Abstract

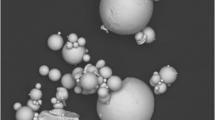

Amorphous magnetic alloy powders were prepared from bulk metallic glasses Fe74Cr2Mo2Sn2P10Si4B4C2 with supercooled liquid region of 32 K by water atomization. Amorphous magnetic powder core precursor was produced from a mixture of the amorphous alloy powder with addition of insulation and bonding materials by mold compacting at room temperature. After annealing the core precursor, the amorphous magnetic core exhibits superior magnetic properties as compared with molypermalloy powder core. The initial permeability up to 1 MHz was about 80, the flux density at 300 Oe was 1.06 T and the core loss at 100 kHz for B m =0.1 T was only 329 kW/m3. The ultra-low core loss is attributed to the combination of relatively high resistivity and the amorphous structure of the Fe-based amorphous powder. Besides the outstanding magnetic properties, the Fe-based amorphous magnetic powder core had a much lower cost which renders the powder cores a potential candidate for a variety of industrial applications.

Similar content being viewed by others

References

Egami T, Flanders P J, Graham C D. Low-field magnetic properties of ferromagnetic amorphous alloys. Appl Phys Lett, 1975, 26: 128–130

Yoshizawa Y, Oguma S, Yamauchi K. New Fe-based soft magnetic alloys composed of ultrafine grain structure. J Appl Phys, 1988, 64: 6044–6046

Inoue A, Gook J S. Fe-based ferromagnetic glassy alloys with wide supercooled liquid region. Mater Trans JIM, 1995, 36: 1180–1183

Inoue A, Shinohala Y, Gook J S. Thermal and magnetic properties of bulk Fe-based glassy alloys prepared by copper mold casting. Mater Trans JIM, 1995, 36: 1427–1433

Shen T D, Schwarz R B. Bulk ferromagnetic glasses prepared by flux melting and water quenching. Appl Phys Lett, 1999, 75: 49–51

Shen B L, Kimura H M, Inoue A, et al. Bulk glassy Fe-Co-Ga-P-C-B alloys with high glass-forming ability, high saturation magnetization and good soft magnetic properties. Mater Trans JIM, 2000, 41: 1675–1678

Inoue A, Shen B L. Soft magnetic bulk glassy Fe-B-Si-Nb alloys with high saturation magnetization above 1.5 T. Mater Trans JIM, 2002, 43: 766–769

Yagi M, Endo I, Otsuka I, et al. Magnetic properties of Fe-based amorphous powder cores produced by a hot-pressing method. J Magn Magn Mater, 2000, 215–216: 284–287

Shen B L, Inoue A, Kimura H, et al. Bulk glassy soft-magnetic cores produced by spark-plasma sintering Fe65Co10Ga5P12C4B4 glassy powder. Mater Sci Eng A, 2004, 375–377: 666–670

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Zhang, L., Li, D., Lu, Z. et al. Novel Fe-based amorphous magnetic powder cores with ultra-low core losses. Sci. China Technol. Sci. 53, 1290–1293 (2010). https://doi.org/10.1007/s11431-010-0055-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11431-010-0055-y