Abstract

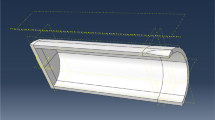

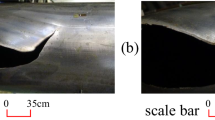

This paper presents the analysis of stress and strain data acquired with the finite element method and with tests that used post-yielding strain gages bonded onto the external surface of pipes that suffered thickness metal loss and that had been loaded with internal pressure. These metal loss areas were produced by three different processes: actual internal corrosion, careful machining of external patches by spark-erosion, and milling of internal or external patches to simulate limited or extensive strip corrosion defects with depths up to 70% of the pipe’s thickness. Results show that: (1) the extensive longitudinal internal or external defect areas behave as extensive strips with a high degree of freedom to deform elastically and plastically in the circumferential and thickness directions, and (2) large restraints are offered to the longitudinal strains by the non-corroded thick walls parallel to the strip. Using the above experimental observation, a simple mathematical model was developed to predict the burst pressure of pipes with longitudinal extensive and reasonably constant depths of metal loss. This model employed thin-pipe-strength-of-material equations associated to a bulging correction factor, the material’s uniaxial ultimate strength and the von Mises criterion. The onset of plastic collapse predicted by the simple model was successfully compared with results determined from actual hydrostatic tests that were carried out with full scale pipe specimens and from finite element results generated by the use of a commercial program. The developed model was also helpful in showing that the yield and burst behaviors of new or corroded pipeline specimens under laboratory test conditions can be directly compared and extended to the yield and burst behaviors of buried pipeline in field operation.

Similar content being viewed by others

References

Benjamin A, Vieira RD, Freire JLF, Castro JTP (2000) Burst tests on pipeline with long external corrosion. In: Proceedings of IPC 00, 2nd International Pipeline Conference, ASME Paper IPC2000 0087.

Freire JLF, Vieira RD, Benjamin A (2006) Experimental strain analysis of metal loss defects in pipeline. Experimental Techniques, 30:42–47.

Freire JLF, Vieira RD, Diniz JLC, e Castro JTP (2003) Validation of FE models of pipelines with localized metal loss. SEM Annual Conference on Experimental and Applied Mechanics.

Noronha DB, Benjamin AC, Andrade EQ (2002) Finite element models for the prediction of the failure pressure of pipelines with long corrosion defects. In: Proceedings of IPC02, 4th International Pipeline Conference, ASME Paper IPC2002 27191.

Kim W, Kim Y, Kho Y, Choi J (2002) Full scale burst tests and finite element analysis on corroded gas pipeline. In: Proceedings of IPC02, 4th International Pipeline Conference, ASME Paper IPC2002 27037.

Fu P, Kirkwood MG (1995) Predicting failure pressure of internally corroded linepipe using the finite element method. OMAE-vol. V, pipeline technology. ASME, 175–184.

Chouchaoui BA, Pick RJ, Yost DB (1992) Burst pressure predictions of line pipe containing single corrosion pits using the finite element method. OMAE-vol. V-A, Pipeline Technology. ASME, 203–210.

Freire JLF, Vieira RD, Diniz JLC, Meniconi LC (2002) Hydrostatic tests of pipelines with composite repairs. SEM Annual Conference on Experimental and Applied Mechanics.

Souza RD, Benjamin AC, Vieira RD, Freire JLF, Castro JTP (2007) Rupture tests of pipeline segments containing long real corrosion defects (In press).

Diniz JLC (2002)Resistência de Dutos com Defeitos Usinados. M.Sc.Thesis, Mechanical Engineering Department, Catholic University of Rio de Janeiro, DEM, PUC-Rio. Experimental Techniques (In press).

Freire JLF, Vieira RD, Diniz JLC (2005) Evaluating the remaining strength factor for repaired pipeline. Rio Pipeline Conference and Exposition, Paper IBP1235_05.

ANSYS (1998) ANSYS software and user manual. version 5.5, ANSYS Inc.

DNV (1999) Corroded pipelines—recommended practice RP-F101. Det Norske Veritas, Norway.

Bjornoy OH, Sigurdsson G, Cramer EH, Fu B, Ritchie D (1999) Introduction to DNV RP-F101 “Corroded Pipelines”. OMAE 99/PIPE-5030.

Sigurdsson G, Cramer EH, Bjornoy OH, Fu B, Ritchie D (1999) Background to DNV RP-F101 “Corroded Pipelines.” OMAE 99/PIPE-5031.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Diniz, J.L.C., Vieira, R.D., Castro, J.T. et al. Stress and Strain Analysis of Pipelines with Localized Metal Loss. Exp Mech 46, 765–775 (2006). https://doi.org/10.1007/s11340-006-9826-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11340-006-9826-6