Moreover, by matching the toughening polymer surface-loaded and design of the surface pattern, in-plane mechanical properties are unaffected or even improved over laminates made from the identical materials. The proprietary preforms, so-called ES™-Fabrics, may be handled and infused with the high-temperature RTMable resins such as bismaleimide and polyimide in exactly the same manner as traditional fabrics without surface modification. The RTM conditions for the preform-based toughening is fully compatible with the traditional process procedure, making the technology cost-effective in production. This technology represents a key enabler for the use of low-cost RTM processes for high-temperature resins to supplant prepreg as the building-block material of choice for aeronautical composite structures.

Similar content being viewed by others

References

Tsotsis T K. Interlayer toughening of composite materials. Polym Compos, 2009, 30(1): 70–86

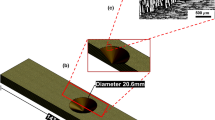

Yi X S, An X F, Tang B M, et al. Ex-situ formation of periodic interlayer structure to significantly improve the impact damage resistance of carbon laminates. Adv Eng Mater, 2002, 14(83): 3117–3122

An X F, Ji S Y, Tang B M, et al. Toughness improvement of carbon laminates by periodic interleaving thin thermoplastic films. J Mater Sci Lett, 2002, 21: 1763–1765

Long W, Xu J, Yi X S, et al. A preliminary study on resin transfer molding of highly toughed carbon laminates by ex-situ method. J Mater Sci Lett, 2003, 22: 1763–1765

Yi X S, An X F. Effect of interleaf sequence on impact damage and residual strength in a graphite/epoxy laminate. J Mater Sci Lett, 2004, 22: 3253–3255

Yi X S. Theory and Application of High-performance Polymer Matrix Composites (in Chinese). Beijing: National Defense Industry Press, 2011

Yi X S, An X F, Tang B M, et al. A Toughened Composite Laminate and a Process forPreparing the Same. PCT Patent No. FP1060809P, 2010.8.4

Yi X S, An X F, Zhang M, et al. A Preform for Liquid Molding Technology of Composites and the Process for Manufacturing Them. Chinese Patent No. ZL200510075276.7, 2010.9.8

Trademark Registration (in Chinese). No. 6962151, 6962152, 6962153. Beijing, 2010.5.28

Cheng Q F. Studies on Toughening Composites based on BMI Resin by Ex-Situ Concept (in Chinese). Disertation of Doctoral Degree. Hangzhou: Zhejiang University, 2007

Liu Z Z, Guo E, Xing J, et al. Application of carbon fiber/RTMable polyimide composites by Ex-situ toughening method. Acta Materiae Compositae Sinica, 2010, 27(6): 1–8

Inoue T. Reaction-induced phase decomposition in polymer blends. Prog Polym Sci, 1995, 20: 119–153

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Yi, X., Cheng, Q. & Liu, Z. Preform-based toughening technology for RTMable high-temperature aerospace composites. Sci. China Technol. Sci. 55, 2255–2263 (2012). https://doi.org/10.1007/s11431-012-4949-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11431-012-4949-8