Abstract

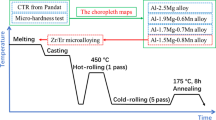

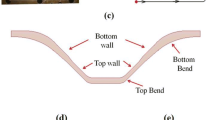

Several alloying elements involving Zr, Cu, Zn and Sc were added to Al-Mg sheet alloys in order to obtain an excellent combination of high strength and good high-temperature formability. Microstructural examination showed that coarse intermetallic particles were formed in the microstructure and their amounts changed with variations of the alloying elements. During warm rolling of thermomechanical treatments prior to warm deformation, the coarse particles initiated cracks, decreasing the warm formability. For healing the crack damage and further improving the warm formability, a process of hot isothermal press was developed and optimized to the sheet alloys. With this process, the biaxial stretch formability at 350°C was improved by 22% for an aluminum alloy containing a large amount of coarse particles.

Similar content being viewed by others

References

Mcnelley T R, Ishi K O, Zhilyaev A P, et al. Characteristics of the transition from grain-boundary sliding to solute drag creep in superplastic AA5083. Metal Mater Trans A, 2008, 39(1): 50–64

Li D, Ghosh A K. Tensile deformation behavior of aluminum alloys at warm forming temperatures. Mater Sci Eng A, 2003, 352(1–2): 279–286

Li D, Ghosh A K. Biaxial warm forming behavior of aluminum sheet alloys. J Mater Process Technol, 2004, 145(3): 281–293

Taleff E M, Nevland P J, Krajewski P E. Tensile ductility of several commercial aluminum alloys at elevated temperatures. Metal Mater Trans A, 2001, 32(5): 1119–1130

Cahn R W, Haasen P. Physical Metallurgy. Amsterdam: Elsevier Science B.V., 1996. 2106

Lassance D, Fabregue D, Delannay F, et al. Micromechanics of room and high temperature fracture in 6xxx Al alloys. Prog Mater Sci, 2007, 52(1): 62–129

Toda H, Kobayashi T, Takahashi A. Mechanical analysis of toughness degradation due to premature fracture of course inclusions in wrought aluminium alloys. Mater Sci Eng A, 2000, 280(1): 69–75

Bae D H, Ghosh A K. Cavity formation and early growth in a superplastic Al-Mg alloy. Acta Mater, 2002, 50(3): 511–523

Liu J, Morris J G. Recrystallization microstructures and textures in AA 5052 continuous cast and direct chill cast aluminum alloy. Mater Sci Eng A, 2004, 385(1–2): 342–351

Røyset J, Ryum N. Scandium in aluminium alloys. Int Mater Rev, 2005, 50(1): 19–44

Koike J, Ohyama R. Geometrical criterion for the activation of prismatic slip in AZ61 Mg alloy sheets deformed at room temperature. Acta Mater, 2005, 53(7): 1963–1972

Hosford W F, Caddell R M. Metal Forming: Mechanics and Metallurgy. 2nd edition. Englewood Cliffs: PTR Prentice Hall, 1993. 309

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Zhu, H., Dahle, A.K. & Ghosh, A.K. Improvement of warm formability of Al-Mg sheet alloys containing coarse second-phase particles. Sci. China Ser. E-Technol. Sci. 52, 41–45 (2009). https://doi.org/10.1007/s11431-008-0275-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11431-008-0275-6