Abstract

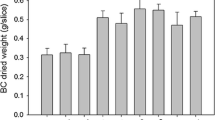

Continuous usage of bioreactor causes early degradation of most bioreactor liner materials due to the effects of various chemicals, consequently resulting in contamination in the bioprocess. Performance of PP-ternary nanocomposite (PPTN) for its potential application in the fabrication of bioreactor liner material was investigated in this study. The chemical resistance of the composite samples obtained was tested by exposing them to chemicals such as acid, alkaline, water and bacterial solutions, according to ASTM 543-06, and their effects on the composite samples were carefully observed. Specifically, the investigation focused on the changes in the physico-mechanical properties of PPTN following long term of exposure to these chemicals. The results show slight increase in the weight and dimensions of samples in the first few days, followed by constant reading for the period of 4 weeks. The performance in terms of physical properties was in the range of PPTN with 0.61% MWCNT > PPTN 0.45% > PPTN 0.17%. The maximum percentage change in tensile properties, observed in this study, was approximately 10% against PPTN (0.17%), which indicates stable mechanical properties of the composite and invariably suggests that the nanocomposites could serve as a better alternative for bioreactor liner fabrication.

Similar content being viewed by others

References

Van Krevelin, Te Nijenhuis K. Properties of Polymers: Their Correlation with Chemical Structure; Their Numerical Estimation and Prediction from Additive Group Contributions. 4th ed. Amsterdam, Boston, London, New York, Sydney: Elsevier, 2009. 779–786

Donna A J, David A J, James L U, et al. Weathering characteristics of fibre-polymer composites. Proceeding of the Fifth International Conference on Woodfibre-Plastic Composites Madison, Wisconsin, 2002. 203–209

Nicole M S. Consideration in the weathering of wood-plastic composites. Proceeding of the 3rd Wood Fibre Polymer Composites International Symposium. Cite Mondiale Bordeaux, France, 2007. 2–10

Ramakrishna S, Mayer J, Winter-mantel E, et al. Applications of polymer-composite. Mater, Rev Comp Sci Technol, 2001, 61: 1189–1224

Chisti Y. Assure bioreactor sterility. Chem Eng Progr, 1992, 88: 80–85

Soderberg A C. Fermentation design. In: Vogel H C, ed. Fermentation and Biochemical Engineering Hand Book. Park Ridge, NJ: Noyes Publication, 1983

Susan J P, Baltimore Md, Michael J Y, et al. Bone Replacement Compound Comprising Poly(polypropylene) Fumarate. United State Patent, 2000, 19: Pat. No. 6,124,373

Százdi L, Ábrányi Á, Pukánszky Jr, B, et al. Morphology characterization of PP/clay nanocomposites across the length scales of the structural architecture. Macromol Mater Eng, 2006, 291(7): 858–868

Gilman J W. Flammability and thermal stability studies of polymer layered-silicate (clay) nanocomposites. Appl Clay Sci, 1999, 15: 31–49

Cheng T K, Tien Y I, Wei K H. Synthesis and characterization of novel segmented polyurethane/clay nanocomposite. Polymer, 2000, 41(4): 1345–1353

Oya A Kurokawa, Y, Yasuda H. Factors controlling mechanical properties of clay mineral/polypropylene nanocomposites. J Mater Sci, 2000, 35(5): 1045–1050

Fornes T D, Yoon PJ, Keskkula H, et al. Nylon 6 nanocomposites: the effect of matrix molecular weight. Polymer, 2001, 42(25): 9929–9940

Beyer G. Flame retardancy of TPU and PVC nanocomposites. Gummi, Fersern, Kunststoffe, 2006, 59(8): 493–498

Sudip R, Siew Y Q, Allan E, et al. The potential use of polymer-clay nanocomposites in food packaging. Int J Food Eng, 2006, 2(4): 1–13

Chin-Chun T, Chen-Chi M M, Yen-Wei H, et al. Effect of MWCNT content on rheological and dynamic mechanical properties of MWCNT/PP composites. Composite, Part A: Appl Sci Manuf, 2008, 39(12): 1860–1875

Oliver D, Michael C. Carbon nanotubes: Reviewing their multifunctional properties for polymers. high performance fillers. Proceeding of the 2nd International Conference on Fillers for Polymers, Cologne, Germany, 2006, Paper 17

Salawudeen T O, Suleyman A M, Qasim H S, et al. Improving the polypropylene clay composite using carbon nanotube as secondary filler. Energy Res J, 2010, 1(2): 68–72

Myer K. Hand Book of Materials Selection. New York: John Willey, 2002

Rowell R M. Advances and challenges of wood polymer composites. Proceedings of the 8th Pacific Rim Bio-Based Composite Symposium, USDA Forest Services, University of Wisconsin, Madison, 2006. 1–11

Reda M B, Xin M, Firat V S, et al. Chemical resistance tests on four polymeric liner materials. Proceedings of North American Society for Trenchless Technology (NASTT), 2004. 1–10

Caciari I, Quatrini P, Zirletta G, et al. Isotactic polypropylene biodegradation by microbial community. Physicochemical characterization of metabolites produced. Appl Environ Microbiol, 1993, 59(11): 3695–3700

Mikulasova M, Kosikova B. Biodegradability of lignin-polypropylene composite films. Can J Microbiol, 2002, 48(3): 200–203

Arutchelvi J, Sudhakar M, Arkatkar A, et al. Biodegradation of polyethylene and polypropylene. Indian J Biotechnol, 2008, 7: 9–22

Nguyen Q T, Baird D G. An improve technique for exfoliating and dispersing nanoclay particles into polymer matrices using supercritical carbon dioxide. Polymer, 2007, 48: 6923–6933

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Farida, Y., Salawudeen, T.O., Qasim, H.S. et al. Chemical resistance tests on PP-ternary nanocomposite for its application in bioreactor liner fabrication. Sci. China Technol. Sci. 54, 2217–2223 (2011). https://doi.org/10.1007/s11431-011-4431-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11431-011-4431-z