Abstract

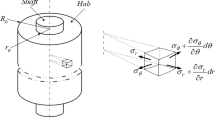

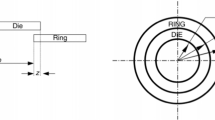

Shear stresses along the shaft/hub interface in shrink-fit components, generated by torsional loads, can drive premature failure through fretting mechanisms. It is difficult to numerically predict these shear stresses, and the associated circumferential slip along the shaft/hub interface, due to uncertainties in frictional behaviour and the presence of steep stress gradients which can cause meshing problems. This paper attempts to provide validation of a numerical modelling methodology, based on finite element analysis, so the procedure may be used with confidence in fitness-for-purpose cases. Very few experimental techniques offer the potential to make measurements of stress and residual stress interior to metallic components. Even fewer techniques provide the possibility of measuring shear stresses. This paper reports the results of neutron diffraction measurements of shear stress and residual shear stress in a bespoke test specimen containing a shrink-fit. One set of measurements was made with a torsional load ‘locked-in’. A second set of measurements was made to determine the residual shear stress when the torsional load had been applied and removed. Overall, measurement results were consistent with numerical models, but the necessity for a small test specimen to allow penetration of the neutron beam to the measurement locations meant the magnitude of shear stresses was at the limits of what could be measured experimentally.

Similar content being viewed by others

References

Kutz M (1986) Mechanical engineers’ handbook. Wiley, New York

Wick C, Veilleux RF (1987) Quality control and assembly—tool and manufacturing engineers handbook, vol 4. Society of Manufacturing Engineers, Dearborn

Timoshenko SP (1956) Strength of materials part II: advanced theory and problems, 3rd edn. Krieger, Malabar, pp 205–213

Hills DA, Barber JR, Sackfield A, Truman CE (2002) A shrink-fit shaft subject to torsion. Eur J Mech A - Solids 21(1):73–84

Sackfield A, Truman CE, Hills DA (2002) A stepped shrink-fitted shaft subject to torsion. IMechE C: J Mech Eng Sci 216:997–1004

Truman CE, Sackfield A, Hills DA (2002) Torsional loading of a finite shrink-fit shaft. IMechE C: J Mech Eng Sci 216:1109–1115

Booker JD, Truman CE, Wittig S, Mohammed Z (2004) A comparison of shrink-fit holding torque using probabilistic, micro-mechanical and experimental approaches. IMechE B: J Eng Manufacture 218:175–187

Truman CE, Booker JD (2007) Analysis of a shrink-fit failure on a gear hub/shaft assembly. Eng Fail Anal 14(4):557–572

Withers PJ, Bhadeshia HKDH (2001) Overview – residual stress part 1 – measurement techniques. Mat Sci Tech 17:355–365

Jones IA, Truman CE, Booker JD (2008) Photoelastic investigation of slippage in shrink-fit assemblies. Exp Mech. doi:10.1007/s11340-008-9140-6

BSI London (1970) BS970: part 3 specification for wrought steels for mechanical and allied engineering purposes. BSI, London

Bolz RW (ed) (1981) Production processes: the productivity handbook, 5th edn. Industrial, New York

BSI London (1970) BS4500A: specification for ISO limits and fits. Data sheet: selected ISO fits–hole basis. BSI, London

Beitz W, Kuttner KH (eds) (1993) Dubbel handbook of mechanical engineering. Springer, London

Furman TT (1981) Approximate methods in engineering design. Academic, London

Fitzpatrick ME (ed) (2003) Analysis of residual stress by diffraction using neutron and synchrotron radiation. Taylor and Francis, London

Stuhr U, Spitzer H, Egger J, Hofer A, Rasmussen P, Graf D, Bollhalder A, Schild M, Bauer G, Wagner W (2005) Time of flight diffraction with multiple frame overlap, part ii: the strain scanner poldi at psi. Nucl Instrum Methods A 545:330–338

Stuhr U (2005) Time of flight diffraction with multiple pulse overlap; part i: the concept. Nucl Instrum Methods A 545:319–329

Daymond MR, Bourke MAM, Von Dreele RB (1999) Use of rietveld refinement to fit a hexagonal crystal structure in the presence of elastic and plastic anisotropy. J Appl Phys 85(2):739–747

Booker JD, Raines M, Swift KG (2001) Designing capable and reliable products. Butterworth-Heinemann, Oxford

Winholtz RA, Krawitz AD (1996) Neutron measurement of triaxial residual stress tensors in an aerospace weldment before and after post-weld-heat-treatment. In: Trends in welding research, 4th international conference. Gatlinburg, Tennessee, pp 93–97

Acknowledgements

The authors would like to thank Dr A. Mahmoudi for his help in conducting the neutron measurements at ISIS. For this work we are grateful for the use of the experimental facilities at ISIS, Rutherford Appleton Laboratories and SINQ, Paul Scherrer Institute. This research project has been supported by the European Commission under the 6th Framework Programme through the Key Action: Strengthening the European Research Area, Research Infrastructures. Contract number: RII3-CT-2003-505925.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Lewis, S.J., Hossain, S., Booker, J.D. et al. Measurement of Torsionally Induced Shear Stresses in Shrink-Fit Assemblies. Exp Mech 49, 637–651 (2009). https://doi.org/10.1007/s11340-008-9175-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11340-008-9175-8