Abstract

Purpose

The accessibility to most metals is crucial to modern societies. In order to move towards more sustainable use of metals, it is relevant to reduce losses along their anthropogenic cycle. To this end, quantifying dissipative flows of mineral resources and assessing their impacts in life cycle assessment (LCA) has been a challenge brought up by various stakeholders in the LCA community. We address this challenge with the extension of previously developed impact assessment methods and evaluating how these updated methods compare to widely used impact assessment methods for mineral resource use.

Methods

Building on previous works, we extend the coverage of the average dissipation rate (ADR) and lost potential service time (LPST) methods to 61 metals. Midpoint characterization factors are computed using dynamic material flow analysis results, and endpoint characterization factors, by applying the market price of metals as a proxy for their value. We apply these methods to metal resource flows from 6000 market data sets along with the abiotic depletion potential and ReCiPe 2016 methods to anticipate how the assessment of dissipation using the newly developed methods might compare to the latter two widely used ones.

Results and discussion

The updated midpoint methods enable distinguishing between 61 metals based on their global dissipation patterns once they have been extracted from the ground. The endpoint methods further allow differentiating between the value of metals based on their annual average market prices. Metals with a high price that dissipate quickly have the highest endpoint characterization factors. The application study shows that metals with the largest resource flows are expected to have the most impacts with the midpoint ADR and LPST methods, metals that are relatively more expensive have a greater relative contribution to the endpoint assessment.

Conclusion

The extended ADR and LPST methods provide new information on the global dissipation patterns of 61 metals and on the associated potentially lost value for humans. The methods are readily applicable to resource flows in current life cycle inventories. This new information may be complementary to that provided by other impact assessment methods addressing different impact pathways when used in LCA studies. Additional research is needed to improve the characterization of the value of metals for society and to extend the methods to more resources.

Similar content being viewed by others

Explore related subjects

Find the latest articles, discoveries, and news in related topics.Avoid common mistakes on your manuscript.

1 Introduction

All metals in the periodic table can provide a socio-economic benefit for modern societies (Graedel et al. 2013). Yet, mineral resources are non-renewable and accessible in constrained quantities (Drielsma et al. 2016; Schulze et al. 2020), driving the will to keep them in the economy for as long as possible through, e.g., recycling or other circular economy strategies (Blomsma and Tennant 2020; European Commission 2020a; Reuter et al. 2019; UNEP 2013). Dissipative flows of mineral resources are flows that become inaccessible for future use (Beylot et al. 2020b; Helbig et al. 2020). They can include flows to the environment, to waste disposal facilities, and flows to materials where their specific physicochemical characteristics are no longer positively contributing to the material characteristics (non-functional recycling) (Beylot et al. 2020b; Charpentier Poncelet et al. 2021; Helbig et al. 2020).

In this context, it is proposed to develop methods to assess the dissipation of mineral resources and its impacts in life cycle assessment (LCA) (Berger et al. 2020; Beylot et al. 2020b, 2021; van Oers et al. 2020; Zampori and Sala 2017). Charpentier Poncelet et al. (2019) proposed a framework to consider the impacts of the dissipative flows of metals on the area of protection (AoP) natural resources in LCA. Based on that idea, we developed two dissipation-oriented midpoint methods for life cycle impact assessment (LCIA) applicable to extraction flows in the life cycle inventories (LCI) and computed characterization factors (CF) for 18 metals (Charpentier Poncelet et al. 2021). These methods relied on the results from the dynamic material flow analysis (MFA) model of Helbig et al. (2020). The first method is the lost potential service time (LPST), which quantifies the lost opportunity to use metallic elements in the economy due to dissipative flows over time horizons of 25, 100, or 500 years. The second one is the average dissipation rate (ADR), which assesses the expected dissipation rates of metals from extraction until their complete dissipation.

The main objective of this article is to increase the coverage of the LPST and ADR methods based on our extension of the aforementioned dynamic MFA model to 61 metals (Charpentier Poncelet et al. 2022b). We also explore the use of price-based endpoint CFs to represent the loss of value associated with the dissipation of metals. Complementarily, we investigate potential impact assessment results using these new methods, and compare them with widely used LCIA methods. To do so, we apply the newly developed CFs to all non-empty market data sets from the ecoinvent database version 3.7.1 (Moreno Ruiz et al. 2020; Wernet et al. 2016) and compare the LCIA results with those for the abiotic depletion potential (ADP) ultimate reserves method (van Oers et al. 2019, 2002), the surplus ore potential (SOP) method (Vieira et al. 2016) and the surplus cost potential (SCP) method (Vieira et al. 2016). The latter two methods are included in ReCiPe 2016 (Huijbregts et al. 2017). Materials and methods are detailed in “Sect. 2,” results are presented and analyzed in “Sect. 3,” and conclusions are drawn in “Sect. 4.”

2 Materials and methods

2.1 Extending the coverage of the ADR and LPST methods

The MaTrace model initially developed by Nakamura et al. (2014) allows quantifying losses of a cohort of extracted metals to the environment, other material flows (non-functional recycling), and waste disposal facilities (including tailings and slags) over time (Helbig et al. 2020). As in former studies (Beylot et al. 2020a, 2021; Charpentier Poncelet et al. 2021; Helbig et al. 2020), these losses are considered as dissipative flows in this study. With this model, the global anthropogenic cycles of metals are studied one at a time, meaning there are no direct links between the material flow models of each metal. Contrastingly, Helbig et al. (2021) analyzed seven major metals simultaneously with MaTrace-multi, which adds another level of information and another level of modeling complexity that would not be possible to handle for 61 metals at this point. Therefore, despite the potential limitations associated with the study of single cycles (e.g., mass-balance discrepancies between different metals used in the same applications), we here focus on the individual cycles of 61 metals as studied by Charpentier Poncelet et al. (2022b). In the latter article, the losses of metals are evaluated over time and their average lifetimes in the economy are estimated based on the most recent data possible (most typically between 2010 and 2020). The latter correspond to the average duration over which metals remain in use in the economy after extraction.

Midpoint CFs for 61 metals are derived from the results of that article. The Python code and compiled datasets underlying that study are accessible online (Helbig and Charpentier Poncelet 2022). The overview of developments proposed in this article based on our previous work is presented in Fig. 1.

Overview of impact pathway and further development of the ADR and LPST methods based on previous work (adapted from Charpentier Poncelet et al. 2021). References to previous works: method for computing midpoint CFs (Charpentier Poncelet et al. 2021); dynamic MFA results for 18 metals (Helbig et al. 2020); and extended dynamic MFA results (Charpentier Poncelet et al. 2022b)

2.1.1 Midpoint characterization factors based on dynamic MFA data

The midpoint CFs for the ADR and LPST methods are computed using the approach described by Charpentier Poncelet et al. (2021). The ADR method allows distinguishing between the relative dissipation rates of metals after extraction in current conditions of consumption and recycling in the economy. The LPST method measures the (relative) lost opportunity to make use of metals over time once dissipated based on these same conditions. The rationale for the LPST method is summarized in the supporting information (SI). The main equations for the ADR and LPST methods are replicated below.

The ADR is calculated as the inverse of the average lifetime of metals in the economy, referred to as the total service time (STTOT) in Eq. (1):

where the STTOT represents the total expected service time of metal i in the economy after extraction and until its complete dissipation (expressed in kg.yr/kg = yr). The ADR is expressed in kg/kg.yr = yr−1.

The LPST is calculated as the difference between the optimal service time, OST, defined as the total service time if no dissipation occurred, and the expected service time, ST, given the expected dissipation pattern of metal i over a given time horizon of 25, 100, or 500 years, as shown in Eq. (2):

where the LPST, OST, and ST are expressed in kg.yr/kg (= yr).

The CFs of the ADR method are calculated as the ratio between the ADR of metal i and that of iron (Fe), as shown in Eq. (3):

where the \({\mathrm{CF}}_{\mathrm{ADR}}\) for metal i is expressed in kg Fe-eq./kg. There is no time horizon for the ADR method, as it integrates the time function in its computation to provide a yearly rate of dissipation (Charpentier Poncelet et al. 2021).

Similarly, those of the LPST method are calculated as shown in Eq. (4):

where the \({\mathrm{CF}}_{\mathrm{LPST}}\) for metal i is expressed in kg Fe-eq./kg.

2.1.2 Endpoint characterization factors based on metal prices

As the final step of the impact pathway, we evaluate the potential socio-economic impacts due to the dissipation of different mineral resources (cf. Fig. 1). The Joint Research Centre (JRC) of the European Commission suggested that the average prices of resources over a given period can be used as a proxy to reflect the complex utility that resources have for humans and are practical to do so since the data is easily available (Beylot et al. 2020a). The underlying assumption of using the prices of metals as an indication of their socio-economic value is that prices reflect at least to some extent the value of metals for society, albeit not perfectly (see discussion in, e.g., Beylot et al. 2020a; Ecorys 2012; Henckens et al. 2016; Huppertz et al. 2019; and Watson and Eggert 2021). The most expensive metals are generally used in specialized applications, because their high price does not justify their use in low value-added applications in which less specific or cheaper materials can be used.

For this study, we consider that recent price statistics are most likely to be representative of the value of resources answering the current demand for different applications. We further assume that this value is maintained over time as long as metals remain in the economy. This assumption is likely to be more realistic for the short than the long term for most metals, given that it is impossible to predict the long-term trends in demand for given applications, nor the development of new applications. Whenever possible, the 10-year average prices from 2006 to 2015 are considered. This period is chosen because most price statistics are obtained from US Geological Survey (USGS) statistics (Kelly and Matos 2014) for which 2015 is the most recent year for which data are available for most metals. Details for specific metals are presented below. Price averages and references are provided in the SI.

The price of barium is derived from statistics for barites because barium is almost exclusively consumed in compound forms (Johnson et al. 2017). We considered a barium content of 58.9% in barites (BaSO4) based on its stoichiometric content. Other data are gathered to fill data gaps and cover the platinum group metals and rare earth elements that are not covered separately in USGS statistics. All of the prices are adjusted to $US1998 to match the reference unit of the USGS price data. Prices for individual platinum group metals (PGMs) except osmium are compiled from Johnson Matthey (2021). The price of niobium is calculated from data provided by Metalary (2021) considering a niobium content of 69.9% in niobium oxides (Nb2O5). Prices for ten of the rare earth elements (REEs) are compiled from data underlying a report of the French geological survey (BRGM) (Bru et al. 2015, p. 151–158). These are yttrium (Y), lanthanum (La), cerium (Ce), praseodymium (Pr), neodymium (Nd), samarium (Sm), europium (Eu), gadolinium (Gd), dysprosium (Dy), and terbium (Tb).

Different periods are considered to estimate the price of other metals due to a lack of data. Given that iron ores are directly refined into steel, the price of iron is derived from that of steel. The 10-year period for the latter ranges from 2001 to 2010 because no data are available for subsequent years (Kelly and Matos 2014). Osmium (one of the PGMs), for which no price data is available, is estimated to remain at a constant price of $US400 per ounce (Labbé and Dupuy 2014). The price of scandium is estimated from the price of scandium oxides between 2012 and 2018, which ranged between $US4600 and $US5400 per kilogram (European Commission 2020b). For the latter, we consider an average yearly price of $US5000 per kg from 2012 to 2018 and a scandium content of 65.2% in scandium oxides (Sc2O3). The price of thulium (Tm) is calculated based on the price of its oxides in the third semester of 2015 (Bru et al. 2015) and considering a stoichiometric content of 87.4%. Similarly, the prices of the remaining REEs, namely erbium (Er), ytterbium (Yb), holmium (Ho), and lutetium (Lu), are calculated from the average yearly prices of their oxides between 2009 and 2014 as reported by Stormcrow (2014) and considering their respective stoichiometric contents in oxides (approximately 87.5%). It should be noted that the prices of REEs underwent an important price peak in 2011 due to Chinese bans on exports in the early 2010s (Bru et al. 2015), which has a notable effect on the reported prices for these metals. Such potential limitations associated with using the market price data are discussed in “Sect. 3.1.2.”

Endpoint CFs are computed by multiplying the midpoint indicators with the average price of metals, allowing to compare the relative potential value lost due to the dissipation of different metals over time. This approach differs from the JRC approach proposing to directly characterize dissipative flows identified in the LCI with price-based CFs (Beylot et al. 2020a). Yet, metals retain value for humans for as long as they are in use and quantifying the problem of inaccessibility necessitates a time dimension (Dewulf et al. 2021) that is taken into account with the proposed ADR and LPST methods.

The ADR and LPST values are used for the calculation of endpoint CFs in order to keep the units in mass and mass.years (rather than their respective normalized midpoint CFs expressed in iron equivalents). The endpoint CFs for the ADR method represent a potential value loss rate (PVLR) due to average yearly dissipation rates of metals and are calculated as shown in Eq. (5):

where \({\mathrm{CF}}_{{\mathrm{PVLR}}_{i}}\) is measured in $US1998/kg.yr.

Multiplying LPST with the price of metals indicates the lost potential value (LPV) due to the inaccessibility of metals over time. It is assumed that the potential value of metals remains the same over time, thus no discounting is applied. Endpoint CFs for the LPV are calculated as shown in Eq. (6):

where \({\mathrm{CF}}_{{\mathrm{LPV}}_{i}}\) is measured in $US1998/kg.

The total PVLR (TPVLR) and the total LPV (TLPV) are calculated analogously to their corresponding midpoint category totals as defined by Charpentier Poncelet et al. (2021), as shown in Eqs. (7) and (8):

where the \(\mathrm{TPVLR}\) is measured in $US1998/yr and the \(\mathrm{TLPV}\) is measured in $US1998.

2.1.3 Uncertainty

A Monte Carlo simulation of 1000 iterations allowed computing 95% confidence intervals for the underlying dynamic MFA results (Charpentier Poncelet et al. 2022b). The uncertainty is also taken into account to compute the midpoint CFs derived from these results. It should be noted that the computed uncertainty reflects the uncertainty due to variation of input variables, and not the model’s ability to correctly reflect the real-life global system. Price uncertainties are not accounted for given that a potentially large and unquantifiable uncertainty can be associated with the assumption of the representativeness of the annual average market price information for the relative value of metals for humans over time.

2.2 Application of characterization factors to 6000 life cycle inventory data sets

This objective of this application study is to investigate the general trends that could arise from using the ADR and LPST methods to evaluate the potential impacts due to the dissipation of mineral resources, and to compare these impact assessment results with those of widely used LCIA methods characterizing flows of metal resources in order to determine how they might differ. The assessment is realized by applying LCIA methods to multiple data sets rather than compare their CFs together. In order to do so, CFs from the selected LCIA methods are applied to the metal resource flows for all of the 5999 non-empty market LCI data sets of the ecoinvent database version 3.7.1 (Moreno Ruiz et al. 2020; Wernet et al. 2016), using allocation at point of substitution (APOS). Market data sets represent the average consumption mixes for a given region and product (Wernet et al. 2016).

We consider flows of metal resources included in the ecoinvent 3.7.1 database that are covered by the ADR and LPST methods. These include 45 flows, categorized as “metals, in ground” (e.g., aluminum, in ground) as identified in Table S4 of the SI. In order to support the analysis of the contribution of different sections of economic activity to the inventory totals, the LCI data sets are subdivided by the International Standard Industrial Classification of All Economic Activities (ISIC) classification (United Nations 2008). Sections of economic activity regroup multiple sectors (e.g., section A includes the agriculture, forestry and fishing sectors). This facilitates the study’s intelligibility and indicates general trends expected from using the developed ADR and LPST methods. The number of data sets included in each economic section and the total mass of extracted metal flows for each section are detailed in section S4 of the SI.

This approach is inspired by the study of Rørbech et al. (2014). However, unlike the latter study, we only characterize the impacts from metal resource flows and not other mineral forms of metallic elements nor energy minerals. It should be kept in mind that this study assesses the potential impacts of data sets whose functional units are not necessarily comparable (cf. “Sect. 3.2.3”).

2.2.1 Selected LCIA methods

We compare the midpoint and endpoint CFs for the LPST and ADR methods developed in this article with the latest ADP ultimate reserves method for elements based on the cumulative production in 2015 (van Oers et al. 2019, 2002) and the midpoint and endpoint CFs for the “mineral resource scarcity” category in the ReCiPe 2016 method (Huijbregts et al. 2017). The latter method includes 18 impact pathways covering three areas of protection. Its midpoint CFs for the mineral resource scarcity category originate from the SOP method (Vieira et al. 2017), and its endpoint CFs, from the SCP method (Vieira et al. 2016).

The ADP ultimate reserves, SOP and SCP methods are briefly described in section S3 of the SI. Midpoint CFs are available for all methods, while no endpoint CFs are proposed in the ADP method. All of the CFs are normalized to kg Fe-eq./kg to facilitate the comparison of impact scores between metals and methods. The normalization is done by dividing all of the CFs by that of iron for the corresponding method. It should be noted that endpoint CFs for metals included in ReCiPe 2016 are equivalent to midpoint ones when normalized to iron equivalents because the former are calculated from the latter using the same conversion factor calculated for copper (Berger et al. 2020).

The ADP ultimate reserves method is currently recommended for use in the product environmental footprint (PEF) (Zampori and Pant 2019). The ADP ultimate reserves and SOP methods are recommended by the life cycle initiative to answer different questions linked with mineral resource use (Berger et al. 2020). The former is recommended to answer the question “How can I quantify the relative contribution of a product system to the depletion of mineral resources?.” The latter is interim recommended to answer the question “How can I quantify the relative consequences of the contribution of a product system to changing mineral resource quality?.” The midpoint ADR method could address the question “How can I quantify the relative contribution of a product system to the dissipation of mineral resources?” and the LPST method, “How can I quantify the relative contribution of a product system to the inaccessibility of mineral resources due to dissipation?.” Their endpoint versions could answer the question “How can I quantify the relative contribution of a product system to the potential mineral resource value lost due to dissipation?.”

While we here focus on two widely used LCIA methods addressing mineral resource use, we refer readers to the study of Rørbech et al. (2014) and the critical review of the life cycle initiative’s task force on mineral resources (Berger et al. 2020; Sonderegger et al. 2020). Rørbech et al. (2014) applied the CFs from eleven LCIA methods to mineral resource flows (including energy minerals, minerals, and metals) for all market data sets included in the ecoinvent version 3.0 database. The life cycle initiative’s taskforce on mineral resources critically reviewed 27 LCIA methods assessing the impacts of mineral resource use (Sonderegger et al. 2020).

2.2.2 Coverage of mineral resource flows by selected LCIA methods

The ReCiPe 2016 method includes CFs for 75 resource flows of mineral resources, 26 of which are mineral compounds or ores. Parts of the latter 26 flows are no longer included in the ecoinvent database because many mineral compounds were converted to pure flows of metal content since version 3.6 (Moreno Ruiz et al. 2019). The latest update for the ADP ultimate reserves method for elements (van Oers et al. 2019) covers 76 elements. These include the 61 metallic elements that are also covered by the ADR and LPST methods, in addition to calcium, cesium, potassium, sodium, and a few non-metals (e.g., halogens). Table S3 in the SI presents the 65 metallic elements included in the latest ADP method for elements (van Oers et al. 2019) and indicates whether they are included in the ReCiPe 2016 and the ADR/LPST methods or not. Table S4 shows all of the CFs considered for the selected methods considered in the application study, including their value.

3 Results and discussion

3.1 Extended ADR and LPST methods

3.1.1 Midpoint and endpoint characterization factors

Table 1 presents the ADR and STTOT for 61 metals as computed by Charpentier Poncelet et al. (2022b) and their corresponding midpoint and endpoint CFs calculated for the ADR and LPST methods. The 95% confidence intervals for CFs are provided in Tables S1 and S2 of the SI.

Higher CFADR and CFLPST indicate that a metal has a higher average dissipation rate and thus a shorter lifetime in the economy (based on data for the recent past; see Charpentier Poncelet et al. 2022b). Given the coverage of 61 metals, we may not provide extensive details for each of them. The underlying dynamic MFA model and results as well as its supplementary materials should be consulted for additional information on losses for each metal (Charpentier Poncelet et al. 2022b). We here discuss a few examples. It can be seen from the latter work that iron is second best preserved in the economy after gold. It has an expected lifetime of 154 years thanks to relatively long-lived applications (e.g., infrastructure and mechanical equipment), a small percentage of dissipation in use, and a combined yield of about 80% for the collection and recycling processes (Charpentier Poncelet et al. 2022b). Its midpoint CFADR is 1.0 kg Fe-eq./kg. The corresponding CFADR of chromium (Cr), which is relatively well conserved in the economy (e.g., as chromium and stainless steels used in long-lived applications such as infrastructure and transport) although less than iron, is 5.5 kg Fe-eq./kg. In comparison, gallium is quickly dissipated at the production phase (> 99%) for technical and economic reasons (Helbig et al. 2020; Løvik et al. 2016, 2015), resulting in relatively high midpoint CFADR, CFLPST25, and CFLPST100, with 1383 kg Fe-eq./kg, 6.0 kg Fe-eq./kg, and 3.2 kg Fe-eq./kg, respectively. At the same time, the CFADR of indium, which is also relatively rapidly lost after extraction due to overall low process yields and a lack of end-of-life recycling, is 105 kg Fe-eq./kg. The corresponding midpoint CFs for, e.g., the LPST100 method, are 2.3 kg Fe-eq./kg for chromium and 3.1 kg Fe-eq./kg for indium.

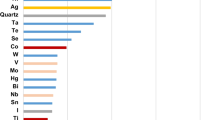

Below, we discuss general trends per categories of metals established by the UNEP (2011): ferrous, non-ferrous, precious, and specialty metals. Figures 2 and 3 show midpoint and endpoint CFs for the ADR and LPST100 methods, respectively. Figs. S2 and S3 provided in the SI depict CFs for the LPST25 and LPST500 methods.

Midpoint and endpoint characterization factors for the ADR method. CFs are shown in ascending order and log scale to facilitate comparison between methods. Black lines indicate the 95% confidence intervals. Average values for all CFs are provided in Table 1; values for the 95% confidence intervals are provided in Tables S1 and S2 of the SI

Midpoint and endpoint characterization factors for the LPST100 method. CFs are shown in ascending order and log scale to facilitate comparison between methods. Black lines indicate the 95% confidence intervals. Average values for all CFs are provided in Table 1; values for the 95% confidence intervals are provided in Tables S1 and S2 of the SI

The highest CFs for the midpoint ADR method are almost entirely specialty metals because they are typically dissipated the fastest. Endpoint CFs are dramatically different for precious metals, whose price indexes are consistently the highest. The latter are among the highest ranked endpoint CFs. Still, a few rapidly dissipating specialty metals with a high annual average market price, i.e., scandium (Sc), germanium (Ge), hafnium (Hf), and gallium (Ga), remain among the highest CFs, i.e., the first, second, fourth, and fifth CFs, respectively. Conversely, endpoint CFs for ferrous and non-ferrous metals remain in the bottom half of CFs for both the midpoint and the endpoint.

As for the ADR method, the highest CFs for the midpoint LPST100 method are almost entirely those of specialty metals, and endpoint CFs are much higher for precious metals. The most rapidly dissipating metals with the largest endpoint CFs in the ADR method feature less prominently in the ranking of CFs. The six highest CFs are precious metals, i.e., rhodium (Rh), osmium (Os), platinum (Pt), iridium (Ir), gold (Au), and palladium (Pd). It shows that the price has a greater influence on the ranking of endpoint CFs for the LPST method than for the ADR method, because the midpoint CFLPST are less differentiated than the midpoint CFADR.

3.1.2 Limitations for the endpoint characterization factors

The limitations of the midpoint ADR and LPST methods were highlighted in previous work (Charpentier Poncelet et al. 2021). We here identify limitations linked with the use of price statistics for the computation of endpoint CFs. Firstly, the prices of metals include production costs influenced by several factors such as the price of energy (Watson and Eggert 2021) that may cause a diversion from the assumed relationship between the price and the actual value of metals for humans over time. We decided to maintain this information in the price statistics because there is not much precise information available on the share of different production costs on the price of most metals (Huppertz et al. 2019), and because we assumed that the efforts put into production also partly reflect the utility of metals for humans. It should be noted that market prices tend to be more volatile than the value of metals over time that we intend to quantify using these data. Secondly, the large indirect investments and production costs associated with by-product metals may lead to both low production yields and market inefficiencies, potentially keeping their prices up (Watson and Eggert 2021). Consequently, some by-product metals like gallium and scandium have relatively high midpoint CFs (production losses are here accounted for as dissipation, leading to highly dissipative profiles for these metals) and even greater endpoint CFs (due to their relatively high prices). Thirdly, unquantified uncertainty may arise from using price data from different sources, for metals of possibly different qualities or purities, and in a few instances, over different time series. Fourthly, some metals that are often used in a compound form, such as the magnesium content of magnesia or the lanthanum content of lanthanum oxides, may not have the same potential value as their refined metal form. Nevertheless, most metals are almost exclusively used as pure metals or alloys (Graedel et al. 2022; UNEP 2011). Fifthly, the price of a few metals are determined from the price of compounds by considering the stoichiometric content of the metals in the compounds, which may not be consistent with how other price statistics are calculated. Finally, the volatility of market prices may have a significant effect on the average price of metals. For instance, the price of different REEs increased by a factor of 3 to 27 during the price peak of 2011 (Bru et al. 2015). For other metals, price variations typically ranged between ± 50 and 150% of the average price over the 2006–2015 period. Thus, using the average of yearly prices over a decade reduces the short-term variations associated with volatility and may provide more stable indications of the value of metals. Additional research is needed to address these challenging limitations.

3.2 Application study

3.2.1 Midpoint impact assessment per section of economic activity

Figure 4 shows the relative contribution of metals to inventory results split in eight sections of economic activity and relative midpoint impacts for selected LCIA methods. Metals contributing to over 10% of the total impacts for at least one method are shown individually on the figure for all columns of the corresponding economic section; others are grouped altogether.

Contribution of metals to inventory totals and impact scores for four midpoint LCIA methods. Graphs present results per section of economic activity established in the ISIC. ADP 2015: ADP ultimate reserves method for elements based on the cumulative production in 2015 (van Oers et al. 2019); ReCiPe 2016: results for the SOP method (Vieira et al. 2017) included in the latter. Metals contributing over 10% of the total impacts for at least one impact method are shown individually for all columns of the corresponding section of economic activity; others are grouped altogether. The inventory column presents the relative mass of resource flows in the compiled LCI data sets

Iron largely dominates resource extraction in the inventories among all sections, with 76% (section C: manufacturing) to 98% (section B: mining and quarrying) of their respective inventory shares. Despite its CF being one of the two smallest for the ADR and LPST methods, iron consistently comes out as one of the main contributors for the ADR method, and is increasingly important for the LPST25, 100 and 500 methods. It should be noted that, given the overall great recyclability of iron (or steel) in most of its applications (Pauliuk et al. 2017), its relative impacts would likely be much lower for LCI that account for the recycling in the end-of-life modeling beyond what is already accounted for in LCI databases (the same could be expected for other well-recycled metals). In this case, the extraction of metal would be allocated between different product systems (or between different life cycles) and therefore would be lower than a product system using only primary metal. As for other metals, iron’s relative share of impacts is increasingly similar to its share of the inventory flows when considering longer time horizons for the assessment using the LPST method, because the midpoint CFLPST25 are more differentiated than the CFLPST100 and the CFLPST500 (i.e., they spread from 1.0 to 6.0, 1.0 to 3.2, and 1.0 to 1.4 kg Fe-eq./kg, respectively).

Aside from iron, the only metals showing up among the highest relative contributions to the midpoint ADR and LPST impact assessments are other widely extracted metals typically representing around 1 to 5% of inventory shares for different economic sections. For instance, barium is more often than not part of the main contributors for the total dissipation impacts as assessed with the ADR and LPST methods. Indeed, it is mostly used for gas and oil well drilling under its mineral form of barites, explaining both its extensive use in multiple economic sections and its highly dissipative profile that is best distinguished with the midpoint ADR method. Zinc also importantly contributes to the impact scores for the ADR and LPST methods for section C (manufacturing) and the other sections. As an indication, barium and zinc represent 0.7% and 4.5% of the inventory flows by weight for section C, while they respectively account for 18% and 12% of the total impacts for the midpoint ADR method. Nickel is widely used in section F (construction) with 3.1% of the inventory total, and comes up as the third highest contribution to the ADR and LPST assessments for that section with approximately 3 to 5% of their total impacts. Similarly, aluminum flows represent 4.7% of the inventory totals for section C (just over zinc), but its midpoint CFADR and CFLPST100 are 67% and 35% lower than the corresponding CFs for zinc, explaining its lower share of the impacts for that section (i.e., 4.0% for ADR and 5.8% for LPST100). For the same reason as aluminum and nickel, chromium and manganese do not contribute over 10% of the impacts for the midpoint ADR and LPST methods for any section of economic activity despite being widely extracted.

Similarly to the ADR and LPST methods, widely extracted copper, iron, and nickel recurrently show up as important contributors to the impact assessment with the SOP method included in ReCiPe2016. For that method, iron contributes over 10% of the total impacts for all economic sections except section C (manufacturing), i.e., from 36% of the total impacts for section H (transportation and storage) to 87% for section B (mining and quarrying). Meanwhile, nickel generally contributes to a larger share of the impacts for the SOP method than for the ADR and LPST methods, with, e.g., 45% of the relative impacts of section F (construction) and 11% of those of section H (transportation and storage). Finally, copper represents 12% of the total impacts for the SOP method for section A (agriculture, forestry and fishing), 14% for section D (electricity, gas, steam and air conditioning supply), 10% for section E (water supply; sewerage, waste management and remediation activities), and 9.0% for section F (construction).

In contrast to the other methods, the relative impacts of iron are negligible for ADP ultimate reserves because its CF is among the lowest for that method, while those of the scarcest metals are several orders of magnitude higher (van Oers et al. 2019). For example, the CF of gold in the latter method is 2 billion times higher than iron (cf. Table S4). Copper, which has a lower crustal concentration (28 ppm) than other widely extracted metals (e.g., 63 ppm for barium, and 774 ppm for manganese: van Oers et al. 2019), is the only widely extracted metal with over 10% of the total impacts for the ADP method for at least one section of economic activity. It contributes most to the impact assessment for sections A (18% of the impact total), B (15%), D (16%), E (12%), and F (16%), while its shares of inventory totals range from 0.94 to 1.5% across these economic sections.

Aside from copper, only scarce metals with very low crustal concentrations recurrently come up as important contributors for the ADP ultimate reserves method. These are gold, palladium, platinum, silver, and tellurium. Precious metals are also revealed to be important contributors to the ReCiPe 2016’s impact assessments, but only for sections with the highest shares of these metals in the inventory totals, i.e., gold, palladium, and platinum in sections C and H, and silver in other sections. Indeed, although the difference is less marked than for ADP, the CFs for precious metals are also among the highest in the SOP method because they require a lot of additional ores to produce. For instance, the CFs of gold and platinum are 5 and 6 orders of magnitude greater than iron’s and rank thirtieth and thirty-third highest out of 33 CFs of the ReCiPe 2016 method considered in this study, respectively (cf. Table S4). In contrast to the ADP and SOP methods, precious metals do not appear among highest contributors to total impact scores for the midpoint ADR and LPST methods because their midpoint CFs consistently rank among the smallest, as observable in Figs. 2 and 3.

3.2.2 Midpoint versus endpoint impact assessment

We here investigate differences between the midpoint and the endpoint impacts assessed with the selected LCIA methods, as depicted in Fig. 5. Especially, we observe the effect of considering the price of metals in the endpoint assessment. For brevity, we here focus on general observations, and the comparison is elaborated with quantitative examples in section S5 of the SI. ReCiPe 2016’s relative impacts are the same for the midpoint and endpoint assessment for the reason exposed in “Sect. 2.2.1.” Contrastingly, there is an important shift in the relative shares of impacts between midpoint and endpoint for the ADR and LPST methods, because the price information allows further differentiation between metals. The impacts due to expensive metals increase dramatically, while those of cheaper ones diminish. Because of the way the CFADR are computed, the effect is most dramatic for metals that dissipate relatively quickly and that have relatively high annual average market prices (such as gallium) putting forward potentially substantial differences between the endpoint impact assessment results for the ADR or the LPST methods. Since the prices have a stronger effect on the endpoint CFs for the LPST method, the increase is more dramatic for the most expensive metals (e.g., gold) in the LPST method than the ADR method. Cheaper metals such as barium and iron see their shares of the impacts diminish importantly in the endpoint assessment.

Inventory contributions and total midpoint and endpoint impact scores for selected LCIA methods applied to 5999 market data sets from the ecoinvent 3.7.1 database. ADP 2015: ADP ultimate reserves method for elements based on the cumulative production in 2015 (van Oers et al. 2019); ReCiPe 2016 (midpoint): results for the SOP method (Vieira et al. 2017); ReCiPe 2016 (endpoint): results for the SCP method (Vieira et al. 2016). Metals representing the top five contributions to the total inventory flows and for each LCIA method are shown in their respective columns; others are grouped altogether

This convergence of results for the endpoint LPST100 and ReCiPe 2016 methods can be explained by the similarities between the surplus amount of ores assumed to be required to produce scarcer metals in the future, its assumed cost, and the higher economic value of these same metals. Indeed, production costs represent approximately 50–75% of the market price of metals (Huppertz et al. 2019). The price strongly influences the computation of endpoint CFs for the LPST methods, especially over longer time horizons (cf. Figure 3 for the LPST100 method, and Figs. S2 and S3 for the LPST25 and LPST500 methods, respectively). As shown in Fig. S5 of the SI, these endpoint methods are similarly sensitive to the relative shares of inventory totals for iron, copper, gold, and nickel. The dissipation of scarcer metals is costlier for society because they require relatively more ore to produce (as accounted for in the midpoint ReCiPe 2016 method, i.e., SOP), and the endpoint ReCiPe 2016 method, i.e., SCP, assumes they are also more costly to produce. The cost of production is also reflected in the price information underlying the endpoint CFs for the ADR and LPST methods.

3.2.3 Comparison of the impacts of data sets across methods

Figure 6 shows the total impact scores for the selected LCIA methods applied to the forty-five studied metals across all market processes from the ecoinvent 3.1.7 database. Both X- and Y-axes are in log scale. Please note that the scale of the X-axes may vary between graphs. R2 values represent the correlation of the log–log regression of impact scores per data set. Lower R2 values indicate that the compared methods present different impact hotspots among the covered metals. Three additional scatter plots are presented in the SI.

Comparison of impact assessment for six selected pairs of LCIA methods, covering 5,999 market data sets organized by section of economic activity defined in the ISIC. a Midpoint LPST100 vs. ADP 2015; b midpoint LPST100 vs. ReCiPe 2016; c midpoint ADR vs. LPST100; d midpoint ADR vs. ADP 2015; e endpoint ADR vs. LPST100; and f endpoint LPST100 vs. ReCiPe 2016. R2 values represent the correlation of the log–log regression of impact scores per data set

The impact scores range over 18 orders of magnitude across the data sets. The relatively high correlations between impact scores can partially be explained by the differences in the relative size of functional units (i.e., the variations in their total resource extraction flows). Indeed, the sum of metal resource flows spreads over nine orders of magnitude across data sets. Normalizing or rescaling functional units could reduce such variations, going beyond what could be achieved in this article. For instance, the results of Rørbech et al. (2014) show that correlations between impact scores per data set could be expected to be much smaller after rescaling functional units to a more comparable scale.

The impact scores for the midpoint ADR and LPST100 methods, as shown in Fig. 6c, are rather well correlated (R2 = 0.991) given that they both rely on the service time (albeit with a different conceptual approach; cf. Equations 1 and 2) and on the same underlying data. Thus, their CFs rank almost the same across metals. The comparison between impact scores for the midpoint ADR method and those of the ADP ultimate reserves method have the lowest correlation (Fig. 6d; R2 = 0.927), followed by those of midpoint LPST100 versus ADP methods (Fig. 6a; R2 = 0.937). Data sets responsible for most impacts for the ADP 2015 are expected to be quite different from those for the ADR and LPST methods. The former are influenced almost exclusively by data sets with larger resource flows of the scarcest elements in the crust (e.g., precious metals and tellurium), whereas the latter are influenced not only by the dissipation patterns of different metals but also by the mass of their resource flows (cf. “Sect. 3.2.1”). The impact scores for the latter midpoint methods thus result mostly from iron flows because they are the largest resource flows, and from other widely extracted metals with higher CFs than others (e.g., barium and zinc).

The impact scores of the LPST100 midpoint method are better correlated with ReCiPe 2016 (Fig. 6b; R2 = 0.985) than those of ADP 2015 (Fig. 6a; R2 = 0.937). Logically, ReCiPe 2016’s impact scores have a lower correlation with those of ADP 2015 (R2 = 0.967; cf. Fig. S6 of the SI) than with the other two methods. This can partially be explained by the fact that the CFs of the ReCiPe 2016 method present a stronger convergence with those of the LPST100 method than the ADP2015 method (cf. Table S4 in the SI). Another reason for the stronger convergence between ReCiPe 2016 and the LPST100 results is that their CFs are much less differentiated than those of ADP 2015. Therefore, their impact scores are more determined by the relative size of metal flows in the LCI in comparison to the ADP 2015 method. Contrastingly, the pronounced differentiation between CFs for the ADP 2015 method (cf. Table S4 in the SI) leads to acute hotspots for a few very scarce metals, despite their very small resource flows in the inventory.

The correlation between endpoint ADR and LPST100 results is similar to their midpoint assessments, as shown by comparing Fig. 6c (R2 = 0.991) and Fig. 6e (R2 = 0.991). Even though the price of metals have a greater influence on the CFLPST100 than the CFADR, their endpoint CFs have similar rankings. The few metals with much larger CFs in the ADR method are metals with the highest dissipation rates and high prices. Relatively small resource flows of such metals in the inventories translate into relatively large shares of the total impacts, the most obvious example being gallium (as observable in Fig. 5). It should be noted that other similar metals with high CFs do not have resource flows in the ecoinvent 3.7.1 database (e.g., germanium and scandium). Thus, data sets are expected to present noticeably greater impact scores with the endpoint ADR method than the endpoint LPST100 method due to higher-than-average resource flows of highly dissipative, relatively expensive metals (e.g., gallium and germanium; cf. Figure 2). For instance, gallium contributes an average of 0.016% to the inventory totals for the 100 data sets with the largest difference between the total impact scores for the endpoint ADR and LPST100 methods. In contrast, gallium’s average share of inventory totals is of 0.0054% across all of the data sets. Finally, the comparison between endpoint category totals for the LPST100 method and those of the ReCiPe 2016 method (Fig. 6f; R2 = 0.995) shows an even higher convergence than for the respective midpoint assessments, as partly explained by the relation between the SCP and the price information used for the computation of endpoint CFs for the LPST method exposed in “Sect. 3.2.2.”

3.3 Evaluation of ADR and LPST methods

We evaluated the extended ADR and LPST methods against five criteria adapted from the ILCD handbook (European Commission 2010). We hereby summarize our observations; the detailed evaluation can be found in section S7 of the SI. Completeness of scope: the methods provide a significant coverage of metal resources at the global scale, but do not include mineral compound flows (e.g., sand and talc), nor fossil fuels and their derived products like plastics. Relevance for the assessment of mineral resource use on the AoP natural resources: the methods rely on real-life statistics and provide a global evaluation of dissipation patterns for the studied metals. The CFs apply to extraction flows, and hence do not allow distinguishing between different product systems that may dissipate metals differently. They address the safeguard subject for mineral resource use established by the Life Cycle Initiative, i.e., the “potential to make use of the value that mineral resources can hold for humans in the technosphere” (Berger et al. 2020). Scientific robustness and certainty: the methods rely on data and methods that are published or to be published as peer-reviewed articles. Uncertainty is addressed and where practical accounted for Documentation, Transparency, and Reproducibility: The underlying data and model are documented transparently and are available in open-access (Helbig and Charpentier Poncelet 2022). The methods can be replicated, and additional CFs can be recomputed or newly developed with the help of published articles (dynamic MFA methods: Charpentier Poncelet et al. 2022b and LCIA methods: Charpentier Poncelet et al. 2021 and this article). Applicability: The large-scale application study presented in “Sect. 3.2” demonstrated that the ADR and LPST methods are readily usable with current LCI databases in LCA studies, albeit with some limitations to keep in mind (cf. “Sect. 3.1.2”).

3.4 Perspectives for the ADR and LPST methods

Some perspectives to improve the ADR and LPST methods can be identified. Additional CFs could be developed for other minerals such as construction aggregates and sand. It would be possible for third-party users to generate CFs for additional mineral resources by using the framework and methods for dynamic MFA of Charpentier Poncelet et al. (2022b), along with the methods presented by Charpentier Poncelet et al. (2021) and complemented in this article. It could also be possible to adapt the model to assess the dissipation of plastics and that of biotic resources used in similar sectors as mineral resources (e.g., wood).

Furthermore, additional research could aim to improve the evaluation of the economic and use values (i.e., the value of services provided by applications) of mineral resources, as defined by Charpentier Poncelet et al. (2022a). A different methodology could be developed to evaluate endpoint damage in a more reliable way than by using annual average market prices. Other metrics could also be considered such as the global economic importance of resources computed for criticality studies (Graedel et al. 2012). Moreover, efforts could be spent on developing CFs considering different assumptions on the future recovery of metals from, e.g., waste disposal facilities (see e.g. Dewulf et al. 2021). Such assumptions could build on different cultural perspectives, as discussed by Charpentier Poncelet et al. (2022a). Finally, CFs of the ADR and LPST methods could apply to dissipative flows (or “resource inaccessibility” flows) rather than extraction flows if these were identified in the LCI. For instance, dissipative flows due to a given product system could be estimated by subtracting functionally recycled metal flows from extracted metal flows. We discuss such perspectives in more details in section S8 of the SI, and investigate how different future recovery scenarios could be implemented in such an assessment under different cultural perspectives.

4 Conclusion

The extended ADR and LPST methods presented in this article allow evaluating the impacts of dissipation of metals in LCA. Because of the lack of information on dissipative flows in the LCI, they so far apply to extraction flows, and thus no distinction is made between processes or product systems that allow for recycling. Potential workaround solutions addressing this issue are presented in section S8 of the SI, along with potential ways forward to account for the future recovery of metals in dissipation-oriented approaches. Further research is needed to compare LCIA results when applying the CFs from the ADR and LPST methods to dissipative flows in the inventory (e.g., using the process-based JRC approach; see Beylot et al. 2021) instead of extraction flows and evaluate how that would influence impact assessment results.

The midpoint CFs for the ADR and LPST methods rely on replicable results from open-source data and model (Charpentier Poncelet et al. 2022b; Helbig and Charpentier Poncelet 2022). Endpoint CFs introduce the use of price statistics in the assessment, which is helpful to distinguish between the value of different metals but presents some limitations at this point (cf. “Sect. 3.1.2”). The identified limitations are expected to be most relevant for metals with very small resource flows in the LCI or for which no resource flows are currently reported in widespread databases like ecoinvent. For instance, it was observed that by-product metals like gallium are likely to be over-represented in the endpoint results for the ADR method. Moreover, while price statistics were here considered to be the best applicable proxy to represent the value of metals for humans as defined by the Life Cycle Initiative’s taskforce on mineral resources (Berger et al. 2020; Sonderegger et al. 2020), other metrics might be considered in the future to improve the way the economic and use values of resources are taken into account. Future research could aim to improve upon price statistics or explore the use of other proxies to reflect the value of metals for humans. Therefore, we recommend the use of midpoint CFs to evaluate the physical dissipation rates of metals (ADR) or the related inaccessibility to potential users (LPST). The use of endpoint CFs provides additional information on the potentially lost value of metals, but should be done cautiously and keeping their limitations in mind.

The application study revealed that the midpoint impact assessments are expected to diverge between selected LCIA methods, as impact hotspots are expected to be due to different metals. The divergence is expected to be smaller between the ADR/LPST methods and ReCiPe 2016, because their CFs spread over less orders of magnitude, thus being more dependent on the size of resource flows than ADP 2015. Moreover, the scarcest metals (e.g., precious metals) consistently have higher CFs in the ADP 2015, midpoint and endpoint ReCiPe 2016 methods (SOP and SCP, respectively), and endpoint ADR and LPST methods. However, their CFs are so high in the ADP 2015 method that they consistently dominate impact scores for that method, while they only show up in top impact scores for data sets with relatively high amounts of these scarce metals with the other methods. Rather, widely used metals with relatively large resource flows can generally be expected to come out as being responsible for the most impacts when assessed with the midpoint ADR, LPST, and midpoint/endpoint ReCiPe 2016 methods. This remains generally true for the endpoint ADR and LPST methods, although the metals that dissipate the fastest tend to be more represented in the endpoint assessment using the ADR method, and most expensive metals in the endpoint assessment using the LPST method.

Finally, we would like to conclude this article with a short discussion on assessing multiple aspects related to mineral resource use in the AoP natural resources. Charpentier Poncelet et al. (2022a) suggested that multiple LCIA methods should be used to assess the impacts of mineral resource use on the AoP natural resources exhaustively. Indeed, resources provide economic values and use values to different users, and practitioners with different cultural perspectives could attempt to characterize the impacts of mineral resource use in different ways depending on their beliefs. Therefore, the assessment of mineral resource use on the AoP natural resources in the LCA or life cycle sustainability assessment (LCSA) contexts could be realized by using the ADR or LPST methods along with other LCIA methods with complementary pathways such as those covered by the ADP 2015 and ReCiPe 2016 methods (cf. Charpentier Poncelet et al. 2022a). Measuring the impacts of dissipation in terms of lost potential to use the economic and use values (in monetary units or in different units) could enable the comparison with the impacts for other biotic and abiotic resources as well as values obtained from ecosystems (cf. discussion in Charpentier Poncelet et al. 2022a). Nevertheless, as discussed by the authors, significant developments are needed to address impact pathways related to natural resource use consistently. Moreover, important method developments and harmonization between existing or new LCIA methods would be needed for an exhaustive impact assessment of different aspects of mineral resource use to become viable (Charpentier Poncelet et al. 2022a).

Data availability

Data and results depicted in the article are provided in the Supporting information documents. The data and model used to compute midpoint characterization factors may be accessed online at https://doi.org/10.17605/OSF.IO/CWU3D (Helbig and Charpentier Poncelet 2022). Price data and references are detailed in the article and in the Supporting information. Data from the ecoinvent database are subject to copyright and may not be divulged.

References

Berger M, Sonderegger T, Alvarenga R, Bach V, Cimprich A, Dewulf J, Frischknecht R, Guinée J, Helbig C, Huppertz T, Jolliet O, Motoshita M, Northey S, Peña CA, Rugani B, Sahnoune A, Schrijvers D, Schulze R, Sonnemann G, Valero A, Weidema BP, Young SB (2020) Mineral resources in life cycle impact assessment: part II – recommendations on application-dependent use of existing methods and on future method development needs. Int J Life Cycle Assess. https://doi.org/10.1007/s11367-020-01737-5

Beylot A, Ardente F, Marques A, Mathieux F, Pant R, Sala S, Zampori L (2020a) Abiotic and biotic resources impact categories in LCA : development of new approaches. Publications Office of the European Union, Luxembourg. https://doi.org/10.2760/232839

Beylot A, Ardente F, Sala S, Zampori L (2021) Mineral resource dissipation in life cycle inventories. Int J Life Cycle Assess. https://doi.org/10.1007/s11367-021-01875-4

Beylot A, Ardente F, Sala S, Zampori L (2020b) Accounting for the dissipation of abiotic resources in LCA: status, key challenges and potential way forward. Resour Conserv Recycl 157:104748. https://doi.org/10.1016/j.resconrec.2020.104748

Blomsma F, Tennant M (2020) Circular economy: preserving materials or products? Introducing the Resource States framework. Resour Conserv Recycl 156:104698. https://doi.org/10.1016/j.resconrec.2020.104698

Bru K, Christmann P, Labbé J-F, Lefebvre G (2015) Panorama 2014 du marché des Terres Rares. Orléans, France

Charpentier Poncelet A, Beylot A, Loubet P, Laratte B, Muller S, Villeneuve J, Sonnemann G (2022a) Linkage of impact pathways to cultural perspectives to account for multiple aspects of mineral resource use in life cycle assessment. Resour Conserv Recycl 176:105912. https://doi.org/10.1016/j.resconrec.2021.105912

Charpentier Poncelet A, Helbig C, Loubet P, Beylot A, Muller S, Villeneuve J, Laratte B, Thorenz A, Tuma A, Sonnemann G (2022b) Losses and lifetimes of metals in the economy. Nat Sustain. https://doi.org/10.1038/s41893-022-00895-8

Charpentier Poncelet A, Helbig C, Loubet P, Beylot A, Muller S, Villeneuve J, Laratte B, Thorenz A, Tuma A, Sonnemann G (2021) Life cycle impact assessment methods for estimating the impacts of dissipative flows of metals. J Ind Ecol jiec.13136. https://doi.org/10.1111/jiec.13136

Charpentier Poncelet A, Loubet P, Laratte B, Muller S, Villeneuve J, Sonnemann G (2019) A necessary step forward for proper non-energetic abiotic resource use consideration in life cycle assessment: the functional dissipation approach using dynamic material flow analysis data. Resour Conserv Recycl 151:104449. https://doi.org/10.1016/j.resconrec.2019.104449

Dewulf J, Hellweg S, Pfister S, León MFG, Sonderegger T, de Matos CT, Blengini GA, Mathieux F (2021) Towards sustainable resource management: identification and quantification of human actions that compromise the accessibility of metal resources. Resour Conserv Recycl 167:105403. https://doi.org/10.1016/j.resconrec.2021.105403

Drielsma J, Russell-Vaccari AJ, Drnek T, Brady T, Weihed P, Mistry M, Simbor LP (2016) Mineral resources in life cycle impact assessment—defining the path forward. Int J Life Cycle Assess 21:85–105. https://doi.org/10.1007/s11367-015-0991-7

Ecorys (2012) Mapping resource prices: the past and the future

European Commission (2020a) Communication from the Commission to the European Parliament, the Council, the European Economic and Social Committee and the Committee of the Regions. A new Circular Economy Action Plan For a cleaner and more competitive Europe. Brussels, Belgium.

European Commission (2020b). Study on the EU’s list of Critical Raw Materials. Critical Raw Materials Factsheets. https://doi.org/10.2873/92480

European Commission (2010) Framework and requirements for life cycle impact assessment models and indicators, international reference life cycle data system (ILCD) handbook. https://doi.org/10.2788/38719

Graedel TE, Barr R, Chandler C, Chase T, Choi J, Christoffersen L, Friedlander E, Henly C, Jun C, Nassar NT, Schechner D, Warren S, Yang MY, Zhu C (2012) Methodology of metal criticality determination. Environ Sci Technol 46:1063–1070. https://doi.org/10.1021/es203534z

Graedel TE, Harper EM, Nassar NT, Reck BK (2013) On the materials basis of modern society. Proc Natl Acad Sci 112:6295–6300. https://doi.org/10.1073/pnas.1312752110

Graedel TE, Reck BK, Miatto A (2022) Alloy information helps prioritize material criticality lists. Nat Commun 13:1–8. https://doi.org/10.1038/s41467-021-27829-w

Helbig C, Charpentier Poncelet A (2022) ODYM MaTrace dissipation - code and datasets. https://doi.org/10.17605/OSF.IO/CWU3D

Helbig C, Kondo Y, Nakamura S (2021) Simultaneously tracing the fate of seven metals with MaTrace-multi (accepted manuscript). J Ind Ecol

Helbig C, Thorenz A, Tuma A (2020) Quantitative assessment of dissipative losses of 18 metals. Resour Conserv Recycl. https://doi.org/10.1016/j.resconrec.2019.104537

Henckens MLCM, van Ierland EC, Driessen PPJ, Worrell E (2016) Mineral resources: geological scarcity, market price trends, and future generations. Resour Policy 49:102–111. https://doi.org/10.1016/j.resourpol.2016.04.012

Huijbregts MAJ, Steinmann ZJN, Elshout PMF, Stam G, Verones F, Vieira M, Zijp M, Hollander A, van Zelm R (2017) ReCiPe2016: a harmonised life cycle impact assessment method at midpoint and endpoint level. Int J Life Cycle Assess 22:138–147. https://doi.org/10.1007/s11367-016-1246-y

Huppertz T, Weidema B, Standaert S, De Caevel B, van Overbeke E (2019) The social cost of sub-soil resource use. Resources 8:19. https://doi.org/10.3390/resources8010019

Johnson CA, Piatak NM, Miller MM (2017) Barite (Barium), in: Critical mineral resources of the United States—economic and environmental geology and prospects for future supply. U.S. Geological Survey, Reston, Virginia.

Johnson Matthey (2021) Price charts [WWW Document]. http://www.platinum.matthey.com/prices/price-charts (Accessed 13 June 2021).

Kelly T, Matos GR (2014) Historical statistics for mineral and material commodities in the United States (2016 version) [WWW Document]. US Geol Surv Data Ser. 140. https://www.usgs.gov/centers/nmic/historical-statistics-mineral-and-material-commodities-united-states (Accessed 15 Aug 2021)

Labbé J-F, Dupuy J-J (2014) Panorama 2012 du marché des platinoïdes, Brgm/Rp-63169-Fr. Orléans, France.

Løvik AN, Restrepo E, Müller DB (2016) Byproduct metal availability constrained by dynamics of carrier metal cycle: the gallium-aluminum example. Environ Sci Technol 50:8453–8461. https://doi.org/10.1021/acs.est.6b02396

Løvik AN, Restrepo E, Müller DB (2015) The global anthropogenic gallium system: determinants of demand, supply and efficiency improvements. Environ Sci Technol 49:5704–5712. https://doi.org/10.1021/acs.est.5b00320

Metalary (2021) Niobium price [WWW Document]. https://www.metalary.com/niobium-price/

Moreno Ruiz E, Valsasina L, FitzGerald D, Brunner F, Symeonidis A, Bourgault G, Wernet G (2019) Documentation of changes implemented in the ecoinvent database v3.6. Zürich, Switzerland

Moreno Ruiz E, Valsasina L, FitzGerald D, Symeonidis A, Turner D, Müller J, Minas N, Bourgault G, Vadenbo C, Ioannidou D, Wernet G (2020) Documentation of changes implemented in the ecoinvent database v3.7 & v3.7.1. Zürich, Switzerland.

Nakamura S, Kondo Y, Kagawa S, Matsubae K, Nakajima K, Nagasaka T (2014) MaTrace: tracing the fate of materials over time and across products in open-loop recycling. Environ Sci Technol 48:7207–7214. https://doi.org/10.1021/es500820h

Pauliuk S, Kondo Y, Nakamura S, Nakajima K (2017) Regional distribution and losses of end-of-life steel throughout multiple product life cycles—insights from the global multiregional MaTrace model. Resour Conserv Recycl 116:84–93. https://doi.org/10.1016/j.resconrec.2016.09.029

Reuter MA, van Schaik A, Gutzmer J, Bartie N, Abadías-Llamas A (2019) Challenges of the circular economy: a material, metallurgical, and product design perspective. Annu Rev Mater Res 49:253–274. https://doi.org/10.1146/annurev-matsci-070218-010057

Rørbech JT, Vadenbo C, Hellweg S, Astrup TF (2014) Impact assessment of abiotic resources in LCA: quantitative comparison of selected characterization models SUPP INFO. Environ Sci Technol 48:11072–11081. https://doi.org/10.1021/es5023976

Schulze R, Guinée J, van Oers L, Alvarenga R, Dewulf J, Drielsma J (2020) Abiotic resource use in life cycle impact assessment—Part II – Linking perspectives and modelling concepts. Resour Conserv Recycl. https://doi.org/10.1016/j.resconrec.2019.104595

Sonderegger T, Berger M, Alvarenga R, Bach V, Cimprich A, Dewulf J, Frischknecht R, Guinée J, Helbig C, Huppertz T, Jolliet O, Motoshita M, Northey S, Rugani B, Schrijvers D, Schulze R, Sonnemann G, Valero A, Weidema BP, Young SB (2020) Mineral resources in life cycle impact assessment—part I: a critical review of existing methods. Int J Life Cycle Assess 25:784–797. https://doi.org/10.1007/s11367-020-01736-6

Stormcrow (2014) Rare Earth Industry Report

UNEP (2013) Metal recycling: opportunities, limits, infrastructure, A Report of the Working Group on the Global Metal Flows to the International Resource Panel.

UNEP (2011) Recycling rates of metals: a status report, A Report of the Working Group on the Global Metal Flows to the International Resource Panel. United Nations Environment Programme, Nairobi, Kenya.

United Nations (2008) International Standard Industrial Classification of All Economic Activities (ISIC), Rev. 4. United Nations Publication, New York.

van Oers L, de Koning A, Guinée JB, Huppes G (2002) Abiotic resource depletion in LCA: improving characterisation factors for abiotic resource depletion as recommended in the new Dutch LCA Handbook, Road and Hydraulic Engineering Institute.

van Oers L, Guinée JB, Heijungs R (2019) Abiotic resource depletion potentials (ADPs) for elements revisited—updating ultimate reserve estimates and introducing time series for production data. Int J Life Cycle Assess. https://doi.org/10.1007/s11367-019-01683-x

van Oers L, Guinée JB, Heijungs R, Schulze R, Alvarenga RAF, Dewulf J, Drielsma J, Sanjuan-Delmás D, Kampmann TC, Bark G, Uriarte AG, Menger P, Lindblom M, Alcon L, Ramos MS, Torres JME (2020) Top-down characterization of resource use in LCA: from problem definition of resource use to operational characterization factors for dissipation of elements to the environment. Int J Life Cycle Assess. https://doi.org/10.1007/s11367-020-01819-4

Vieira M, Ponsioen T, Goedkoop M, Huijbregts M (2016) Surplus cost potential as a life cycle impact indicator for metal extraction. Resources 5:2. https://doi.org/10.3390/resources5010002

Vieira MDM, Ponsioen TC, Goedkoop MJ, Huijbregts MAJ (2017) Surplus ore potential as a scarcity indicator for resource extraction. J Ind Ecol 21:381–390. https://doi.org/10.1016/j.jcrc.2017.02.030

Watson BJ, Eggert RG (2021) Understanding relative metal prices and availability: combining physical and economic perspectives. J Ind Ecol 25:890–899. https://doi.org/10.1111/jiec.13087

Wernet G, Bauer C, Steubing B, Reinhard J, Moreno-Ruiz E, Weidema B (2016) The ecoinvent database version 3 (part I): overview and methodology. Int J Life Cycle Assess 21:1218–1230. https://doi.org/10.1007/s11367-016-1087-8

Zampori L, Pant R (2019) Suggestions for updating the product environmental footprint (PEF) method. Publications Office of the European Union, Luxembourg. https://doi.org/10.2760/424613

Zampori L, Sala S (2017) Feasibility study to implement resource dissipation in LCA. Luxembourg. https://doi.org/10.2760/869503

Acknowledgements

We thank F. Ardente for providing a compilation of price statistics retrieved from the US Geological Survey data available on the latter’s website. We are grateful to the two anonymous reviewers whose comments greatly helped us improve the quality of this manuscript.

Funding

Open Access funding enabled and organized by Projekt DEAL. This article was mostly developed and written during the PhD thesis of A.C.P., which was co-financed by the French agency for the ecological transition (ADEME) and the French geological survey (BRGM).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Communicated by Matthias Finkbeiner

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Charpentier Poncelet, A., Loubet, P., Helbig, C. et al. Midpoint and endpoint characterization factors for mineral resource dissipation: methods and application to 6000 data sets. Int J Life Cycle Assess 27, 1180–1198 (2022). https://doi.org/10.1007/s11367-022-02093-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11367-022-02093-2