Abstract

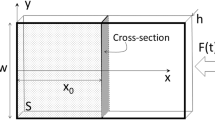

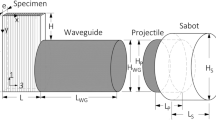

In the present work Image-Based Inertial Impact (IBII) tests are performed on Ti6Al4V material. The IBII test uses an impact on the edge of the specimen to generate a short pulse that loads the specimen. Three specimen geometries have been tested: a classic rectangular specimen, and two specimen geometries with stress concentrating geometries (i.e. a hole and notches) to enhance high levels of plastic strain. Full-field measurement of the acceleration and strain are successfully used in combination with the Virtual Fields Method (VFM) to identify the strain rate sensitivity parameter of the Johnson-Cook model. The strain/strain rate spectra covered by each specimen are analysed. Finally, the influence of the virtual field used in the identification process is discussed as well as the simultaneous identification of the Johnson-Cook model strain rate sensitivity parameter and the strain rate threshold parameter.

Similar content being viewed by others

References

ASTM E8 - 04 (2004) Standard test methods for tension testing of metallic materials, ASTM International, West Conshohocken, PA

Markiewicz E, Langrand B, Notta-Cuvier D (2017) A review of characterisation and parameters identification of materials constitutive and damage models: From normalised direct approach to most advanced inverse problem resolution. Int J Impact Eng 110:371–381

Avril S, Bonnet M, Bretelle A S, Grédiac M, Hild F, Ienny P, Latourte F, Lemosse D, Pagano S, Pagnacco E, Pierron F (2008) Overview of identification methods of mechanical parameters based on full-field measurements. Exp Mech 48:381–402

Grédiac M, Hild F (2012) Full-Field Measurements and Identification in Solid Mechanics. ISTE Wiley

Zhang L, Thakku S G, Beotra M R, Baskaran M, Aung T, Goh J C H, Strouthidis N G, Girard M J A (2017) Verification of a virtual fields method to extract the mechanical properties of human optic nerve head tissues in vivo. Biomechanics and Modeling in Mechanobiology 16(3):871–887

Martins J M P, Andrade-Campos A, Thuillier S (2018) Comparison of inverse identification strategies for constitutive mechanical models using full-field measurements. Int J Mech Sci 145:330–345

Pierron F, Grédiac M (2012) The virtual fields method: Extracting constitutive mechanical parameters from full-field deformation measurements. Springer, New York

Moulart R, Pierron F, Hallett S R, Wisnom M R (2011) Full-field strain measurement and identification of composites moduli at high strain rate with the virtual fields method. Exp Mech 51:509–536

Notta-Cuvier D, Langrand B, Markiewicz E, Lauro F, Portemont G (2013) Identification of Johnson-Cook’s viscoplastic model parameters using the virtual fields method : Application to titanium alloy Ti6Al4V. Strain 49:22–45

Valeri G, Koohbor B, Kidane A, Sutton M A (2017) Determining the tensile response of materials at high temperature using DIC and the virtual fields method. Optics and Lasers in Engineering 91:53–61

Koohbor B, Kidane A, Sutton M A, Zhao X, Mallon S (2017) Analysis of dynamic bending test using Ultra High Speed DIC and the virtual fields method. Int J Impact Eng 110:299–310. Special Issue in honor of Seventy Fifth Birthday of Professor N. K. Gupta

Koohbor B, Kidane A, Sutton M A, Zhao X, Mallon S (2018) Corrigendum to “Analysis of dynamic bending test using Ultra High Speed DIC and the Virtual Fields Method” [Int. J. Impact Eng. 110 (2017) 299–310]. Int J Impact Eng 116:127–128

Pierron F, Sutton M A, Tiwari V (2010) Ultra high Speed DIC and virtual fields method analysis of a three point bending impact test on a aluminium bar. Exp Mech 51:537–563

Pierron F, Zhu H, Siviour C (2014) Beyond Hopkinson’s bar. Philosophical Transactions of the Royal Society of London A: Mathematical, Physical and Engineering Sciences, 372

Dreuilhe S (2017) Development of novel inertial tests for the identification of non-linear material model parameters at high strain rates. University of Southampton, PhD thesis

Bouda P, Langrand B, Notta-Cuvier D, Markiewicz E, Pierron F (2019) A computational approach to design new tests for viscoplasticity characterization at high strain-rates. Computational Mechanics

Fletcher L, Pierron F (2018) An image-based inertial impact (IBII) test for tungsten carbide cermets. Journal of Dynamic Behavior of Materials

Avril S, Pierron F, Sutton M A, Yan J (2008) Identification of elasto-visco-plastic parameters and characterization of Lüders behavior using digital image correlation and the virtual fields method. Mech Mater 40:729–742

Pierron F, Avril S, Tran VT (2010) Extension of the virtual fields method to elasto-plastic material identification with cyclic loads and kinematic hardening. International Journal of Solids and Structures, 47:2993–3010

Notta-Cuvier D, Langrand B, Lauro F, Markiewicz E (2015) An innovative procedure for characterising a coupled elastoplastic damage model of behaviour using the virtual fields method. International Journal of Solids and Structures 69-70:415–427

Pierron F, Forquin P (2012) Ultra-high-speed full-field deformation measurements on concrete spalling specimens and stiffness identification with the virtual fields method. Strain 48:388–405

Yoon S-H, Winters M, Siviour C R (2016) High strain-rate tensile characterization of EPDM rubber using non-equilibrium loading and the virtual fields method. Experimental Mechanics 56:25–25

Van Blitterswyk J, Fletcher L, Pierron F (2018) Image-based inertial impact test for composite interlaminar tensile properties. Journal of Dynamic Behavior of Materials. Available online

Le Louëdec G, Pierron F, Sutton M A, Siviour C, Reynolds A P (2015) Identification of the dynamic properties of Al 5456 FSW welds using the virtual fields method. Journal of Dynamic Behavior of Materials 1(2):176–190

Grédiac M, Blaysat B, Sur F (2017) A critical comparison of some metrological parameters characterizing local digital image correlation and grid method. Exp Mech 57(6):871–903

Grédiac M, Sur F, Blaysat B (2016) The grid method for in-plane displacement and strain measurement: A review and analysis. Strain 52(3):205–243

Abdul-Rahman H, Gdeisat M, Burton D, Lalor M (2005) Fast three-dimensional phase-unwrapping algorithm based on sorting by reliability following a non-continuous path. In: Proc SPIE, vol 5856, pp 32–40

Holoborodko P (n.d) Smooth noise-robust differentiators. Retrieved from http://www.holoborodko.com/pavel/numerical-methods/noise-robust-smoothing-filters/ http://www.holoborodko.com/pavel/numerical-methods/noise-robust-smoothing-filters/

Surrel Y (2018) Grid printing part I. http://photodyn.org/wp-content/uploads/2016/03/Report_UniversityPrintCentre.pdf

Surrel Y (2018) Grid printing part II. http://photodyn.org/wp-content/uploads/2016/03/Report_UniversityPrintCentre_2.pdf

Bouda P (2019) Méthode des Champs Virtuels pour la caractérisation du comportement dynamique de matériaux métalliques sous chargement purement inertiel. Université Polytechnique Hauts-de-France, PhD thesis

Lemaitre J, Chaboche J L (1994) Mechanics of solid materials. Cambridge University Press, Cambridge

Zerilli F J, Armstrong R W (1987) Dislocation mechanics based constitutive relations for material dynamics calculations. J Appl Phys 61(5):1816–1825

Rusinek A, Klepaczko J R (2001) Shear testing of a sheet steel at wide range of strain rates and a constitutive relation with strain-rate and temperature dependence of the flow stress. International Journal of Plasticity 17 (1):87–115

Cowper GR, Symonds PS (1957) Strain-hardening and Strain-rate Effects in the Impact Loading of Cantilever Beams. Technical report (Brown University. Division of Applied Mathematics). Brown University, Division of Applied Mathematics

Johnson GR, Cook WH (1983) A constitutive model and data for metals subjected to large strains, high strain rates and high temperatures. Proceedings 7th International Symposium on Balistics, The Hague, The Netherlands, pp 541–547

Jones N (1990) Structural impact. Cambridge University Press, Cambridge

Holmquist T J, Johnson G R (1991) Determination of constants and comparison of results for various constitutive models, vol 01

Borvik T, Langseth M, Hopperstad O S, Malo K A (1999) Ballistic penetration of steel plates. International Journal of Impact Engineering 22:855–886

Gupta A K, Krishnamurthy H N, Puranik P, Singh S K, Balu A (2014) An exponential strain dependent Rusinek–Klepaczko model for flow stress prediction in austenitic stainless steel 304 at elevated temperatures. Journal of Materials Research and Technology 3(4):370–377

Iqbal M A, Senthil K, Sharma P, Gupta N K (2016) An investigation of the constitutive behavior of Armox 500T steel and armor piercing incendiary projectile material. International Journal of Impact Engineering 96:146–164

Meyer HW Jr, Kleponis D S (2001) Modeling the high strain rate behavior of titanium undergoing ballistic impact and penetration. International Journal of Impact Engineering 26:509–521

Peirs J, Verleysen P, Van Paepegem W, Degrieck J (2011) Determining the stress-strain behaviour at large strains from high strain rate tensile and shear experiments. International Journal of Impact Engineering 38:406–415

Mocko W, Brodecki A (2015) Application of optical field analysis of tensile tests for calibration of the Rusinek–Klepaczko constitutive relation of Ti6Al4V titanium alloy. Materials and Design 88:320–330

Hopkinson B (1914) A method of measuring the pressure produced in the detonation of high explosives of by the impact of bullets. Phil Trans R Soc A 213:437–456

Nicholas T (1981) Tensile testing of materials at high rates of strain. Exp Mech 21(5):177–185

Grédiac M, Pierron F, Avril S, Toussaint E (2006) The virtual fields method for extracting constitutive parameters from full-field measurements: A review. Strain 42:233–253

Hansen N, Ostermeier A (2001) Completely derandomized self-adaptation in evolution strategies. Evolutionary Computation 9(2):159–195

Marek A, Davis F M, Pierron F (2017) Sensitivity-based virtual fields for the non-linear virtual fields method. Comput Mech 60(3):409–431

Marek A, Davis F, Rossi M, Pierron F (2019) Extension of the sensitivity-based virtual fields to large deformation anisotropic plasticity. Int J Mater Form 12(3):457–476

Acknowledgments

The authors are grateful to Onera and the Région Hauts-de-France for cofunding this project. Prof. Pierron acknowledges support by EPSRC through grant EP/L026910/1.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Fourest, T., Bouda, P., Fletcher, L.C. et al. Image-Based Inertial Impact Test for Characterisation of Strain Rate Dependency of Ti6Al4V Titanium Alloy. Exp Mech 60, 235–248 (2020). https://doi.org/10.1007/s11340-019-00559-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11340-019-00559-3