Abstract

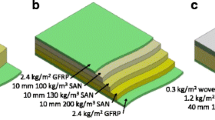

The dynamic behavior of two types of sandwich composites made of E-Glass Vinyl-Ester (EVE) facesheets and Corecell™ A-series foam with a polyurea interlayer was studied using a shock tube apparatus. The materials, as well as the core layer arrangements, were identical, with the only difference arising in the location of the polyurea interlayer. The foam core itself was layered with monotonically increasing wave impedance of the core layers, with the lowest wave impedance facing the shock loading. For configuration 1, the polyurea interlayer was placed behind the front facesheet, in front of the foam core, while in configuration 2 it was placed behind the foam core, in front of the back facesheet. A high-speed side-view camera, along with a high-speed back-view 3-D Digital Image Correlation (DIC) system, was utilized to capture the real time deformation process as well as mechanisms of failure. Post mortem analysis was also carried out to evaluate the overall blast performance of these two configurations. The results indicated that applying polyurea behind the foam core and in front of the back facesheet will reduce the back face deflection, particle velocity, and in-plane strain, thus improving the overall blast performance and maintaining structural integrity.

Similar content being viewed by others

References

Xue Z, Hutchinson JW (2003) Preliminary assessment of sandwich plates subject to blast loads. Int J Mech Sci 45:687–705

Fleck NA, Deshpande VS (2004) The resistance of clamped sandwich beams to shock loading. J Appl Mech 71:386–401

Dharmasena KP, Wadley HNG, Xue Z, Hutchinson JW (2008) Mechanical response of metallic honeycomb sandwich panel structures to high-intensity dynamic loading. Int J Imp Eng 35(9):1063–1074

Apetre NA, Sankar BV, Ambur DR (2006) Low-velocity impact response of sandwich beams with functionally graded core. Int J Solid Struct 43(9):2479–2496

Li Y, Ramesh KT, Chin ESC (2001) Dynamic characterization of layered and graded structures under impulsive loading. Int J Solid Struct 38(34–35):6045–6061

Wang E, Gardner N, Shukla A (2009) The blast resistance of sandwich composites with stepwise graded cores. Int J Solid Struct 46:3492–3502

Yi J, Boyce MC, Lee GF, Balizer E (2005) Large deformation rate-dependent stress-strain behavior of polyurea and polyurethanes. Poly 47(1):319–329

Amirkhizi AV, Isaacs J, McGee J, Nemat-Nasser S (2006) An experimentally-based constitutive model for polyurea, including pressure and temperature effects. Phil Mag 86(36):5847–5866

Hoo Fatt MS, Ouyang X, Dinan RJ (2004) Blast response of walls retrofitted with elastomer coatings. Struct Mater 15:129–138

Roland CM, Twigg JN, Vu Y, Mott PH (2006) High strain rate mechanical behavior of polyurea. Poly 48(2):574–578

Tekalur SA, Shukla A, Shivakumar K (2008) Blast resistance of polyurea based layered composite materials. Comp Struct 84:271–281

Bahei-El-Din YA, Dvorak GJ, Fredricksen OJ (2006) A blast-tolerant sandwich plate design with a polyurea interlayer. Int J Solid Struct 43:7644–7658

Amini MR, Isaacs JB, Nemat-Nasser S (2010) Experimental investigation of response of monolithic and bilayer plates to impulsive loading. Int J Imp Eng 37:82–89

Amini MR, Amirkhizi AV, Nemat-Nasser S (2010) Numerical modeling of response of monolithic and bilayer plates to impulsive loading. Int J Imp Eng 37:90–102

Amini MR, Isaacs JB, Nemat-Nasser S (2010) Numerical modeling of effect of polyurea on response of steel plates to impulsive loads in direct pressure-pulse experiments. Mech Mater 42:615–627

Amini MR, Isaacs JB, Nemat-Nasser S (2010) Investigation of effect of polyurea on response of steel plates to impulsive loads in direct pressure-pulse experiments. Mech Mater 42:628–639

http://www.gurit.com/page.asp?section=00010001002200160009§ionTitle=Corecell%99+A-Foam+–+For+Hulls+%26+Dynamic+Loading. Accessed 21 Dec 2010.

http://www.specialty-products.com/polyurea-products/Polyurea-Plural-Component-Coatings/dragonshield-ht-erc/. Accessed 21 Dec 2010.

Chen W, Zhang B, Forrestal MJ (1999) A split hopkinson bar technique for low impedance materials. Exp Mech 39(2):81–85

Liang Y, Spuskanyuk AV, Flores SE, Hayhurst DR, Hutchinson JW, McMeeking RM, Evans AG (2007) The response of metallic sandwich panels to water blast. J Appl Mech 74:81–99

Tilbrook MT, Deshpande VS, Fleck NA (2006) The impulsive response of sandwich beams: analytical and numerical investigation of regimes of behavior. J Mech Phys Sol 54:2242–2280

Wang E, Shukla A (2010) Analytical and experimental evaluation of energies during shock wave loading. Int J Imp Eng 37:1188–1196

Acknowledgement

The authors kindly acknowledge the financial support provided by Dr. Yapa D. S. Rajapakse, under Office of Naval Research Grant No. N00014-04-1-0268. The authors acknowledge the support provided by the Department of Homeland Security under Cooperative Agreement No. 2008-ST-061-ED0002. Authors thank Gurit SP Technology and Specialty Products Incorporated (SPI) for providing the material as well as Dr. Stephen Nolet and TPI Composites for providing the facility for creating the composites used in this study.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Gardner, N., Wang, E., Kumar, P. et al. Blast Mitigation in a Sandwich Composite Using Graded Core and Polyurea Interlayer. Exp Mech 52, 119–133 (2012). https://doi.org/10.1007/s11340-011-9517-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11340-011-9517-9