Abstract

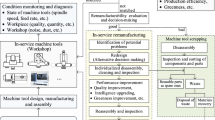

Low parts utilization, high resource consumption, and low profit margins have become the main factors hindering the development of machine tool remanufacturing in China. A machine tool manufacturing company was taken as a case to investigate the improvement of the remanufacturing production line. The remanufacturing workshop and production line of the case enterprise have been completely re-planned, adding remaining life assessment, additive manufacturing, quality monitoring, and reassembly quality control. After applying the new production line, the energy consumption and water consumption of each remanufacturing machine tool were reduced by 29.87 kgce and 0.042 m3, respectively, and the pollutants generated were reduced by 4.352 kg. With the increase in remanufactured machine tool capacity, the part reutilization has increased by 26.9%. Despite satisfactory results, machine remanufacturing still faces many difficulties in China. Combined with case enterprises, the current situation of machine tool remanufacturing in China was discussed, and several suggestions for promoting remanufacturing in Chinese manufacturing companies were put forward.

Similar content being viewed by others

Data availability

Data and materials will be available on reasonable request.

References

Abu MY, Jamaludin KR, Abdul Sani AS, Abdullah TA, Wahab DA (2014) Current situation in cleaning process of remanufacturing in Malaysia: a case study, in: Advanced Materials Research. pp. 904–914. https://doi.org/10.4028/www.scientific.net/AMR.845.904

Andrew-Munot M, Ibrahim RN (2013) Development and analysis of mathematical and simulation models of decision-making tools for remanufacturing. Prod Plan Control 24:1081–1100. https://doi.org/10.1080/09537287.2012.654667

Calleja A, Tabernero I, Ealo JA, Campa FJ, Lamikiz A, de Lacalle LNL (2014) Feed rate calculation algorithm for the homogeneous material deposition of blisk blades by 5-axis laser cladding. Int J Adv Manuf Technol 74:1219–1228. https://doi.org/10.1007/s00170-014-6057-3

Cao H, Li H, Cheng H, Luo Y, Yin R, Chen Y (2012) A carbon efficiency approach for life-cycle carbon emission characteristics of machine tools. J Clean Prod 37:19–28. https://doi.org/10.1016/j.jclepro.2012.06.004

Coro A, Macareno LM, Aguirrebeitia J, De Lacalle LNL (2019) A methodology to evaluate the reliability impact of the replacement of welded components by additive manufacturing spare parts. Metals (Basel). 9. https://doi.org/10.3390/met9090932

Du Y, Li C (2014) Implementing energy-saving and environmental-benign paradigm: machine tool remanufacturing by OEMs in China. J Clean Prod. https://doi.org/10.1016/j.jclepro.2013.10.033

Fegade V, Shrivatsava RL, Kale AV (2015) Design for remanufacturing: methods and their approaches, in: Materials Today: Proceedings. pp. 1849–1858. https://doi.org/10.1016/j.matpr.2015.07.130

Ha JH, Woo WS, Roh YH, Lee CM (2017) A study on the development of standardization technology for remanufacturing process of used vertical machining center. J Korean Soc Precis Eng 34:517–524. https://doi.org/10.7736/KSPE.2017.34.8.517

Ikeda A (2017) Remanufacturing of automotive parts in Japanese Market, in: Procedia CIRP. https://doi.org/10.1016/j.procir.2016.11.258

Jiang X, Dai M, Li L, Song B, Zhang H (2018) Quality control method of used product remanufacturing process based on dynamic and non-normal EWMA control charts. Jisuanji Jicheng Zhizao Xitong/Computer Integr Manuf Syst CIMS 24 1171–1178. https://doi.org/10.13196/j.cims.2018.05.011

Jiang X, Song B, Li L, Dai M, Zhang H (2019a) The customer satisfaction-oriented planning method for redesign parameters of used machine tools. Int J Prod Res 57:1146–1160. https://doi.org/10.1080/00207543.2018.1502483

Jiang X, Wang W, Zhang HY, Zhang K, L.L., (2019b) Optimal selective assembly method for remanufacturing product considering quality, cost and resource utilization. J Mech Eng 55:180–188. https://doi.org/10.3901/JME.2019.01.180

Jiang Z, Jiang Y, Wang Y, Zhang H, Cao H, Tian G (2019c) A hybrid approach of rough set and case-based reasoning to remanufacturing process planning. J Intell Manuf. https://doi.org/10.1007/s10845-016-1231-0

Jiang Z, Zhou T, Zhang H, Wang Y, Cao H, Tian G (2016) Reliability and cost optimization for remanufacturing process planning. J Clean Prod 135:1602–1610. https://doi.org/10.1016/j.jclepro.2015.11.037

Jin M, Nie J, Yang F, Zhou Y (2017) The impact of third-party remanufacturing on the forward supply chain: a blessing or a curse? Int J Prod Res 55:6871–6882. https://doi.org/10.1080/00207543.2017.1357860

Jinlong, Wang, Yu Jing, Yang Yuxing, Du Fengming, and Wang Jingsi (2020) Study of the remanufacturing critical threshold and remanufacturability evaluation for FV520B-I blade based on fatigue life and FEA. Engineering Failure Analysis 112. https://doi.org/10.1016/j.engfailanal.2020.104509

Karmakar S, De SK, Goswami A (2018) A pollution sensitive remanufacturing model with waste items: triangular dense fuzzy lock set approach. J Clean Prod 187:789–803. https://doi.org/10.1016/j.jclepro.2018.03.161

Krystofik M, Luccitti A, Parnell K, Thurston M (2018) Adaptive remanufacturing for multiple lifecycles: a case study in office furniture. Resour Conserv Recycl. https://doi.org/10.1016/j.resconrec.2017.07.028

Kurilova-Palisaitiene J, Sundin E, Poksinska B (2018) Remanufacturing challenges and possible lean improvements. J Clean Prod. https://doi.org/10.1016/j.jclepro.2017.11.023

Li X, Li Y, Cai X (2015) Remanufacturing and pricing decisions with random yield and random demand. Comput Oper Res 54:195–203. https://doi.org/10.1016/j.cor.2014.01.005

Liu W, Wu C, Chang X, Chen Y, Liu S (2017) Evaluating remanufacturing industry of China using an improved grey fixed weight clustering method-a case of Jiangsu Province. J Clean Prod. https://doi.org/10.1016/j.jclepro.2016.11.083

Liu Y, Xu BS, Shi PJ, Liu BH (2011) A research on remanufacturing products quality control. Adv Mater Res 314–316:2162–2167. https://doi.org/10.4028/www.scientific.net/AMR.314-316.2162

Low JSC, Ng YT (2018) Improving the economic performance of remanufacturing systems through flexible design strategies: a case study based on remanufacturing laptop computers for the Cambodian market. Bus Strateg Environ. https://doi.org/10.1002/bse.2017

Lu RS, Xu B, Huang HT, Zhang GS, Wu ZX (2013) Application of cleaning technology in the remanufacturing for loader’s axles and transmission box components, in: Appl Mech Mater. https://doi.org/10.4028/www.scientific.net/AMM.397-400.25

Matsumoto M, Yang S, Martinsen K, Kainuma Y (2016) Trends and research challenges in remanufacturing. Int. J. Precis. Eng. Manuf. - Green Technol. https://doi.org/10.1007/s40684-016-0016-4

Shi J, Fan S, Wang Y, Cheng J (2019) A GHG emissions analysis method for product remanufacturing: a case study on a diesel engine. J Clean Prod. https://doi.org/10.1016/j.jclepro.2018.09.200

Song S, Liu M, Ke Q, Huang H (2015) Proactive remanufacturing timing determination method based on residual strength. Int J Prod Res 53:5193–5206. https://doi.org/10.1080/00207543.2015.1012599

Tian G, Fathollahi-Fard AM, Ren Y, Li Z, Jiang X (2022a) Multi-objective scheduling of priority-based rescue vehicles to extinguish forest fires using a multi-objective discrete gravitational search algorithm. Inf Sci 608:578–596. https://doi.org/10.1016/j.ins.2022.06.052

Tian G, Liu Y, Ke H, Chu J (2012) Energy evaluation method and its optimization models for process planning with stochastic characteristics: a case study in disassembly decision-making. Comput Ind Eng 63(3):553–563. https://doi.org/10.1016/j.cie.2011.08.011

Tian G, Yuan G, Aleksandrov A, Zhang T, Li Z, Fathollahi-Fard AM, Ivanov M (2022b) Recycling of spent Lithium-ion Batteries: a comprehensive review for identification of main challenges and future research trends. Sustain Energy Technol Assess 53:102447. https://doi.org/10.1016/j.seta.2022.102447

Tian G, Zhang C, Fathollahi-Fard AM, Li Z, Zhang C, Jiang Z (2022c) An enhanced social engineering optimizer for solving an energy-efficient disassembly line balancing problem based on bucket brigades and cloud theory. IEEE Trans Indust Inform. https://doi.org/10.1109/TII.2022.3193866

Vasanthakumar C, Vinodh S, Vishal AW (2017) Application of analytical network process for analysis of product design characteristics of lean remanufacturing system: a case study. Clean Technol Environ Policy. https://doi.org/10.1007/s10098-016-1293-x

Wang H, Jiang Z, Zhang X, Wang Y, Wang Y (2017) A fault feature characterization based method for remanufacturing process planning optimization. J Clean Prod. https://doi.org/10.1016/j.jclepro.2017.05.178

Wang Y, Chang X, Chen Z, Zhong Y, Fan T (2014) Impact of subsidy policies on recycling and remanufacturing using system dynamics methodology: a case of auto parts in China. J Clean Prod. https://doi.org/10.1016/j.jclepro.2014.03.023

Wang, Xianlin, Wei Luo, Hua Zhang, Binbin Dan, and Fei Li. 2016a. “Energy consumption model and its simulation for manufacturing and remanufacturing systems.” Intl J Adv Manuf Technol 87 (5–8). https://doi.org/10.1007/s00170-015-7057-7.

Wang Y, Jinqiang Hu, Ke Q, Song S (2016b) Decision-making in proactive remanufacturing based on online monitoring. In Procedia CIRP 48:176–181. https://doi.org/10.1016/j.procir.2016.04.081

Xiong Y, Zhao Q, Zhou Y (2016) Manufacturer-remanufacturing vs supplier-remanufacturing in a closed-loop supply chain. Int J Prod Econ 176:21–28. https://doi.org/10.1016/j.ijpe.2016.03.001

Xu BX, Liang XB, Shi PJ et al. (2015) Remanufacturing engineering and its industrial development in China. Surface Engineering & Remanufacturing, 2015(02):16–20. CNKI:SUN:BMZX.0.2015–02–005

Yao J, Zhu S, Cui P (2011) Design for remanufacturing and remanufacturability based on process, in: Advanced Materials Research. pp. 18–21. https://doi.org/10.4028/www.scientific.net/AMR.338.18

Yang S, Raghavendra MRA, Kaminski J, Pepin H (2018) Opportunities for industry 4.0 to support remanufacturing. Appl. Sci. https://doi.org/10.3390/app8071177

Zhang JH, Chen M (2015) Assessing the impact of China’s vehicle emission standards on diesel engine remanufacturing. J Clean Prod. https://doi.org/10.1016/j.jclepro.2015.03.103

Zhang W, He Y (2019) Optimal policies for new and green remanufactured short-life-cycle products considering consumer behavior. J Clean Prod. https://doi.org/10.1016/j.jclepro.2018.12.213

Zhou F, Jiang Z, Zhang H, Wang Y (2014a). A case-based reasoning method for remanufacturing process planning. Discret Dyn Nat Soc. 2014a. https://doi.org/10.1155/2014/168631

Zhou J, Deng Q, Li T (2018) Optimal acquisition and remanufacturing policies considering the effect of quality uncertainty on carbon emissions. J Clean Prod 186:180–190. https://doi.org/10.1016/j.jclepro.2018.03.150

Zhou XY, Shi PJ, Wang WY, Liu BH (2014b) Research process of remanufacturing standard system. Adv Mater Res 513–517:4244–4247. https://doi.org/10.4028/www.scientific.net/AMM.513-517.4244

Funding

This work was supported by 2016 Green Manufacturing System Integration Project of Ministry of Industry and Information Technology of China under Grant [201675514] and National Natural Science Foundation of China under Grant no. 52075088. The project has been successfully completed in early 2019. The information of the problem can be found on the website of the Ministry of Industry and Information Technology of China and other websites, e.g., 2016 Green Manufacturing System Integration Project Public Notice: http://www.ocn.com.cn/chanjing/201612/jyfwd16154404-2.shtml. 2019 Ministry of Industry and Information Technology of the People’s Republic of China Green Supply Chain Management Demonstration Enterprises List: https://www.miit.gov.cn/n1146295/n1652858/n1652930/n3757016/c7413818/part/7413932.pdf. 2020 On the announcement of the acceptance of the mechanical and electrical products remanufacturing pilot unit list (the second batch) notice: http://finance.sina.com.cn/chanjing/cyxw/2020-12-31/doc-iiznctke9546831.shtml. The relevant data in this article are true and reliable, but some data sources (such as related financial status) involve the trade secrets of the enterprise and cannot be provided.

Author information

Authors and Affiliations

Contributions

Conceptualization: Xingyu Jiang; Methodology: Tianbiao Yu; Writing—original draft preparation: Boxue Song; Writing—review and editing: Qing Liu; Funding acquisition: Xingyu Jiang. Tianbiao Yu; Supervision: Song Wang.

Corresponding author

Ethics declarations

Ethics approval

Not applicable.

Consent to participate and publish

All authors agreed with the content and that all gave explicit consent to submit and that authors obtained consent from the responsible authorities at the institute/organization where the work has been carried out.

Competing interests

The authors declare no competing interests.

Additional information

Responsible Editor: Philippe Garrigues

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Highlights

1. New remanufacturing production lines and remanufacturing systems.

2. Achieved energy-saving and material-saving, higher remanufacturing and reutilization rates.

3. Higher remanufactured machine tool sales and profits, and more jobs.

4. Urgent need for more financial and policy support.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Song, B., Jiang, X., Wang, S. et al. The promotion and application of green remanufacturing: a case study in a machine tool plant. Environ Sci Pollut Res 30, 40870–40885 (2023). https://doi.org/10.1007/s11356-022-24722-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11356-022-24722-x