Abstract

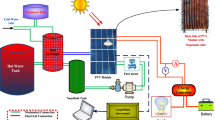

Productivity, distillate exergy, and energy efficiency of the conventional passive single-basin double-slope solar still is minimum, due to low evaporation and condensation rate. This research article attempts to increase the production rate, distillate exergy, and energy efficiency of the single-basin glasswool-insulated double-slope solar still by attaching novel solar-operated vacuum fan, external condenser and adding 0.1% volume concentration of copper oxide, aluminium oxide, and zinc oxide nanofluid. Inclusion of vacuum fan and external condenser enhances the production rate in the modified solar still. It is evident that as the vacuum fan exhales the vapour in the basin, the temperature of water in the basin and transparent glass are reduced significantly and so the vaporization amount increases considerably. It makes that a large amount of vapour is extracted by the vacuum fan and allowed to pass though the condenser, and therefore, the entire condensate of the solar still is increased significantly. To attain a comparative study, conventional and modified double-slope solar still of identical dimensions were developed utilizing aluminium and an experimental investigation carried out during the peak of summer. The inclusion of solar-operated vacuum fan and external condenser in the modified glasswool insulated double-slope solar still enhances the maximum energy efficiency, exergy efficiency, and cumulative production by 28.37%, 78.60%, and 64.29% due to enhancement in the evaporation rate of liquid in the solar still basin. Also, the addition of 0.1% volume concentration of copper oxide, aluminium oxide, and zinc oxide nanofluid in the conventional double-slope solar still possess the maximum increase in the energy efficiency and exergy efficiency by 20.96%, 18.01%, 10.76% and 52.53%, 38.52%, 30.35% as compared to conventional solar still without nanofluid. It is primarily due to increase in the thermal conductivity and radiative property of nanofluid. The result also signifies that the addition of 0.1% volume concentration of copper oxide, aluminium oxide, and zinc oxide nanofluid in the modified double-slope solar still possess the maximum enhancement in the energy efficiency and exergy efficiency by 21.33%, 19.36%, 17.03% and 50.11%, 36.82%, 23.75% as compared to modified solar still without nanofluid. Combined effect of using solar-operated vacuum fan, water cooled condenser, and 0.1% volume concentration of copper oxide, aluminium oxide, and zinc oxide nanofluid in the double-slope solar still enhances the maximum production rate and cumulative production by 59.26%, 55.56%, 51.85% and 96.43%, 82.14%, 75% as compared to conventional double-slope solar still. Among the three different nanofluids, the copper oxide nanofluid produced the highest cumulative production, energy efficiency, and exergy efficiency.

Similar content being viewed by others

Data availability

Not applicable.

Abbreviations

- Al2O3 :

-

aluminium oxide

- CSS:

-

conventional solar still

- CuO:

-

copper oxide

- D.C.:

-

direct current

- DSSS:

-

double-slope solar still

- Fe2O3 :

-

iron oxide

- FPC:

-

flat plate collector

- h :

-

heat transfer coefficient (W/m2°C)

- h c :

-

convective heat transfer coefficient (W/m2°C)

- h e :

-

evaporative heat transfer coefficient (W/m2°C)

- PTC:

-

parabolic trough collector

- PV:

-

photovoltaic

- SAC:

-

solar air collector

- SDBS:

-

sodium dodecyl benzene sulfonate

- SEM:

-

scanning electron microscope

- SS:

-

solar still

- SSSS:

-

single-slope solar still

- TEC:

-

thermoelectric cooler

- TEH:

-

thermoelectric heater

- TiO2 :

-

titanium dioxide

- ZnO:

-

zinc oxide

References

Abd Elbar AR, Hassan H (2020) Energy, exergy and environmental assessment of solar still with solar panel enhanced by porous material and saline water preheating. J Clean Prod 277:124175. https://doi.org/10.1016/j.jclepro.2020.124175

Abdullah AS, Younes MM, Omara ZM, Essa FA (2020) New design of trays solar still with enhanced evaporation methods – Comprehensive study. Sol Energy 203(February):164–174. https://doi.org/10.1016/j.solener.2020.04.039

Adun H, Kavaz D, Wole-Osho I, Dagbasi M (2021) Synthesis of Fe3O4-Al2O3-ZnO/water ternary hybrid nanofluid: investigating the effects of temperature, volume concentration and mixture ratio on specific heat capacity, and development of Hybrid machine learning for prediction. J Energy Storage 41(April):102947. https://doi.org/10.1016/j.est.2021.102947

Agrawal A, Rana RS (2018) Energy and exergy analysis of single slope single basin solar still in Indian condition: An experimental analysis. Mater Today: Proc 5(9):19656–19666. https://doi.org/10.1016/j.matpr.2018.06.328

Agrawal A, Rana RS (2019) Theoretical and experimental performance evaluation of single-slope single-basin solar still with multiple V-shaped fl oating wicks. Heliyon 5:e01525. https://doi.org/10.1016/j.heliyon.2019.e01525

Ahmed FE, Hashaikeh R, Hilal N (2019) Solar powered desalination — technology, energy and future outlook. In: In Desalination, 453rd edn. Elsevier B.V., Amsterdam, pp 54–76. https://doi.org/10.1016/j.desal.2018.12.002

Al-Molhem YA, Eltawil MA (2020) Enhancing the double-slope solar still performance using simple solar collector and floatable black wicks. Environ Sci Pollut Res 27(28):35078–35098. https://doi.org/10.1007/s11356-020-09509-2

Andrés-Mañas JA, Roca L, Ruiz-Aguirre A, Acién FG, Gil JD, Zaragoza G (2020) Application of solar energy to seawater desalination in a pilot system based on vacuum multi-effect membrane distillation. Appl Energy 258(October 2019):114068. https://doi.org/10.1016/j.apenergy.2019.114068

Asadikia A, Ali S, Mirjalily A, Nasirizadeh N, Kargarsharifabad H (2020a) Characterization of thermal and electrical properties of hybrid nanofluids prepared with multi-walled carbon nanotubes and Fe 2 O 3 nanoparticles. In Commun Heat Mass Transfer 117:104603. https://doi.org/10.1016/j.icheatmasstransfer.2020.104603

Asadikia A, Ali S, Mirjalily A, Nasirizadeh N, Kargarsharifabad H (2020b) Hybrid nanofluid based on CuO nanoparticles and single- walled. Carbon Nanotubes: Optim Thermal Electr Proper 11(3):277–289

Azari P, Mirabdolah Lavasani A, Rahbar N, Eftekhari Yazdi M (2021) Performance enhancement of a solar still using a V-groove solar air collector—experimental study with energy, exergy, enviroeconomic, and exergoeconomic analysis. Environ Sci Pollut Res 28(46):65525–65548. https://doi.org/10.1007/s11356-021-15290-7

Bait O (2020) Direct and indirect solar–powered desalination processes loaded with nanoparticles: a review. Sustain Energy Technol Assess 37:100597. https://doi.org/10.1016/j.seta.2019.100597

Balan R, Chandrasekaran J, Shanmugan S, Janarthanan B, Kumar S (2011) Review on passive solar distillation. Desalin Water Treat 28(1–3):217–238. https://doi.org/10.5004/dwt.2011.1742

Bhardwaj R, Ten Kortenaar MV, Mudde RF (2015) Maximized production of water by increasing area of condensation surface for solar distillation. Appl Energy 154:480–490. https://doi.org/10.1016/j.apenergy.2015.05.060

Chamkha AJ, Armaghani T, Mansour MA, Rashad AM, Kargarsharifabad H (2021) MHD Convection of an Al2O3–Cu/water hybrid nanofluid in an inclined porous cavity with internal heat generation/absorption. Iran J Chem Chem Eng (IJCCE). https://doi.org/10.30492/ijcce.2021.136201.4328

Dibaei MH, Kargarsharifabad H (2017) New achievements in Fe 3 O 4 nanofluid fully developed forced convection heat transfer under the effect of a magnetic field : an experimental study. J Heat Mass Transfer Res 4:1–12. https://doi.org/10.22075/jhmtr.2016.486

Dubey A, Kumar S, Arora A (2021) Enviro-energy-exergo-economic analysis of ETC augmented double slope solar still with ‘N’ parallel tubes under forced mode: Environmental and economic feasibility. J Clean Prod 279:123859. https://doi.org/10.1016/j.jclepro.2020.123859

Dumka P, Jain A, Mishra DR (2020) Energy, exergy, and economic analysis of single slope conventional solar still augmented with an ultrasonic fogger and a cotton cloth. J Energy Storage 30(May):101541. https://doi.org/10.1016/j.est.2020.101541

Elango T, Kalidasa Murugavel K (2015) The effect of the water depth on the productivity for single and double basin double slope glass solar stills. Desalination 359:82–91. https://doi.org/10.1016/j.desal.2014.12.036

Elango T, Kannan A, Kalidasa Murugavel K (2015) Performance study on single basin single slope solar still with different water nanofluids. Desalination 360:45–51. https://doi.org/10.1016/j.desal.2015.01.004

El-Samadony YAF, El-Maghlany WM, Kabeel AE (2016) Influence of glass cover inclination angle on radiation heat transfer rate within stepped solar still. Desalination 384:68–77. https://doi.org/10.1016/j.desal.2016.01.031

El-Sebaey MS, Ellman A, Hegazy A, Panchal H (2022) Experimental study and mathematical model development for the effect of water depth on water production of a modified basin solar still. Case Stud Thermal Eng 33(March):101925. https://doi.org/10.1016/j.csite.2022.101925

Elsheikh AH, Sharshir SW, Mostafa ME, Essa FA, Ahmed Ali MK (2018) Applications of nanofluids in solar energy: A review of recent advances. Renew Sust Energ Rev 82(September):3483–3502. https://doi.org/10.1016/j.rser.2017.10.108

Eltawil MA, Omara ZM (2014) Enhancing the solar still performance using solar photovoltaic, flat plate collector and hot air. Desalination 349:1–9. https://doi.org/10.1016/j.desal.2014.06.021

Feilizadeh M, Estahbanati MRK, Khorram M, Rahimpour MR (2019) Experimental investigation of an active thermosyphon solar still with enhanced condenser. Renew Energy 143:328–334. https://doi.org/10.1016/j.renene.2019.05.013

Hassan H (2020) Comparing the performance of passive and active double and single slope solar stills incorporated with parabolic trough collector via energy, exergy and productivity. Renew Energy 148:437–450. https://doi.org/10.1016/j.renene.2019.10.050

Heydari A, Shateri M, Sanjari S (2018) Numerical analysis of a small size baffled shell-and-tube heat exchanger using different nano-fluids. Heat Transfer Eng 39(2):141–153. https://doi.org/10.1080/01457632.2017.1288052

Kabeel AE, Khalil A, Omara ZM, Younes MM (2012) Theoretical and experimental parametric study of modified stepped solar still. Desalination 289:12–20. https://doi.org/10.1016/j.desal.2011.12.023

Kabeel AE, Omara ZM, Essa FA (2014) Improving the performance of solar still by using nanofluids and providing vacuum. Energy Convers Manag 86:268–274. https://doi.org/10.1016/j.enconman.2014.05.050

Kabeel AE, Omara ZM, Essa FA, Abdullah AS (2016) Solar still with condenser — a detailed review. Renew Sust Energ Rev 59:839–857. https://doi.org/10.1016/j.rser.2016.01.020

Kalidasa Murugavel K, Chockalingam KKSK, Srithar K (2008a) An experimental study on single basin double slope simulation solar still with thin layer of water in the basin. Desalination 220(1–3):687–693. https://doi.org/10.1016/j.desal.2007.01.063

Kalidasa Murugavel K, Chockalingam KKSK, Srithar K (2008b) Progresses in improving the effectiveness of the single basin passive solar still. Desalination 220(1–3):677–686. https://doi.org/10.1016/j.desal.2007.01.062

Kargarsharifabad H (2020a) Experimental and numerical study of natural convection of Cu-water nanofluid in a cubic enclosure under constant and alternating magnetic. In Commun Heat Mass Transfer 119:104957. https://doi.org/10.1016/j.icheatmasstransfer.2020.104957

Kargarsharifabad H (2020b) Optimization of arrangement of conducting fins and insulated obstacles inside a cavity: the couple of numerical solutions and genetic algorithm methods. J Therm Anal Calorim:0123456789. https://doi.org/10.1007/s10973-020-10276-y

Kaushal A, Varun (2010) Solar stills: a review. Renew Sust Energ Rev 14(1):446–453. https://doi.org/10.1016/j.rser.2009.05.011

Khalifa AJN (2011) On the effect of cover tilt angle of the simple solar still on its productivity in different seasons and latitudes. Energy Convers Manag 52(1):431–436. https://doi.org/10.1016/j.enconman.2010.07.018

Khalifa AJN, Ibrahim HA (2010) Effect of inclination of the external reflector of simple solar still in winter: An experimental investigation for different cover angles. Desalination 264(1–2):129–133. https://doi.org/10.1016/j.desal.2010.07.016

Khanmohammadi S, Khanmohammadi S (2019) Energy, exergy and exergo-environment analyses, and tri-objective optimization of a solar still desalination with different insulations. Energy 187:115988. https://doi.org/10.1016/j.energy.2019.115988

Manchanda H, Kumar M (2018) Study of water desalination techniques and a review on active solar distillation methods. Environ Prog Sustain Energy 37(1):444–464. https://doi.org/10.1002/ep.12657

Mevada D, Panchal H, Ahmadein M, Zayed ME, Alsaleh NA, Djuansjah J, Moustafa EB, Elsheikh AH, Sadasivuni KK (2022) Investigation and performance analysis of solar still with energy storage materials: an energy- exergy efficiency analysis. Case Stud Thermal Eng 29(December 2021):101687. https://doi.org/10.1016/j.csite.2021.101687

Minea AA (2015) Numerical simulation of nanoparticles concentration effect on forced convection in a tube with nanofluids. Heat Transfer Eng 36(13):1144–1153. https://doi.org/10.1080/01457632.2015.987628

Mohaisen HS, Esfahani JA, Ayani MB (2021) Improvement in the performance and cost of passive solar stills using a finned-wall/built-in condenser: an experimental study. Renew Energy 168:170–180. https://doi.org/10.1016/j.renene.2020.12.056

Muthu Manokar A, Kalidasa Murugavel K, Esakkimuthu G (2014) Different parameters affecting the rate of evaporation and condensation on passive solar still — a review. In: In Renewable and Sustainable Energy Reviews, 38th edn. Elsevier Ltd, Oxford, pp 309–322. https://doi.org/10.1016/j.rser.2014.05.092

Muthu Manokar A, Taamneh Y, Kabeel AE, Prince Winston D, Vijayabalan P, Balaji D, Sathyamurthy R, Padmanaba Sundar S, Mageshbabu D (2020) Effect of water depth and insulation on the productivity of an acrylic pyramid solar still — an experimental study. Groundw Sustain Dev 10:100319. https://doi.org/10.1016/j.gsd.2019.100319

Nazari S, Safarzadeh H, Bahiraei M (2019) Experimental and analytical investigations of productivity, energy and exergy efficiency of a single slope solar still enhanced with thermoelectric channel and nanofluid. Renew Energy 135:729–744. https://doi.org/10.1016/j.renene.2018.12.059

Nehar L, Rahman T, Tuly SS, Rahman MS, Sarker MRI, Beg MRA (2022) Thermal performance analysis of a solar still with different absorber plates and external copper condenser. Groundw Sustain Dev 17(March):100763. https://doi.org/10.1016/j.gsd.2022.100763

Omara ZM, Hamed MH, Kabeel AE (2011) Performance of finned and corrugated absorbers solar stills under Egyptian conditions. Desalination 277(1–3):281–287. https://doi.org/10.1016/j.desal.2011.04.042

Pal P, Dev R, Singh D, Ahsan A (2018) Energy matrices, exergoeconomic and enviroeconomic analysis of modified multi–wick basin type double slope solar still. Desalination 447(April):55–73. https://doi.org/10.1016/j.desal.2018.09.006

Peng G, Sharshir SW, Wang Y, An M, Kabeel AE, Zang J, Zhang L and Yang N (2019) Micro/nanomaterials for improving solar still and solar evaporation-A review. Appl Phys 1906.08461:1–53. https://doi.org/10.48550/arXiv.1906.08461

Rabbi HMF, Sahin AZ (2021) Performance improvement of solar still by using hybrid nanofluids. J Therm Anal Calorim 143(2):1345–1360. https://doi.org/10.1007/s10973-020-10155-6

Rabhi K, Nciri R, Nasri F, Ali C, Ben Bacha H (2017) Experimental performance analysis of a modified single-basin single-slope solar still with pin fins absorber and condenser. Desalination 416(April):86–93. https://doi.org/10.1016/j.desal.2017.04.023

Rahbar N, Gharaiian A, Rashidi S (2017) Exergy and economic analysis for a double slope solar still equipped by thermoelectric heating modules—an experimental investigation. Desalination 420(April):106–113. https://doi.org/10.1016/j.desal.2017.07.005

Rahmani A, Boutriaa A (2017) Numerical and experimental study of a passive solar still integrated with an external condenser. Int J Hydrog Energy 42(48):29047–29055. https://doi.org/10.1016/j.ijhydene.2017.07.242

Rajamanickam MR, Ragupathy A (2012) Influence of water depth on internal heat and mass transfer C in a double slope solar still. Energy Proc 14:1701–1708

Sahoo BB, Sahoo N, Mahanta P, Borbora L, Kalita P, Saha UK (2008) Performance assessment of a solar still using blackened surface and thermocol insulation. Renew Energy 33(7):1703–1708. https://doi.org/10.1016/j.renene.2007.09.009

Sahota L, Tiwari GN (2016) Effect of nanofluids on the performance of passive double slope solar still: A comparative study using characteristic curve. Desalination 388:9–21. https://doi.org/10.1016/j.desal.2016.02.039

Sahota L, Shyam, Tiwari GN (2017a) Analytical characteristic equation of nanofluid loaded active double slope solar still coupled with helically coiled heat exchanger. Energy Convers Manag 135:308–326. https://doi.org/10.1016/j.enconman.2016.12.078

Sahota L, Shyam, Tiwari GN (2017b) Energy matrices, enviroeconomic and exergoeconomic analysis of passive double slope solar still with water based nanofluids. Desalination 409:66–79. https://doi.org/10.1016/j.desal.2017.01.012

Sahota L, Arora S, Singh HP, Sahoo G (2019) Thermo-physical characteristics of passive double slope solar still loaded with mwcnts and al2o3-water based nanofluid. Mater Today: Proc 32(40):344–349. https://doi.org/10.1016/j.matpr.2020.01.600

Saini V, Sahota L, Jain VK, Tiwari GN (2019) Performance and cost analysis of a modified built-in-passive condenser and semitransparent photovoltaic module integrated passive solar distillation system. J Energy Storage 24(November 2018):100809. https://doi.org/10.1016/j.est.2019.100809

Sampathkumar K, Arjunan TV, Pitchandi P, Senthilkumar P (2010) Active solar distillation—a detailed review. In Renew Sustain Energy Rev 14(6):1503–1526. https://doi.org/10.1016/j.rser.2010.01.023

Sharshir SW, Peng G, Elsheikh AH, Edreis EMA, Eltawil MA, Abdelhamid T, Kabeel AE, Zang J, Yang N (2018) Energy and exergy analysis of solar stills with micro/nano particles: a comparative study. Energy Convers Manag 177(September):363–375. https://doi.org/10.1016/j.enconman.2018.09.074

Sharshir SW, Ellakany YM, Eltawil MA (2020) Exergoeconomic and environmental analysis of seawater desalination system augmented with nanoparticles and cotton hung pad. J Clean Prod 248(40):119180. https://doi.org/10.1016/j.jclepro.2019.119180

Shoeibi S, Rahbar N, Abedini Esfahlani A, Kargarsharifabad H (2020) Application of simultaneous thermoelectric cooling and heating to improve the performance of a solar still: an experimental study and exergy analysis. Appl Energy 263(September 2019):114581. https://doi.org/10.1016/j.apenergy.2020.114581

Shoeibi S, Kargarsharifabad H, Mirjalily SAA, Zargarazad M (2021) Performance analysis of finned photovoltaic/thermal solar air dryer with using a compound parabolic concentrator. Appl Energy 304(August):117778. https://doi.org/10.1016/j.apenergy.2021.117778

Shoeibi S, Mirjalily SAA, Kargarsharifabad H, Panchal H and Dhivagar R (2022a) Comparative study of double-slope solar still, hemispherical solar still, and tubular solar still using Al2O3/water film cooling: a numerical study and CO2 mitigation analysis. Environ Sci Pollut Res. https://doi.org/10.1007/s11356-022-20437-1

Shoeibi S, Kargarsharifabad H, Mirjalily SAA, Muhammad T (2022b) Solar district heating with solar desalination using energy storage material for domestic hot water and drinking water – Environmental and economic analysis. Sustain Energy Technol Assess 49(November 2021):101713. https://doi.org/10.1016/j.seta.2021.101713

Shoeibi S, Kargarsharifabad H, Mirjalily SAA, Sadi M, Arabkoohsar A (2022c) A comprehensive review of nano-enhanced phase change materials on solar energy applications. J Energy Storage 50(November 2021):104262. https://doi.org/10.1016/j.est.2022.104262

Shoeibi S, Kargarsharifabad H, Rahbar N, Khosravi G, Sharifpur M (2022d) An integrated solar desalination with evacuated tube heat pipe solar collector and new wind ventilator external condenser. Sustain Energy Technol Assess 50(December 2021):101857. https://doi.org/10.1016/j.seta.2021.101857

Shoeibi S, Kargarsharifabad H, Sadi M, Arabkoohsar A, Mirjalily SAA (2022e) A review on using thermoelectric cooling, heating, and electricity generators in solar energy applications. Sustain Energy Technol Assess 52(PB):102105. https://doi.org/10.1016/j.seta.2022.102105

Shoeibi S, Rahbar N, Abedini Esfahlani A, Kargarsharifabad H (2022f) Energy matrices, economic and environmental analysis of thermoelectric solar desalination using cooling fan. J Therm Anal Calorim. https://doi.org/10.1007/s10973-022-11217-7

Sivakumar V, Ganapathy Sundaram E (2013) Improvement techniques of solar still efficiency: A review. In Renew Sustain Energy Rev 28:246–264. https://doi.org/10.1016/j.rser.2013.07.037

Srivastava PK, Agrawal SK (2013) Experimental and theoretical analysis of single sloped basin type solar still consisting of multiple low thermal inertia floating porous absorbers. Desalination 311:198–205. https://doi.org/10.1016/j.desal.2012.11.035

Tuly SS, Islam MS, Hassan R, Das BK, Sarker MRI (2022) Investigation of a modified double slope solar still integrated with nanoparticle-mixed phase change materials: energy, exergy , exergo-economic, environmental, and sustainability analyses. Case Stud Thermal Eng 37(May):102256. https://doi.org/10.1016/j.csite.2022.102256

Velmurugan V, Srithar K (2011) Performance analysis of solar stills based on various factors affecting the productivity — a review. In Renew Sustain Energy Rev 15(2):1294–1304. https://doi.org/10.1016/j.rser.2010.10.012

Velmurugan V, Gopalakrishnan M, Raghu R, Srithar K (2008) Single basin solar still with fin for enhancing productivity. Energy Convers Manag 49(10):2602–2608. https://doi.org/10.1016/j.enconman.2008.05.010

Yousef MS, Hassan H (2020) Energy payback time, exergoeconomic and enviroeconomic analyses of using thermal energy storage system with a solar desalination system: an experimental study. J Clean Prod 270:122082. https://doi.org/10.1016/j.jclepro.2020.122082

Author information

Authors and Affiliations

Contributions

Methodology: Rasaiah Naveenkumar; formal analysis and investigation: Rasaiah Naveenkumar; writing — original draft preparation: Rasaiah Naveenkumar; conceptualization-supervision, review and editing: Subramaniam Shanmugam, Arunachalam Veerappan

Corresponding author

Ethics declarations

Ethical approval

Not applicable

Consent to participate

Not applicable

Consent for publication

Not applicable

Competing interests

The authors declare no competing interests.

Additional information

Responsible Editor: Philippe Garrigues

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Highlights

• Solar stills integrated with vacuum fan, condenser, and nanofluids were studied.

• Copper oxide nanofluid enhances the distillate yield by 96.43% in modified still.

• Aluminium oxide and zinc oxide nanofluids enhance the yield by 82.14% and 75%.

• Copper oxide nanofluid attained the maximum yield, energy, and exergy efficiency.

Rights and permissions

Springer Nature or its licensor holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Naveenkumar, R., Shanmugam, S. & Veerappan, A. Performance and exergy analysis of solar-operated vacuum fan and external condenser integrated double-slope solar still using various nanofluids. Environ Sci Pollut Res 30, 12883–12902 (2023). https://doi.org/10.1007/s11356-022-22919-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11356-022-22919-8