Abstract

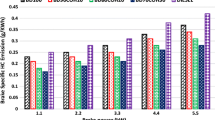

In the present experimental analysis, two non-edible oils namely neem oil and pumpkin seed oil were considered. They are converted into respective biodiesels namely neem oil methyl ester (B1) and pumpkin seed oil methyl ester (B2) through transesterification process and their physical and chemical properties were examined using ASTM standards. Diesel was used as a baseline fuel in Kirloskar TV1 model direct injection four stroke diesel engine. A fuel preheater was designed and fabricated to operate at various temperatures (60, 70, and 80 °C). Diesel showed higher brake thermal efficiency (BTE) than biodiesel samples. Lower brake specific fuel consumption (BSFC) was obtained with diesel than B1 sample. B1 exhibited lower BSFC than B2 sample without preheating process. High preheating temperature (80 °C) results in lower fuel consumption for B1 sample. The engine emission characteristics like carbon monoxide (CO), hydrocarbon (HC), and smoke were found lower with B1 sample than diesel and B2 except oxides of nitrogen (NOx) emission. In preheating of fuel, B1 sample with high preheating temperature showed lower CO, HC, and smoke emission (except NOx) than B2 sample.

Similar content being viewed by others

Abbreviations

- ASTM:

-

American Society for Testing and Materials

- D:

-

100% diesel

- B1:

-

100% neem oil methyl ester

- B2:

-

100% pumpkin seed oil methyl ester

- DI:

-

Direct injection

- HE:

-

Heat exchanger

- WPH:

-

Without preheating

- PH-60 °C:

-

Preheating at 60 °C

- PH-70 °C:

-

Preheating at 70 °C

- PH-80 °C:

-

Preheating at 80 °C

- BTE:

-

Brake thermal efficiency

- BSFC:

-

Brake specific fuel consumption

- CO:

-

Carbon monoxide

- HC:

-

Hydrocarbon

- NOx:

-

Oxides of nitrogen

References

Agarwal D, Agarwal AK (2007) Performance and emissions characteristics of Jatropha oil ( preheated and blends ) in a direct injection compression ignition engine. Appl Therm Eng 27(13):2314–2323. https://doi.org/10.1016/j.applthermaleng.2007.01.009

Ashok B, Thundil Karuppa Raj R, Nanthagopal K, Krishnan R, Subbarao R (2017) Lemon peel oil—a novel renewable alternative energy source for diesel engine. Energy Convers Manag 139:110–121. https://doi.org/10.1016/j.enconman.2017.02.049

Balaji G, Cheralathan M (2014) Study of antioxidant effect on oxidation stability and emissions in a methyl ester of neem oil fuelled di diesel engine. J Energy Inst 87(3):188–195. https://doi.org/10.1016/j.joei.2014.03.018

Balaji G, Cheralathan M (2015) Experimental investigation of antioxidant effect on oxidation stability and emissions in a methyl ester of neem oil fueled DI diesel engine. Renew Energy 74:910–916. https://doi.org/10.1016/j.renene.2014.09.019

Hazar H, Aydin H (2010) Performance and emission evaluation of a CI engine fueled with preheated raw rapeseed oil (RRO)–diesel blends. Appl Energy 87(3):786–790. https://doi.org/10.1016/j.apenergy.2009.05.021

Holman JP (2007) Experimental techniques for engineers, 7th edn. Tata MCGraw Hill, New Delhi

Kakati J, Gogoi TK, Pakshirajan K (2017) Production of biodiesel from Amari (Amoora Wallichii King) tree seeds using optimum process parameters and its characterization. Energy Convers Manag 135:281–290. https://doi.org/10.1016/j.enconman.2016.12.087

Karabektas M, Ergen G, Hosoz M (2008) The effects of preheated cottonseed oil methyl ester on the performance and exhaust emissions of a diesel engine. Appl Therm Eng 28(17-18):2136–2143. https://doi.org/10.1016/j.applthermaleng.2007.12.016

Karmee SK (2017) Enzymatic biodiesel production from Manilkara zapota (L.) seed oil. Waste Biomass Valoriz 0:0. https://doi.org/10.1007/s12649-017-9854-8

Karthickeyan V (2017) Impact of partially stabilised zirconia on a single-cylinder diesel engine’s performance, using orange oil methyl ester biodiesel. Int J Ambient Energy 0:1–10. https://doi.org/10.1080/01430750.2017.1341429

Karthickeyan V, Arulraj P (2014) Experimental investigation on emission characteristics of catalytic converter using different wash coat material. Appl Mech Mater 550:62–70. https://doi.org/10.4028/www.scientific.net/AMM.550.62

Karthickeyan V, Balamurugan P (2017a) Effect of thermal barrier coating with various blends of pumpkin seed oil methyl ester in DI diesel engine. Heat Mass Transf 53(10):1–14. https://doi.org/10.1007/s00231-017-2058-8

Karthickeyan V, Balamurugan P (2017b) Studies on piston bowl geometries using single blend ratio of various non-edible oils. Environ Sci Pollut Res 24(20):17068–17080. https://doi.org/10.1007/s11356-017-9344-3

Karthickeyan V, Balamurugan P, Senthil R (2015a) Investigation of CI engine fueled with ethanol nano additives blended diesel. Proc First Int Conf Recent Adv Bioenergy Res 1:121–130. https://doi.org/10.1007/978-81-322-2773-1

Karthickeyan V, Balamurugan P, Senthil R (2015b) Experimental investigation of tyre pyrolysis oil (TPO) in diesel engine without any engine modification. J Biofuels Bioenergy 1(2):170–183. https://doi.org/10.5958/2454-8618.2015.00018.8

Karthickeyan V, Balamurugan P, Senthil R (2016a) Production of orange oil methyl ester and experimental investigation on thermal barrier coated diesel engine. Asian J Res Soc Sci Humanit 6(8):156–178. https://doi.org/10.5958/2249-7315.2016.00601.8

Karthickeyan V, Balamurugan P, Senthil R (2016b) Studies on orange oil methyl ester in diesel engine with hemispherical and toroidal combustion chamber. Therm Sci 20(suppl. 4):981–989. https://doi.org/10.2298/TSCI16S4981K

Karthickeyan V, Balamurugan P, Rohith G, Senthil R (2017a) Developing of ANN model for prediction of performance and emission characteristics of VCR engine with orange oil biodiesel blends. J Braz Soc Mech Sci Eng 39(7):1–12. https://doi.org/10.1007/s40430-017-0768-y

Karthickeyan V, Balamurugan P, Senthil R (2017b) Comparative studies on emission reduction in thermal barrier coated engine using single blend ratio of various non-edible oils. J Braz Soc Mech Sci Eng 39(5):1823–1833. https://doi.org/10.1007/s40430-016-0645-0

Karthickeyan V, Balamurugan P, Senthil R (2017c) Investigation on environmental effects of thermal barrier coating with waste cooking palm oil methyl ester blends in diesel engine. Biofuels 1–14. https://doi.org/10.1080/17597269.2017.1316142

Kumar MS, Kerihuel A, Bellettre J, Tazerout M (2005) Experimental investigations on the use of preheated animal fat as fuel in a compression ignition engine. Renew Energy 30(9):1443–1456. https://doi.org/10.1016/j.renene.2004.11.003

Parida MK, Rout AK (2017) Investigation of performance and emission analysis of Argemone mexicana biodiesel blends as a fuel in a DICI engine at part load conditions. Energy Sources, Part A Recover Util Environ Eff 39(6):623–629. https://doi.org/10.1080/15567036.2016.1252812

Pradhan P, Raheman H, Padhee D (2014) Combustion and performance of a diesel engine with preheated Jatropha curcas oil using waste heat from exhaust gas. Fuel 115:527–533. https://doi.org/10.1016/j.fuel.2013.07.067

Sathiyamoorthi R, Sankaranarayanan G, Pitchandi K (2017) Combined effect of nanoemulsion and EGR on combustion and emission characteristics of neat lemongrass oil (LGO)-DEE-diesel blend fuelled diesel engine. Appl Therm Eng 112:1421–1432. https://doi.org/10.1016/j.applthermaleng.2016.10.179

Schinas P, Karavalakis GÃ, Davaris C et al (2009) Pumpkin (Cucurbita pepo L.) seed oil as an alternative feedstock for the production of biodiesel in Greece. Biomass Bioenergy 33(1):44–49. https://doi.org/10.1016/j.biombioe.2008.04.008

Singh B, Kumar N, Du Y, Bae K (2010) Performance and emission study of preheated Jatropha oil on medium capacity diesel engine. Energy 35(6):2484–2492. https://doi.org/10.1016/j.energy.2010.02.043

Sivalakshmi S, Balusamy T (2012) Influence of ethanol addition on a diesel engine fuelled with neem oil methyl ester. Int J Green Energy 9(3):218–228. https://doi.org/10.1080/15435075.2011.621477

Sivalakshmi S, Balusamy T (2014) The performance, combustion, and emission characteristics of neem oil methyl ester and its diesel blends in a diesel engine. Energy Sources, Part A Recover, Util, Environ Eff 36(2):142–149. https://doi.org/10.1080/15567036.2011.582614

Tamilselvan P, Nallusamy N (2017) Reduced emissions using blends of diesel fuel and Chicha oil biodiesel. Energy Sources, Part A Recover Util Environ Eff 1–6. https://doi.org/10.1080/15567036.2017.1289281

Yadav AK, Khan ME, Pal A, Dubey AM (2017) Experimental investigations of performance and emissions characteristics of Kusum (Schleichera oleosa) biodiesel in a multi-cylinder transportation diesel engine. Waste Biomass Valorization 8(4):1331–1341. https://doi.org/10.1007/s12649-016-9658-2

Funding

The authors would like to express their thanks to the University Grants Commission-South Eastern Regional Office, Hyderabad, India, for financial support through Minor research project for teachers with grant number 4-4/2013-14 (MRP-SEM/UGC-SERO).

Author information

Authors and Affiliations

Corresponding author

Additional information

Responsible editor: Philippe Garrigues

Highlights

• Neat neem oil and pumpkin seed oil were considered as a prime source for the biodiesel production and investigated in the diesel engine.

• The application of preheater technique tends to improve the performance and emission characteristics of biodiesels.

• For neat biodiesels, the improved performance characteristics were observed with high preheating temperature.

• Lower CO, HC, and smoke emissions were observed with preheating of fuels.

Rights and permissions

About this article

Cite this article

Ramakrishnan, M., Rathinam, T.M. & Viswanathan, K. Comparative studies on the performance and emissions of a direct injection diesel engine fueled with neem oil and pumpkin seed oil biodiesel with and without fuel preheater. Environ Sci Pollut Res 25, 4621–4631 (2018). https://doi.org/10.1007/s11356-017-0838-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11356-017-0838-9