Abstract

Purpose

Landfilling can result in a loss in revenue that would otherwise have been accrued from recycling plastic waste, loss in potential jobs, and groundwater contamination. Plastics in landfills may also eventually find their way into marine environments, where they can be damaging to animals. This work aims to establish the environmental sustainability of current plastic waste management practices in South Africa using the City of Johannesburg (CoJ) as a case study.

Methodology

Five scenarios encompassing combinations of landfilling, mechanical recycling, incineration with energy recovery, gasification, and use of plastic waste in a cement kiln were assessed through an environmental Life Cycle Assessment (e-LCA). Scenarios were developed based on an extensive literature review, current practices in South Africa and Europe, and the country’s National Waste Management strategy, which aims to achieve “zero waste to landfill”. SimaPro 9.1.1 software and the Ecoinvent Database were used to assess the life cycle impacts of each scenario over seven impact categories. The ReCiPe endpoint method, Egalitarian version, was employed in determining the impact potentials. A sensitivity analysis was also carried out to evaluate the model’s robustness.

Results and discussion

Overall, the impact assessment results, including damage assessments and single score results, revealed that moving away from landfilling and combining mechanical recycling, incineration, gasification, and use of plastic waste (PW) as solid refuse fuel in a cement kiln is the least environmentally impactful scenario when managing plastic waste. Landfilling alone was the worst-performing scenario, resulting in adverse effects on human health, ecosystems, and resource depletion. This agrees with the waste hierarchy. On sensitivity analysis, the increase in transportation distances and reduction in market substitution factor in mechanical recycling did not change the ranking of scenarios despite reducing the net benefits to the environment. Including open dumping as an end-of-life scenario significantly increased the negative impact of the current plastic waste management scenario being practised in South Africa, while assuming a 100% mechanical recycling rate had the least environmental impact when compared to the other modelled scenarios.

Conclusions

The current plastic waste management practices in South Africa were found to be environmentally unsustainable based on the modelled scenarios, and a move away from landfilling is encouraged. The outcomes of this study will assist policymakers and other stakeholders in making informed decisions based on scientific evidence when formulating sustainability-related waste management policies.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Managing plastic waste is a complex problem worldwide, and South Africa is also not immune to it (Mazhandu et al. 2020a). Depending on existing local conditions, various plastic waste management methods are employed through different spatial scales. For example, Europe uses a combination treatment that entails incineration with energy recovery, mechanical recycling, and landfilling (Mazhandu et al. 2020b). In North America, landfilling is common, with limited recycling and energy recovery as quantities above 70% of landfilled plastic waste have been reported for both the USA and Canada (Mazhandu et al. 2020a; Mazhandu et al. 2021b; CCME 2018). In Latin America, open dumping is common, with limited recycling (UNEP 2021). In Australia, plastic waste is managed through recycling, landfilling, and as solid refuse fuel in cement kilns, although this type of energy recovery is small scale (O’farrell and Allan 2020). In Asia, energy recovery, mechanical recycling, landfilling, and minimal chemical recycling are used. However, low and middle-income countries in the same region practice indiscriminate dumping in open dumps or aquatic systems, while some waste is openly burnt (Liang et al. 2021; UN 2020; World Bank 2021). A paltry 4% of municipal solid waste (MSW) in Africa undergoes recycling (Godfrey et al. 2019). This low recycling rate also indicates that considerable quantities of plastic waste are mismanaged in the region and, therefore, illegally dumped, burnt, or disposed of in landfills with other MSW constituents (Mazhandu et al. 2020b). In South Africa, plastic waste management is through recycling and landfilling, with the bulk of plastic waste ending up in landfills. Although some of the plastic waste in landfills is recovered and sent for recycling, the plastic waste is contaminated. Therefore, this increases the cost of recycling, and the plastic can only be made into lower-value products (Mazhandu et al. 2020a, b).

In this work, five scenarios for managing plastic waste were developed. Through an environmental life cycle assessment (e-LCA), environmental impact loads were calculated to determine the best plastic waste management scenario for South Africa. The City of Johannesburg was used as a case study. LCA is a robust tool that can be used to quantify environmental loads over a broad range of categories encompassing human health (carcinogenic and non-carcinogenic), the ecosystem, and resource depletion (Antelava et al. 2019). Although LCA is growing in popularity worldwide, its application in Africa is limited, possibly due to a lack of the necessary skills and limited data (Khandelwal et al. 2019). This has also resulted in limited research of this nature in Africa. In a review of 153 studies done by Khandelwal (2019), 47% were from Asia, 35% from Europe, 6.5% from North America, 5.9% from South America, and 2% from Africa. Mølgaard (1995), Song and Hyun (1999), Lazarevic et al. (2010), Shonfield et al. (2008), Aryan et al. (2019), Chilton et al. (2010), Moberg et al. (2005), Arena et al. (2003), Dodbiba et al. (2008), Al-Salem et al. (2014), and Zackrisson et al. (2014) carried LCAs on plastic waste management practices. Policymakers can utilise LCA in decision-making (ISO 2006). This study’s outcomes will assist in formulating sound plastic waste management policies and practices, and to the best of our knowledge, there have been no studies of such a nature in South Africa. This work is part of Zvanaka Mazhandu’s Final PhD Thesis draft, University of Johannesburg, 2022.

2 Methodology

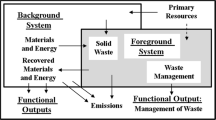

The e-LCA conducted in this study was complemented by an extensive literature search and analysis and field observations which aided the development of five scenarios for managing plastic waste in South Africa and acquiring relevant data. The LCA methodology is governed by the standards, ISO 14040:2006 and ISO 14044:2006, which are reviewed every 5 years (ISO 2006; Antelava et al. 2019). An LCA study is comprised of four phases, namely (ISO 2006; Mazhandu et al. 2021c):

-

Goal and scope definition Study objectives and system boundaries are outlined (Shen et al. 2011).

-

Life cycle inventory (LCI) analysis Input and output data (foreground and background data) are either determined from the site of interest, mass and energy balances, literature, and/or databases such as Ecoinvent (Antelava et al. 2019; SimaPro 2021).

-

Life cycle impact assessment (LCIA) Environmental impact loads are determined across various impact categories.

-

Interpretation of results All acquired results are assessed, followed by conclusions and recommendations (ISO 2006).

SimaPro 9.1.1 software and the Recipe endpoint method, Egalitarian version, were used to assess impacts associated with the developed scenarios (Huijbregts et al. 2016). The Recipe method was selected due to its ability to assess a broad number of impact categories (PRé Sustainability 2016). This was subsequently followed by a sensitivity analysis in which transportation distance was increased, followed by a reduction in market substitution factor for recycled granulate from 1 to 0.5, the introduction of plastic waste leakage, and the assumption of a 100% mechanical recycling rate to assess environmental impact.

2.1 Description of locality

The CoJ is in South Africa and is also the provincial capital city of Gauteng Province and the economic hub of South Africa. The CoJ covers an area of approximately 1645 km2 (Risimati and Gumbo 2018). The CoJ is considered the wealthiest city in South Africa (Wealth 2021) and has the highest population density among other municipalities (Wikipedia 2022). There are four operational landfills in the CoJ, and these are Robinson Deep, Goudkoppies, Marie Louise, and Ennerdale. However, these landfills are remaining with less than five years before they reach the end of their life span (Farvacque-Vitkovic and Kopanyi 2014; Otto 2020). This underlines the need to develop alternative ways of managing plastic waste.

2.2 Goal and scope

The environmental impacts of five developed scenarios were compared to determine the least environmentally impactful scenario of managing plastic waste in South Africa, using CoJ as a case study. Conventional and emerging technologies implemented globally in plastic waste management were considered in forming scenarios. These are landfilling, mechanical recycling, incineration, gasification, and the use of plastic waste in cement kilns as solid refuse fuel (SRF). In the South African context, incineration is practised for medical waste (Chisholm et al. 2021), use of cement kilns is also practised, albeit at a small scale (Plastics 2019), while gasification is employed for coal (Nkosi et al. 2021). The waste hierarchy, which places landfilling as the worst waste management method, was also taken into consideration in formulating these scenarios.

To enable the use of avoided products, a consequential approach and system expansion were followed (Fan et al. 2022). The business-as-usual (BAU) approach entailing a 45.7% input recycling rate and landfilling of the remaining plastic (Plastics 2019) waste was also modelled. The amount of plastic waste generated in CoJ was estimated to be 134,067 tonnes, which is, therefore, the functional unit. Table 1 shows the various scenarios and proportions of plastic waste treated or managed in each scenario. Scenarios were developed based on an extensive literature review, current practices in South Africa and Europe, and South Africa’s National Waste Management Strategy, which aims to achieve “zero waste to landfill”.

Environmental loads associated with plastics production, transportation to the market, use, and disposal phases followed by transport to a material recovery facility (MRF) were not considered since it was assumed that these would be similar (Shonfield 2008; Demetrious and Crossin 2019). The system boundary for this study commenced from the point at which baled plastic waste leaves the MRF to the waste management facility. The methodology where waste does not carry impacts associated with upstream processes is known as “burden-free”.

The avoided processes, including assumptions used in modelling scenarios are tabulated in Table 2.

2.3 Life cycle inventory

2.3.1 Plastic waste inventory

The plastic waste inventory stage brought to the fore data inconsistencies in statistics reported for South Africa, as highlighted in an earlier publication by Mazhandu et al. (2021b). Deficiencies in accurate data can be attributed to the under-reporting of plastic streams (Verster and Bouwman 2020), including imports, lack of waste separation at source programmes, absence of weighbridges and classification of MSW at landfill sites, and lack of formal waste collection services for 34.1% of households in South Africa (DEFF 2020). To minimise underestimating the environmental impacts associated with the developed scenarios, a worst-case scenario approach in scenario development was adopted as proposed by Welford (Welford 1994). Therefore, it was assumed that the amount of plastic converted in the country would be equal to the amount of plastic waste available for treatment using various technologies. Quantities of plastic resin converted between 2000 and 2019 determined from the output recycling rates illustrated in Fig. 1 were considered. From this data, the average annual plastic waste generation for South Africa and Johannesburg were determined and are indicated in Table 3. Other data used in the models was also generated from peer-reviewed literature and the Ecoinvent databases.

Plastic waste recycled between 2000 and 2019 in South Africa. (Plastics 2019)

The calculated value for plastic waste generated per capita per day shown in Table 3 as 0.062 kg/capita/day is comparable to the value determined by Verster and Bouwman of 0.053 kg/capita/day (Verster and Bouwman 2020).

Plastic waste composition

The average composition of generated plastic waste was determined using the triangular distribution method. Data from 2016 to 2019, shown in Fig. 2, was considered. Table 4 illustrates the determined approximate composition.

Tonnages recycled per plastic type, 2016–2019. (Plastics 2019)

2.3.2 Transportation mode and distances

Table 5 shows the transportation data used in the study. It was assumed that plastic waste would be transported from the MRF by road in a truck with specifications outlined in Table 5. The distances used were based on mean distances in CoJ and are shown in Table 6. To determine baseline distances to use in this study, Remade Recycling in Johannesburg central was selected as the focal point. It was assumed that the MRF would be located there. Using google maps, the distance to the Afrisam cement kiln, which is in existence and in the West of Johannesburg (Westrand), was determined. For the landfill process, distances to the four landfills in Johannesburg were also considered from the focal point in Johannesburg central. Then, using triangular distribution TD (4.6, 39, 19), 21 km was determined. For the mechanical recycling distance, Nampak Petpak in the Eastrand (Johannesburg East) was considered the location point for the recycling plant; therefore, the distance between Remade recycling (potential MRF) and Petpak was determined. Uncertainty arose when distances for gasification and incineration had to be estimated, as these are technologies not currently implemented in the country. It was therefore assumed that the incinerator would be located 20 km away from the MRF like the cement kiln, while for gasification, it was assumed that it would be located close to the mechanical recycling plant in the East of Johannesburg. Sensitivity analysis using transport was done to test the robustness of the model to distance changes.

3 Life cycle impact assessment (LCIA)

The LCIA results of seven impact categories from this study are shown in Figs. 3, 4, 5, 6, 7, 8, 9. A scenario with a positive result indicates its negative impact on the environment. In contrast, negative results indicate that the scenario is not damaging to the environment since it benefits from environmental credits.

4 Discussion

Scenario 1 (S1), which denotes landfilling, had a negative impact on human health, ecosystems, and resources as evidenced by its positive impact values in the seven impact categories studied. A detailed discussion of impacts is given in the following sections.

4.1 Global warming, human health, and terrestrial ecosystems

Scenario 5 had the highest negative environmental impacts of 2280 DALYs and 4.56 species.yr for human health and terrestrial ecosystems impacts, respectively. This is attributed to the SRF (cement kiln) and gasification options which had high GW human health impacts of 2820 DALYs and 1470 DALYs, respectively, and GW terrestrial ecosystems impacts of 5.65 species.yr and 2.94 species.yr, respectively. GW terrestrial ecosystems define the extinction of a species in one year from GW. In comparison, the GW human health impacts for mechanical recycling (MR) and incineration with energy recovery were −2052.6 DALYs and 23.35 DALYs, respectively, while GW terrestrial ecosystems impacts were −4.1 species.yr and 0.05 species.yr respectively. This indicates a considerable net benefit on GW for MR compared to incineration (with energy recovery). Several LCA studies on plastic waste management have also highlighted the superior net positive impact of MR on climate change compared to other processes, including incineration (with or without energy recovery), cement kiln SRF, and landfilling (Shonfield 2008; Aryan et al. 2019; Chilton et al. 2010; Moberg et al. 2005; Dodbiba et al. 2008).

In the cement kiln process, the overall contribution to GW impacts from clinker production was considerably high at 93.1% due to process and energy-related emissions. The impact values determined were 2700 DALYs and 5.4 species.yr respectively. These results are in agreement with Mbohwa and Moyo (2008), Nigri et al. (2010), and Mousavi (2013), whose LCA studies on cement kilns revealed that clinker and energy production negatively impacted climate change. The calcination process, which results in the generation of calcium oxide (lime) during clinker production, is associated with the release of substantial amounts of carbon dioxide, the most significant greenhouse gas which leads to high GW potentials (Mann 2022). Cement production contributes 5 to 7% of anthropogenic carbon dioxide emissions globally (Thwe et al. 2021); (Çankaya and Pekey 2019). Thwe et al. (2021) mentioned that calcination and fuel combustion accounted for approximately 50% each in CO2 emissions, while according to Çankaya and Pekey (2019), the contribution to GW associated with clinker production was 93%. According to Mousavi (2013), individual contributions towards CO2 emissions for the production of energy and calcination were 46% and 52%, respectively, resulting in an overall contribution of 98%. These contributions are within the same magnitude of the value of 93.1% obtained in this work.

High GW impacts associated with the gasification process were due to (1) lime production, including calcination, energy usage, and transport, and (2) fossil CO2, calculated to be 46,777 tonnes. The lime market contributed 66.2%, while syngas production contributed 26.8% towards the GW impact. Lime is used to remove halide compounds such as hydrogen chloride or hydrogen fluoride and sulphur compounds (SOx) (Waldheim 2018). It is critical to evaluate alternative solid regenerative sorbents to lime to reduce the high GW impact of the gasification process. According to Waldheim (2018), oxides of metals such as zinc, tin, and copper or zinc ferrite, copper chromite, and zinc titanate can be used with varying degrees of efficiency at different operating temperatures. In this study, since a value of 6.5 kg, lime/tonne of plastic waste was assumed from literature (Ardolino et al. 2017; Ardolino et al. 2018), gasification experiments coupled with process simulations are essential to determining the optimum lime quantity. A reduction in the lime used is expected to lead to a lower GW impact. Ardolino et al. (2017) observed that, although gasification increased GW by 200%, the overall environmental footprint of the scenario was improved due to reduced impacts in the human carcinogenic and non-carcinogenic, respiratory inorganics, and fossil depletion impact categories. Ardolino et al. (2017) also highlighted the contribution of fossil carbon from the waste to the high GW impact.

Scenario 1 (100% landfilling) also had positive impact values of 83.9 DALYs and 0.168 species.yr. The incorporation of recycling and incineration processes under scenario 4 contributed to reduced impacts compared to scenario 1. For scenario 1, PE landfilling and transport to landfill contributed 49.6% and 16.2% towards the GW impact values respectively. For scenario 4, the gasification process and PE incineration accounted for 70.6% and 17.3% of the GW (human health and ecosystems) impact values. Scenarios 2 (MR and L), 3 (MR, I, L), and 4 (MR, I, L, G) had a net positive impact on the environment as indicated by the negative GW human health and ecosystems impact values: −1 380 DALYs and −2.75 species.yr, −891 DALYs and −1.78 species.yr, and −126 DALYs and −0.251 species.yr respectively. Scenario 2 outperformed all the scenarios in this regard because of the combination of MR and landfilling in which MR had hugely negative impact values relative to the total impact values (−1438 DALYs and −2.9 species.yr). Scenario 3 also performed well in this category due to the incorporation of MR and slightly positive impact values for landfilling and incineration. Overall, MR as a standalone process had negative impact values compared to other individual processes in the global warming human health and terrestrial ecosystem categories. This is attributable to the avoided virgin polymer (PE, PP, PET, PS, WEE, PVC) production processes when post-consumer plastic is recycled, preferably in a closed loop, to avoid downcycling the recyclate.

4.2 Fine particulate matter (FPM) formation

Tiny particles or liquid drops suspended in air are classified as fine particulate matter (Epa 2021a). Particulate matter with sizes 10 µm or less can result in respiratory that has an adverse impact on human health as they increase incidences of respiratory illnesses (Xing et al. 2016); (Ciobanu et al. 2021; US EPA 2021b; WHO 2021). In the FPM group of particles, particles of diameter 2.5 µm or less (PM2.5) account for about 50 to 70% (Ciobanu et al. 2021). In this study, scenario 3 was the most beneficial for the environment, with an impact value of −263 DALYs, followed by scenario 4 with −260 DALYs, scenario 5 with −190 DALYs, and scenario 2 with −97.4 DALYs. Scenario 1 had a negative impact on the environment, as indicated by the impact value of 3.62 DALYs. This is attributed to burdens associated with vehicle exhaust-related fumes from transport to landfill and landfilling of polyethylene waste which accounts for 39.6% and 32.8%, respectively. The main substances accounting for almost 100% to FPM were NOx, PM2.5, and sulphur dioxide (SO2), with contributions of 41%, 39%, and 20% respectively for transport and 32%, 44%, and 23%, respectively, for PE landfilling.

Chilton et al. (2010) reported that waste transportation was the most significant contributor of volatile organic chemicals (VOCs) in the incineration of PET. Similar to NOx and SO2, VOCs are recognised precursors to PM2.5 secondary formation (Environment and Climate Change Canada 2013), while acid gas cleaning chemicals such as lime were the primary source of PM (Chilton et al. 2010). PM2.5 particles can (1) lead to smog formation, (2) cause transportation of toxins into the air, (3) damage lung tissue on penetration, (4) damage other organs when air exchange occurs with the lungs, (5) increase mortality, and (6) result in cancers or asthma (Xing et al. 2016; Ciobanu et al. 2021). Communities residing close to landfills or people working at landfill sites are at an increased risk of experiencing these medical challenges (Njoku et al. 2019), due to the complexity of chemical and biological reactions happening at landfills, harmful emissions in the form of gases, particulate matter, and heavy metals are common (Njoku et al. 2019).

In a LCA study by Ismail and Hanafiah (Ismail and Hanafiah 2021), the authors also observed the negative impact of landfilling in the FPM category compared to incineration and MRF with and without energy recovery. This is due to the absence of avoided processes in landfilling compared to other processes where negative impacts are offset by avoided processes of production of virgin resin, heat and electricity production, and coal mining and its subsequent combustion. This argument agrees with findings by Chilton et al. (2010), who also observed net reductions in PM for recycling and energy recovery and therefore explains the negative impact values for scenarios 3, 4, 5, and 2. The authors also noted the increase in net emission reductions when the thermal efficiency in a CHP plant increased (Chilton et al. 2010). Although scenario 5 did not have the landfilling option, the magnitude of its net benefit on FPM was reduced due to the presence of the cement kiln option (SRF), which had a high positive impact value of 41.8 DALYs and transportation of waste to the various plants making up the scenario with an impact value of 2.0 DALYs. In the SRF process, clinker production, electricity production, magnetite (iron ore) generation and transportation, and limestone extraction and crushing accounted for 47.9%, 27.6%, 12.5%, and 5.5%, respectively, in the FPM category.

Thwe et al. (2021) highlight the generation of particulate matter during raw material extraction (limestone, iron ore), raw meal preparation, calcination, and cement preparation in cement kiln operations. However, the authors do not give the individual contribution of calcination to PM but instead give a total of 85% contribution to PM and photochemical oxidants. In the study, iron ore extraction contribution to PM is 32%. Çankaya and Pekey (2019) found that PM2.5 contribution to respiratory inorganics (RI) was 60%, with electricity supply as the primary contributing process. Mbohwa and Moyo (2008) also observed the high contribution of clinker production to the RI category. To manage negative impacts associated with particulate matter, dust control measures are critical in processes that include quarrying, crushing, and solids conveyance and storage. Such measures include installing dedusting technologies and installing more bag filters (Thwe et al. 2021; Convention 2012). Sulphur dioxide and nitrogen oxides from the electricity supply were the main contributors to FPM, accounting for 70% and 18%. Therefore, using desulphurisation and denitrification techniques like those proposed by Thwe et al. (2021) would be beneficial.

4.3 Marine ecotoxicity

Marine ecotoxicity impact assesses the impact of substances on the ecosystem (Dincer and Bicer 2018). These impacts include mortality or hindered growth of aquatic animals or bioaccumulation of substances and possible transfer to the food chain (Briffa et al. 2020; Zaynab 2022). In this study, scenarios 1, 2, and 3 posed an environmental threat in this category, evidenced by the positive impact values, of 16.7 species.yr, 6.95 species.yr, and 5.05 species.yr respectively. Scenario 1 had the worst environmental impact due to burdens associated with PE, PP, and PET landfilling accounting for 66.4%, 16.9%, and 9.22% respectively. In scenarios 2 and 3, the net benefit of mechanical recycling on marine ecotoxicity was offset by incineration and landfilling methods, with PE, PET, and PP landfilling contributing a total of 92.8% towards the impact value in scenario 2, while for scenario 3, contributions for incineration and landfilling were 33.3% and 31.4% for PE respectively, 8.72% and 8% for PP respectively, and 6.81% and 4.37% for PET respectively.

In a study by Erses Yay (2015), it was observed that incineration contributed significantly to the marine ecotoxicity impact category, while a combination of incineration and landfilling had the greatest negative impact on marine ecotoxicity. According to (Chen et al. 2019), landfilling had a negative impact on the environment compared to recycling and incineration. Scenarios 4 and 5 had a net benefit in this category with impact values – 0.267 species.yr and – 5.19 species.yr respectively. The adverse effect associated with landfilling and incineration in this category was offset by the net reductions from cement kiln, gasification, and mechanical recycling options. The major pollutants that contributed to marine ecotoxicity in this study are indicated in Table 7. These pollutants may disrupt the endocrine system, hinder growth, and increase mortality of marine life (Epa 2021c); (Lira et al. 2011; Spangenberg and Cherr 1996; Taylor et al. 1985; Conradi and Depledge 1999; Nam et al. 2009; Fisher et al. 1999; Eisler 1989).

Bromine was released from the landfilling and incineration of electronic waste while PVC landfilling and also recycling generated chlorides. According to Verma et al. (2016), vinyl chloride and hydrogen chloride are released during the PVC extrusion process. Ye et al. (2017) reiterate that chlorine from PVC production and recycling is a major contributor to marine ecotoxicity. Erses Yay (2015) also highlighted the significant contribution to this category, of vanadium emitted during incineration, similar to findings in this study. Another pollutant determined by Erses Yay (2015) was barium, released from landfilling and incineration. The results underline the need to find alternative ways of managing plastic waste and move away from landfilling while the incineration of electronic waste should also be avoided. Additionally, wastewater from the recycling of PVC plastics should be treated before disposal to remove chlorides (Verma et al. 2016).

4.4 Human carcinogenic (HC) and non-carcinogenic toxicity (HnCT)

Human carcinogenic toxicity assesses the possible harm to human health that can be caused by carcinogenic (cancer-causing) substances released into the environment (Hertwich et al. 2001). Scenarios 2, 3, 4, and 5 had negative impact values under this category, of – 729 DALYs, – 1200 DALYs, – 1860 DALYs, and – 2290 DALYs, while scenario 1 had a positive impact value of 46.1 DALYs. As is evident from these results, scenario 5 was the most beneficial to the environment. The human carcinogenic toxicity category is significantly influenced negatively by the landfilling process and transportation of wastes to a smaller extent. This also explains the higher net benefit on the environment associated with scenario 5 due to the diminishing of deleterious substances associated with landfilling. Moreover, recycling, cement kiln, gasification, and incineration options making up the scenario also had a net benefit on the environment with impact percentage values of – 47.9%, – 17.7%, – 28.7%, and – 5.6% respectively, owing to their avoided processes. Although scenarios 2, 3, and 4 had landfilling options, their overall impact was beneficial to the environment due to the net reductions from recycling (– ≈ 100%, – 44.3%, and – 47.5% respectively), incineration (– 55.4% and – 17.3% for scenarios 3 and 4 respectively), and gasification (– 35.1% for scenario 4).

The primary pollutants entering the environment through air, water, and/or soil in this category were arsenic, benzene, beryllium, cadmium, lead, mercury, nickel, polycyclic aromatic hydrocarbons (PAHs), chromium VI, formaldehyde, and dioxins were some of the main pollutants released into air, water or soil. These pollutants and the group they belong to are illustrated in Table 8 (Zhou and Xi 2018; Loomis et al. 2017; Jakubowski and Palczynski 2007; Waalkes 2000; Silbergeld 2003; Zefferino et al. 2017; Guo et al. 2019; Straif et al. 2005; Nasirzadeh et al. 2021; Paladino and Massabò 2017).

During the manufacture of plastics, inorganic pigments, antioxidants, heat stabilisers, and curing agents used may contain compounds of cadmium, chromium, lead, and formaldehyde. Acrylonitrile butadiene and high impact polystyrene (HIPS) reportedly contain considerable quantities of cadmium and lead compared to polyolefins (Hahladakis et al. 2020). It is important to redesign plastics including finding safer replacement additives. Dastjerdi et al. (2021) found that scenarios involving landfilling as an option impacted the environment negatively compared to other scenarios including those utilising waste to energy processes such as incineration and gasification. Waste to energy processes were also found to have lower environmental impacts in most of the categories assessed by the authors. Vishwakarma (Vishwakarma 2020) reiterates that landfilling of plastic waste increases the content of carcinogens in landfill leachates which in turn results in groundwater contamination, and unlike surface water, groundwater treatment is difficult to conduct.

Human non-carcinogenic toxicity assesses possible human damage caused by non-carcinogenic substances released to the environment (Huijbregts et al. 2005). Scenarios 3, 4, and 5 had the least impact in this category with impact values; – 2990 DALYs, – 6790 DALYs, and – 11,600 DALYs respectively compared to scenarios 1 and 2 with 19,600 DALYs and 6120 DALYs respectively. The best-performing scenario was scenario 5. Similarly, to the human carcinogenic toxicity category, this category is also negatively impacted by the presence of landfilling, while transportation contributes a small amount towards the impact category and explains why scenario 5 was the best performing process. Recycling, cement kiln, gasification, and incineration options making up the scenario also had a net benefit on the environment with impact percentage values of – 67.6%, – 13.7%, – 11.4%, and – 7.6% respectively, owing to their avoided processes.

Scenarios 3 and 4 benefited from net reductions in recycling, incineration, and gasification, while for scenario 2, the benefits were diminished by landfilling which had a high percentage contribution to the impact of 99.4%. Zinc, vanadium, barium, titanium, and chlorides from landfilling were primary pollutants. Incineration also released vanadium into the environment while PVC recycling generated chloride emissions. Such chemicals can result in gastrointestinal system disorders, neurological conditions, respiratory diseases, or renal-related challenges (Plum et al. 2010; Nielsen 2013; Kravchenko et al. 2014; Vasantharaja et al. 2015). Shonfield (2008) observed that landfilling had a negative impact in the human toxicity category in contrast to other processes that included incineration, cement kiln, recycling, and pyrolysis. The authors also observed that in this category, recycling outperformed the cement kiln option, while the cement kiln option was superior to incineration as has been shown in this work. Erses Yay (2015) reported that landfilling and its combination with recycling (scenario 2) had high impact potentials in this category, due to barium, chromium, lead, and nickel emissions generated from landfilling and transport. The authors concluded that scenario 2 was beneficial due to the presence of recycling compared to landfilling alone. Arsenic, polycyclic aromatic hydrocarbons, cadmium, barium, and chromium emitted from incineration and electricity production also significantly contributed to the human toxicity impacts.

4.5 Water consumption, human health

Scenario 3 was the best performing scenario with an impact value of – 17.5 DALYs, followed by scenarios 4, 5, and 2 with impact values of – 11.2, – 7.53 DALYs, and – 3.57 DALYs respectively. Scenario 1 impact in this category was close to 0 with a value 0.07 DALYs. In scenario 5, gasification, cement kiln option, and transport to the various processing facilities had positive impact values in this category, which reduced the net benefits associated with recycling, and incineration. Magnetite production accounted for 45.6% towards water consumption in the cement kiln operations. During magnetite beneficiation in a wet process, water consumption is high (Baawuah et al. 2020).

In scenarios 2 and 3, landfilling and transport had positive impact values, although these were not sufficiently high to offset the benefits associated with recycling and incineration (with energy recovery). It is expected that if the water consumption in recycling can be reduced to 2–3 m3 per tonne of material, then its impact values will significantly reduce. According to Hopewell et al. (2009), due to new technology that is capable of dry-cleaning plastic flakes to remove contaminants, the water consumption in recycling can be reduced or halved.

Reduction of water use in magnetite production can be implemented by employing water saving measures including rainwater harvesting. Use of groundwater, surface water, or sea water can be considered too. Since South Africa is a water-scarce country, such measures will be key (Global Cement 2013; Mack-Vergara and John 2017). A summary of the characterisation results discussed in this study is provided in Table 9.

Figures 10, 11, 12 show the damage assessments conducted. Scenario 5 had the least negative impact in the human health, ecosystems, and resources depletion categories. Overall, as illustrated by the single score in Fig. 13, scenario 5 was most beneficial for the environment followed by scenarios 4 and 3 respectively.

4.6 Increase in transport distances

The sensitivity of the generated model was evaluated by increasing the distance from the material recovery facility. In scenario 5, the distance to the cement kiln was increased from 20 to 266 km representing an approximate 13 times increase. This was in line with the proposal by Plastics SA (Plastics 2019) where Lafarge-Holcim’s Lichtenburg cement kiln is located. Distances to other plastic waste treatment facilities were increased facilities were increased to a large distance of 100 km. The results showed that the ranking of scenarios is unaffected with scenario 5 remaining as the best performing scenario, followed by scenarios 4, 3, 2, and 1 respectively as illustrated in Fig. 14.

4.7 Market substitution factor

In the city of Johannesburg, the contamination of post-consumer plastics is common as illustrated in Figs. 15 and 16. This is attributed to the absence of waste separation at source initiatives. Lack of such initiatives including deposit refund schemes results in the dumping of plastics in bins with other municipal solid waste including organic waste before their retrieval by waste pickers. Furthermore, some plastic waste is transported to the landfills and collected by waste pickers who then take it to Buy-Back centres. At these centres, waste is baled by type and transported to recycling plants where it is processed into granulate.

Contaminated recyclables are difficult to use for their original purpose, more so, in the food industry where hygiene is critical. Therefore, they end up being downcycled into products of lower value consequently reducing the virgin resin to recyclate ratio. In this study, a market substitution factor of 50% was used for the various plastic types to test the model’s robustness. The single score results illustrated in Fig. 17 show that scenario 5 remained the least environmentally impactful scenario overall compared to other scenarios. However, there is a reduction in the net benefit on the environment when transportation distances increase. The lack of markets for recycled products also affects substitution factor. For example, in Johannesburg, Buy-Back centres are not keen to accept PVC and PS, and therefore, informal waste pickers do not collect it, while some waste picker cooperatives stockpile it on their properties.

4.8 Plastic waste leakage

According to Von Blottnitz et al. (2018), approximately 24% of total plastic waste generated leaks into the environment in South Africa through self-help disposal and littering. Self-help disposal is common in South Africa since around 34.1% of households lack waste collection services (Plastics 2019). The authors also cite the Department of Environmental Affairs, which mentions that the litter component accounts for about 1%. The accurate estimation of the amount of plastic waste that leaks into the environment is a challenge in that litter, and plastic waste in dumps are recovered through litter removal campaigns and reclamation by informal waste pickers who play a vital role in the country’s recycling sector. Such litter removal campaigns include Clean-up and Recycle SA Week and the Kleena Joburg campaign (Mazhandu et al. 2021a). To assess the potential impacts of littering and open dumping, it was assumed that 10% of plastic waste would remain uncaptured in the environment (Ryberg et al. 2019), possibly eventually finding its way into the marine environment. Ryberg et al. (2019) also do, however, elude to the fact that the value bears some uncertainty. Scenario 2, the current scenario, was remodelled to involve 45.7% mechanical recycling, 44.3% landfilling and 10% open dump; an open dump represents plastic waste lost to the environment. The results show that introducing open dumping as an end-of-life process in the current scenario increases the human health and ecosystem impact potentials by 70% and 28%, respectively. Figure 18 shows the single score results.

4.9 Circular economy principle

A circular economy scenario denoted as scenario 6 (S6) was modelled to assess the impact of increasing recycling rate on the environment. In this scenario, it was assumed that all plastic waste generated would undergo mechanical recycling. The results are shown in Fig. 19. Increasing the mechanical recycling rate to 100% was the most beneficial scenario for the environment, with a single score of – 88.1 MPt.

5 Conclusion

An analysis of the environmental impacts of various plastic waste management scenarios has been given to determine the best environmentally performing scenario in CoJ, South Africa, using LCA. Scenario 1 involved landfilling of all plastic waste generated (100%); scenario 2 involved 45.7% mechanical recycling and 54.3% landfilling; scenario 3 encompassed 27.3% landfilling, 31.1% mechanical recycling, and 41.4% incineration; scenario 4 had 15% landfilling, 45% mechanical recycling, 20% incineration, and 20% gasification; while scenario 5 had 50% mechanical recycling, 8% incineration, 20% gasification, and 22% cement kiln. Overall, moving away from landfilling and implementing scenario 5 was found in this study to be the least environmentally impactful scenario when managing plastic waste. Additionally, apart from introducing various environmental and human health challenges, landfilling plastic waste has no economic value. The findings of this study also agree with the waste hierarchy, which shows landfilling as the least preferred method of waste management. Therefore, there exists an opportunity for energy recovery techniques to be integrated into Johannesburg’s waste management plan and possibly South Africa’s National Plastics plan. On sensitivity analysis, the increase in transportation distances and reduction in market substitution factor in mechanical recycling did not change the ranking of scenarios despite reducing the net benefits to the environment, while the introduction of open dumping as an end-of-life process to the current scenario, 2, increased the scenario’s negative impact on the environment. Assuming 100% mechanical recycling of plastic waste resulted in the least environmental impact compared to scenarios 1 to 5. Despite the findings that mechanical recycling was the most beneficial process on the environment, there is a possibility of a reduction in the net benefits associated with recycling if the waste has to be transported from other provinces in South Africa that lack recycling capacity to economic hubs such as Gauteng. The study is also cognisant of the fact that there is plastic waste that is lost to the environment, which is causing serious environmental impacts. Further studies are necessary to ensure that various scenarios are modelled to include plastic waste leakage indicators for the different plastic types, as some plastic products will have a higher leakage propensity than others. Conducting litter surveys on land and rivers will be key in determining these indicators. It is expected that the introduction of mandatory Extended Producer Responsibility (EPR) in South Africa in 2021 and the implementation of initiatives such as Deposit Refund Schemes (DRS) and waste separation at source programmes will assist in reducing the amount of plastic waste that leaks into the environment by improving waste management and collection services.

Data availability

The datasets generated during the study are available from the corresponding author upon request.

References

Al-Salem SM, Evangelisti S, Lettieri P (2014) Life cycle assessment of alternative technologies for municipal solid waste and plastic solid waste management in the Greater London area. Chem Eng J 244:391–402. https://doi.org/10.1016/j.cej.2014.01.066

Antelava A et al (2019) Plastic solid waste (PSW) in the context of life cycle assessment (LCA) and sustainable management. Environ Manage 64(2):230–244. https://doi.org/10.1007/s00267-019-01178-3

Ardolino F, Berto C, Arena U (2017) Environmental performances of different configurations of a material recovery facility in a life cycle perspective. Waste Manag 68:662–676. https://doi.org/10.1016/J.WASMAN.2017.05.039

Ardolino F, Lodato C, Astrup TF, Arena U (2018) Energy recovery from plastic and biomass waste by means of fluidized bed gasification: a life cycle inventory model. Energy 165:299–314. https://doi.org/10.1016/J.ENERGY.2018.09.158

Arena U, Mastellone ML, Perugini F (2003) Life cycle assessment of a plastic packaging recycling system. Int J Life Cycle Assess 8(2):92–98. https://doi.org/10.1007/BF02978432

Aryan Y, Yadav P, Samadder SR (2019) Life cycle assessment of the existing and proposed plastic waste management options in India: a case study. J Clean Prod 211:1268–1283. https://doi.org/10.1016/j.jclepro.2018.11.236

Baawuah E, Kelsey C, Addai-Mensah J, Skinner W (2020) Economic and socio-environmental benefits of dry beneficiation of magnetite ores. Miner 10(11):955. https://doi.org/10.3390/MIN10110955

Basel Convention (2012) Technical guidelines on the environmentally sound co-processing of hazardous wastes in cement kilns

Briffa J, Sinagra E, Blundell R (2020) Heavy metal pollution in the environment and their toxicological effects on humans. Heliyon 6(9):e04691. https://doi.org/10.1016/J.HELIYON.2020.E04691

Çankaya S, Pekey B (2019) A comparative life cycle assessment for sustainable cement production in Turkey. J Environ Manage 249:109362. https://doi.org/10.1016/J.JENVMAN.2019.109362

CCME (2018) Strategy on zero plastic waste

Chen Y et al (2019) Life cycle assessment of end-of-life treatments of waste plastics in China. Resour Conserv Recycl 146:348–357. https://doi.org/10.1016/J.RESCONREC.2019.03.011

Chilton T, Burnley S, Nesaratnam S (2010) A life cycle assessment of the closed-loop recycling and thermal recovery of post-consumer PET. Resour Conserv Recycl 54(12):1241–1249. https://doi.org/10.1016/j.resconrec.2010.04.002

Chisholm JM et al (2021) Sustainable waste management of medical waste in African developing countries: A narrative review. Waste Manag Res 39(9):1149–1163. https://doi.org/10.1177/0734242X211029175/ASSET/IMAGES/LARGE/10.1177_0734242X211029175-FIG1.JPEG

Ciobanu C, Istrate IA, Tudor P, Voicu G (2021) Dust emission monitoring in cement plant mills: a case study in Romania. Int J Environ.Res Public Health 18(17). https://doi.org/10.3390/IJERPH18179096

Conradi M, Depledge MH (1999) Effects of zinc on the life-cycle, growth and reproduction of the marine amphipod Corophium volutator. Mar Ecol Prog Ser 176:131–138. https://doi.org/10.3354/MEPS176131

Dastjerdi B, Strezov V, Kumar R, He J, Behnia M (2021) Comparative life cycle assessment of system solution scenarios for residual municipal solid waste management in NSW, Australia. Sci Total Environ 767:144355. https://doi.org/10.1016/J.SCITOTENV.2020.144355

DEFF (2020) A Circular Economy Guideline for the Waste Sector-A Driving force towards Sustainable Consumption and Production

Demetrious A, Crossin E (2019) Life cycle assessment of paper and plastic packaging waste in landfill, incineration, and gasification-pyrolysis. J Mater Cycles Waste Manag 21(4):850–860. https://doi.org/10.1007/S10163-019-00842-4

Dincer I, Bicer Y (2018) 1.27 Life cycle assessment of energy. Compr Energy Syst 1–5:1042–1084. https://doi.org/10.1016/B978-0-12-809597-3.00134-6

Dodbiba G, Takahashi K, Sadaki J, Fujita T (2008) The recycling of plastic wastes from discarded TV sets: comparing energy recovery with mechanical recycling in the context of life cycle assessment. J Clean Prod 16(4):458–470. https://doi.org/10.1016/j.jclepro.2006.08.029

Eisler R (1989) Tin hazards to fish, wildlife, and invertebrates: a synoptic review

Environment and Climate Change Canada (2013) Common air pollutants: volatile organic compounds. https://www.canada.ca/en/environment-climate-change/services/air-pollution/pollutants/common-contaminants/volatile-organic-compounds.html. Accessed 23 Aug 2021

Erses Yay AS (2015) Application of life cycle assessment (LCA) for municipal solid waste management: a case study of Sakarya. J Clean Prod 94:284–293. https://doi.org/10.1016/J.JCLEPRO.2015.01.089

Farvacque-Vitkovic C, Kopanyi M (2014) Municipal finances: a handbook for local governments - Google Books. The World Bank, Washington DC

Fisher DJ, Burton DT, Yonkos LT, Turley SD, Ziegler GP (1999) The relative acute toxicity of continuous and intermittent exposures of chlorine and bromine to aquatic organisms in the presence and absence of ammonia. Water Res 33(3):760–768. https://doi.org/10.1016/S0043-1354(98)00278-4

Global Cement (2013) Analysis: Gimmie Water - water conservation in the cement industry - Cement industry news from Global Cement. https://www.globalcement.com/news/item/1772-analysis-gimmie-water-water-conservation-in-the-cement-industry. Accessed 28 Aug 2021

Godfrey L et al (2019) Solid waste management in Africa: governance failure or development opportunity? Reg Dev Africa. https://doi.org/10.5772/INTECHOPEN.86974

Guo H et al (2019) Nickel carcinogenesis mechanism: DNA damage. Int J Mol Sci 20(19):4690. https://doi.org/10.3390/IJMS20194690

Hahladakis JN, Iacovidou E, Gerassimidou S (2020) Plastic waste in a circular economy. Elsevier Inc.

Hertwich EG, Mateles SF, Pease WS, McKone TE (2001) Human toxicity potentials for life-cycle assessment and toxics release inventory risk screening. Environ Toxicol Chem 20(4):928–939. https://doi.org/10.1002/ETC.5620200431

Hopewell J, Dvorak R, Kosior E (2009) Plastics recycling: challenges and opportunities. Philos Trans R Soc B Biol Sci 364(1526):2115–2126. https://doi.org/10.1098/rstb.2008.0311

Huijbregts MAJ et al (2016) ReCiPe2016: a harmonised life cycle impact assessment method at midpoint and endpoint level. Int J Life Cycle Assess 22(2):138–147. https://doi.org/10.1007/S11367-016-1246-Y

Huijbregts MAJ, Rombouts LJA, Ragas AMJ, van de Meent D (2005) Human-toxicological effect and damage factors of carcinogenic and noncarcinogenic chemicals for life cycle impact assessment. Integr Environ Assess Manag 1(3):181–244. https://doi.org/10.1897/2004-007R.1

Ismail H, Hanafiah MM (2021) Evaluation of e-waste management systems in Malaysia using life cycle assessment and material flow analysis. J Clean Prod 308:127358. https://doi.org/10.1016/J.JCLEPRO.2021.127358

ISO (2006) ISO 14040:2006 - Environmental management — life cycle assessment — principles and framework. https://www.iso.org/standard/37456.html. Accessed 03 Aug 2021

Jakubowski M, Palczynski C (2007) Beryllium. Handb Toxicol Met 415–431. https://doi.org/10.1016/B978-012369413-3/50076-8

Khandelwal H, Dhar H, Thalla AK, Kumar S (2019) Application of life cycle assessment in municipal solid waste management: a worldwide critical review. J Clean Prod 209:630–654. https://doi.org/10.1016/J.JCLEPRO.2018.10.233

Kravchenko J, Darrah TH, Miller RK, Lyerly HK, Vengosh A (2014) A review of the health impacts of barium from natural and anthropogenic exposure. Environ Geochem Health 36(4):797–814. https://doi.org/10.1007/S10653-014-9622-7

Lazarevic D, Aoustin E, Buclet N, Brandt N (2010) Plastic waste management in the context of a European recycling society: comparing results and uncertainties in a life cycle perspective. Resour Conserv Recycl 55(2):246–259. https://doi.org/10.1016/j.resconrec.2010.09.014

Liang Y, Tan Q, Song Q, Li J (2021) An analysis of the plastic waste trade and management in Asia. Waste Manag 119:242–253. https://doi.org/10.1016/J.WASMAN.2020.09.049

Lira VF, Santos GAP, Derycke S, Larrazabal MEL, Fonsêca-Genevois VG, Moens T (2011) Effects of barium and cadmium on the population development of the marine nematode Rhabditis (Pellioditis) marina. Mar Environ Res 72(4):151–159. https://doi.org/10.1016/J.MARENVRES.2011.07.003

Loomis D et al (2017) Carcinogenicity of benzene. Lancet Oncol 18(12):1574–1575. https://doi.org/10.1016/S1470-2045(17)30832-X

Mack-Vergara YL, John VM (2017) Life cycle water inventory in concrete production—a review. Resour Conserv Recycl 122:227–250. https://doi.org/10.1016/J.RESCONREC.2017.01.004

Mann M (2022) Global warming - Carbon dioxide | Britannica. https://www.britannica.com/science/global-warming/Carbon-dioxide. Accessed 20 Aug 2021

Mazhandu ZS, Muzenda E, Belaid M (2021a) Mamvura TA A review of plastic waste management practices: what can South Africa learn? https://doi.org/10.25046/aj0602116

Mazhandu ZS, Muzenda E, Belaid M, Mamvura TA, Nhubu T (2020b) Incineration as a potential solution to Africa’s plastic waste challenges: a narrative review. Int Conf Energy Environ Stor Energy 1–11

Mazhandu ZS, Muzenda E, Belaid M, Mamvura TA, Nhubu T (2021b) A review of plastic waste management practices: what can South Africa learn? Adv Sci Technol Eng Syst J 6(2):1013–1028. https://doi.org/10.25046/aj0602116

Mazhandu ZS, Muzenda E, Belaid M, Nhubu T (2021c) Application of life cycle assessments in waste management : a mini review

Mazhandu ZS, Muzenda E, Mamvura TA, Belaid M, Nhubu T (2020a) Integrated and consolidated review of plastic waste management and bio-based biodegradable plastics: Challenges and opportunities. Sustain 12(20):1–57. https://doi.org/10.3390/su12208360

Mbohwa C, Moyo S (2008) Life cycle assessment of the cement industry in Zimbabwe. 15th CIRP Int Conf Life Cycle Eng

Moberg Å, Finnveden G, Johansson J, Lind P (2005) Life cycle assessment of energy from solid waste - Part 2: landfilling compared to other treatment methods. J Clean Prod 13(3):231–240. https://doi.org/10.1016/j.jclepro.2004.02.025

Mølgaard C (1995) Environmental impacts by disposal of plastic from municipal solid waste. Resour Conserv Recycl 15(1):51–63. https://doi.org/10.1016/0921-3449(95)00013-9

Mousavi M (2013) Life cycle assessment of Portland cement and concrete bridge concrete bridge vs. wooden bridge. Royal Inst Technol Stockholm

Nam SH, Yang CY, An YJ (2009) Effects of antimony on aquatic organisms (Larva and embryo of Oryzias latipes, Moina macrocopa, Simocephalus mixtus, and Pseudokirchneriella subcapitata). Chemosphere 75(7):889–893. https://doi.org/10.1016/J.CHEMOSPHERE.2009.01.048

Nasirzadeh N, Mohammadian Y, Dehgan G (2021) Health risk assessment of occupational exposure to hexavalent chromium in Iranian workplaces: a meta-analysis study. Biol Trace Elem Res 2021:1–10. https://doi.org/10.1007/S12011-021-02789-W

Nielsen F (2013) Ultratrace Elements. Encycl Hum Nutr 4–4:299–310. https://doi.org/10.1016/B978-0-12-375083-9.00270-1

Nigri EM, Denise S, Rocha F, Filho ER (2010) Portland cement: an application of life cycle assessment. 8(2)

Njoku PO, Edokpayi JN, Odiyo JO (2019) Health and environmental risks of residents living close to a landfill: a case study of Thohoyandou Landfill, Limpopo Province, South Africa. Int J Environ Res Public Health 16(12). https://doi.org/10.3390/IJERPH16122125

Nkosi N, Muzenda E, Gorimbo J, Belaid M (2021) Developments in waste tyre thermochemical conversion processes: gasification, pyrolysis and liquefaction. RSC Adv 11(20):11844–11871. https://doi.org/10.1039/D0RA08966D

O’farrell K, Allan P (2020) 2018–19 Australian plastics recycling survey national report final report client. Dept Agric Water Environ

Otto K (2020) Current Status of Landfill Airspace in Gauteng

Paladino O, Massabò M (2017) Health risk assessment as an approach to manage an old landfill and to propose integrated solid waste treatment: a case study in Italy. Waste Manag 68:344–354. https://doi.org/10.1016/J.WASMAN.2017.07.021

Plastics SA (2019) South African Plastics Recycling Survey

Plum LM, Rink L, Haase H (2010) The essential toxin: impact of zinc on human health. Int J Environ Res Public Health 7(4):1342. https://doi.org/10.3390/IJERPH7041342

PRé Sustainability (2016) ReCiPe. https://pre-sustainability.com/articles/recipe/. Accessed 13 May 2022

Risimati B, Gumbo T (2018) Exploring the applicability of location-based services to delineate the state public transport routes integratedness within the city of Johannesburg. Infrastructures 3(3). https://doi.org/10.3390/INFRASTRUCTURES3030028

Ryberg MW, Hauschild MZ, Wang F, Averous-Monnery S, Laurent A (2019) Global environmental losses of plastics across their value chains. Resour Conserv Recycl 151:104459. https://doi.org/10.1016/J.RESCONREC.2019.104459

Shen L, Nieuwlaar E, Worrell E, Patel MK (2011) Life cycle energy and GHG emissions of PET recycling: Change-oriented effects. Int J Life Cycle Assess 16(6):522–536. https://doi.org/10.1007/s11367-011-0296-4

Shonfield P (2008) LCA of management options for mixed waste plastics

Silbergeld EK (2003) Facilitative mechanisms of lead as a carcinogen. Mutat Res Mol Mech Mutagen 533(1–2):121–133. https://doi.org/10.1016/J.MRFMMM.2003.07.010

SimaPro (2021) ecoinvent | High-quality LCI database integrated in SimaPro. https://simapro.com/databases/ecoinvent/. Accessed 03 Aug 2021

Song HS, Hyun JC (1999) A study on the comparison of the various waste management scenarios for PET bottles using the life-cycle assessment (LCA) methodology. Resour Conserv Recycl 27(3):267–284. https://doi.org/10.1016/S0921-3449(99)00022-1

Spangenberg JV, Cherr GN (1996) Developmental effects of barium exposure in a marine bivalve (Mytilus californianus). Environ Toxicol Chem 15(10):1769–1774. https://doi.org/10.1002/ETC.5620151018

Straif K, Baan R, Grosse Y, Secretan B, El Ghissassi F, Cogliano V (2005) Carcinogenicity of polycyclic aromatic hydrocarbons. Lancet Oncol 6(12):931–932. https://doi.org/10.1016/S1470-2045(05)70458-7

Taylor D, Maddock BG, Mance G (1985) The acute toxicity of nine ‘grey list’ metals (arsenic, boron, chromium, copper, lead, nickel, tin, vanadium and zinc) to two marine fish species: Dab (Limanda limanda) and grey mullet (Chelon labrosus). Aquat Toxicol 7(3):135–144. https://doi.org/10.1016/S0166-445X(85)80001-1

Thwe E, Khatiwada D, Gasparatos A (2021) Life cycle assessment of a cement plant in Naypyitaw, Myanmar. Clean Environ Syst 2:100007. https://doi.org/10.1016/J.CESYS.2020.100007

UN (2020) United Nations Centre for Regional Development in collaboration with Ministry of the Environment, Government of Japan 10th Regional 3R and Circular Economy Forum in Asia and the Pacific Series of Webinar

UNEP (2021) Policies, regulations and strategies in Latin America and the Caribbean to prevent marine litter and plastic waste

US EPA (2021a) Integrated Science Assessment (ISA) for oxides of nitrogen, oxides of sulfur, and particulate matter - ecological criteria. https://www.epa.gov/isa/integrated-science-assessment-isa-oxides-nitrogen-oxides-sulfur-and-particulate-matter. Accessed 23 Aug 2021

US EPA (2021b) Health and environmental effects of particulate matter (PM). https://www.epa.gov/pm-pollution/health-and-environmental-effects-particulate-matter-pm. Aaccessed 08 Jul 2022

US EPA (2021c) Aquatic life criteria - cadmium. https://www.epa.gov/wqc/aquatic-life-criteria-cadmium. Accessed 26 Aug 2021

Van Fan Y, Čuček L, Jaromír J, Vujanovic A (2022) Life cycle assessment approaches of plastic recycling with multiple cycles : mini review. Chem Eng Trans 94(June):85–90. https://doi.org/10.3303/CET2294014

Vasantharaja D, Ramalingam V, Reddy GA (2015) Oral toxic exposure of titanium dioxide nanoparticles on serum biochemical changes in adult male Wistar rats

Verma R, Vinoda KS, Papireddy M, Gowda ANS (2016) Toxic pollutants from plastic waste- a review. Procedia Environ Sci 35:701–708. https://doi.org/10.1016/j.proenv.2016.07.069

Von Blottnitz H, Chitaka T, Rodseth C (2018) South Africa beats Europe at plastics recycling, but also is a top 20 ocean polluter. Really?

Verster C, Bouwman H (2020) Land-based sources and pathways of marine plastics in a South African context. S Afr J Sci 116(5–6):1–9. https://doi.org/10.17159/sajs.2020/7700

Vishwakarma A (2020) Unsustainable management of plastic wastes in India: a threat to global warming and climate change. Contemp Environ Issues Chall Era Clim Chang 235–244. https://doi.org/10.1007/978-981-32-9595-7_13

Waalkes MP (2000) Cadmium carcinogenesis in review. J Inorg Biochem 79(1–4):241–244. https://doi.org/10.1016/S0162-0134(00)00009-X

Waldheim L (2018) Gasification of waste for energy carriers a review gasification of waste for energy carriers A review Content

Wealth NW (2021) The Wealthiest Cities in the World 2021. https://newworldwealth.com/reports/f/the-wealthiest-cities-in-the-world-2021. Accessed 10 Nov 2022

Welford R (1994) Cases in environmental management and business strategy. 216

WHO (2021) Ambient (outdoor) air pollution. https://www.who.int/news-room/fact-sheets/detail/ambient-(outdoor)-air-quality-and-health. Accessed 08 Jul. 2022

Wikipedia (2022) Wikipedia, the free encyclopedia. https://en.wikipedia.org/wiki/Main_Page. Accessed 10 Nov 2022

World Bank (2021) Managing plastic waste to combat marine pollution in Southeast Asia. https://www.worldbank.org/en/news/press-release/2021/03/21/better-managing-plastic-waste-could-combat-marine-pollution-and-unlock-billions-of-dollars-for-a-circular-economy-southe. Accessed 17 Aug 2021

Xing YF, Xu YH, Shi MH, Lian XY (2016) The impact of PM2.5 on the human respiratory system. J Thorac Dis 8(1):E69. https://doi.org/10.3978/J.ISSN.2072-1439.2016.01.19

Ye L, Qi C, Hong J, Ma X (2017) Life cycle assessment of polyvinyl chloride production and its recyclability in China. J Clean Prod 142:2965–2972. https://doi.org/10.1016/J.JCLEPRO.2016.10.171

Zackrisson M, Jönsson C, Olsson E (2014) Life cycle assessment and life cycle cost of waste management—plastic cable waste. Adv Chem Eng Sci 04(02):221–232. https://doi.org/10.4236/aces.2014.42025

Zaynab M et al (2022) Health and environmental effects of heavy metals. J King Saud Univ Sci 34(1):101653. https://doi.org/10.1016/J.JKSUS.2021.101653

Zefferino R, Piccoli C, Ricciardi N, Scrima R, Capitanio N (2017) Possible mechanisms of mercury toxicity and cancer promotion: involvement of gap junction intercellular communications and inflammatory cytokines. Oxid Med Cell Longev 2017. https://doi.org/10.1155/2017/7028583

Zhou Q, Xi S (2018) A review on arsenic carcinogenesis: epidemiology, metabolism, genotoxicity and epigenetic changes. Regul Toxicol Pharmacol 99:78–88. https://doi.org/10.1016/J.YRTPH.2018.09.010

Acknowledgements

The authors thank the University of Johannesburg and Botswana International University of Science and Technology for providing financial assistance to conduct the work as well as PRé Sustainability for the provision of SimaPro Software.

Funding

Open access funding provided by University of Johannesburg.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no competing interests.

Additional information

Communicated by Shabbir Gheewala.

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Mazhandu, Z.S., Muzenda, E., Belaid, M. et al. Comparative assessment of life cycle impacts of various plastic waste management scenarios in Johannesburg, South Africa. Int J Life Cycle Assess 28, 536–553 (2023). https://doi.org/10.1007/s11367-023-02151-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11367-023-02151-3