Abstract

Purpose

Currently, the bio-based plastics have been drawing considerable attention from the packaging industry as a sustainable solution for replacing petroleum-based plastics in order to reduce the accumulation of plastic waste in the environment. This work has benchmarked the environmental impact of bio-based against petroleum-based plastics for single use boxes. In this paper, the cradle to consumer gate environmental impact data of these boxes was calculated and reported as part 1. End-of-life options of both bio- and petroleum-based boxes are an important subject which will be further studied for part 2. The energy sources in this work were taken from the Thailand energy database namely: Thai electricity grid mix (TEGM), Thai coal electricity (TCE), Thai natural gas combine cycle (TNGCC), and Thai coal integrated gasification combine cycle (TIGCC).

Methods

The materials studied were polystyrene (PS) derived from petroleum, polylactic acid (PLA) derived from corn, and PLA/cassava starch blend (PLA/starch). The tray with lid (herein after called box) was processed in a plastic manufacturing in Thailand using cast sheet extrusion and then thermoforming techniques. The functional unit is specified as 10,000 units of 8.0 × 10.0 × 2.5 cm of PS, PLA, and PLA/starch boxes which weigh 447.60, 597.60, and 549.56 kg, respectively. Three impact categories; namely global warming potential including direct greenhouse gas, and indirect land use change (LUC) emissions, acidification, and photochemical ozone formation are investigated. Finally, the normalization results including and excluding LUC consideration were compared and reported.

Results and discussion

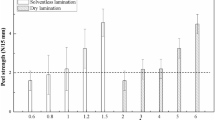

The results from this study have shown that the total environmental impact including LUC emission of bio-based boxes were different when the various energy sources were supplied throughout the life cycle production stage. It can be seen that the PS box has lower environmental impact than PLA and PLA/starch boxes when TEGM, TCE, TNGCC, and TIGCC were used as energy supplied. LUC of renewable feedstocks, such as corn and cassava, were considered as the biggest impact of absolute scores of PLA and PLA/starch boxes. These results are consistent with Piemonte and Gironi (2010).

Conclusions

PLA and PLA/starch boxes give a slightly higher environmental impact than the PS box by 1.59 and 1.09 times, respectively, when LUC was not accounted in the absolute scores and clean energy TIGCC was used throughout the life cycle.

Similar content being viewed by others

References

Andrae ASG, Zou G, Liu J (2004) LCA of electronic products, an environmental assessment of gallium arsenide monolitthic microwave integrated circuit system-in-a-package (SIP) switch product. Int J Life Cycle Assess 9(1):45–52

Avella M, Vlieger JJD, Errico ME, Fischer S, Vacca P, Volpe MG (2005) Biodegradable starch/clay nanocomposite films for food packaging applications. Food Chem 93:467–474

Bohlmann GM (2004) Biodegradable packaging life cycle assessment. Environ Prog 23:342–346

Chen CC, Chueh JY, Tseng H, Huang HM, Lee SY (2003) Preparation and characterization of biodegradable PLA polymeric blends. Biomaterials 24:1167–1173

Chen L, Qiu X, Xie Z, Hong Z, Sun J, Chen X, Jing X (2006) Poly(l-lactide)/starch blends compatibilized with poly(l-lactid)-g-starch copolymer. Biomaterials 65:75–80

Intergovernmental Panel on Climate Change (2006) Guidelines for national greenhouse gas inventories, in agriculture, forestry and other land use volume4. Publishing PhysicsWeb. http://www.ipcc-nggip.iges.or.jp/public/2006gl/vol4.html. Accessed 30 December 2011

Department of Alternative Energy Development and Efficiency (2007) Thailand’s Enegy Consumption. Publishing PhysicsWeb. http://www.dede.go.th. Accessed 30 April 2010

Department of Energy Development and Promotion (2000) Source emission inventory. Publishing PhysicsWeb. http://www.dedp.go.th. Accessed 20 April 2010

Department of Highway (2010) Distance between provinces in Thailand. Publishing PhysicsWeb. http://map-server.doh.go.th. Accessed 15 March 2010

Department of Provincial Administration (2007) Query database for population and house statistics at the present time. Publishing PhysicsWeb. http://www.dopa.go.th/English/. Accessed 3 April 2010

Dornburg V, Faaij A, Meuleman B (2006) Optimising waste treatment systems: part A: methodology and technological data for optimising energy production and economic performance. Resour Conserv Recycl 49:68–88

Duke Energy (2007) Edwardsport integrated gasification combined cycle (IGCC) station. Publishing PhysicsWeb. http://www.duke-energy.com. Accessed 2 June 2010

ETH-ESU (1996) Database

Fang Q, Hanna A (2001) Characteristics of biodegradable matter-Bi(R)-starch based foams as affected by ingredient formulations. Ind Crops Prod 13(3):219–227

FAO (2006) Maize: international market profile 2006. Publishing PhysicsWeb. http://www.fao.org Accessed 23 May 2012

Gajria AM, Dave V, Gross RA, McCarthy SP (1996) Miscibility and biodegradability of blends of poly(lactic acid) and poly(vinyl acetate). Polymer 37(3):437–444

Ganjyal GM, Weber R, Hanna MA (2007) Laboratory composting of extruded starch acetate and poly lactic acid blended foams. Bioresour Technol 98:3176–3179

Groot WM, Boren T (2010) Life cycle assessment of manufacture of lactide and PLA biopolymer from sugarcane Thailand. Int J Life Cycle Assess 9:970–984

Hauschild M, Potting J (2005) Spatial differentiation in life cycle impact assessment—the EDIP 2003 methodology. Institute for Production Development Technical University of Denmark

Huneault MA, Li H (2007) Morphology and properties of compatibilized polylactide/thermoplastic starch blends. Polymer 48:270–280

Iovio R, Zullo R, Rao MA, Cassar L, Gianfreda L (2008) Biodegradation of poly(lactic acid)/starch/coir biocomposites under controlled composting conditions. Polym Degrad Stab 93:147–157

ISO14040 (2006) Environmental management–life cycle assessment–principles and framework

ISO14044 (2006) Environmental management–life cycle assessment–requirement and guidelines

Jeong KM, Hong SJ, Lee JY, Hur T (2007) Life cycle assessment on end-of-life vehicle treatment system in Korea. J Ind Eng Chem 13(4):624–630

Joint Graduate School of Energy and Environment (2010) Final report technical, economic and environmental evaluation of biofuel production in Thailand. Publishing PhysicsWeb. http://www.jgsee.kmutt.ac.th. Accessed 30 December 2011

Khoo HH, Tan RBH, Chng KWL (2010) Environmental impacts of conventional plastic and bio-based carrier bags part 1: life cycle production. Int J Life Cycle Assess 15:284–293

Klopffer W (2005) Life cycle assessment as part of sustainability assessment for chemicals. Environ Sci Pollut Res 12(3):173–177

Lee C, Lee SJ (2007) Evaluation on the performance and NOx of IGCC power plant integrated with air separation unit. Int Energy J 8:37–44

Leejarkpai T, Suwanmanee U, Rudeekit Y, Mungcharoen T (2010) Biodegradable kinetic of plastics under controlled composting conditions. Waste Manage 31:1153–1161

Lim LT, Auras R, Rubino M (2008) Processing technologies for poly(lactic acid). Prog Polym Sci 33:820–852

Madival S, Auras R, Singh SP, Narayan R (2009) Assessment of the environmental profile of PLA, PET and PS clamshell container using LCA methodology. J Clean Prod 17:1183–1194

Narayan R (2004) Drivers and rationale for use of bio-based materials based on life cycle assessment (LCA). Global Plastics Environmental Conference, Atlanta. March 2004

Narita N, Sagisaka M, Inaba A (2002) Life cycle inventory analysis of CO2 emissions manufacturing commodity plastics in Japan. Int J Life Cycle Assess 7:277–282

National Innovation Agency (2008) National roadmap for the development of bioplastics industry. Publishing PhysicsWeb. http://www.nia.or.th/bioplastics/download/bioplast_roadmap_en.pdf. Accessed 30 December 2011

NatureWork LLC (2011) Natureworks attracts $150 million equity investment from leading Thailand company PTT Chemical: Thailand preferred location for next state-of-art Ingeo™ manufacturing facility. Publishing PhysicsWeb. http://www.natureworksllc.com/News-and-Events/Press-Releases/2011/10-12-11-NatureWorks-attracts-PTT-Chemical-equity-investment.aspx

OECD-FAO (2006) Agricultural outlook 2009–2018. Publishing PhysicsWeb. http://www.fao.org Accessed 23 May 2012

PAS 2050 (2008) Specification for the assessment of the life cycle greenhouse gas emissions of goods and services

Phumpradab K, Gheewala SH, Sagisaka M (2009) Life cycle assessment of natural gas power plants in Thailand. Int J Life Cycle Assess 14:354–363

Piemonte V, Gironi F (2011) Land-use change emissions: how green are the bioplastics? Environ Prog Sustain Energy 30(4):685–691

Energy Policy and Planning Office (2003) EPPO annual report 2003. Publishing PhysicsWeb. http://www.eppo.go.th/doc/report-2546/3-thai-energy. Accessed 12 May 2010

Plastic Intelligence Unit (2007) Plastics consumption in Thailand. Publishing PhysicsWeb. http://plastic.oie.go.th/SizingThaiMarket.aspx. Accessed 30 December 2011

Razza F, Fieschi M, Innocenti FD, Bastioli C (2009) Compostable cutlery and waste management: an LCA approach. Waste Manage 29:1424–1433

Ren J, Fu H, Ren T, Yuan W (2009) Preparation, characterization and properties of binary and ternary blends with thermoplastic starch, poly(lactic acid) and poly(butylene adipate-co-terephthalate). Carbohydr Polym 77:576–582

Ross S, Evans D (2003) The environmental effect of reusing and recycling a plastic-based packaging system. J Clean Prod 11:561–567

Sarazin P, Li G, Orts WJ, Favis BD (2008) Binary and ternary blends of polylactide, polycaprolactone and thermoplastic starch. Polymer 49:599–609

Sheehan J, Camobreco V, Duffield J, Graboski M. Shapouri H (1998) Life cycle inventory of biodiesel and petroleum diesel for use in the urban bus. National Renewable Energy Laboratory, NREL/SR-580-24089 UC Category 1503

Shen L, Patel MK (2008) Life cycle assessment of polysaccharide materials: a review. J Polym Environ 16:154–167

Sheth M, Ananda KR, Dave V, Gross RA, McCarthy SP (1997) Biodegradable polymer blends of poly (lactic acid) and poly(ethylene glycol). J Appl Polym Sci 66:1495–1505

Signori F, Coltelli MB, Bronco S (2008) Thermal degradation of poly(lactic acid) (PLA) and poly(butylene adipate-co-terephthalate) (PBAT) and their blends upon melt processing. Polym Degrad Stab 94:74–82

Silalertruksa T, Gheewala SH (2009) Environmental sustainability assessment of bio-ethanol production in Thailand. Energy 34:1933–1946

Singh A, Berghorn G, Joshi S, Syal M (2011) Review of life-cycle assessment applications in building construction. J Archit Eng. doi:10.1061/(ASCE)AE.1943-5568.0000026

Smith R (2005) Biodegradable polymers for industrial applications. CRC Press, New York

Spath PL, Mann MK (2000a) Life cycle assessment of national gas combined-cycle power generation system. National Renewable Energy Laboratory, NREL/TP-570-27715

Spath PL, Mann MK (2000b) Life cycle assessment of national gas combined-cycle power generation system. Report no. NREL/TP-570-27715. National Renewable Energy Laboratory, Washington

Suwanmanee U, Leejarkpai T, Rudeekit Y, Mungcharoen T (2010) Life cycle energy consumption and greenhouse gas emission of polylactic (PLA) and polystyrene (PS) trays. Nat Sci 44(4):703–716

Tan RBH, Khoo HH (2005) Life cycle assessment of EPS and CPB inserts: design consideration and end of life scenarios. J Environ Manage 74:195–205

United Nations Statistics Division (2007) Environment statistics country snapshot. UN Publication Board, Thailand

Varabuntoonvit V (2008) Development of life cycle assessment tool with environmental cost accounting based on NETs method. PhD. Thesis, Kasetsart University, Thailand

Vink ETH, Rabago KR, Glassner DA, Gruber PR (2003) Application of life cycle assessment to NatureWork™ polylactide (PLA) production. Polym Degrad Stab 80:403–419

Vink ETH, Glassner DA, Kolstad JJ, Wooley RJ, O’Connor RP (2007) The eco-profile for current and near-future NatureWorks® polylactide (PLA) production. Ind Biotechnol 3(1):58–81

Vink ETH, Davies S, Kolstad JJ (2010) The eco-profile for current Ingeo® polylactide production. Ind Biotechnol 6(4):212–224

Wang N, Yu J, Chang PR, Ma X (2008) Influence of formamide and water on the properties of thermoplastic starch/poly(lacticacid) blends. Carbohydr Polym 71(1):109–118

Xing S, Xu Z, Jun G (2008) Inventory analysis of LCA on steel- and concrete-construction office building. Energy Build 40:1188–1193

Yokensahachart C, Yoksan R (2011) Effect of amphiphilic molecules on characteristics and tensile properties of thermoplastic starch and its blends with poly(lactic acid). Carbohydr Polym 83:22–31

Yokohara T, Yamaguchi M (2008) Structure and properties for biomass-based polyester blends of PLA and PBS. Eur Polym J 44:677–685

Yu L, Dean K, Li L (2006) Polymer blends and composites from renewable resources. Prog Polym Sci 31:576–602

Acknowledgments

This work has been supported by Department of Chemical Engineering, Faculty of Engineering Srinakharinwirot University, the Postgraduate Education and Research Program at the Department of Chemical Engineering, Kasetsart University under the National Excellence Center for Petroleum Petrochemicals and Advanced Materials, National Innovation Agency (NIA) and National Metal and Materials Technology Center (MTEC). The authors would like to express gratitude to the Polymer Chemistry Research Unit (MTEC) and the Life Cycle Assessment Laboratory (MTEC) for their kind assistance. The authors are grateful to Dr. JTH Pearce for advice on English.

Author information

Authors and Affiliations

Corresponding author

Additional information

Responsible editor: Gerald Rebitzer

Rights and permissions

About this article

Cite this article

Suwanmanee, U., Varabuntoonvit, V., Chaiwutthinan, P. et al. Life cycle assessment of single use thermoform boxes made from polystyrene (PS), polylactic acid, (PLA), and PLA/starch: cradle to consumer gate. Int J Life Cycle Assess 18, 401–417 (2013). https://doi.org/10.1007/s11367-012-0479-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11367-012-0479-7