Abstract

The emissions of vessels are higher when they sail at sea than when they are at a port, and such emissions affect air quality considerably. In this study, an activity-based method was used to calculate the quantities of various pollutants emitted by large container ships sailing at optimal speed on Far East–Europe trunk routes, which cover seven of the largest economies with high population density. We determined the emission quantities of various pollutant, such as carbon dioxide (CO2), sulfide \(({\mathrm{SO}}_{\mathrm{x}}\)), nitride (\({\mathrm{NO}}_{\mathrm{x}}\)), and particulate matter—for the newest mega container ships deployed on the aforementioned routes by THE Alliance. This study considered vessel speed as a critical variable and found that to reduce vessel emissions, port authorities should mandate that vessels reduce their speed when entering and leaving a port. Considering maritime practice, setting the optimal speed of a vessel as 15–18 knots is the most effective method for reducing emissions. On the basis of the obtained results, appropriate recommendations are made to the International Maritime Organization, international shipping companies, and port authorities.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

To respond to the world’s emphasis on sustainable environmental development, the International Maritime Organization (IMO) has stipulated various environmental protection regulations for reducing the pollution caused by vessels. For instance, the IMO has proposed regulations for the transportation of fuels and hazardous materials, ship pollutant and waste treatment, and air pollution control. In April 2018, the Marine Environmental Protection Committee adopted an initial greenhouse gas reduction strategy [IMO 2018, annex 1; United Nations Conference on Trade and Development (UNCTAD) 2019–2020] with the aim of reducing the total greenhouse gas emissions from international shipping by at least 50% by 2050 compared with those in 2008. This strategy includes concrete measures such as improving the current fleet’s condition, promoting energy-saving shipbuilding processes, and restricting vessels’ emission of sulfur oxides to improve air quality and protect humanity’s health and the environment. Furthermore, “New Technologies for Greener Shipping” was selected as the World Maritime Theme of 2022 at the 125th Session of the IMO Council. This theme emphasizes the maritime industry’s aim of achieving a sustainable future with low pollution through a “green transformation” that matches the targets of the sustainable development goals (SDGs) set by the United Nations. Climate change and sustainable maritime resources are crucial aspects that require close attention, and the maritime transport industry has critical influences on these aspects.

Container shipping transport is a highly efficient goods transfer method in global trade activities. Vessel upsizing has become a trend in recent years, and most newly built 15,000–24,000 TEU mega container ships are deployed on Far East–Europe trunk routes. These trunk routes feature the newest mega container ships with the highest transport capacity ratios worldwide and encompass regions such as Northeast Asia, China, Southeast Asia, South Asia, India, Pakistan, the Middle East, the Persian Gulf, the Mediterranean Sea, and Northern Europe. Because the aforementioned routes connect seven of the largest economies with high population density, each country pays close attention to the emissions generated by vessels traveling on these routes.

In addition, considerable changes have been observed in the hub port selection and fleet deployment methods adopted on Far East–Europe trunk routes under the trend of vessel upsizing since 2015. To meet the trading requirements of seven of the largest economies with high population densities, shipping companies deploy the newest and largest container ships on Far East–Europe trunk routes. These routes comprise three to four hub ports and multiple destination ports, which are connected to the hub ports through feeder services at both Far East and Europe area. The deployment of the newest container ships increases the transportation efficiency and hub ports’ loading performance but might also increase vessel emissions. Thus, this study calculated the emissions of vessels traveling on Far East–Europe trunk routes. We determined the emission quantities of various pollutants—such as carbon dioxide (CO2), sulfide \(({\mathrm{SO}}_{\mathrm{x}}\)), nitride (\({\mathrm{NO}}_{\mathrm{x}}\)), and particulate matter (PM)—for the newest mega container ships deployed on the aforementioned routes at sea and ports by THE Alliance. On the basis of the obtained results, appropriate recommendations are made to the IMO, international shipping companies, and port authorities.

Current situation and literature review

Container shipping and Far East–Europe trunk routes

Container shipping is a highly effective and efficient transportation method, and its role in maritime transport is becoming increasingly important. Because of advancement in shipbuilding technology, vessel upsizing is becoming a trend for shipping companies. For instance, China COSCO Shipping, which is a major shipping company in terms of total fleet capacity, uses the newest design concepts and most advanced shipbuilding techniques for manufacturing their fleet to fulfill their commitment to a “greener future” and corporate social responsibilities to reduce carbon emissions. Many vessels in their fleet have an optimized ship design with a highly efficient propeller and an energy-saving system, and these vessels exhibit advantages such as low energy consumption and low emissions. China COSCO Shipping configures its technical parameters and equipment layout such that fuel consumption and emission can be minimized while fuel economy can be improved. Its fleet has already achieved the Energy Efficiency Design Index (EEDI) goal set by MARPOL 2025 (Corporate Sustainability 2020, 2021). After the bankruptcy of the Hanjin Group, South Korea released a 5-year plan for restructuring its maritime transport industry. This plan includes the construction of 140 bulk carriers and 60 container ships by Hyundai Merchant Marine (HMM), twelve 24,000 TEU mega container ships by DSME, and eight 16,000 TEU large container ships by Samsung. After deploying the aforementioned 140 bulk carriers and 60 container ships on two Far East–Europe trunk routes (FE3 and FE4), HMM became the second shipping company after MSC to deploy 24,000 TEU vessels. In addition, CMA CGM will become the first customer to order these mega container ships from a Chinese shipbuilder (Alphaliner 2020a, b). Since 2005, all the new vessels constructed by Evergreen Marine have been equipped with the newest environmentally friendly devices for calculating the optimal loading, improving the energy efficiency, and reducing greenhouse gas emissions. The ten 23,000 TEU ships ordered in 2019 have an improved design and include active energy-saving technology for reducing fuel consumption. These ships are compliant with EEDI phase 3 and thus have low carbon emissions per transport unit (Evergreen Marine 2021).

According to the most recent data published by Alphaliner (2020a), most newly constructed mega container ships with a capacity of ≥ 15,000 TEU are deployed on Far East–Europe trunk routes. This route accounts for the highest vessel transport capacity ratio (TEU) worldwide (18.73%) and is traversed by the newest and largest container ships. Although many studies have been conducted on vessel emission reduction, few studies have focused on the emissions of new mega container ships. In addition, with the economic emergence of Asian countries and increased economic and trade activities under globalization, trade between Asia and Europe has flourished. For example, Far East–Europe trunk routes play a critical role in the Belt and Road Initiative that has been heavily promoted by China. Although the aforementioned regional economic and trade activities can promote economic growth, they can also cause environmental pollution because of the associated industrialization and increased vessel traffic. For instance, financial development, an urban population, and foreign direct investment can have negative influences on carbon footprint in Asia and Europe (Hafeez et al. 2019). In addition, a nonlinear causal relationship exists between foreign direct investment and carbon dioxide emissions in countries located along Far East–Europe trunk routes, especially China, where apparent structural breaks have been identified in the relationship between foreign direct investment and carbon dioxide emissions. Economies covered by Far East–Europe trunk routes should acquire green and high-tech foreign investment to protect their environments (Gong et al. 2021).

Although many scholars have investigated Far East–Europe trunk routes and their impact on the environment, no study has been conducted on the air pollution caused by vessels sailing on these routes during their sailing and berthing under various speeds. Moreover, few studies have focused on the air quality in ports and their neighboring cities when mega container ships berth there.

Pollution from container ships

We referred to the studies of Chang and Wang (2012), Song and Xu (2012), and Tai and Lin (2013, 2016) to develop a research model for predicting the pollution caused by container ships during their voyage. The aforementioned studies focused on variables such as vessel size, vessel speed, fuel efficiency, and pollutants. Many variables, such as ship design and the fuel employed, can affect the air pollutants emitted by vessels. Changing a shipping company’s operation method through measures such as the optimization of fleet deployment and port services, the development of vessel economies of scale, the selection of new routes, and the reduction of vessel speed and vessel resistance can result in emission reduction (Tai and Lin 2013; Xing et al. 2020). Among the aforementioned variables, vessel size and vessel speed have received the most attention from shipping companies.

Larger container ships have higher total emissions but lower carbon emissions per transport unit because of their larger transport capacity (Tai 2015). Small container ships (with a capacity of ≤ 999 TEU) have twice the carbon emissions per transport unit than large container ships do (UNCTAD 2019–2020). Furthermore, larger and newer vessels feature optimizations, such as improved ship design to decrease resistance and increase propeller and power generation efficiencies, thus lowering emissions. Vessel resistance is affected by displacement tonnage (e.g., light weight), vessel speed, and vessel fluid dynamics (Xing et al. 2020).

Vessel resistance strongly affects vessel speed. During a voyage, weather, sea, and ship conditions influence the distribution of additional power by a propeller to compensate for additional resistance. Shipping companies often reduce a vessel’s weight, ballast water, and speed to conserve fuel (Xing et al. 2020). A reduction in speed can result in lower cost and fuel consumption related to vessel idling. According to the studies of Tai and Lin (2013) and Tai (2015), a 10% decrease in vessel speed can decrease the required power by 27%. When vessels sailing along Far East–Europe trunk routes decrease their speed, their emissions also decrease considerably, with the per-transport-unit emissions decreasing from 1.08 to 0.64 tons. This decrease in the per-transport-unit emissions signifies that speed reduction is beneficial for emission reduction (Tai and Lin 2013; Xing et al. 2020). Moreover, vessel upsizing has become an industrial trend since 2000, and this trend has resulted in a considerable decrease in the average annual emissions from each container ship; thus, vessel upsizing is beneficial for emission reduction (Zakaria and Rahman 2017; Zhao et al. 2021). Nevertheless, most of the aforementioned studies assumed that most vessels sail at a fixed speed when estimating the overall emissions.

According to data from the IMO, the vessel upsizing and improved fuel efficiency brought by advanced shipbuilding technology can decrease the quantity of air pollutants emitted by vessels. UNCTAD (2019–2020) indicated that container ships worldwide improved their capacity by 45% between 2011 and 2019; however, the emissions of these ships during the same period increased by merely 2% because the ships were designed under considerations of eco-friendliness and old vessels were being retired from the market.

The introduction of new technology can reduce the emissions of container ships. For example, to comply with IMO 2020 and other environmental regulations, shipping companies have begun to develop green vessels equipped with high-efficiency scrubbers and generators, which are cost-effective (Schinas et al. 2018; Zhao et al. 2021). In addition, switching to low-sulfur fuel oil (LSFO) enables shipping companies to remain compliant with new global environmental guidelines, and shipping companies are more willing to make the switch to LSFO if governments provide subsidies (Wang and Jiao 2021). Autonomous ships that use fuel cell technology have relatively low hazardous gas emissions, accidental risk, personnel requirements, and fuel costs. Nevertheless, such technology requires further development and support by international laws (Li and Fung 2019). Moreover, alternative maritime power (AMP) is a technology used to provide electricity to vessels from land. AMP enables berthing vessels to connect to onshore generators and shut off their diesel generators (Ballini and Bozzo 2015). This technology enables container ships to reduce their emissions during berthing. Moreover, it improves air quality and reduces noise and vibration in port areas (Yang et al. 2011).

Port authorities implement green port policies to achieve the SDGs of the United Nations; however, whether such policies enhance efficiency, cost, regulatory supervision, and environmental performance is unclear. Nevertheless, global competitiveness and environmental performance can be maintained through innovative measures, such as an onshore power supply or alternative fuels (Acciaro et al. 2014). Most of the pollutants emitted during berthing concentrate near the port’s anchorage area, and pollution problems tend to be more severe at ports with higher traffic; however, pollutant emissions are not necessarily distributed evenly (Olukanni and Esu 2018; Buber et al. 2020). Thus, optimizing port operations, improving the port’s operational efficiency, and reducing vessel berthing and anchorage times are critical tasks for reducing vessel emissions at a port. Shipping companies can also reduce vessel emissions through measures such as increasing the loading or unloading efficiency (Gibbs et al. 2014), strengthening cooperation with port authorities (Venturini et al. 2017), improving berthing distribution planning (Du et al. 2011), and scheduling port machinery and equipment use in a reasonable manner (Liu and Ge 2018). Emissions caused by container shipping affect ports, local governments, consumers, and the environment. By encouraging port authorities to use clean fuel and reduce the per-transport-unit emission of pollutants, local governments can establish a cooperative mechanism with port authorities to achieve pollution control (Wang et al. 2021).

Fleet deployment method on Far East–Europe trunk routes

Before fleet deployment, shipping companies must assess the market and demand of a particular route, import and export trade volumes, inland transport demand, and trade surplus and deficit. Thus, various variables—such as frequency, fleet size and combination, transport time, number of hub ports, sailing time, berthing cost, and operation efficiency—must be considered when planning a route (Tai and Lin 2013, 2016). The economies of scale for vessels are crucial factors, especially for long-distance routes. Excluding the route from Australia to Europe, container shipping and transport operators usually deploy their largest vessels on the longest routes (UNCTAD 2019-2020; Alphaliner 2020a, b).

The voyage distance for Far East–Europe trunk routes is 27,456 nm. If a vessel moves with an average speed of 18 nm, it would take approximately 77.54 days, which includes the time for berthing, to complete the voyage; thus, these routes are considered long-distance routes. The aforementioned routes begin from Northeast Asia. During the journey along a Far East–Europe trunk route, a vessel passes near or through China, Southeast Asia, the Indian Ocean, South Asia, India, Pakistan, and the Middle East before entering the Red Sea and the Mediterranean Sea prior to reaching its destination of Northern Europe. These routes cover seven of the largest economies worldwide excluding those in the Americas and Oceania. As presented in Table 1, Far East–Europe trunk routes cover eight of the world’s 10 largest economies. These eight economies represent 10.44% of the world’s gross domestic product and 41.79% of the world’s population. Shipping companies compete against each other for trade volume along the aforementioned routes. After assessing the cargo import and export flow, trade demand, and service frequency, companies tend to deploy their newest and largest container ships to serve the aforementioned seven of the largest economies. Midsize and small vessels are used for river transport, whereas inland transport is used to move cargo from hub ports along Far East–Europe trunk routes to nearby cities in the aforementioned seven of the largest economies.

According to Alphaliner (2020a), the use of midsize container ships with a capacity of < 10,000 TEU was a market trend. However, from 2008, the use of large container ships with a capacity of ≥ 10,000 TEU increased, and these ships became the primary vessels used for cargo transport. The use of mega container ships with a capacity of ≥ 15,000 TEU has increased each year since 2014, and most of these ships are deployed along Far East–Europe routes. Of all the major east–west routes, Far East–Europe routes have the highest transport capacity ratio (18.73%, Table 2). Currently, most shipping companies deploy their newest and largest container ships on these routes.

Because of the trend for vessel upsizing in the global container shipping and transport market, an increasing number of companies are deploying large vessels to reduce their cost of transportation capacity per transport unit and thus increase their market competitiveness. However, the initial vessel-upsizing trend led to a sharp decline in the freight rate for reasons such as oversupply. Therefore, many shipping companies experienced financial crises. To overcome these crises, the companies formed strategic alliances or merged to increase their market share and reduce their operating costs. Because Far East–Europe trunk routes favor the deployment of mega container ships, the majority of the market share on these routes is cornered by three major alliances in the marine industry. As presented in Table 3, the Ocean Alliance—which comprises China COSCO, CMA CGM, and Evergreen Marine—has the highest capacity ratio (37.08%) for these routes, followed by the 2 M Alliance, which comprises Maersk and MSC (36.30%), and THE Alliance, which comprises ONE, HMM, YML, and Hapag Lloyd (26.14%).

Short voyages are employed where manufacturers and consumers are concentrated around the port, and such voyages provide feeder services as a dual function. Small ships (with a capacity of ≤ 9999 TEU) are deployed on intra-Asia trunk routes according to the port-to-port mode. The use of Pacific trunk routes is limited by the insufficient port capacity along the western coast of the USA. Ships with a capacity of ≤ 14,999 TEU are deployed on these routes as per the pendulum mode; however, this approach only extends the reach of the original ports at Southeast Asia. However, considerable changes have been observed in the methods of hub port selection and fleet deployment on Far East–Europe trunk routes under the trend of vessel upsizing since 2015. To meet the trade demands of seven of the largest economies with high population densities, shipping companies deploy the newest and largest container ships on Far East–Europe trunk routes. These routes encompass three to four hub ports, with Rotterdam (the Netherlands) being the main hub port in Europe, followed by Hamburg (Germany). The major hub ports in the Far East region include Busan in South Korea (Northeast Asia); Shanghai, Ningbo, and Shenzhen in China; and Singapore in Southeast Asia (Tai and Lin 2013, 2016). We examined vessel and deployment data for the aforementioned three alliances obtained from the study of Alphaliner (2020a). We discovered that the shipping companies within these alliances deploy 329 midsize and large container ships over 29 Far East–Europe trunk routes. Moreover, more than two-thirds of the vessels berth at the aforementioned hub ports. Mega container ships with a capacity of ≥ 15,000 TEU are the major ships on the aforementioned routes, making additional calls at hub ports in Southeast Asia, South Asia, the Middle East, and the Mediterranean Sea. In this study, we considered findings in the literature, practical experience, and data obtained from the official site of YML. For example, 18 mega container ships are deployed along route FE2 of THE Alliance (7 from Hapag Lloyd, 6 from ONE, and 5 from HMM). These vessels entered service between 2015 and 2021; have a capacity of 15,000–24,000 TEU; and stop at Busan, Shanghai, Ningbo, Yantian, and Singapore in the Far East as well as Rotterdam, Hamburg, Southampton, and Le Havre in Europe.

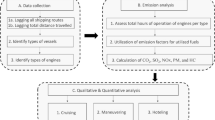

Design of a pollutant discharge model

This study used the academic literature and operation data as references. It examined the Far East–Europe trunk routes used by the vessels of various shipping companies and calculated the quantities of major pollutants emitted by these vessels during their entire voyage and berthing. The quantities of five pollutants were calculated: \({\mathrm{NO}}_{\mathrm{x}}\), \({\mathrm{SO}}_{\mathrm{x}}\), \({\mathrm{CO}}_{2}\), hydrocarbons (HCs), and PM (including PM2.5 and PM10).

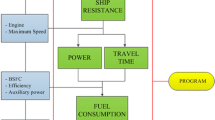

Description of the designed pollutant discharge model

In the designed pollutant emission model, activity-based methods are used to consider the total quantities of pollutants emitted in various stages of vessel operation. Many studies have used activity-based methods; however, relevant models and calculations are often influenced by several variables, such as routing, vessel size, and fuel type. We examined theoretical and practical information presented in the studies of Song and Xu (2012), Tai and Lin (2013, 2016), Tai (2015), and the Ministry of Transportation and Communication of Taiwan (2016). These studies performed their calculations by using a fixed vessel speed for the entire voyage and obtained pollution emission results with different speed models (Tai and Lin 2013; Tai 2015). However, in the present study, actual vessel operation was accounted for, and the quantities of pollutant emissions were determined by considering that a vessel sails at different speeds in different stages of a voyage. We determined the quantities of five pollutants generated by a container ship during voyage and berthing: \({\mathrm{NO}}_{\mathrm{x}}\), \({\mathrm{SO}}_{\mathrm{x}}\), \({\mathrm{CO}}_{2}\), HCs, and PM. Table 4 lists and explains all the parameters used in the calculations conducted in this study. Such a method can be used for effectively calculating the quantities of pollutants emitted by a container ship during its voyage. It can also be used to obtain the emissions associated with different vessel activities for various vessel types and routes.

When calculating \({F}_{t}^{o}\) (fuel economy of the engine) for estimating the emissions of a vessel, we assumed that a container ship uses heavy oil (HO) and diesel oil (DO) as primary fuel sources during its voyage. A vessel uses fuel (mainly DO) to run its auxiliary power generator during berthing even when the main engine is shut off. Therefore, we referred to the studies of Corbett and Koehler (2003), Liao et al. (2009), Tai and Lin (2013), Tai (2015), Tezdogan et al. (2016), and Dere and Deniz (2019) to obtain the fuel economy of vessel engines by oil type (Table 5). We could determine the hourly fuel consumption when using different types of fuel in vessels of different sizes that traveled with different speeds. We also conducted interviews with experts who had served as captains in the ten largest container shipping companies worldwide for over 20 years. On the basis of their experience, these experts believed that the distance of a voyage, time, propeller speed, load (draft), and current direction—especially distance, time, and propeller speed—are critical factors determining fuel consumption. Propeller speed can be used to calculate oil consumption for a certain speed through the load (draft) and ocean current. Our interviews indicated that the oil consumption data listed in Table 5 are similar to those of the 20,000 TEU mega container ships that are currently in service. Table 5 also indicates that HO consumption tends to be greater for larger vessels and when vessels have higher speed. The fuel consumption (Q) varies nonlinearly with vehicle speed (V; \({Q}_{is}=\mathrm{as}\times {V}_{bs}\); Tezdogan et al. 2016; Zakaria and Rahman 2017; Tsai and Tai 2019; Dere and Deniz 2019) and can influence emission quantity directly. Actual emissions can be calculated using the equations presented in the following text.

Another critical factor that may affect pollutant emissions is the fuel emission factor \({K}_{n,e}^{o}\), which represents the total quantity of pollutants generated per fuel unit (ton) burned. Table 6 indicates that emission levels differ under different scenarios. \({\mathrm{CO}}_{2}\) emission tends to be greater than \({\mathrm{NO}}_{\mathrm{x}}\), \({\mathrm{SO}}_{\mathrm{x}}\), HC, and PM emissions during sailing and maneuvering. However, most studies that have examined vessel pollution emissions have focused on emissions of \({\mathrm{NO}}_{\mathrm{x}}\), \({\mathrm{SO}}_{\mathrm{x}}\), HCs, and PM, which are hazardous and can negatively affect human health.

Table 4 presents the definition of each symbol used in Eqs. (1)–(4). By multiplying the time (hours), a vessel spends on sailing, maneuvering, and loading–unloading at the port terminal with the fuel economy of the vessel’s engine (F value) and the emission coefficient (K value: the tonnage of pollutant generated through the burning of 1 ton of fuel), the total emission of a single pollutant (ton; \({P}_{e}^{n}\)) could be determined. Then, the overall amount of emitted pollution (Pe) was obtained by summing the emission amount for each pollutant.

The following equation was used for calculating the emission of a single pollutant:

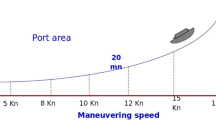

The total emission refers to the sum of the emissions during sailing (\({P}_{\mathrm{sailing}}^{n}\)) and berthing at a port. The emissions occurring during berthing at a port comprise the emissions that occur during maneuvering (\({P}_{\mathrm{maneuvering}}^{n}\)) and loading–unloading at the port terminal (\({P}_{\mathrm{terminal}}^{n}\)). A container ship emits different quantities of pollutants during sailing, maneuvering, and berthing at a port.

Fuel is used to power a vessel, and its consumption is affected by many variables, such as vessel size, engine power, load, weather conditions, sea conditions, vessel operation mode, and vessel speed. A vessel has different speeds during sailing (full speed), maneuvering (reduced speed), and berthing; and fuel is required to power its engine, generator, and boiler. When a vessel is sailing at full speed, a large quantity of HO is required to power its engine and boiler, and DO (light oil) is required to power its generator. HO consumption decreases but DO consumption is maintained with a decrease in vessel speed. Thus, the numbers must be summed. Although the engine is not running when a vessel is berthed, diesel is still required to power the boiler and generator.

The amount of a particular pollutant emitted during the sailing stage is obtained by multiplying the sailing time (obtained by dividing covered distance by the vessel speed) by the fuel economy (F value) and emission factor (K value), as presented in Eq. (2).

A container ship usually slows down and generates high quantities of pollutants during the maneuvering stage when approaching a port. As presented in Eq. (3), the amount of a particular pollutant emitted during the maneuvering stage is obtained by multiplying the time required for maneuvering by F and K.

As presented in Eq. (4), although HO is not consumed when a container ship is docked at a port, DO is still required to power the ship’s generator to maintain basic electricity on board. During berthing, although the engine is not running and thus no HO is consumed, pollutants are still emitted by the generator. The amount of a particular pollutant emitted during port operation can be obtained by multiplying the time for which the vessel is stopped at the port (obtained by dividing the estimated workload at Port i by the operation efficiency) by F and K. Most of the major hub ports frequented by mega container ships are equipped with advanced piers and machinery, and multiple gantry cranes are often used at these ports for loading multiple containers simultaneously. Thus, a high discrepancy rarely exists in the operation efficiency (EF) of hub ports. In this study, the time for which a vessel is stopped at a port was calculated using the gross efficiency. The hourly average operation capacity of most ports where large and mega container ships berth is approximately 135 TEU; however, hub ports such as Shanghai, Busan, and Rotterdam have an average operation capacity of 155 TEU/h (Tsai and Tai 2019).

Setting of the sailing route

A vessel sailing on a Far East–Europe trunk route typically berths at three or four European ports (mainly Rotterdam, followed by Hamburg) and Far Eastern hub ports such as Shenzhen, Hong Kong, Singapore, Shanghai, and Ningbo (Tai and Lin 2013; Tsai and Tai 2019). We examined the actual operation data of container shipping operators to calculate and compare the fuel economy (F) for seven vessel speeds between 8 and 22 knots (1 knot = 1.852 km/h) for determining the optimal vessel speed. For example, the optimal vessel speed is 15–18 knots for the FE2 route used by THE Alliance.

We examined a Far East–Europe trunk route with five stops in the Far East, namely Busan, Shanghai, Ningbo, Yantian, and Singapore, and four stops in Europe, namely Rotterdam, Hamburg, Southampton, and Le Havre. After completing this route, vessels follow the same route back to the Far East. The entire voyage covers approximately 27,404 nm and can be completed in approximately 77.52 days, which includes the berthing time, under an average vessel speed of 18 nm. We used data provided by port authorities and shipping companies to consider several variables, such as the supply and demand for import and export at each port. Table 7 presents the space allocation ratios determined after interviewing experts from the 10 largest shipping companies or from port management.

The experts mentioned that although vessel speed is determined by the power generated by the propeller, the actual speed may be affected by variables such as weather conditions, time pressure at the port, sea conditions, and vessel resistance. Vessel resistance can be overcome by obtaining additional power from the propeller. An optimal speed of 15–18 knots was assumed in this study for 88% of the entire voyage. The remainder of a voyage is affected by various levels of vessel resistance and time pressure, and the vessel speed in this part of the voyage may vary from the optimal speed. Table 8 presents the proportions of vessels traveling at various speeds on the selected Far East–Europe trunk route. These data were obtained from shipping studies.

Assessment of pollutant discharge

This study estimated the quantities of pollutants emitted by large container ships sailing on the FE2 route used by THE Alliance. Moreover, it analyzed whether vessel speed affected the emission quantity. Consider the example of the largest container ship on the aforementioned route (capacity of 24,000 TEU). We found that after completing its voyage from Busan in the Far East to Europe and back, this ship had emitted 15,786 tons of pollutants. \({\mathrm{CO}}_{2}\) accounted for most (94.64%, 14,940.73 tons) of these pollutants, followed by \({\mathrm{NO}}_{\mathrm{x}}\) (3.1%) and \({\mathrm{SO}}_{\mathrm{x}}\) (1.91%; Table 9 and Fig. 1). The aforementioned data are more accurate than those presented in other relevant studies, such as that of Tai and Lin (2016), because variability of vessel speed was considered when obtaining the aforementioned data. In addition, the order of emission quantity obtained in the present study (i.e., \({\mathrm{CO}}_{2}\) > \({\mathrm{NO}}_{\mathrm{x}}\) > \({\mathrm{SO}}_{\mathrm{x}}\)) is identical to that presented in a report from UNCTAD (2019–2020).

A total of 425.32 tons of pollutants were emitted by a vessel after berthing at nine ports. These pollutants accounted for 2.69% of all the pollutants emitted. The investigated vessels sailed at varying speed during the entire voyage; thus, they emitted different quantities of pollutants at different stages of the voyage. Most of the pollutants were emitted when the vessels sailed at a speed of 15–18 knots, which indicates that ships traveling Far East–Europe trunk routes mainly emit pollutants at sea. These pollutants have a minimal impact on the air quality of cities surrounding ports.

Our results also indicated that the faster a ship sailed, the higher the quantities of pollutants emitted per day (\({P}^{e}\)/day), per nautical mile (\({P}^{e}\)/nm), and per TEU (\({P}^{e}\)/TEU; \({\mathrm{CO}}_{2}^{e}\)/TEU). As indicated by Figs. 2, 3, and 4, the quantities of emitted pollutants were constant when a ship traveled at 12–15 knots. However, the quantities of emitted pollutants increased considerably when the vessel moved at ≥ 18 knots. This finding validates the results of Tai and Lin (2016), who found that a vessel that engages in slow steaming during its voyage can reduce its overall pollutant emissions. Most shipping companies set their vessel speed to 15–18 knots because this speed has been found to be appropriate for large container ships; thus, ships traveling at this speed need not reduce their speed for decreasing their fuel consumption and emissions. Shipping companies can make their operations more environmentally friendly by using our recommended speed when deploying their ships.

We also found that most ports pay attention to sulfide and carbon dioxide emissions by ships. Nevertheless, shipping companies can reduce and minimize emissions when a ship is berthed at a port. The only exogenous variable is operation efficiency, which is controlled by the port authority or operator in charge of loading and unloading. Table 10 presents the results of sensitivity analysis regarding the efficiency of port operations. Assuming that four to six cranes can be operated simultaneously at the deepwater terminal of large hub ports, such as Busan, Shanghai, and Rotterdam, and that the hourly operation capacity is 155 TEU at hub ports and 135 TEU at other ports, \({\mathrm{SO}}_{\mathrm{x}}\) and \({\mathrm{CO}}_{2}\) emissions can be reduced by 1.28% and 1.03% if the operation efficiency of all hub ports is increased to 155 TEU/h.

Conclusion

In this study, we employed a practical marine transport method to calculate the quantities of various pollutants emitted by large container ships sailing on Far East–Europe trunk routes under various sailing speeds. The results of this study act as a valuable reference for comparison with the results of relevant previous studies. Although large container ships sailing on Far East–Europe trunk routes travel long distances to seven of the largest economies with high population density, most of their emissions tend to occur at sea, with only a small proportion of total emissions occurring during berthing at a port. Furthermore, improving the operation efficiency during a port stay can reduce sulfide and carbon dioxide emissions. Global shipping container companies operating on Far East–Europe trunk routes have formed three alliances, and large container ships with a capacity of > 18,000 TEU are mainly deployed on these routes. The results of this study clearly indicate that the newest and largest container ships are highly effective in reducing vehicle emissions and saving energy. In addition, these ships can enable hub ports to receive increased transshipment from ports in Asia or the Middle East. The operation efficiency of hub ports, including the efficiency of terminal loading–unloading and transshipment operations, affects the berthing time of container ships. The present results verify that a reduction in vessel berthing time can reduce vessel emissions. Policy makers or port authorities can improve the port operation efficiency by adopting appropriate policies and management mechanisms and improving infrastructure.

In addition to fuel type, vessel speed plays a vital role in reducing emissions. A vessel sailing at a lower speed has lower emissions. In practical shipping operations, companies often set their optimal vessel speed as 15–18 knots, which we believe to be highly reasonable. Experience indicates that such a sailing speed can help shipping companies reduce fuel consumption, traveling time, and emissions while meeting their operating cost and time constraints and contributing to sustainable environmental development. Unless absolutely necessary, the vessels of shipping companies should not sail at speeds higher than 18 knots. Although the calculation model adopted in the present study has been used in previous studies, this study is the first to incorporate practical operation data for Far East–Europe trunk routes into this model. The calculation results of this study were verified, and these results are explained in this paper.

Furthermore, large container ships can reduce their speed when entering or exiting a port to reduce the impact of their emissions on air quality in the port and nearby cities. Therefore, we recommend that port authorities mandate all large container ships to sail at a low speed when entering or exiting a port. However, we found that most port authorities advocate for a vessel speed reduction policy only under the vessel traffic service or apply the Vessel Speed Reduction Surveillance System with an automatic identification system. To pursue more specific energy-saving effects and emission reduction benefits, port authorities and shipping companies may cooperate according to the JIT (Just In Time) ship arrival guide promoted by the IMO.

The deployment of the newest and largest container ships on Far East–Europe trunk routes can reduce operating costs and ensure that the commitment to environmental sustainability is met; however, mergers, acquisitions, or alliances between shipping companies; uncertain shipping prospects after the COVID-19 pandemic; and the shipbuilding strategy might influence the fleet deployment strategy. These crucial aspects should be explored in a future study. In addition, policy makers and port authorities should optimize the port operating efficiency and the logistics flow between the port area and the hinterland, especially after the COVID-19 pandemic. The presence of insufficient staff at ports and the insufficient port capacity along the western coast of the USA cause operating inefficiency and port congestion and affect the global supply chain. The emissions of vessels mooring in the anchorage for extended periods because of port congestion is a crucial concern that must be considered by policy makers and port authorities.

Data availability

This study calculated the quantities of various pollutants emitted by large container ships sailing on the FE2 route (a Far East–Europe trunk route) used by THE Alliance. The calculation results of this study are not applicable to other routes or ships.

References

Acciaro M, Vanelslander T, Sys C et al (2014) Environmental sustainability in seaports: a framework for successful innovation. Marit Policy Manag 41:480–500. https://doi.org/10.1080/03088839.2014.932926

Alphaliner (2020a) “VLCS fleet by year of delivery” and “trade capacity breakdown by carrier”. Monthly Monitor, July, 2020

Alphaliner (2020b) HMM megamax deliveries deferred - but only slightly. Weekly Newsletter, 2020, Issue 17, pp 2–3

Alphaliner (2021) Trade capacity breakdown by carrier. Monthly Monitor, May 2021

Ballini F, Bozzo R (2015) Air pollution from ships in ports: the socio-economic benefit of cold-ironing technology. Res Transp Bus Manag 17:92–98. https://doi.org/10.1016/j.rtbm.2015.10.007

Buber M, Toz AC, Sakar C, Koseoglu B (2020) Mapping the spatial distribution of emissions from domestic shipping in Izmir Bay. Ocean Eng 210:107576. https://doi.org/10.1016/j.oceaneng.2020.107576

Chang CC, Wang CM (2012) Evaluating the effects of green port policy: case study of Kaohsiung harbor in Taiwan. Transp Res D Trans Environ 17:185–189. https://doi.org/10.1016/j.trd.2011.11.006

Corbett JJ, Koehler HW (2003) Updated emissions from ocean shipping. J Geophys Res Atmos 108:4650–4666. https://doi.org/10.1029/2003JD003751

Corporate Sustainability (2020) Website of China COSCO shipping. https://lines.coscoshipping.com/lines_resource/pdf/quality2019en.pdf. Accessed 19 June 2022

Corporate Sustainability (2021) Website of evergreen marine corp. https://csr.evergreen-marine.com/csr/tw/jsp/CSR_SustainableShipping.jsp. Accessed 19 June 2022

Country Meters (2021) World population. https://countrymeters.info/cn/World. Accessed 8 June 2022

Dere C, Deniz C (2019) Load optimization of central cooling system pumps of a container ship for the slow steaming conditions to enhance the energy efficiency. J Clean Prod 222:206–217. https://doi.org/10.1016/j.jclepro.2019.03.030

Du Y, Chen Q, Quan X, Long L, Fung RYK (2011) Berth allocation considering fuel consumption and vessel emissions. Transp Res E Logist Transp Rev 47:1021–1037. https://doi.org/10.1016/j.tre.2011.05.011

Gibbs D, Rigot-Muller P, Mangan J, Lalwani C (2014) The role of sea ports in end-to-end maritime transport chain emissions. Energy Policy 64:337–348. https://doi.org/10.1016/j.enpol.2013.09.024

Gong M, Zhen S, Liu H (2021) Research on the nonlinear dynamic relationship between FDI and CO2 emissions in the “one belt, one road” countries. Environ Sci Pollut Res 28:27942–27953. https://doi.org/10.1007/s11356-021-12532-6

Hafeez M, Yuan C, Shahzad K, Aziz B, Iqbal K, Naqvi SSR (2019) An empirical evaluation of financial development-carbon footprint nexus in one belt and road region. Environ Sci Pollut Res 26:25026–25036. https://doi.org/10.1007/s11356-019-05757-z

IMO (2018) International maritime organization. Initial IMO strategy on reduction of GHG [Greenhouse Gas] Emissions from Ships. MEPC 72/17/Add.1. Annex 11. APRIL. IMO, London

International Monetary Fund (2021) World economic outlook database. https://www.imf.org/en/Publications/WEO/weo-database/2021/April. Accessed 20 May 2022

Li S, Fung KS (2019) Maritime Autonomous Surface Ships (MASS): implementation and legal issues. Marit Bus Rev 4:330–339. https://doi.org/10.1108/MABR-01-2019-0006

Liao CH, Tseng PH, Lu CS (2009) Comparing carbon dioxide emissions of trucking and intermodal container transport in Taiwan. Transp Res D Trans Environ 14:493–496. https://doi.org/10.1016/j.trd.2009.05.002

Liu D, Ge YE (2018) Modeling assignment of quay cranes using queueing theory for minimizing CO2 emission at a container terminal. Transp Res D Trans Environ 61:140–151. https://doi.org/10.1016/j.trd.2017.06.006

MOTC (2016) Ministry of transportation and communication, a study of adaptive capacity strengthened for Taiwan container ports. MOTC-IOT-104-H1DB005a. Institute of Transportation, Taiwan. Accessed 25 May 2022

Olukanni DO, Esu CO (2018) Estimating greenhouse gas emissions from port vessel operations at the Lagos and Tin Can ports of Nigeria. Cogent Eng 5:1507267. https://doi.org/10.1080/23311916.2018.1507267

Schinas O, Ross HH, Rossol TD (2018) Financing green ships through export credit schemes. Transp Res D Trans Environ 65:300–311. https://doi.org/10.1016/j.trd.2018.08.013

Song DP, Xu J (2012) An operational activity-based method to estimate CO2 emissions from container shipping considering empty container repositioning. Transp Res D Trans Environ 17:91–96. https://doi.org/10.1016/j.trd.2011.06.007

Tai HH (2015) A comparative study on pollutant emissions and hub-port selection in Panama Canal expansion. Marit Econ Logist 17:163–178. https://doi.org/10.1057/mel.2014.15

Tai HH, Lin DY (2013) Comparing the unit emissions of daily frequency and slow steaming strategies on trunk route deployment in international container shipping. Transp Res D Trans Environ 21:26–31. https://doi.org/10.1016/j.trd.2013.02.009

Tai HH, Lin DY (2016) The impact of trunk route deployment changes on pollutant emissions in international container shipping after Panama Canal expansion. Int J Logist Manag 27:335–352. https://doi.org/10.1108/IJLM-09-2014-0142

Tezdogan T, Incecik A, Turan O, Kellett P (2016) Assessing the impact of a slow steaming approach on reducing the fuel consumption of a containership advancing in head seas. Transp Res Proc 14:1659–1668. https://doi.org/10.1016/j.trpro.2016.05.131

Tsai TY, Tai HH (2019) The evaluation of competitiveness on cost advantage of regional hub port: the case study of trans-pacific route against Kaohsiung port. J Mar Eng Technol 161:A381–A400. https://doi.org/10.3940/rina.ijme.2019.a4.544

UNCTAD (2019~2020) Review of maritime transport, 2019~2200. United Nations conference on trade and development. United Nations Publication, New York and Geneva

Venturini G, Iris C, Kontovas CA, Larsen A (2017) The multi-port Berth allocation problem with speed optimization and emission considerations. Transp Res D Trans Environ 54:142–159. https://doi.org/10.1016/j.trd.2017.05.002

Wang C, Jiao Y (2021) Shipping companies’ choice of low sulfur fuel oil with government subsidy and different maritime supply chain power structures. Marit Policy Manag 1–24. https://doi.org/10.1080/03088839.2021.1950860

Wang J, Huang Q, Lin X, Yu M (2021) Container terminal competition and cooperation considering emission tax. Marit Policy Manag 1–24https://doi.org/10.1080/03088839.2021.1914875

Xing H, Spence S, Chen H (2020) A comprehensive review on countermeasures for CO2 emissions from ships. Renew Sustain Energy Rev 134:110222. https://doi.org/10.1016/j.rser.2020.110222

Yang X, Bai G, Schmidhalter R (2011) Shore to ship converter system for energy saving and emission reduction. 8th International Conference on Power Electronics - ECCE Asia, Jeju, Korea (South), pp 2081–2086, https://doi.org/10.1109/ICPE.2011.5944522. Accessed 30 June 2022

Zakaria NMG, Rahman S (2017) Energy Efficiency Design Index (EEDI) for Inland vessels in Bangladesh. Procedia Eng 194:362–369. https://doi.org/10.1016/j.proeng.2017.08.158

Zhao Y, Fan Y, Fagerholt K, Zhou J (2021) Reducing sulfur and nitrogen emissions in shipping economically. Transp Res D Trans Environ D 90:102641. https://doi.org/10.1016/j.trd.2020.102641

Funding

This research was supported by the Ministry of Science and Technology, Taiwan, under Project No. MOST 110–2410-H-992–034.

Author information

Authors and Affiliations

Contributions

Hui-Huang Tai: conceptualization, methodology, project administration, resources, software, supervision, and writing—review and editing. Yu-Meng Wang: data curation, formal analysis, investigation, visualization, validation, and writing—original draft.

Corresponding author

Ethics declarations

Ethical approval

The authors of this article consent to the ESPR’s general principles for ethical approval.

Consent to participate

The authors of this article consent to participate in the research process and design.

Consent for publication

The authors of this article consent to publish after receiving the acceptance from ESPR.

Competing interests

The authors declare no competing interests.

Additional information

Responsible Editor: Philippe Garrigues

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Tai, HH., Wang, YM. Influence of vessel upsizing on pollution emissions along Far East–Europe trunk routes. Environ Sci Pollut Res 29, 65322–65333 (2022). https://doi.org/10.1007/s11356-022-20390-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11356-022-20390-z