Abstract

Background, aims, and scope

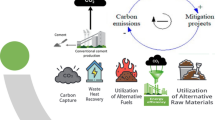

China has been the largest primary magnesium producer in the world since year 2000 and is an important part of the global magnesium supply chain. Almost all of the primary magnesium in China is produced using the Pidgeon process invented in the 1940s in Canada. The environmental problems of the primary magnesium production with the Pidgeon process have already attracted much attention of the local government and enterprises. The main purposes of this research are to investigate the environmental impacts of magnesium production and to determine the accumulative environmental performances of three different scenarios. System boundary included the cradle-to-gate life cycle of magnesium production, including dolomite ore extraction, ferrosilicon production, the Pidgeon process, transportation of materials, and emissions from thermal power plant. The life cycle assessment (LCA) case study was performed on three different fuel use scenarios from coal as the overall fuel to two kinds of gaseous fuels, the producer gas and coke oven gas. The burden use of gaseous fuels was also considered.

Methods

The procedures, details, and results obtained are based on the application of the existing international standards of LCA, i.e., the ISO 14040. Depletion of abiotic resources, global warming, acidification, and human toxicity were adopted as the midpoint impact categories developed by the problem-oriented approach of CML to estimate the characterized results of the case study. The local characterization and normalization factors of abiotic resources were used to calculate abiotic depletion potential (ADP). The analytic hierarchy process was used to determine the weight factors. Using the Umberto version 4.0, the emissions of dolomite ore extraction were estimated and the transportation models of the three scenarios were designed.

Results and conclusions

The emissions inventory showed that both the Pidgeon process of magnesium production and the Fe–Si production were mainly to blame for the total pollutant emissions in the life cycle of magnesium production. The characterized results indicated that ADP, acidification potential, and human toxicity potential decreased cumulatively from scenarios 1 to 3, with the exception of global warming potential. The final single scores indicated that the accumulative environmental performance of scenario 3 was the best compared with scenarios 1 and 2. The impact of abiotic resources depletion deserves more attention although the types and the amount of mineral resources for Mg production are abundant in China. This study suggested that producer gas was an alternative fuel for magnesium production rather than the coal burned directly in areas where the cost of oven gas-produced coke is high. The utilization of “clean” energy and the reduction of greenhouse gases and acidic gases emission were the main goals of the technological improvements and cleaner production of the magnesium industry in China.

Recommendation and perspective

This paper has demonstrated that the theory and method of LCA are actually helpful for the research on the accumulative environmental performance of primary magnesium production. Further studies with “cradle-to-cradle” scheme are recommended. Furthermore, other energy sources used in magnesium production and the cost of energy production could be treated in further research.

Similar content being viewed by others

References

Bisio G, Rubatto G (2000) Energy saving and some environment improvements in coke-oven plants. Energy 25:247–265

Chen WK, Shi JW (1995) Development for nonferrous metals (light metals). Central South University of Technology Press, Hunan, China, pp 165–166 (in Chinese)

Di XH, Nie ZR, Zuo TY (2005) Life cycle emission inventories for the fuels consumed by thermal power in China. China Environ Sci 25(5):632–635 (in Chinese)

Di XH, Nie ZR, Yuan BR et al (2007) Life cycle inventory for electricity generation in China. Int J Life Cycle Assess 12(4):217–224

Editorial Board of the Yearbook of Nonferrous Metals Industry of China (2005) The yearbook of nonferrous metals industry of China 2005. China Nonferrous Metals Industry Association, Beijing, 503–504 (in Chinese)

Gao F, Nie ZR, Wang ZH et al (2009) Characterization and normalization factors of abiotic resource depletion for life cycle impact assessment in China. Sci China (Ser E Technol Sci) 52(1):215–222

Guinée JB, Gorrée M, Heijungs R et al (2001) Life cycle assessment: an operational guide to the ISO standards. Kluwer Academic, Amsterdam, Netherlands

Guo ZC, Tang HQ, Liu JL (2005) Desulfurization of coke by recycling COG in coking process. Fuel 84:893–901

Hauksdóttir AS, Gestsson A, Vésteinsson A (2002) Current control of a three-phase submerged arc ferrosilicon furnace. Control Eng Pract 10:457–463

Institut für Umweltinformatik (2001) Umberto user manual (version 4). Institut für Umweltinformatik, Hamburg GmbH, Germany

ISO (2006) ISO 1440: Environmental management—life cycle assessment—principles and framework. International Organisation for Standardisation, Brussels

Liu BC (2003) Material processing technology in the 21st century. Aeronautical Manufacturing Technology 6:17–21 (in Chinese)

Liu Z, Wang ZG, Wang Y et al (1999) Application and developing tendency of magnesium die casting alloys in automobile industry. Special Casting & Nonferrous Alloys 5:55–58 (in Chinese)

Meng SK (2006) Report for the magnesium industry of China in 2005. China Met Bull 21:3–10 (in Chinese)

Mordike BL, Ebert T (2001) Magnesium properties application potential. Mater Sci Eng A 302:37–45

Ong SK, Koh TH, Nee AYC (2001) Assessing the environmental impact of materials processing techniques using an analytical hierarchy process method. J Mater Process Technol 113:424–431

Ramakrishnan S, Koltun P (2004) Global warming impact of the magnesium produced in China using the Pidgeon process. Resources Conservation and Recycling 24:49–64

Ramana PV, Singh RN, Patil KN (2005) Development and performance evaluation of a producer gas based system for hardening of steels. Renew Energy 30:773–782

Saaty TL (1980) The analytic hierarchy process, planning, priority setting, resource allocation. McGraw-Hill, New York

Toguri JM, Pidgeon LM (1962) High-temperature studies of metallurgical processes Part II. The thermal reduction of calcined dolomite with silicon. Can J Chem 40:1769–1776

Wang SY (2002) China land & resources almanac 2002. China Land & Resources Almanac Press, Beijing (in Chinese)

Wu ZX, Chen WY (2001) The diversified clean energy resources strategies with coal as the backbone. Tsinghua University Press, Beijing (in Chinese)

Yang JX, Xu C, Wang RS (2002) Methodology and application of product life cycle assessment. Weather Press, Beijing (in Chinese)

Zhou HM (2001) Life cycle assessment on iron and steel process. Ph.D. Dissertation of Beijing University of Technology (in Chinese)

Acknowledgments

This work was carried out under the support from the National Natural Science Foundation of China (NSFC, Project no. 50525413), the National Basic Research Program of China (973 Program, Project no. 2007CB613706), and the Beijing Natural Science Foundation (Project no. 2081001). We thank CMA for scheduling and providing data and information.

Author information

Authors and Affiliations

Corresponding author

Additional information

Responsible editor: Martin Baitz

Rights and permissions

About this article

Cite this article

Gao, F., Nie, Z., Wang, Z. et al. Life cycle assessment of primary magnesium production using the Pidgeon process in China. Int J Life Cycle Assess 14, 480–489 (2009). https://doi.org/10.1007/s11367-009-0101-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11367-009-0101-9