Abstract

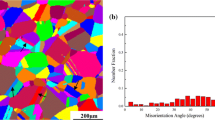

The effect of dendrite arm spacing and the size of γ′ phase on stress rupture properties of as-cast Ni3Al-based single crystal superalloy IC6SX was studied. It has been found that the stress rupture properties were affected by dendrite arm spacing and the size of γ′ phase significantly, i.e., the stress rupture lives of as-cast specimens under the test condition of 1100°C/120 MPa were significantly increased from about 10 h to 31 h with decreasing dendrite arm spacing and the size of γ′ phase from 3.0 μm and 1.6 μm to 1.3 μm and 0.8 μm, respectively. The creep cracks generated easily in the brittle Y-NiMo phase. Then the cracks gradually mergered and grew up during creep, and finally led to specimens fracture. The orientated coarsening of γ′ phase has been found in the stress ruptured specimens, due to the elements diffusion. However, the γ′ phase did not form the integrated structure during the short periods of 10–31 h as the creep tests lasted.

Similar content being viewed by others

References

Caron P, Henderson P J, Khan T, et al. On the effects of heat treatments on the creep behaviour of a single crystal superalloy. Scripta Metall, 1986, 20(6): 875–880

Xia P C, Yu J J, Sun X F. Influence of heat treatment on the microstructure and stress rupture property of DZ951 alloy. J Mater Process Technol, 2007, 186(1-3): 315–322

Li S S, Zheng Y R, Han Y F. Effect of Al content on the microstructure and stress rupture properties of DS Ni3Al based alloy. Rare Metal Mater Eng, 2004, 33(12): 1329–1332

Ma W Y, Han Y F, Li S S. Effect of Mo content on the microstructure and stress rupture of an Ni based single crystal superalloy. Acta Metall Sin, 2006, 42(11): 1191–1196

Yin F S, Sun X F, Li Y B. Effect of melt superheating treatment on the microstructure and high temperature stress rupture properties of M963 superalloy. Acta Metall Sin, 2003, 39(1): 75–78

Zhao L, Liu J R, Wang Q J, et al. Effect of precipitates on the high temperature creep and creep rupture properties of Ti60 alloy. Chinese J Mater Res, 2009, 23(1): 1–5

Zhao J Q, Li J R, Liu S Z, et al. Effects of low angle grain boundaries on stress rupture properties of single crystal superalloy DD6. J Aeronaut Mater, 2007, 27(6): 6–10

Jiang L W, Li S S, Qiu Z C, et al. Effects of withdrawal rate on microstructure and stress rupture properties of a Ni3Al-based single crystal superalloy IC6SX. Acta Metall Sin, 2009, 45(5): 547–552

Han Y F, Li S H, Jin Y, et al. Effect of 900–1150°C aging on the microstructure and mechanical properties of a DS casting Ni3Al-base alloy IC6. Mater Sci Eng A, 1995, 192–193(2): 899–905

Author information

Authors and Affiliations

Corresponding author

Additional information

This work was supported by the National Natural Science Foundation of China (Grant No. 50971005) and Beihang University Innovation Fund.

Rights and permissions

About this article

Cite this article

Jiang, L., Li, S., Wu, M. et al. Effect of dendrite arm spacing and the γ′ phase size on stress rupture properties of Ni3Al-base single crystal superalloy IC6SX. Sci. China Technol. Sci. 53, 1460–1465 (2010). https://doi.org/10.1007/s11431-010-3223-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11431-010-3223-1