Abstract

Background, aim, and scope

Life cycle assessment (LCA) was initially developed to answer questions about the environmental impact of available products and services, implying that the product system under study was possible to investigate in detail; however, if new products or processes are to be evaluated, several complications occur. So, this paper aims to review the methodological issues that need careful attention when LCA is used for evaluating novel products, processes, or production from an environmental standpoint, as well as to draw some recommendations related to the best approach when dealing with them.

Materials and methods

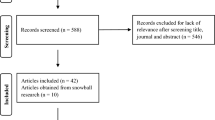

An initial brainstorming on the identification of methodological issues when applying the standard LCA methodology for the evaluation of novel products allowed the identification of the relevant aspects, on which a literature review was then performed. Periodical meetings took place for discussion of the significant references and an agreed approach validated through three case studies on the food sector was defined as result of the procedure.

Results

Five elements were identified as relevant for the specific application of LCA to novel products: type of LCA, functional unit, system boundaries, data gathering, and scenarios development. An analysis of the state of the art of the LCA methodology concerning each of them led to the definition of the recommended approach:

-

Type of LCA: prospective attributional LCA.

-

Functional unit (FU): physical FU or the inclusion of the economic dimension in the FU.

-

Scenarios development: future perspective of scenarios is required, although the particular method for scenarios development will depend on the aim of the study.

-

System boundaries: system expansion when possible and exclusion of those steps that are not affected.

-

Data gathering: specific data for the foreground system, while average data—but checking the suitability of using actual data—for the background system.

Discussion

The recommended approach was described through three case studies related to food products and processing. All were comparative studies, with the common element of including novel products (such as the production of new products from by-products) or novel processes (such as membrane technology or high pressure processing).

Conclusions

This paper has, in our opinion, helped in cleaning the area of the application of LCA to novel systems in particular related to food products and food processing which is an area of great development in the last years. The working procedure defined and applied here has worked fluently allowing the identification of the key methodological elements of an LCA and the associated state of the art, together with the validation through different case studies. The general application of our approach is difficult to assess; however, we feel confident regarding the recommendations proposed here and we hope they can be of use for other LCA users.

Recommendations and perspectives

We recommend using the approach defined here in order to check its applicability to other industrial sectors. By doing so, both us and other LCA users will benefit from the methodological improvements of this environmental management tool.

Similar content being viewed by others

Notes

The author named his approach Dynamic LCA, considering that "dynamic does not necessarily mean that the development of the product and background system is modelled continuously, but rather it means that a future state of the system is modelled considering the future characteristics of the background and the model system" (Pehnt 2006).

Schols et al. (1990) described the isolation and characterization of a cell-wall polysaccharide from the liquefaction of apple juice, which are called modified hairy regions. Its beneficial uses are still under research and the possible replaced products are not yet identified. As a result, this product was disregarded and excluded in all the scenarios.

References

Andersson K (2000) LCA of food products and production systems. Int J Life Cycle Assess 5(4):239–248

Azapagic A (1999) Life cycle assessment and its application to process selection, design and optimisation. Chem Eng J 73:1–21

Baumann H, Tillman AM (2004) The hitchhiker's guide to LCA: an orientation in life cycle assessment methodology and application. Studentlitteratur, Lund, Sweden. ISBN: 91-44-02364-2

Berlin J (2005) Environmental improvements of the post-farm dairy chain production management by systems analysis methods. Thesis. Department of Energy and Environment, Chalmers University of Technology; Gothenburg, Sweden

Berlin J, Sonesson U (2008) Minimising environmental impact by sequencing cultured dairy products: two case studies. J Clean Prod 16:483–498

Börjesson L, Höjer M, Dreborg K-H, Ekvall T, Finnveden G (2005) Towards a user’s guide to scenarios—a report on scenario types and scenario techniques. Environmental strategies research—fms; Stockholm, Sweden

Cederberg C, Wivstad M, Bergqvist P, Mattsson B, Ivarsson K (2003), Analys av olika strategier för att minska risken med kemiska bekämpningsmedel (analysis of different strategies to reduce the risk of pesticides, in Swedish), Rapport MAT21 no 6/2005, SIK—The Swedish Institute for Food and Biotechnology, Gothenburg, Sweden

Clift R (2005). Integrating LCA and process flow sheeting to analyse industrial ecosystems. Presented at the Seminar on Energy and Industrial Ecology. Norwegian University of Science and Technology, 11 may, Trondheim (Norway). http://www.indecol.ntnu.no/indecolwebnew/events/guestlectures/documents/energyseminar110505/Roland%20Clift.pdf

Curran M (2004) The status of life cycle assessment as an environmental management tool. Environ Prog 23(4):277–283

Davis J, Sonesson U, Östergren K (2007) Development of an LCA methodology to assess the environmental impacts of process changes: two case studies in Sweden. Food Manuf Effic 1(2):1–10

Davis J, Moates G, Waldron K (2009) High-pressure processing: a step toward sustainability?, Food Safety Magazine, October/November 2009

Frischknecht R, Althaus HJ, Bauer C, Doka G, Heck T, Jungbluth N, Kellenberger D, Nemecek T (2007) The environmental relevance of capital goods in life cycle assessments of products and services. Int J Life Cycle Assess 12(1):7–17

Hedemann J, König U (2007) Technical Documentation of the ecoinvent Database. Final report ecoinvent v2.0 No. 4, Institut für Umweltinformatik, Hamburg, DE, Swiss Centre for Life Cycle Inventories, Duebendorf, CH, for ecoinvent members only

Högberg J (2009) European tomatoes—comparing global warming potential, energy use and water consumption form growing tomatoes in Sweden, the Netherlands and the Canary Islands using life cycle assessment, Master thesis from Department of Environmental Systems Analysis at Chalmers University of Technology. Gothenburg (Sweden)

Hospido A (2005) Life cycle assessment as a tool for analysing the environmental performance of key food sectors in Galicia (Spain): milk and canned tuna. Thesis. Department of Chemical Engineering, University of Santiago de Compostela, Santiago de Compostela, Spain

Hospido A, Milà i Canals L, McLaren S, Truninger M, Edwards-Jones G, Clift R (2009) The role of seasonality in lettuce consumption: a case study of environmental and social aspects. Int J Life Cycle Assess 14(5):381–391

ISO14040 (2006) Environmental management—life cycle assessment—principles and framework

ISO14044 (2006) Environmental management—life cycle assessment—requirements and guidelines

Jonasson K, Sandén BA (2004) Time and scale aspects in LCA of emerging technologies: case study on alternative transport fuels. CPM-report 2004:6. http://www.cpm.chalmers.se/document/reports/04/CPM_Report_2004_6_Time%20and%20Scale%20Aspects%20in%20LCA.pdf

Jungbluth N, Tietje O, Scholz RW (2000) Food purchases: impacts from the consumers’ point of view investigated with a modular LCA. Int J Life Cycle Assess 5(3):134–142

Kilgus D (2005) Life cycle assessment of a demonstration project—vehicle use of hydrogen-blended natural gas. ESA report 2005:16. http://www.esa.chalmers.se/Publications/PDF-files/Thesis/ESA200516.pdf

Krewer C (2008) Environmental LCA of utilizing red cabbage trimmings as novel products Simulation of environmental impact, costs and microbiological activity related to processing red cabbage trimmings Master thesis from Department of Environmental Systems Analysis at Chalmers University of Technology. Gothenburg, Sweden

Mattsson B, Sonesson U (2003) Environmentally friendly food processing. Woodhead Publishing Limited, Cambridge, UK. ISBN 85573 6772

Muñoz I, Domenech X, Malato S (2006) Life cycle assessment as a tool for green chemistry: application to different advanced oxidation processes for wastewater treatment. CIEMAT, Madrid, Spain. ISBN 84-7834-520-5

Norgate TE, Jahanshahi S, Rankin WJ (2007) Assessing the environmental impact of metal production processes. J Clean Prod 15:838–848

Pehnt M (2006) Dynamic life cycle assessment (LCA) of renewable energy technologies. Renew Energy 31:55–71

Sandén BA, Karlström M (2007) Positive and negative feedback in consequential life-cycle assessment. J Clean Prod 15:1469–1481

Sandén BA, Jonasson KM, Karlström M, Tillman AM (2005) LCA of emerging technologies: a methodological framework. LCM 2005—innovation by life cycle management; Book of Proceedings. Barcelona, Spain, September 5–7, 2005, pp 37–41

Schau EM, Fet AM (2008) LCA studies of food products as background for environmental product declarations. Int J Life Cycle Assess 13(3):255–264

Schols HA, Posthumus MA, Voragen AJG (1990) Structural features of hairy regions of pectins isolated from apple juice produced by the liquefaction process. Carbohydr Res 206:117–129

SIK (2007) The Swedish Institute of Food and Biotechnology. 5th International Conference LCA in foods. Book of Proceedings. SIK, Gothenburg, Sweden, 25–26 April. http://www.sik.se/lcafoods2007

Sonesson U, Berlin J (2003) Environmental impact of future milk supply chains in Sweden: a scenario study. J Clean Prod 11:253–266

Reap J, Roman F, Duncan S, Bras B (2008a) A survey of unresolved problems in life cycle assessment. Part 1: goal and scope and inventory analysis. Int J Life Cycle Assess 13:290–300

Reap J, Roman F, Duncan S, Bras B (2008b) A survey of unresolved problems in life cycle assessment. Part 2: impact assessment and interpretation. Int J Life Cycle Assess 13:374–388

Tillman AM (2000) Significance of decision-making for LCA methodology. Environ Impact Assess Rev 20(1):113–123

Tillman AM, Ekvall T, Baumann H, Rydberg T (1994) Choice of system boundaries in life cycle assessment. J Clean Prod 2(1):21–29

von Gleich A, Steinfeldt M, Petschow U (2008) A suggested three-tiered approach to assessing the implications of nanotechnology and influencing its development. J Clean Prod 16:899–909

Weidema BP (2003) Market information in life cycle assessments. Technical report, Danish Environmental Protection Agency (Environmental Project no. 863). http://www2.mst.dk/udgiv/publications/2003/87-7972-991-6/pdf/87-7972-992-4.pdf

Weidema BP, Ekvall T, Pesonen HL, Rebitzer G, Sonnemann GW, Spielmann M (2004) Scenarios in life cycle assessment. SETAC, Pensacola FL, USA. ISBN 1-880611-57-0

Acknowledgements

This work has been carried within the framework of two EU-6FP-funded projects: Novel Processing Methods for the Production and Distribution of High-Quality and Safe Foods (NovelQ; ref: FOOD-CT-2005-015710) and Reducing food processing waste (REPRO; ref: FOOD-CT-2005-006922). Dr. Hospido acknowledges the Spanish Ministry of Education and Science for financial support during her postdoctoral stay at SIK (Jose Castillejo Programme) as well as the Xunta de Galicia for her postdoctoral fellow position (Isidro Parga Pondal Programme).

Author information

Authors and Affiliations

Corresponding author

Additional information

Responsible editor: Niels Jungbluth

An erratum to this article can be found at http://dx.doi.org/10.1007/s11367-010-0168-3

Rights and permissions

About this article

Cite this article

Hospido, A., Davis, J., Berlin, J. et al. A review of methodological issues affecting LCA of novel food products. Int J Life Cycle Assess 15, 44–52 (2010). https://doi.org/10.1007/s11367-009-0130-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11367-009-0130-4