Abstract

Purpose

Novel process windows allow the development of faster, flexible, and greener processes. Therefore, novel process windows were applied to develop a greener process for the synthesis of vitamin D3. In this study the environmental impacts of several batch pathways to obtain vitamin D3 are benchmarked against the continuous microflow process, where novel process windows such as high temperature and pressure were applied. To evaluate the environmental impact of these processes, life cycle assessments were conducted.

Methods

A new process concept was developed to optimize and simplify the synthesis of crystalline vitamin D3. This process was conducted in microflow by combining UV photoirradiation and high-p,T (photo-high-p,T) processing. Microreactors allow a high photon flux and enable the harsh conditions, respectively. The process was coupled with an integrated continuous crystallization, and its feasibility has been proven and reported before. The potential environmental impacts were assessed from a cradle-to-gate perspective. Both processes, continuous and batch, were modeled in Aspen Plus using foreground data from the experimental continuous setup, and background data from different patents. The assessment was performed in the software Umberto NXL LCA using the ReCiPe Midpoint 2008 method.

Results and discussion

The continuous process has a significantly lower environmental impact than the batch processes. This lower impact is largely due to the fact that fewer amounts of material, particularly solvents, are used. Moreover, the continuous process is faster and has fewer steps, i.e., process-simplified. Among the industrial processes, the synthesis conducted in isopropanol has the lowest environmental impact, although, even in this case, the impact is between 20 and 30 times higher—depending on the conditions—compared with the continuous process. When the batch process is conducted in benzene, the worst environmental impact is obtained. Finally, recycle of the solvent for the best batch case was assessed. This improved the batch process to make it comparable with the continuous process.

Conclusions

The continuous production of vitamin D3 leads to an interesting alternative to the industrial process. Continuous manufacturing of vitamin D3 is faster, requires fewer steps, and uses less solvents compared with the industrial synthesis. However, although the environmental impact of this continuous process is already lower than that of the batch processes, the continuous process can still benefit from further optimization, particularly the introduction of a recycle loops for the solvents methyl tert-butyl ether and acetonitrile.

Similar content being viewed by others

Explore related subjects

Find the latest articles, discoveries, and news in related topics.Avoid common mistakes on your manuscript.

1 Introduction

In the last decades, continuous processing has become a hot topic in the pharmaceutical industry because of (i) the increased quality and its reproducibility, (ii) the reduction of safety concerns when using hazardous chemicals and thus a faster and more predictable scale-up, (iii) the reduction in the size of the factories with increased flexibility and modularity and lower capital costs, (iv) the use of novel process windows and green chemistry to reduce the complexity of multistep synthesis, (v) the shorter time-to-market by using modular smart factories, and (vi) overall lower cost and environmental impact (Hempel 2009; Malet-Sanz and Susanne 2012; Sahlodin and Barton 2015; Wegner et al. 2012). In the process of transfer from batch to continuous processing, microreactors have contributed greatly; their use fulfills all the above requirements and enables the possibility to work in harsh conditions, also called novel process windows (NPWs) (Hessel et al. 2008, 2011). Such NPW intensification allows to shorten residence times, therefore increasing the productivity and optimizing the sustainability.

Driven by the advantages that continuous processing offers, the Food and Drug Administration (FDA) is promoting the change from batch to flow in the pharmaceutical industry (Hartman et al. 2011; Lee et al. 2015; Porta et al. 2016). To promote and trigger innovation as well as to address the issues around the economic constraints (Benyahia et al. 2012; Malet-Sanz and Susanne 2012) and the implementation of green chemistry and green engineering, the American Chemistry Society Green Chemistry Institute (ACS GCI) has created the pharmaceutical roundtable (Jimenez-Gonzalez et al. 2011). The roundtable, motivated by the legislative authority (FDA), has put continuous manufacturing in the top green engineering research areas (Jimenez-Gonzalez et al. 2011).

Microreaction technology plays an important role in continuous processing. It improves mixing and heat transfer, facilitates scale-up, and has lower space-time demand (Plutschack et al. 2017). It has, in addition, opened the possibility for NPWs (Hessel et al. 2011), where the synthesis can be conducted at higher temperatures and higher pressures. Moreover, it is highly promising for the greening of the pharmaceutical industry, e.g., microreactors as a key component in modular plants (containers) which are seen as part of the 50% idea (half time reduction of process development and a faster transition from lab to pilot to production) (Vural- Gursel et al. 2012). Cost benefits come from higher yields, purity, shorter reaction time, and significantly reduced environmental impact of the processes (Hempel 2009). Furthermore, the use of raw materials is reduced, purification stages are minimized, and the need for end-of-pipe solutions is avoided (Haswell and Watts 2003). Flow chemistry intensifies a much wider spectrum of chemical reactions, making them faster by boosting the activation via novel process windows. An example of previous process improvements is shown in Borukhova et al. (2016) and Ott et al. (2016) where NPWs were applied to synthesize rufinamide in a continuous-flow reactor under solvent- and catalyst-free conditions. The continuous production showed an improved sustainability profile in terms of life cycle assessment with respect to batch processing given by process simplification and process integration.

Recently, a continuous process for the synthesis (Escribà-Gelonch et al. 2018a, c) and crystallization (Escribà-Gelonch et al. 2018b; Gruber-Woelfler et al. 2017) of vitamin D3 (VD3) using novel process windows was developed. To the best of our knowledge, the combination of these steps forms the first fully continuous process for the synthesis of crystalline vitamin D3. High pressure and high temperature were used in combination with UV photoactivation. High pressure was needed to restrict the processing to a single liquid phase. Another novel process window used was the UV laser irradiation, which allowed pulsed operation in the femtosecond order. This faster pulsing, which is faster than the lifetime excitation of the molecule, has the potential of higher selectivity and changes the chemical pathway, which would go under normal (not pulsed UV irradiation) conditions.

Vitamin D3 is a secosteroid (Mahmoodani et al. 2017) discovered 100 years ago. It has quickly positioned as one of the most relevant nutrients (Khadilkar 2013) as it is necessary for the optimal functioning of many organs, particularly the cardiovascular system (Lee et al. 2008). However, its deficiency is a worldwide problem (Fanari et al. 2015) that both mankind and indoor-raised animal face (Hirsch 2011). Therefore, the efficient and economical production of dietary supplements and the fortification of food have become of great interest to the industry and to the academia (Gruber-Woelfler et al. 2017; Mahmoodani et al. 2017).

The reaction mechanism for the synthesis of vitamin D3 is elucidated in Fig. 1. 7-Dehydrocholesterol (7DHC), also known as provitamin D3, is a by-product obtained after cleansing the wool (Hirsch 2011). It is irradiated with UV light to produce previtamin D3. The optimal wavelength for the conversion of 7DHC is 296 nm, although a spectrum from 280 to 320 nm can also be applied for the synthesis. The sources of light can vary, but the most common in the industry is to use a Hg lamp in a quartz reactor. Other options are bromine and laser light (Escribà-Gelonch et al. 2018a; Hirsch 2011). The photoisomerization step is not selective. Therefore, to minimize the formation of undesired isomers, i.e., tachysterol and lumisterol (as shown in Scheme 1 of Escribà-Gelonch et al. 2018a) (Hirsch 2011), and to ease the separation of the products are necessary to stop the reaction at low conversions (max. 20–30%) (Fuse et al. 2010; Doi et al. 2004). Finally, the irradiation is followed by a thermally driven step to isomerize previtamin D3 to vitamin D3 and conclude the synthesis (Bikle 2014; Hirsch 2011).

In recent years, the environmental assessment, particularly life cycle assessments (LCAs), has become of high importance for the evaluation of a process (Cespi et al. 2015). Life cycle assessment is a methodological framework used to evaluate the environmental burden of a product through its whole life cycle (Ponder and Overcash 2010). As far as the environmental assessment of vitamin D3 is concerned, there is any LCA reported. Therefore, in this paper, a life cycle assessment of this continuous process of vitamin D3 production is presented and compared with the batch synthesis. A scenario-based assessment was selected due to the increasing relevance of scenarios to make a comprehensive and detailed assessment and to identify hot spots for improvement (Guinée 2016).

2 Methodology

2.1 Goal and scope

The goal of this LCA study is to assess the environmental impacts and to compare the intensified continuous production of crystalline of vitamin D3 with the conventional batch production. The scope of this study encompasses the synthesis of vitamin D3 from the irradiation of 7DHC, the extraction of 7DHC from the vitamin D3 resin, and the crystallization of the resin to obtain crystalline vitamin D3. The purification of the vitamin D3, namely the extraction of tachysterol and lumisterol, is excluded since this step was not developed for the continuous process.

2.2 System boundaries

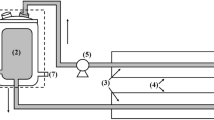

The system boundaries of the vitamin D3 production examined in this LCA study have been defined based on a “cradle-to-gate” approach, which considers the materials, energy flows, and emission associated from the extraction of the raw materials until the yield of the product (Ayres 1995). End-of-life and downstream processing (i.e., waste management) was excluded for both continuous (NPW) and batch productions. The system boundaries are presented in a diagram of the processes (Fig. 2).

It must be noted that the LCA does not include the manufacturing of the equipment such as reactors or heat exchangers, and the transportation of the raw material is excluded as well.

2.3 Life cycle inventory

To build the inventory, the functional unit was defined as 1 g of the product, i.e., crystalline vitamin D3. All life cycle inventory (LCI) analyses are referred to the amount of the product.

To build the inventory, the functional unit was defined as 1 g of the product, i.e., crystalline vitamin D3. All LCI analyses are referred to the amount of the product. Foreground data from the laboratory was used to develop the workflow sheet of the continuous process. Secondary data was used for the batch processes from which the scenarios were developed.

To compile the data to build the inventories, both the continuous and batch processes were modeled in Aspen Plus V9 software. These simulations were developed to produce the amount of product declared in the functional unit.

Firstly, the continuous process and how it was implemented in Aspen Plus is described. Then, the batch case is presented. It is described how the scenarios were constructed for the batch case and what steps entail each of them. Using different scenarios for the industrial process was necessary to reduce the uncertainty caused by the lack of metadata (Cellura et al. 2011). Likewise, the use of scenarios can be used to assess the influence or sensitivity of the input parameters (Björklund 2002; Guo and Murphy 2012). After that, it is detailed how the scenarios were implemented in Aspen Plus.

2.3.1 Continuous process

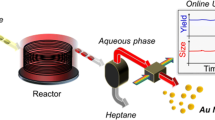

The first approach to continuous processing was proposed by Fuse et al. (2010), where a two-stage continuous microreactor was employed. Recently, an intensification of the process was achieved using either a UV lamp or a laser (Escribà-Gelonch et al. 2018a). With the aid of microreactors, operation at harsh conditions was possible, i.e., to combine UV photoradiation with high pressure and high temperature (photo-high-p,T; see Fig. 3). The solvent selected for the synthesis was tert-butyl methyl ether (t-BME) instead of diethyl ether, trying to avoid the dangerous peroxides.

High-p,T photoreactor. The preheating chamber is located at the entrance, followed by the irradiation chamber, which are represented in Fig. 4, enclosed in the purple rectangle. The UV lamp is located behind the chamber

The intensified process is conducted as follows: a solution of 7DHC (0.22 M) in t-BME is pumped through a quartz-made coil with a pressure of 32 bar, achieving max. 240 °C in the irradiation chamber. The reaction is carried using a HOK 400 W UV lamp. After the reaction, the solution flows out of the chamber and cools down immediately. Conversion of 42% with a 17% yield is achieved, and the resin obtained can be used for animal feed after the recovery of the 7DHC (Escribà-Gelonch et al. 2018c).

To obtain a human-compatible vitamin D3, the resin must follow a crystallization process. To do so, the photochemical synthesis is coupled to a continuous crystallization setup, which allows continuous processing (Escribà-Gelonch et al. 2018b; Gruber-Woelfler et al. 2017). A solvent swap is conducted after the solution leaves the photoreactor, where t-BME is swapped with acetonitrile (ACN) in flow at 40 °C and 290 mbar (see Fig. 3). The new solvent (ACN) enables the separation of the vitamin D3 from the resin, and the removal of the unreacted 7DHC is achieved by precipitation and subsequent filtration. Crystallized 7DHC can be recycled and used in the synthesis step. In addition, the solution becomes supersaturated once it cools down to room temperature, as it can be observed in the temperature profile shown in Escribà-Gelonch et al. (2018b). Later, the solution is pumped into the crystallization section where the capillary is submerged in a cooling bath with a temperature of 7 °C for 1 min. Crystals are formed and filtered. Ahead of the filter, the permeated ACN-vitamin D3 solution can be recycled back to the cooling bath. This recycling step enhances the super saturation and the recovery of vitamin D3 crystals that were too small to be removed by the filter in the first pass.

Figure 4 presents the flow diagram of the continuous process according to the description presented, and it also indicates the stages and materials of the process. The stages were the photoreaction (photo-high-p,T), the solvent swap, and the crystallization.

2.3.2 Modeling in Aspen Plus

To model the intensified flow process in Aspen Plus, the following assumptions were made before the modeling process: (i) photoreactions were not simulated considering the limitations of the software Aspen Plus, (ii) the ambient temperature was defined as 20 °C, (iii) the crystallization process was simplified due to the lack of data in the batch case and to avoid inconsistencies in data quality caused by having a more detailed simulation for continuous case compared to the batch, and (iv) steady state was assumed.

The method selected was universal quasichemical (UNIQUAC) following Aspen recommendations (Aspen Technology Inc. 1995) and the literature (Kim and Douglas 2002; Mato and Berro 1991; Sazonova and Raeva 2015). UNIQUAC is an activity coefficient property method used for liquid and gas-liquid interactions. UNIFAC (Universal Quasichemical Functional Group Activity Coefficients), also an activity coefficient method, was used to estimate missing binary interaction parameters between components. These methods are already incorporated in the property methods from Aspen Plus. All binary systems were modeled as mentioned except for the case of the t-BME-acetonitrile binary system, where thermodynamic properties were modeled according to the literature (Mato and Berro 1991).

Most of the components were present in Aspen databases. The only component not present in the database at the time of the study was the 7DHC. The proxy beta-cholesterol was used instead.

The photoreactor in the continuous process was modeled with a heat exchanger, representing the heating chamber of the reactor. The energy of the UV laser was not considered. After the mixture in the reactor cools down to ambient temperature, this process is done without the need of a heat exchanger. But for the simulation, it was needed to use a heat exchanger to cool down before the solvent swap; however, its cooling requirement was not considered in the final energy balance. For the solvent swap, a conceptual design was done using the Fenske-Underwood-Gilliland method, and the parameters obtained were implemented in a RadFrac unit. The configuration of the RadFrac unit was as follows: a column of 35 stages, with a total condenser, a reflux ratio of 3.1, and a distillate-to-feed ratio of 0.25. For the crystallizer, a heat exchanger was used. No reactive system, crystallization, or precipitation was considered due to the lack of data of the batch process. The filters were modeled using separators and the mixers with a stream mixer.

2.3.3 Batch industrial process

The reliability of the data has a large impact on the applicability of the life cycle assessment. To guarantee the consistency within the data used, data quality indicators (Weidema and Wesnaes 1996) were considered during the data collection. For data completeness, i.e., having a sufficient data, different scenarios for the batch process were developed to model possible pathways of production. From Pfoertner (1971) and Hirsch (2011), the synthesis scenarios were obtained. These consisted in the reaction of 7DHC to vitamin D3 (resin) and the purification of the resin, i.e., removal of 7DHC. Five scenarios were obtained out of these patents, as shown in Fig. 5.

The process details of Hirsch (2011) were used to improve temporal correlation since data from Pfoertner (1971), Roman (1972), and Schaaf et al. (1967) dates from the 1970s. Data from Hirsch (2011) has a temporal correlation of less than 10 years, and with this, it could confirmed that the process for the production of vitamin D3 has barely changed, which improved the overall temporal correlation. Finally, the use of computer simulations enables to score the reliability at the same level.

From Marbet (1972) and Schaaf et al. (1967), the data to model the crystallization step was obtained. The crystallization processes use the resin that is obtained from the synthesis scenarios to obtain crystalline vitamin D3. Three crystallization scenarios were selected to model different crystallization pathways (see Fig. 6).

These scenarios were combined (see Fig. 7) to ensemble the complete process from the 7DHC to crystalline vitamin D3. This gives a total of 15 scenarios that will be compared against the continuous process.

Tree diagram of the scenarios used to model the synthesis and crystallization of vitamin D3 starting from 7DHC. For future references, the scenarios will be called by the number and letter; e.g., “scenario 3B” will be used to refer to the scenario where the synthesis of vitamin D3 resin is in benzene (Pfoertener 1971) and the crystallization is done in acetone (Schaaf 1967)

The conditions to model scenarios 1 and 2 were obtained from example 1 of Pfoertner (1971) and scenario 3 from example 4 of the same patent. Example 1 describes the following process: 2.5 g of 7DHC is dissolved in 2.5 L of solvent (isopropanol or benzene) and irradiated at constant temperature for 2 h. Different temperatures are provided. The best and worst case scenarios were selected, and these correspond to the temperatures of 50 °C and 70 °C. The first temperature of 50 °C or the best scenario is used for scenario 1, and the worst case (70 °C) was used for scenario 2. Afterwards, the mixture is heated to 80 °C for 2 h without irradiation. The solvent is evaporated under vacuum, and the residue is dissolved in hot methanol. Because the temperature was not specified, it was defined to be 37 °C due to the availability of solubility data at this temperature. Then, it is cooled down to − 6 °C to crystallize and remove unreacted 7DHC. Example 4 describes the synthetic procedure using benzene. The process is the same, and the only difference besides the solvent is the irradiation temperature, which is at 73 °C in this solvent.

Scenarios 4 and 5 were modeled from the process described in Hirsch (2011). A similar description of the synthesis of vitamin D3 is presented. In that, the irradiation is conducted in diethyl ether at 30 °C for 2 h. The conversion achieved can be between 20 and 30%; therefore, just like in the case of isopropanol, the best and worst case scenarios were selected. Conversion of 20% was used for scenario 4 and 30% conversion for scenario 5. After the reaction, butylated hydroxyanisole or butylated hydroxytoluene is added to stabilize the vitamin D3 against oxidation. Then, the solvent is distilled, and the product is dissolved in methanol. The temperature of the methanol was not specified, so T = 37 °C was selected as well. The mixture is cooled down to − 6 °C, and the unreacted 7DHC is recovered. Afterwards, the solvent is evaporated, and the resin is recovered.

Once the resin is obtained, the next step is the crystallization. The crystallization scenarios (A and B) were modeled following the description of examples 2 and 3, respectively, from Schaaf et al. (1967). In example 2, the resin is dissolved in benzene, then acetonitrile is added, which makes the solution cloudy and causes the formation of a flocculent. The flocculent separates immediately and is removed by filtration. The solution is then cooled to 5 °C for 1 h and seeded. The temperature is maintained for 48 h to form the crystals. To remove the crystals, it is further cooled down to − 15 °C and washed with acetonitrile at − 15 °C. The yield of crystallized vitamin D3 is 74%. In example 3, the resin is dissolved in equal amounts of acetone and acetonitrile. Then, the solution is cooled to 5 °C for a period of 48 h. Afterwards, the solution is cooled to − 5 °C, and the crystals are filtrated and washed with acetonitrile at − 5 °C. The final yield of crystallized vitamin D3 is 90%.

Finally, scenario C is modeled from the description of example 2 of Marbet (1972). According to example 2 from Marbet (1972), the resin obtained is dissolved in methyl formate at ambient temperature. The solution is cooled down to 12 °C and seeded, then it is further cooled down to 0 °C. Once crystals start to form, it is cooled to − 20 °C and left for 12 h. Then, the crystals are filtered and washed with methyl formate at − 20 °C.

2.3.4 Modeling in Aspen Plus

Mass and energy balances were obtained from the simulations in Aspen Plus.

The following assumptions were made during the modeling process: (i) photoreactions were not simulated considering the limitations of the software Aspen Plus, (ii) the power of the mercury lamp was not considered, and (iii) the ambient temperature was defined as 20 °C.

The integrated method UNIQUAC was selected as the base method to calculate thermodynamic and transport properties. Missing parameters were estimated by the UNIFAC method. These methods (UNIFAC and UNIQUAC) are already incorporated in the property methods from Aspen Plus.

Most of the components were present in Aspen databases. The only component not present in the database at the time of the study was the 7DHC. The proxy beta-cholesterol was used instead.

2.3.5 Synthesis scenarios

The following description applies for scenarios 1, 2, and 3: To model the reaction, a batch reactor was used. The operating specification was constant temperature; besides that, pressure and operating time were also specified. Since 7-HDC and vitamin D3 are isomers and because of the limitations of the software Aspen Plus, the photoreaction was not modeled, and therefore, no reactive system was implemented.

After the reaction, the stabilization of the products at higher temperature was simulated in a batch reactor. The operating specification was constant temperature with fixed pressure and operating time. For the next step, i.e., the distillation, a flash separator was used to model a single-stage distillation.

To bring the methanol to the specified temperature (37 °C), a heater was used. The crystallizer to remove the 7DHC was also modeled with a heat exchanger. No crystallization or precipitation was modeled due to the lack of data. It was assumed that 100% of unreacted 7DHC could be removed in this step. To remove the 7DHC, a separator (Sep) was placed instead of a filter. After that, the solvent (methanol) was removed by distillation, using a single-stage column (flash separator).

The next description applies for scenarios 4 and 5. The irradiation was modeled with a batch reactor using the same conditions as in scenarios 1, 2, and 3. After, the stabilizer was added to the mixture. Only butylated hydroxytoluene was present in the Aspen database; thus, this component was used. After the stabilization, the solvent was distilled using a flash separator to simulate a single-stage distillation column. The following steps (mixing with methanol and removal of unreacted 7DHC) were modeled just like in scenarios 1, 2, and 3.

2.3.6 Crystallization scenarios

The following description applies for scenario A: The resin was mixed with benzene and acetonitrile, then a flocculent is formed. The patent does not specify what the flocculent contains, so it was assumed that it contains the losses of resin (vitamin D3) with traces of the solvents (1% of each solvent). This was considered the yield declared by the patent. The flocculent was removed using a Sep module. Then, to model the crystallization and cooling, batch reactors were used. The operating specification was constant temperature with fixed pressure and operating time. No reactive system, crystallization, or precipitation was considered due to the lack of data. Filtration at − 15 °C was modeled in two stages. First, a heater was used to cool it down to − 15 °C and then a separator was used to remove 100% of the crystals. The acetonitrile used to wash the crystals was cooled down with a heater and then filtered with a separator. Finally, the crystals were dried using a heater.

The following description applies for scenario B: Cooling was modeled using a batch reactor. The operating specification was constant temperature with fixed pressure and operating time. No reactive system, crystallization, or precipitation was considered due to the lack of data. The second cooling step was simulated in a heater, and the crystals were filtrated using the separator module with 100% efficiency. The acetonitrile used to wash the crystals was cooled with a heater and then filtered with a separator. Finally, the crystals were dried using a heater.

The following description applies for scenario C: The cooling steps were modeled using a heater. Only the crystallization at − 20 °C for 12 h was done in a batch reactor. The operating specification for the batch reactor was constant temperature with fixed pressure and operating time. No reactive system, crystallization, or precipitation was considered due to the lack of data. A 75% yield of crystals was assumed due to the lack of data.

2.4 Impact assessment

The LCA study was conducted using Umberto NXT LCA software, from which the environmental impacts were obtained. Mass and energy balances from the continuous process and batch scenarios obtained from Aspen Plus were implemented in Umberto NXT LCA, and they are presented in Tables 1 and 2, respectively.

Background data was mostly available from the database Ecoinvent 2.2, and if possible, Dutch (NL) or European (RER) data were used for consistency on the geographic point. If a material was not present in the database, a similar material or proxy was used. This was the case for butylated hydroxytoluene and 7DHC. A fatty alcohol of plant-based origin was selected to replace 7DHC, considering the resemblance in their environmental impacts such as land use and water consumption of ovine with crops, whereas butylated hydroxyanisole was replaced by a proxy (ethyl benzene). Transportation and cleaning procedures were excluded from the assessment in both cases. For more details, a description of the inventory is present in Table 3.

Emissions to air and water were calculated following the guidelines presented in Hischier et al. (2005).

The impact categories used in this study are from the ReCiPe Midpoint 2008 (Goedkoop et al. 2009) from the hierarchist perspective, namely climate change (GWP), fossil depletion (FDP), freshwater ecotoxicity (FETPinf), freshwater eutrophication (FEP), human toxicity (HTPinf), natural land transformation (NLTP), ozone Depletion (ODPinf), particulate matter formation (PMFP), photochemical oxidant formation (POFP), and water depletion (WDP).

3 Results and discussion

The aforementioned categories were used to conduct the assessment of the continuous and all batch processes. The discussion is structured in three sections. The first section analyzes the flow process with the purpose of finding the areas of improvement, the second section compares the industrial process with the flow process, and the third section explores how the recovery of the solvent reshape the environmental impact of a batch case.

3.1 Continuous process

Results in the selected categories are presented in Table 4. The main contributors of each category are present in Fig. 8. The results are established upon the individual environmental impact of the materials and energy exchanges, along with the emissions and waste generated in the process. As can be deduced from Fig. 8, the solvents represent a large share in the environmental impact. This finding is in agreement with previous results (Cespi et al. 2015), which concluded that solvents are greatly responsible of the environmental impact of several pharmaceutical processes.

The highest contribution in eight out of the ten categories is given by the use of acetonitrile. Large amounts of this solvent are required in comparison with the other solvents or reactants. Hence, among the three stages of the process, i.e., photosynthesis, solvent swap, and crystallization, the solvent swap is the hot spot to improve. t-BME is the material (solvent) with the second highest contribution in five out of the ten categories. These two solvents have a large environmental impact because the process lacks the capacity of recycling them, and it is affecting the FETPinf category because more than 80% of the impact is caused by the emissions and waste solvent. Although the crystallization has a closed loop, the solvent swap does not. Closing the loop in the solvent swap is therefore a necessary step to improve the environmental footprint of the process. However, this step has not been implemented due to the percentage of ACN present in the t-BME after it has been removed in the solvent swap step.

The energy exchanges, i.e., heating and cooling, have a minor contribution except for the ODP and WDP categories. These contributions are the result of the combustion of fossil fuels for the production of energy, the release of recalcitrant chemicals with a long atmospheric life such as chlorine or bromine during the production, the use of refrigerating agents, and the use of water for cooling purposes.

Finally, the NLTP category is largely dominated by 7DHC. Although the material used from the database has a vegetable origin, the impact in this category will be comparable to the impact of livestock which also requires and consumes large amounts of green areas.

3.2 Comparison with batch process

Life cycle impacts of batch scenarios were normalized with respect to the base case, which is the continuous intensified process. The results of the comparisons between the continuous and the batch processes are shown in Figs. 9, 10, 11, and 12.

From the results, it clearly appears that the continuous process developed has a lower environmental impact compared to any of the batch scenarios evaluated. Input materials, in particular solvents, are dominant in the life cycle impact of both continuous and batch processes. This has been also reported in other publications (Lee et al. 2016), and in the case of the batch scenarios presented here, these input solvents counterbalance greatly their environmental impact.

Figure 9 shows the scenarios where the synthesis is conducted in isopropanol. It is shown that the greatest difference is in the WDP category. The continuous process lowers the water depletion by a factor that is 30–22-fold and 33–25-fold (depending on scenario 1 or 2). In the batch scenarios 1A, 1B, 1C, 2A, 2B, and 2C, this category is driven by the input solvent isopropanol. This solvent is prepared through the catalytic hydrogenation of acetone (Hiroshi Fukuhara et al. 1992). Hydrogenation is a process that requires large amounts of water and energy. Little difference is observed in the NLTP category, which, as mentioned before, is mainly monopolized by the 7DHC. Hence, the use of similar amounts of 7DHC is reflected in a similar impact. The other two categories with low impact are HTP, only four- to sixfold higher (lowest and highest limits), and FEP being six- to seven-fold higher (lowest and highest limits). These results are remarkable despite the differences in the mass of solvents needed. Nonetheless, it highlights the importance of the solvent selection. Isopropanol has a lower impact in these categories than acetonitrile, which is used greatly in the continuous process.

The higher conversion at lower temperature favors scenario 1, making it the greener alternative. The disadvantage of scenario 1 is that through this process, higher amounts of tachysterol are obtained compared to scenario 2; however, tachysterol purification was not considered in the scope of this LCA study.

Figure 10 presents the comparison of the intensified process with the industrial case when the solvent used in the synthesis is benzene. This scenario is the most dangerous of all for the humankind and the environment. Benzene is a carcinogenic solvent (carcinogenic group I), and people should not be exposed to it for long periods. This is reflected in the HTPinf category, where the impact is 92–124 times that of the continuous processes, depending on the scenario. Moreover, in terms of safety, the occupational exposure level recommended by the Occupational Safety and Health Administration (OSHA) is 1 ppm (Yardley-Jones et al. 1991), which is very low compared to isopropanol (500 ppm) (Science Lab 2013) or diethyl ether (400 ppm) (Thermo Fisher Scientific 2018). This indicates that other solvents are better alternatives especially in the human safety aspect. The process also represents a high concern to the environment, with high freshwater ecotoxicity caused by benzene waste. This is by large the category that is most affected by the solvent. Therefore, special measures need to be taken in order to avoid water contact and contamination. The categories with respect to the air compartment (GWP, FDP, PMFP, POFP) are also affected by the use of big amounts of this solvent. An increment of 23–31-fold, 27–36-fold, 21–28-fold, and 27–37-fold, respectively, is observed in these categories. On the other side, eutrophication and ozone depletion do not represent a big concern, as it is only four to five times greater, despite the difference in the mass of solvents used.

Finally, Figs. 8 and 9 present the comparison of the continuous process with the batch scenarios where diethyl ether is used in the synthesis of the resin. The results of scenario 4 (A, B, and C) are worse than those in the case of scenario 5 (A, B, and C), which is expected based on the higher conversion achieved in scenario 5. The categories with a larger environmental impact are FEP and FETP. FEP increases by 60 (scenario 5’s lowest value) and 122 (scenario 4’s highest value) and FETP by 174 (scenario 5’s lowest value) and 352 (scenario 4’s highest value). These categories are greatly affected when no solvent waste management strategy is implemented. As far as safety is concern, this solvent is also peroxidizable (Escribà-Gelonch et al. 2018a); therefore, it is necessary to take important safety measures to avoid any risk. The continuous process also shows a better result in the POFP category, reducing the impact from 25 to 52 times. The improvement in the environmental impact in other categories is 10 to 25 times better in the case of the continuous process.

All the batch scenarios are offset with respect to the continuous ones due to the high dilution used. This is in agreement with previous LCA studies (Henderson et al. 2008; Ott et al. 2014), where the ecological impact is largely driven by the input materials, which, in the case of the pharmaceutical industry, corresponds largely to the use of solvents (Jimenez-Gonzalez et al. 2011). Henderson et al. (2008) studied the production of 7-aminocephalosporic acid, a base for many antibiotics. They found that a great part of the impact is caused by the use of raw materials, and the best option for reducing the impact is recycling.

3.3 Solvent recovery case study

The large difference between the impact of the continuous process and the batch processes poses the question of whether or not the recycling of the solvents would reduce the marked contrast. Recycling solvents is a preferred practice over waste management (Henderson et al. 2008; Henderson et al. 2008, Slater et al. 2008). Therefore, currently, there is a great emphasis on solvent recovery to reduce the cost associated with its purchase and disposal. This practice can take place in on-site or off-site facilities (Rachel and Legacy 2008). Due to the importance of solvent recovery, this last section will elaborate on the recovery of the solvent for the batch case. In the literature, it is stated that solvents used in the synthesis, such as isopropanol or benzene (scenarios 1, 2, 3, 4, and 5), can be recycled (Hirsch 2011). However, it is not mentioned how many times and what impact the use of recycled solvent has in the process. Moreover, it would be possible that the solvents would need extra purification (Savelski et al. 2017) before being recycled.

As shown in Section 3.2, the largest disadvantage of the batch process is the use of a diluted system for the reaction. The lowest environmental impact for the batch process is obtained when isopropanol is used as solvent in the synthesis, with scenarios 1A, 2A, and 3A as the best cases. These scenarios are taken to conduct a further sensitivity analysis. Being the impact dominated by the use of isopropanol in the synthesis, it was decided to investigate the potential effect of the recovery of this solvent.

To assess the impact of solvent recovery, the following assumptions were considered which were taken due to the lack of data about recycling and recovering the solvent in the synthesis of vitamin D3: The first assumption was the use of internal recycling to avoid transportation and post-treatment emissions. Furthermore, from the simulation, it was found that the distillation of isopropanol from the product yields high-purity isopropanol (99.999%). Due to this high purity, it was assumed that the isopropanol can be recycled without further treatment.

Pharmaceutical companies have reported recovery of the solvents from 20 to 60%. According to the Toxic Release Inventory (TRI), the amount of solvent recovered has increased to 70% (Rachel and Legacy 2008). Based on these percentages, the amount of solvent recovery was variated in 10%, 25%, 50%, 75%, and 95%. Then, this solvent was mixed with the corresponding fraction of fresh solvent and used in the process. Finally, it was also assumed that the reuse of solvent had no impact over the conversion and selectivity of the reaction. With these considerations, the best case scenario was developed. The results are presented in Fig. 13.

The assessment showed that more than 95% recovery is needed to have a process comparable, yet not equal, to the continuous intensified option. In all the categories, an improvement was observed except for the NLTP. This category as mentioned before is dominated by the use of 7DHC, and without a change in the conversion, this category would not be impacted. However, despite the recycle of isopropanol, the life cycle impact is still greater. This means that other solvents in the batch process would have to be recovered and recycle without the need of extra purification. This may be possible for methanol since it can be obtained with 99.993% purity. Consequently, methanol recyclability was explored as well. It was assumed that 95% of methanol can be recovered and recycled. This together with a case where 95% of isopropanol can be recovered was assessed, and the results are displayed in Fig. 14. As it can be observed, three categories benefit from this recovery, namely FETPinf, FEP, and HTPinf, particularly for scenarios 1C and 1B. In these categories, the impact is lower or equal to that of the continuous process. However, the other categories still display a higher environmental footprint. The rest of the solvents are mixed. Therefore, their recovery would need energy and produce emissions. This has to be assessed more carefully to see if the recovery of them is worthy or their disposal would be a better alternative.

Another alternative that was not presented here is solvent management. Several alternatives for solvent management have been addressed before (Raymond et al. 2010; Savelski et al. 2017) with distillation being the most common.

Besides solvent management, cleaning cycles were not considered. However, as discussed in Lee et al. (2016), the impact of cleaning is larger in the case of batch processes. This is due to the need for a higher number of washes, which is translated not only in more solvents but also in more energy needed to boil up the solvents.

In addition to the higher environmental impact of the batch processes, another great disadvantage of the industrial processes is the duration. The synthesis alone is 2 h, and the crystallization consumes over 48 h. These results in a process of over 50 h length, without even considering dead times (e.g., cleaning) (Roberge et al. 2005).

4 Conclusions and outlook

The continuous and intensified production of vitamin D3 was assessed to evaluate its environmental impact. Moreover, it was benchmarked against different batch scenarios, which were constructed by assembling process conditions from available patents. The life cycle assessment illustrated clear differences between the continuous process and the batch processes. The continuous process exhibits a lower score in all the categories evaluated and optimized use of materials. In addition, the process offers the possibility of working under anoxic conditions, which enhances the resistance of the components and avoids the degradation of the vitamin D3. However, the continuous process can benefit from the implementation of recycling loops for the two solvents used (i.e., t-BME and acetonitrile).

The difference in the environmental foot print is minimized when solvent recycling is implemented in the batch production.

Recycle of the solvent for the batch case was considered, assuming the best case scenario. The results showed it is necessary to recover both isopropanol and methanol, in very high yields (> 95%). Moreover, is necessary to recycle them without further treatment. Although the best case scenario was assumed, only three categories showed a better environmental impact. The rest still displays a higher impact.

Other advantages of the continuous intensified process that were not discussed here are the smaller equipment size (and hence, potentially smaller plant environmental impact), the need for less cleaning, and higher automatization, which may be negative for the environmental impact but potentially increase safety aspects (Lee et al. 2016).

Nevertheless, it is important to consider that an important aspect was disregarded within the scope of the present LCA study, namely the power lamp, which was not considered in the assessment due to the lack of data for an accurate temporal correlation. Taking these aspects into consideration could possibly diminish the sustainability advantage of the continuous process. Future work is needed to address missing process steps (i.e., recycle loops) and incorporate them into the LCA study.

References

Aspen Technology, Inc., Cambridge, Massachusetts, USA (1995) November 1995 ASPEN PLUS users guide, version 10.2

Ayres RU (1995) Life cycle analysis: a critique. Resour Concerv Recycl 14:199–223

Benyahia B, Lakerveld R, Barton PI (2012) A plant-wide dynamic model of a continuous pharmaceutical process. Ind Eng Chem Res 51:15393–15412

Bikle DD (2014) Vitamin D metabolism, mechanism of action, and clinical applications. Chem Biol 21:319–329

Björklund AE (2002) Survey of approaches to improve reliability in LCA. Int J Life Cycle Assess 7:64–72

Borukhova S, Noël T, Metten B, de Vos E, Hessel V (2016) From alcohol to 1,2,3-triazole via a multi-step continuous-flow synthesis of a rufinamide precursor. Green Chem 18:4947–4953

Cellura M, Longo S, Mistretta M (2011) Sensitivity analysis to quantify uncertainty in life cycle assessment: the case study of an Italian tile. Renew Sust Energ Rev 15:4697–4705

Cespi D, Beach ES, Swarr TE, Passarini F, Vassura I, Dunn PJ, Anastas PT (2015) Life cycle inventory improvement in the pharmaceutical sector: assessment of the sustainability combining PMI and LCA tools. Green Chem 17:3390–3400

Doi T, Yoshida M, Hijikuro I, Takahashi T (2004) Selective capture of 1α,25-(OH)2-previtamin D3 utilizing polymer-supported trialkylsilyl triflate in the synthesisof 1a,25-(OH)2-vitamin D3. Tetrahedron Lett 45:5727–5729

Escribà-Gelonch M, Halpin A, Noël T, Hessel V (2018a) Laser-mediated photo-high-p,T intensification of vitamin D3 synthesis in continuous flow. Chem Photo Chem 2:1–10

Escribà-Gelonch M, Hessel V, Maier MC, Noël T, Neira d’Angelo MF, Gruber-Woelfler H (2018b) Continuous-flow in-line solvent-swap crystallization of vitamin D3. Org Process Res Dev 22:178–189

Escribà-Gelonch M, Noël T, Hessel V (2018c) Microflow high-p,T intensification of vitamin D3 synthesis using an ultraviolet lamp. Org Process Res Dev 22:147–155

Fanari Z, Hammami S, Hammami MB, Hammami S, Abdellatif A (2015) Vitamin D deficiency plays an important role in cardiac disease and affects patient outcome: still a myth or a fact that needs exploration? J Saudi Heart Assoc 27:264–271

Fuse S, Tanabe N, Yoshida M, Yoshida H, Doi T, Takahashi T (2010) Continuous-flow synthesis of vitamin D3. Chem Commun 46:8722–8724

Goedkoop M, Heijungs R, Huijbregts M, De Schryver A, Struijs J, van Zelm R (2009) ReCiPe 2008. A life cycle impact assessment method which comprises harmonised category indicators at the midpoint and the endpoint level. Report I: characterisation, first edition. Ministerie van Volkshuisvesting, Ruimtleijke Ordening en Milieubeheer, The Netherlands

Gruber-Woelfler H, Escribà-Gelonch M, Noël T, Maier MC, Hessel V (2017) Effect of acetonitrile-based crystallization conditions on the crystal quality of vitamin D3. Chem Eng Technol 40:2016–2024

Guinée J (2016) Life cycle sustainability assessment: what is it and what are its challenges? In: Clift R, Druckman A (eds) Taking stock of industrial ecology. Springer, Cham

Guo M, Murphy RJ (2012) LCA data quality: sensitivity and uncertainty analysis. Sci Total Environ 435–436:230–243

Hartman RL, McMullen JP, Jensen KF (2011) Deciding whether to go with the flow: evaluating the merits of flow reactors for synthesis. Angew Chem Intl Ed 50:7502–7519

Haswell SJ, Watts P (2003) Green chemistry: synthesis in micro reactors. Green Chem 5:240–249

Hempel M (2009) Novel process windows—a contribution to more sustainable chemistry? Chem Eng Technol 32:1651–1654

Henderson RK, Jiménez-González C, Preston C et al (2008) EHS & LCA assessment for 7-ACA synthesis: a case study for comparing biocatalytic & chemical synthesis. Ind Biotechnol 4:180–192

Hessel V, Kralisch D, Krtschil U (2008) Sustainability through green processing—novel process windows intensify micro and milli process technologies. Energy Environ Sci 1:467–478. https://doi.org/10.1039/b810396h

Hessel V, Cortese B, de Croon MHJM (2011) Novel process windows—concept, proposition and evaluation methodology, and intensified superheated processing. Chem Eng Sci 66:1426–1448

Hiroshi Fukuhara I, Fujihisa Matsunaga W, Yasunori Shibuta I, Toshihiro Tachi K (1990). US Patent 5, 081, 321, 14 Jan 1992

Hirsch AL (2011) Industrial aspects of vitamin D. In: Feldman D, Wesley-Pike J, Adams SJ (eds) Vitamin D, 3rd edn. Elsevier

Hischier R, Hellweg S, Capello C, Primas A (2005) Establishing life cycle inventories of chemicals based on differing data availability. Int J Life Cycle Assess 10:59–67. https://doi.org/10.1065/lca2004.10.181.7

Jimenez-Gonzalez C, Poechlauer P, Broxterman BQ, Yang B, am Ende D, Baird J, Bertsch C, Hannah RE, Dell’Orco P, Noorman H, Yee S, Reintjens R, Wells A, Massonneau V, Manley J (2011) Key green engineering research areas for sustainable manufacturing: a perspective from pharmaceutical and fine chemicals manufacturers. Org Process Res Dev 15:900–911

Khadilkar SS (2013) The emerging role of vitamin D3 in women’s health. J Obstet Gynecol India 63:147–150

Kim S, Douglas PL (2002) Optimisation of methyl tert-butyl-ether (MTBE) synthesis processes using Aspen-Plus. Dev Chem Eng Mineral Process 10:89–103. https://doi.org/10.1002/apj.5500100108

Lee JH, O’Keefe JH, Bell D, Hensrud DD, Holick MF (2008) Vitamin D deficiency. An important, common, and easily treatable cardiovascular risk factor? J Am Coll Cardiol 52:1949–1956

Lee SL, O’Connor TF, Yang X, Cruz NC, Chatterjee S, Madurawe RD, Moore CMV, Yu LX, Woodcock J (2015) Modernizing pharmaceutical manufacturing: from batch to continuous production. J Pharm Innov 10:191–199

Lee CK, Khoo HH, Tan RBH (2016) Life cyle assessment based environmental performance comparison of batch and continuous processing: a case of 4-D-erythronolactone synthesis. Org Process Res Dev 20:1937–1948

Mahmoodani F, Perera CO, Fedrizzi B, Abernethy G, Chen H (2017) Degradation studies of cholecalciferol (vitamin D3) using HPLC-DAD, UHPLC-MS/MS and chemical derivatization. Food Chem 219:373–381

Malet-Sanz L, Susanne F (2012) Continuous flow synthesis. A pharma perspective. J Med Chem 55:4062–4098. https://doi.org/10.1021/jm2006029

Mato FA, Berro C (1991) Vapor-liquid equilibria and excess volumes for binary systems of methyl tert-butyl ether (MTBE) with trans-1,2-dichioroethylene and acetonitrile. J Chem Eng Data 36:262–264

Ott D, Kralisch D, Denčić I, Hessel V, Laribi Y, Perrichon PD, Berguerand C, Kiwi-Minsker L, Loeb P (2014) Life cycle analysis within pharmaceutical process optimization and intensification: case study of active pharmaceutical ingredient production. ChemSusChem 7:3521–3533

Ott D, Borukhova S, Hessel V (2016) Life cycle assessment of multi-step rufinamide synthesis—from isolated reactions in batch to continuous microreactor networks. Green Chem 18:1096–1116

Pfoertner K (1971) Process for the production of vitamin D. US Patent 3,575,831, 20 Apr 1971

Plutschack MB, Pieber B, Gilmore K, Seeberger PH (2017) The Hitchhiker’s guide to flow chemistry. Chem Rev 117:11796–11893

Ponder C, Overcash M (2010) Cradle-to-gate life cycle inventory of vancomycin hydrochloride. Sci Total Environ 408:1331–1337

Porta R, Benaglia M, Puglisi A (2016) Flow chemistry: recent developments in the synthesis of pharmaceutical products. Org Process Res Dev 20:2–25

Raymond MJ, Slater CS, Savelski MJ (2010) LCA approach to the analysis of solvent waste issues in the pharmaceutical industry. Green Chem 12:1826

Roberge DM, Ducry L, Bieler N, Cretton P, Zimmermann B (2005) Microreactor technology: a revolution for the fine chemical and pharmaceutical industries? Chem Eng Technol 28:318–323

Roman M (2006) Process for the preparation of crystalline vitamin D3. US Patent 3, 665,020, 3 May 1972

Sahlodin AM, Barton PI (2015) Optimal campaign continuous manufacturing. Ind Eng Chem Res 54:11344–11359

Savelski MJ, Slater CS, Tozzi PV, Wisniewski CM (2017) On the simulation, economic analysis, and life cycle assessment of batch-mode organic solvent recovery alternatives for the pharmaceutical industry. Clean Techn Environ Policy 19:2467–2477

Sazonova AY, Raeva V (2015) Recovery of acetonitrile from aqueous solutions by extractive distillation—effect of entrainer. Int J Chem Mol Nucl Mater Metall Eng 9:288–291

Schaaf KH, Morris PNJ, Schmukler S, Dalton, Mass, Howard CK (1967) Process for obtaining purified crystalline vitamin D3. US Patent 3, 334, 118, 1 Aug 1967

Science Lab (2013) Material safety data sheet isopropyl alcohol. Science Lab. Com Chemicals and Laboratory Equipment. Available via http://www.sciencelab.com/msds.php?msdsId=992441. Accessed 17 July 2018

Slater CS, Savelski MJ, Carole WA, Constable DJC (2008) Solvent use and waste issues. In: Green chemistry in the pharmaceutical industry: a model for sustainability, pp 49–81. https://doi.org/10.1002/9783527629688

Thermo Fisher Scientific (2018) Safety data sheet diethyl ether. Thermo Fisher Scientific. Available at: https://www.fishersci.com/shop/msdsproxy?productName=AC134450010&productDescription=DIETHYL+ETHER-D10%252C+99+AT+1ML&catNo=AC13445-0010&vendorId=VN00032119&storeId=10652 Accessed 17 July 2018

Vural- Gursel I, Hessel V, Wang Q, Noel T, Lang J (2012) Window of opportunity: potential of increase in profitability using modular compact plants and micro-reactor based flow processing. Green Process Synth 1:315–336

Wegner J, Ceylan S, Kirschning A (2012) Flow chemistry—a key enabling technology for (multistep) organic synthesis. Adv Synth Cat 354:17–57

Weidema BP, Wesnaes MS (1996) Data quality management for life cycle inventories—an example of using data quality indicators. J Clean Prod 4:167–174

Yardley-Jones A, Anderson D, Parke DV (1991) The toxicity of benzene and its metabolism and molecular pathology in human risk assessment. Br J Ind Med 48:37–44

Funding

The authors gratefully acknowledge the financial support given by the Horizon 2020: Marie Skolodowska-Curie Individual Fellowship awarded to Dr. Marc Escriba Gelonch under Grant Agreement number 659233 as well as the funding support by the FET-Open project ONE-FLOW from the European Commission (Project ID 737266; h2020-FETOPEN-2016-2017).

Author information

Authors and Affiliations

Corresponding authors

Additional information

Responsible editor: Ivan Muñoz

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is distributed under the terms of the Creative Commons Attribution 4.0 International License (http://creativecommons.org/licenses/by/4.0/), which permits unrestricted use, distribution, and reproduction in any medium, provided you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made.

About this article

Cite this article

Morales-Gonzalez, O.M., Escribà-Gelonch, M. & Hessel, V. Life cycle assessment of vitamin D3 synthesis: from batch to photo-high p,T. Int J Life Cycle Assess 24, 2111–2127 (2019). https://doi.org/10.1007/s11367-019-01634-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11367-019-01634-6