Abstract

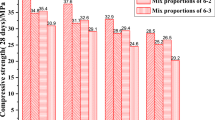

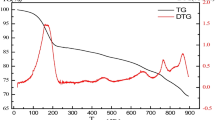

The feasibility of coordinated use of water-based drilling cuttings (WDC), fly ash, and phosphogypsum (PG) as raw materials for the preparation of WDC non-autoclaved aerated concrete (WNAAC) was evaluated by laboratory experiment. The results showed that the pozzolanic reaction of the multi-component cementitious system containing 40% (in mass) of WDC is significantly promoted. Newly formed C-S-H gel and ettringite with the uniform distribution of fibrous and flake-like shape occur, presenting a denser and interlock microstructure. In addition, after cured by steam at 80 °C for 24 h, the mechanical property and unit weight of the WNAAC prepared with 40% WDC fully meet the B06, A3.5 grade of China state standard (GB/T11968-2006). Environmental performance tests confirm that the WNAAC prepared with 40% WDC does not create any secondary contamination.

Similar content being viewed by others

References

Alam I, Ameen MA, Rehman F (2015) Partial replacement of cement by phosphogypsum in concrete. N Asian Int Res J Sci Eng I.T 1(2):1–11

Antemir A, Hills CD, Carey PJ, Magnie MC, Polettini A (2010) Investigation of 4-year-old stabilised/solidied and accelerated carbonated contaminated soil. J Hazard Mater 181:543–555

Chen Q, Zhang Q, Fourie A, Xin C (2017) Utilization of phosphogypsum and phosphate tailings for cemented paste backfill. J Environ Manag 201:19–27

Famy C, Brough AR, Taylor HFW (2003) The C-S-H gel of Portland cement mortars: Part I. The interpretation of energy-dispersive X-ray microanalyses from scanning electron microscopy, with some observations on C-S-H, AFm and AFt phase compositions. Cem Concr Res 33:1389–1398

Galvín AP, Agrela F, Ayuso J, Beltran MG, Barbudo A (2014) Leaching assessment of concrete made of recycled coarse aggregate: physical and environmental characterisation of aggregates and hardened concrete. Waste Manag 34:1693–1704

Garg M, Minocha AK, Jain N (2011) Environment hazard mitigation of waste gypsum and chalk: use in construction materials. Constr Build Mater 25:944–949

Huang Y, Lu J, Chen F, Shui Z (2016) The chloride permeability of persulphated phosphogypsum-slag cement concrete. J Wuhan Univ Technol Mater Sci Ed:1031–1037. https://doi.org/10.1007/s11595-016-1486-5

Leonard SA, Stegemann JA (2010) Stabilization/solidification of petroleum drill cuttings: leaching studies. J Hazard Mater 174:484–491

Li XB, Zhou ZL, Zhao GY, Liu ZX (2008) Utilization of phosphogypsum for backfilling, way to relieve its environmental impact. Gospod Surowcami Min 24(4):225–232

Liu D-s, Wang C-q, Mei X-d, Zhang C (2018) Environmental performance, mechanical and microstructure analysis of non-fired bricks containing water-based drilling cuttings of shale gas. Constr Build Mater 183:215–225

Ma B, Lu W, Su Y, Li Y, Gao C, He X (2018) Synthesis of α-hemihydrate gypsum from cleaner phosphogypsum. J Clean Prod 195:396–405

Mun KJ, Hyoung WK, Lee CW, So SY, Soh YS (2007) Basic properties of non-sintering cement using phosphogypsum and waste lime as activator. Constr Build Mater 21:1342–1350

Nigade S, Bagade M (2015) An experimental investigation of partial replacement of cement by various percentage of phosphogypsum in cement concrete with different water cement ratio. Int J Innov Sci Eng Technol 2(3):347–349

Shen W, Gan G, Dong R, Chen H, Tan Y, Zhou M (2012) Utilization of solidified phosphogypsum as Portland cement retarder. J Mater Cycles Waste Manag 14:228–233

Shen Y, Qian J, Chai J, Fan Y (2014) Calcium sulphoaluminate cements mad with phosphogypsum: production issues and material properties. Cem Concr Compos 48:67–74

Sheng Z, Zhou J, Zhu S, Yakubu Y, Chen Y, Wang W (2018) Calcium sulfate whisker reinforced non-fired ceramic tiles prepared from phosphogypsum. Bol Soc Española Cerámica Vidrio 57:73–78

Taher MA (2007) Influence of thermally treated phosphogypsum on the properties of Portland slag cement. Resour Conserv Recycl 52:28–38

Taylor HFW (1986) Proposed structure for calcium silicate hydrates gel. J Eur Ceram Soc 69:464–467

Türkel S, Aksin E (2012) A comparative study on the use of fly ash and phosphogypsum in the brick production. Indian Acad Sci Sādhanā 37(5):595–607

Wang XM, Zhao B, Zhang QL (2009) Cemented backfill technology based on phosphorous gypsum. J Cent South Univ T 16(2):285–291

Wang C-q, Lin X-y, Zhang C, Mei X-D (2017) Environmental security control of resource utilization of shale gas’ drilling cuttings containing heavy metals. Environ Sci Pollut Res 24(27):21973–21983

Yang L, Zhang Y, Yan Y (2016) Utilization of original phosphogypsum as raw material for the preparation of self-leveling mortar. J Clean Prod 127:204–213

Zhou J, Yu D, Shu Z, Li T, Chen Y, Wang Y (2014) A novel two-step hydration process of preparing cement-free non-fired bricks from waste phosphogypsum. Constr Build Mater Constr Build Mater 73:222–228

Author information

Authors and Affiliations

Corresponding author

Additional information

Responsible Editor: Philippe Garrigues

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Wang, Cq., Mei, Xd., Zhang, C. et al. Mechanism study on co-processing of water-based drilling cuttings and phosphogypsum in non-autoclaved aerated concrete. Environ Sci Pollut Res 27, 23364–23368 (2020). https://doi.org/10.1007/s11356-020-09029-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11356-020-09029-z