Abstract

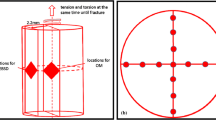

Cu samples were subjected to high-pressure torsion (HPT) with up to 6 turns at room temperature (RT) and liquid nitrogen temperature (LNT), respectively. The effects of temperature on grain refinement and microhardness variation were investigated. For the samples after HPT processing at RT, the grain size reduced from 43 μm to 265 nm, and the Vickers microhardness increased from HV52 to HV140. However, for the samples after HPT processing at LNT, the value of microhardness reached its maximum of HV150 near the center of the sample and it decreased to HV80 at the periphery region. Microstructure observations revealed that HPT straining at LNT induced lamellar structures with thickness less than 100 nm appearing near the central region of the sample, but further deformation induced an inhomogeneous distribution of grain sizes, with submicrometer-sized grains embedded inside micrometer-sized grains. The submicrometer-sized grains with high dislocation density indicated their nonequilibrium nature. On the contrary, the micrometer-sized grains were nearly free of dislocation, without obvious deformation trace remaining in them. These images demonstrated that the appearance of micrometer-sized grains is the result of abnormal grain growth of the deformed fine grains.

Similar content being viewed by others

References

Valiev R Z, Islamgaliev R K, Alexandrov I V. Bulk nanostructured materials from severe plastic deformation. Prog Mater Sci, 2000, 45(2): 103–189

Lu K, Lu J. Surface nanocrystallization (SNC) of metallic materials-presentation of the concept behind a new approach. J Mater Sci Technol, 1999, 15(3): 193–197

Wu X L, Tao N R, Wei Q M, et al. Microstructural evolution and formation of nanocrystalline intermetallic compound during surface mechanical attrition treatment of cobalt. Acta Mater, 2007, 55(17): 5768–5779

Hebesberger T, Stüwe H P, Vorhauer A, et al. Structure of Cu deformed by high pressure torsion. Acta Mater, 2005, 53(2): 393–402

Zhilyaev A P, Langdon T G. Using high-pressure torsion for metal processing: Fundamentals and applications. Prog Mater Sci, 2008, 53(6): 893–979

Segal V M, Reznikov V I, Mulyukov N A. Plastic working of metals by simple shear. Russ Met, 1981, 1: 99–105

Wang J T, Kang S B, Kim H W, et al. Microstructural lamellae deformation and structural evolution in an Al-33%Cu eutectic alloy during ECAP. J Mater Sci, 2002, 37(24): 5223–5227

Saito Y, Utsunomiya H, Tsuji N, et al. Novel ultra-high straining process for bulk materials—development of the accumulative roll-bonding (ARB) process. Acta Mater, 1999, 47(2): 579–583

Sakai G, Horita Z J, Langdon T G. Grain refinement and superplasticity in an aluminum alloy processed by high-pressure torsion. Mater Sci Eng A, 2005, 393(1–2): 344–351

Zhao Y H, Liao X Z, Zhu Y T, et al. Influence of stacking fault energy on nanostructure formation under high pressure torsion. Mater Sci Eng A, 2005, 410–411(25): 188–193

Zhang H W, Hansen N. Deformed metals and alloys with a structural scale from 5 nm to 100 nm. J Mater Sci, 2007, 42(5): 1682–1693

Huang X, Winther G, Hansen N, et al. Microstructures of nickel deformed by high pressure torsion to high strains. Mater Sci Forum, 2003, 420–426: 2819–2824

Xie Z L, Xie J J, Wu X L, et al. Microstructures and compression properties of copper specimens deformed by high-pressure torsion (in Chinese). Acta Metall Sin, 2008, 44(7): 803–809

Schiøtz J. Strain-induced coarsening in nanocrystalline metals under cyclic deformation. Mater Sci Eng A, 2004, 375–377: 975–979

Zhang K, Weertman J R, Eastman J A. The influence of time, temperature, and grain size on indentation creep in high-purity nanocrystalline and ultrafine grain copper. Appl Phys Lett, 2004, 85: 5197–5199

Zhang K, Weertman J R, Eastman J A. Rapid stress-driven grain coarsening in nanocrystalline Cu at ambient and cryogenic temperatures. Appl Phys Lett, 2005, 87: 061921–3

Liao X Z, Kilmametov A R, Valiev R Z, et al. High-pressure torsion-induced grain growth in electrodeposited nanocrystalline Ni. Appl Phys Lett, 2006, 88: 021909–3

Humphreys F J, Hatherly M. Recrystallization and Related Annealing Phenomena. 2nd ed. New York: Pergamon Press, 2004. 11–15

Wang Y M, Jiao T, Ma E. Dynamic processes for nanostructure development in Cu after severe cryogenic rolling deformation. Mater Trans, 2003, 44(10): 1926–1934

Author information

Authors and Affiliations

Corresponding authors

Additional information

This work was supported by the National Natural Science Foundation of China (Grant Nos. 10721202, 10772178, 50571110).

Rights and permissions

About this article

Cite this article

Xie, Z., Xie, J., Hong, Y. et al. Influence of processing temperature on microstructure and microhardness of copper subjected to high-pressure torsion. Sci. China Technol. Sci. 53, 1534–1539 (2010). https://doi.org/10.1007/s11431-010-3157-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11431-010-3157-7