Abstract

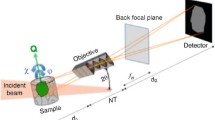

To understand the mesoscale mechanisms responsible for the behavior of heterogeneous materials and to validate models, it is important to experimentally measure the deformation and temperature fields at the microstructure level. So far, there has been no methods that can yield such measurements simultaneously for dynamic experiments. Here, we report the development of a novel capability for simultaneous time- and space-resolved recording of both fields over the same microstructure area of a sample with micron-level spatial resolutions and microsecond time resolutions. Referred to as MINTED (Microscale In-situ Imaging of Dynamic Temperature and Deformation Fields), the system cohesively integrates a high-speed visible light (VL) camera and a state-of-the-art high-speed infrared (IR) camera via a custom-designed dichroic beam splitter-lens assembly. The combined VL and IR images allow the deformation fields to be obtained through digital image correlation (DIC) and the temperature fields over the same area to be obtained through pixel-level calibration of the differing emissivities of heterogeneous constituents in microstructures. Experiments are conducted on granular sucrose in a Kolsky bar [or split-Hopkinson pressure bar (SHPB)] environment, yielding both microstructure level fields along with overall material response. The strain and temperature fields provide detailed first-time insight into the processes of fracture, friction, shear localization, and hotspot development in the microstructures.

Similar content being viewed by others

References

Hartley KA, Duffy J, Hawley RH (1987) Measurement of the temperature profile during shear band formation in steels deforming at high strain rates. J Mech Phys Solids 35(3):283–301. https://doi.org/10.1016/0022-5096(87)90009-3

Marchand A, Duffy J (1988) An experimental study of the formation process of adiabatic shear bands in a structural steel. J Mech Phys Solids 36(3):251–283. https://doi.org/10.1016/0022-5096(88)90012-9

Zhou M, Rosakis AJ, Ravichandran G (1996) Dynamically propagating shear bands in impact-loaded prenotched plates—I. Experimental investigations of temperature signatures and propagation speed. J Mech Phys Solids 44(6):981–1006. https://doi.org/10.1016/0022-5096(96)00003-8

Guduru PR, Rosakis AJ, Ravichandran G (2001) Dynamic shear bands: an investigation using high speed optical and infrared diagnostics. Mech Mater 33(7):371–402. https://doi.org/10.1016/S0167-6636(01)00051-5

Li Z, Lambros J (2001) Strain rate effects on the thermomechanical behavior of polymers. Int J Solids Struct 38(20):3549–3562. https://doi.org/10.1016/S0020-7683(00)00223-7

Li Z, Lambros J (2000) Dynamic thermomechanical behavior of fiber reinforced composites. Compos A: Appl Sci Manuf 31(6):537–547. https://doi.org/10.1016/S1359-835X(99)00102-5

Goretta KC, Park ET, Koritala RE, Cuber MM, Pascual EA, Chen N, de Arellano-López AR, Routbort JL (1998) Thermomechanical response of polycrystalline BaZrO3. Physica C 309(3):245–250. https://doi.org/10.1016/S0921-4534(98)00588-7

Mukherjee K, Sircar S, Dahotre NB (1985) Thermal effects associated with stress-induced martensitic transformation in a Ti-Ni alloy. Mater Sci Eng 74(1):75–84. https://doi.org/10.1016/0025-5416(85)90111-9

McCormick PG, Liu Y, Miyazaki S (1993) Intrinsic thermal-mechanical behaviour associated with the stress-induced martensitic transformation in NiTi. Mater Sci Eng A 167(1):51–56. https://doi.org/10.1016/0921-5093(93)90336-D

Field J, Bourne N, Palmer S, Walley S, Sharma J, Beard B (1992) Hot-spot ignition mechanisms for explosives and propellants [and discussion]. Philos Trans R Soc London A 339(1654):269–283. https://doi.org/10.1098/rsta.1992.0034

Field JE, Swallowe GM, Heavens SN (1982) Ignition mechanisms of explosives during mechanical deformation. Proc R Soc London A 382(1782):231–244. https://doi.org/10.1098/rspa.1982.0099

Tarver CM, Chidester SK, Nichols AL (1996) Critical conditions for impact- and shock-induced hot spots in solid explosives. J Phys Chem 100(14):5794–5799. https://doi.org/10.1021/jp953123s

Winter RE, Field JE (1975) The role of localized plastic flow in the impact initiation of explosives. Proc R Soc London A 343(1634):399–413. https://doi.org/10.1098/rspa.1975.0074

Guirguis RH (2000) Ignition due to macroscopic shear. AIP Conf Proc 505(1):647–650. https://doi.org/10.1063/1.1303556

Skidmore C, Phillips D, Asay B, Idar D, Howe P, Bolme D (2000) Microstructural effects in PBX 9501 damaged by shear impact. AIP Conf Proc 505(1):659–662. https://doi.org/10.1063/1.1303559

Menikoff R (2005) Elastic-plastic response of HMX. Research highlights.

Ravindran S, Tessema A, Kidane A (2017) Multiscale damage evolution in polymer bonded sugar under dynamic loading. Mech Mater 114:97–106. https://doi.org/10.1016/j.mechmat.2017.07.016

Bloomquist D, Sheffield S (1981) Shock-compression temperature rise in polymethyl methacrylate determined from resistivity of embedded copper foils. Appl Phys Lett 38(3):185–187. https://doi.org/10.1063/1.92272

Bloomquist D, Sheffield S (1980) Thermocouple temperature measurements in shock-compressed solids. J Appl Phys 51(10):5260–5266. https://doi.org/10.1063/1.327480

Boboridis K, Obst AW (2003) A high-speed four-channel infrared pyrometer. AIP Conf Proc 684(1):759–764. https://doi.org/10.1063/1.1627219

Long DA (1977) Raman spectroscopy. McGraw-Hill, New York

Yuan V, Bowman JD, Funk D, Morgan G, Rabie R, Ragan C, Quintana J, Stacy H (2005) Shock temperature measurement using neutron resonance spectroscopy. Phys Rev Lett 94(12):125504. https://doi.org/10.1103/PhysRevLett.94.125504

Dolan DH, Ao T, Seagle CT (2013) Reflectance thermometry in dynamic compression experiments. AIP Conf Proc 1552(1):767–770. https://doi.org/10.1063/1.4819639

Dolan DH, Seagle CT, Ao T (2013) Dynamic temperature measurements with embedded optical sensors. SANDIA report no SAND2013-8203.

Coffey C, Jacobs S (1981) Detection of local heating in impact or shock experiments with thermally sensitive films. J Appl Phys 52(11):6991–6993. https://doi.org/10.1063/1.328664

Zehnder AT, Rosakis AJ (1991) On the temperature distribution at the vicinity of dynamically propagating cracks in 4340 steel. J Mech Phys Solids 39(3):385-415. https://doi.org/10.1016/0022-5096(91)90019-K

Costin L, Crisman E, Hawley RH, Duffy J (1980) On the localisation of plastic flow in mild steel tubes under dynamic torsional loading. Proc 2nd Conf mechanical properties of materials at high rates of strain, Oxford, England, pp 90–100.

Soudre-Bau L, Meshaka Y, Parent G, Boulet P, Le Corre B, Jeandel G (2013) Combined temperature and deformation measurement during glass forming in a real scale setup. Exp Mech 53(9):1773–1781. https://doi.org/10.1007/s11340-013-9764-z

Bodelot L, Charkaluk E, Sabatier L, Dufrénoy P (2011) Experimental study of heterogeneities in strain and temperature fields at the microstructural level of polycrystalline metals through fully-coupled full-field measurements by digital image correlation and infrared thermography. Mech Mater 43(11):654–670. https://doi.org/10.1016/j.mechmat.2011.08.006

Bodelot L, Sabatier L, Charkaluk E, Dufrénoy P (2009) Experimental setup for fully coupled kinematic and thermal measurements at the microstructure scale of an AISI 316L steel. Mater Sci Eng A 501(1):52–60. https://doi.org/10.1016/j.msea.2008.09.053

Bertram Hopkinson FRS (1914) A method of measuring the pressure produced in the detonation of high, explosives or by the impact of bullets. Philos Trans R Soc London A 213(497-508):437–456. https://doi.org/10.1098/rsta.1914.0010

Kolsky H (1949) An investigation of the mechanical properties of materials at very high rates of loading. Proc Phys Soc B 62(11):676

Davies EDH, Hunter SC (1963) The dynamic compression testing of solids by the method of the split Hopkinson pressure bar. J Mech Phys Solids 11(3):155–179. https://doi.org/10.1016/0022-5096(63)90050-4

Staab GH, Gilat A (1991) A direct-tension split Hopkinson bar for high strain-rate testing. Exp Mech 31(3):232–235. https://doi.org/10.1007/bf02326065

Gilat A, Cheng C-S (2000) Torsional split Hopkinson bar tests at strain rates above 104s−1. Exp Mech 40(1):54–59. https://doi.org/10.1007/bf02327548

Hartley K, Duffy J, Hawley R (1985) The torsional Kolsky (split-Hopkinson) bar. Metals handbook 8:218–228.

Wang QZ, Li W, Xie HP (2009) Dynamic split tensile test of flattened Brazilian disc of rock with SHPB setup. Mech Mater 41(3):252–260. https://doi.org/10.1016/j.mechmat.2008.10.004

Grantham SG, Siviour CR, Proud WG, Field JE (2004) High-strain rate Brazilian testing of an explosive simulant using speckle metrology. Meas Sci Technol 15(9):1867. https://doi.org/10.1088/0957-0233/15/9/025

Jiang F, Vecchio KS (2009) Hopkinson bar loaded fracture experimental technique: a critical review of dynamic fracture toughness tests. Appl Mech Rev 62(6):060802-060839. https://doi.org/10.1115/1.3124647

Chen R, Xia K, Dai F, Lu F, Luo SN (2009) Determination of dynamic fracture parameters using a semi-circular bend technique in split Hopkinson pressure bar testing. Eng Fract Mech 76(9):1268–1276. https://doi.org/10.1016/j.engfracmech.2009.02.001

Wang QZ, Feng F, Ni M, Gou XP (2011) Measurement of mode I and mode II rock dynamic fracture toughness with cracked straight through flattened Brazilian disc impacted by split Hopkinson pressure bar. Eng Fract Mech 78(12):2455–2469. https://doi.org/10.1016/j.engfracmech.2011.06.004

Zhao H, Gary G (1997) A new method for the separation of waves. Application to the SHPB technique for an unlimited duration of measurement. J Mech Phys Solids 45(7):1185–1202. https://doi.org/10.1016/S0022-5096(96)00117-2

Bacon C (1998) An experimental method for considering dispersion and attenuation in a viscoelastic Hopkinson bar. Exp Mech 38(4):242–249. https://doi.org/10.1007/bf02410385

Bacon C (1999) Separation of waves propagating in an elastic or viscoelastic Hopkinson pressure bar with three-dimensional effects. Int J Impact Eng 22(1):55–69. https://doi.org/10.1016/S0734-743X(98)00048-7

Frew D, Forrestal MJ, Chen W (2001) A split Hopkinson pressure bar technique to determine compressive stress-strain data for rock materials. Exp Mech 41(1):40–46. https://doi.org/10.1007/BF02323102

Song B, Chen W (2004) Dynamic stress equilibration in split Hopkinson pressure bar tests on soft materials. Exp Mech 44(3):300–312. https://doi.org/10.1007/bf02427897

Othman R (2018) The Kolsky-Hopkinson bar machine: selected topics. Springer International Publishing, Cham.

Lindholm US (1964) Some experiments with the split hopkinson pressure bar. J Mech Phys Solids 12(5):317–335. https://doi.org/10.1016/0022-5096(64)90028-6

Noble JP, Goldthorpe BD, Church P, Harding J (1999) The use of the Hopkinson bar to validate constitutive relations at high rates of strain. J Mech Phys Solids 47(5):1187–1206. https://doi.org/10.1016/S0022-5096(97)00090-2

Chen JJ, Guo BQ, Liu HB, Liu H, Chen PW (2014) Dynamic Brazilian test of brittle materials using the Split Hopkinson pressure bar and digital image correlation. Strain 50(6):563–570. https://doi.org/10.1111/str.12118

Hudspeth M, Claus B, Dubelman S, Black J, Mondal A, Parab N, Funnell C, Hai F, Qi ML, Fezzaa K, Luo SN, Chen W (2013) High speed synchrotron x-ray phase contrast imaging of dynamic material response to split Hopkinson bar loading. Rev Sci Instrum 84(2):025102. https://doi.org/10.1063/1.4789780

Yeager JD, Higginbotham Duque AL, Shorty M, Bowden PR, Stull JA (2018) Development of inert density mock materials for HMX. J Energ Mater 36(3):253–265. https://doi.org/10.1080/07370652.2017.1375049

Ramos K, Bahr D (2007) Mechanical behavior assessment of sucrose using nanoindentation. J Mater Res 22(7):2037–2045. https://doi.org/10.1557/jmr.2007.0249

Hardman J, Lilley B (1970) Deformation of particles during briquetting. Nature 228(5269):353. https://doi.org/10.1038/228353b0

Huffine CL (1953) A study of the bonding and cohesion achieved in the compression of particulate materials. Columbia University, New York City.

Bridgman PW (1952) Physics of high pressure. Bell, London.

Blaber J, Adair B, Antoniou A (2015) Ncorr: open-source 2D digital image correlation Matlab software. Exp Mech 55(6):1105–1122. https://doi.org/10.1007/s11340-015-0009-1

Pan B (2009) Reliability-guided digital image correlation for image deformation measurement. Appl Opt 48(8):1535–1542. https://doi.org/10.1364/AO.48.001535

Pan B, Xie H, Guo Z, Hua T (2007) Full-field strain measurement using a two-dimensional Savitzky-Golay digital differentiator in digital image correlation. Opt Eng 46(3):033601. https://doi.org/10.1117/1.2714926

Rubino V, Rosakis AJ, Lapusta N (2017) Understanding dynamic friction through spontaneously evolving laboratory earthquakes. Nat Commun 8:15991. https://doi.org/10.1038/ncomms15991

Forsberg F, Siviour CR (2009) 3D deformation and strain analysis in compacted sugar using x-ray microtomography and digital volume correlation. Meas Sci Technol 20(9):095703. https://doi.org/10.1088/0957-0233/20/9/095703

Keyhani A, Kim S, Horie Y, Zhou M (2018) Energy dissipation in polymer-bonded explosives with various levels of constituent plasticity and internal friction. Comput Mater Sci 159:136–149. https://doi.org/10.1016/j.commatsci.2018.12.008

Acknowledgements

The authors gratefully acknowledge support from the Air Force Office of Scientific Research through grant FA9550-15-1-0499 (Dr. Martin Schmidt). Experiments were performed at the Dynamic Property Research Laboratory (DPRL) at Georgia Tech.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Keyhani, A., Yang, R. & Zhou, M. Novel Capability for Microscale In-situ Imaging of Temperature and Deformation Fields under Dynamic Loading. Exp Mech 59, 775–790 (2019). https://doi.org/10.1007/s11340-019-00495-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11340-019-00495-2