Abstract

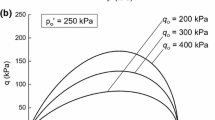

The influences of temperature on the mechanical behavior of saturated clays are discussed first. Based on the concept of true strength and the revised calculation method of the potential failure stress ratio, the equation of the critical state stress ratio for saturated clays under different temperatures is deduced. Temperature is introduced as a variable into the UH model (3-dimensional elastoplastic model for overconsolidated clays adopting unified hardening parameter) proposed by Yao et al. and then the UH model considering temperature effects is proposed. By means of the transformed stress method proposed by Yao et al., the proposed model can be applied conveniently to 3-dimensional stress states. The strain-hardening, softening and dilatancy behavior of overconsolidated clays at a given temperature can be described using the proposed model, and the volume change behavior caused by heating can also be predicted. Compared with the modified Cam-clay model, the proposed model requires only one additional parameter to consider the behavior of the decrease of preconsolidation pressure with an increase of temperature. At room temperature, the proposed model can be changed into the original UH model and the modified Cam-clay model for overconsolidated clays and normally consolidated clays, respectively. The considered temperature range here is from the melting point to the boiling point of the pore water (e.g. the experimental temperatures (20°C-95°C) mentioned in this paper are within this range). Comparison with existing test results shows that the model can reasonably describe the basic mechanical behavior of overconsolidated clays under various temperature paths.

Similar content being viewed by others

References

Laloui L, Modaressi H. Modelling of the thermo-hydroplastic behaviour of clays. In: Hydromechanical and Thermohydromechanical Behaviour of Deep Argillaceous Rock. 2002. 161–170

Bai B, Zhao C G. Temperature effects on mechanical characteristics of clay soil (in Chinese). Rock Soil Mech, 2003, 24(4): 533–537

Laloui L, Nuth M, Vulliet L. Experimental and numerical investigations of the behavior of a heat exchanger pile. Int J Numer Anal Meth Geomech, 2006, 30: 763–781

Mitchell J K, McMillan J, Green S, et al. Field testing of cable backfill systems. In: Underground Cable Thermal Backfill. 1982. 19–33

Laloui L, Moreni M, Fromentin A, et al. In-situ thermo-mechanical load test on a heat exchanger pile. In: 4th International Conference on Deep Foundation Practice. Singapore, 1999. 273–279

Campanella R G, Mitchell J K. Influence of temperature variations on soilm behavior. J Soil Mech Found Division, ASCE, 1968, 94: 709–734

Hueckel T, Borsetto M. Thermoplasticity of saturated soils and shales: Constitutive equations. J Geotech Engrg, ASCE, 1990, 116(12): 1765–1777

Hueckel T, Baldi G. Thermoplasticity of saturated clays: Experimental constitutive study. J Geotech Engrg, ASCE, 1990, 116(12): 1778–1796

Hueckel T, Francois B, Laloui L. Explaining thermal failure in saturated clays. Geotechnique, 2009, 3: 197–212

Tanaka N, Graham J, Crilly T N. Stress-strain behaviour of reconstituted illitic clay at different temperatures. Eng Geol, 1997, 47: 339–350

Sultan N, Delage P, Cui Y J. Temperature effects on the volume change behavior of boom clay. Eng Geol, 2002, 64: 135–145

Cui Y J, Sultan N, Delage P. A thermo-mechanical model for saturated clays. Can Geotech, 2000, 37(3): 607–620

Graham J, Tanaka N, Crilly T, et al. Modified Cam-Clay modeling of temperature effects in clays. Can Geotech, 2001, 38(3): 608–621

Cekerevac C, Laloui L. Experimental study of thermo effects on the mechanical behavior of a clay. Int J Num Anal Meth Geomechanics, 2004, 28: 209–228

Laloui L, Cekerevac C. Thermoplasticity of clays: An isotropic yield mechanism. Comput Geotech, 2003, 30(8): 649–660

Laloui L, Francois B. ACMEG-T: Soil thermo-plasticity model. J Eng Mech, ASCE, 2009, 135(9): 932–944

Abuel-Naga H M, Bergado D T, Lim B F. Effect of temperature on shear strength and yielding behavior of soft Bangkok clay. Soils Found, 2007, 47(3): 423–436

Abuel-Naga H M, Bergado D T, Bouazza A, et al. Volume change behavior of saturated clays under drained heating conditions: Experimental results and constitutive modeling. Can Geotech J, 2007, 44(8): 942–956

Abuel-Naga H M, Bergado D T, Bouazza A, et al. Thermomechanical model for saturated clays. Geotechnique, 2009, 3: 273–278

Chen Z H, Xie Y, Sun S G, et al. Temperature controlled triaxial apparatus for soils and its application (in Chinese). Chin J Geotech Eng, 2005, 27(8): 928–933

Dafalias Y F. Bounding surface plasticity. I: Mathematical foundation and hypoplasticity. J Eng Mech, 1986, 112(9): 966–987

Hashiguchi K. Subloading surface model in unconventional plasticity. Int J Plasticity. 1989, 25(8): 917–945

Asaoka A. Consolidation of clay and compation of sand-an elasto-plastic. In: 12 Asian Regional Conference on Soil Mechanics and Geotechnical Engineering. World Scientific Publishing Company, 2004. 1157–1195

Nakai T, Hinokio M. A simple elastoplastic model for normally and over consolidated soils with unified material parameters. Soils and Foundations, 2004, 44(2): 53–70

Yao Y P, Hou W, Zhou A N. UH model: Three-dimensional unified hardening model for overconsolidated clays. Geotechnique, 2009, 59(5): 451–469

Yao Y P, Li Z Q, Hou W, et al. Constitutive model of over-consolidated clay based on improved Hvorslev envelope (in Chinese). J Hydraul Eng, 2008, 39(11): 1244–1250

Eriksson L G. Temperature effects on consolidaton properties of sulphide clays. In: 12th International Conference on Soil Mechanics and Foundation Engineering, 1989. 2087–2090

Tidfors M, Sällfors S. Temperature effect on preconsolidation pressure. Geotec Test J, 1989, 12(1): 93–97

Boudali M, Leroueil S, Sinivasa M B R. Viscous behaviour of natural clays. In: 13th International Conference on Soil Mechanics and Foundation Engineering, 1994. 411-416

Alonso E E, Gens A, Josa A. A constitutive model for partially saturated soils. Geotechnique, 1990, 40(3): 405–430

Roscoe K H, Burland J B. On the generalized stress-strain behavior of ‘wet’ clay. In: Engineering Plasticity. Cambrige University Press, 1968. 535–609

Matsuoka H, Yao Y P, Sun D A. The cam-clay models revised by the SMP criterion. Soils Found, 1999, 39(1): 81–95

Yao Y P, Sun D A. Application of Lade’s criterion to Cam-clay model. ASCE, J Engrg Mech, 2000, 126(1): 112–119

Towhata I, Kuntiwattanakul P, Seko I, et al. Volume change of clays induced by heating as observed in consolidation test. Soils Found, 1993, 33(4): 170–183

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Yao, Y., Yang, Y. & Niu, L. UH model considering temperature effects. Sci. China Technol. Sci. 54, 190–202 (2011). https://doi.org/10.1007/s11431-010-4209-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11431-010-4209-8