Abstract

Water pollution results from rapid urbanization and industrialization which has harmful effects on human health. Adsorption is one of the most efficient processes to remove pollutants from contaminated water. Natural minerals, such as dolomite, are widely spread around the world and may be easily collected in huge quantities. In this work, dolomite was characterized by X-ray diffraction (XRD), scanning electron microscopy (SEM) with energy dispersive X-ray analysis (EDX) and Fourier-transform infrared spectroscopy (FTIR), and was investigated for its applicability for removal of methylene blue (MB) from aqueous medium in a surfactant-assisted procedure. Using the one-factor one-time approach, batch adsorption studies were performed to establish the best experimental conditions (pH, sorbent amount, shaking time, type and concentration of surfactant and ionic strength) for removal of MB by dolomite. At optimum conditions (pH 8.0, shaking time 90 min, 1.0 g L−1 dolomite, 0.1% w/v sodium dodecyl sulfate, 25 °C), the maximum adsorption capacity was 22.2 mg g−1 and the adsorption process obeyed Langmuir and Freundlich adsorption isotherms. The findings show that dolomite effectively adsorbs MB and may be used as a less expensive sorbent in wastewater treatment to remove MB.

Graphical Abstract

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Methylene blue (MB) is a phenothiazine cationic dye that has many uses. It is used in textile, paper and other dyeing and printing industries. It also acts as chemical indicator and is used in biological staining, and pharmaceutical and food industries (Oz et al., 2011; Su & Nan, 2016; Subramaniam & Ponnusamy, 2015). Reports elucidated that up to 15% of the dye gets lost in the drain during textile dyeing process (Kabra et al., 2012). The leakage of MB from industrial wastewaters may lead to serious environmental problems. The dye can expend the dissolved oxygen in water and thus increase chemical oxygen demand (COD), biological oxygen demand (BOD), total organic carbon (TOC), and toxic chemical compounds in wastewater (Bulc & Ojstršek, 2008). Also, MB threatens the life of marine organisms by preventing light permeation through water (Abdelrahman et al., 2019). Thus, the removal of MB from wastewater becomes environmentally significant.

Different techniques are investigated for elimination of MB from aqueous media (Santoso et al., 2020). The most used manners are enzymatic degradation (Kishor, 2021), photocatalytic degradation (Karuppusamy et al., 2021), electrochemical methods (Fadillah et al., 2019), ozonation (Valdés et al., 2009), and adsorption methods (Gemici et al., 2021; Ghosh et al., 2021; Tuli et al., 2020). The adsorption techniques are superior to the other methods as it shows higher efficiency for treatment and removal of organic contaminants in wastewater treatment. Adsorption has many advantages including simple design, low cost, and efficiency (Mortada et al., 2023). However, most effective adsorbents are financially expensive or consume time and effort for preparation and modification (Seera et al., 2021).

Recently, clays and minerals have been announced for adsorption of dyes. As examples kaolin (Mouni et al., 2018), zeolite (Oukil et al., 2020), diatomite (Mohamed et al., 2019), bentonite (Bergaoui et al., 2018), natural phosphate (Hafdi et al., 2020), and kaolinite clay (Anoop Krishnan et al., 2015) show good adsorption activity toward different types of dyes. These naturally occurring minerals are widely distributed in the world and can be easily obtained in large amounts. Therefore, attention should be focused on the use of these compounds as adsorbents. The natural clays were also used to remove other pollutants from different samples. For example, orange-clay modified by humic acid and 2-mercaptobenzoxazole was employed for removal of Fe(III) from water samples (Dev et al., 2022). The modification of natural clays improves the adsorption activity toward phenols (Alkaram et al., 2009; Xue et al., 2013), organic dyes (Anirudhan & Ramachandran, 2015), and metal ions (Abdel Ghafar et al., 2020).

Dolomite is a sedimentary rock which consists mainly of calcium magnesium carbonate (CaMg(CO3)2). The typical structure of dolomite lattice composed of CO3−2 layers in-between alternating layers of Ca2+ and Mg2+, with varied amounts of Al2O3, SiO2, and Fe2O3 as impurities (Warren, 2000). It is used in ceramics, refractory brick, glass and metallurgical industries (Sadik et al., 2016). The ore powder has good adsorption properties toward potentially toxic substances such as heavy metals (Diwan et al., 2020; Mohammadi et al., 2015), fluoride (Wongrueng et al., 2016), phosphate (Gao et al., 2013), surfactants (Sanati & Malayeri, 2021; Sun et al., 2020), gases (Tao et al., 2021), and dyes (Shirazi et al., 2019, 2020; Ziane et al., 2018).

To meet the needs of the modern world, we need to provide a creative prospective way for disposal of MB from wastewater by an eco-friendly, effective, and cheap procedure. Review of literature showed that there are no studies on removal of MB using dolomite and therefore the current work aimed to explore the use of Egyptian dolomite powder as a felicitous sorbent for disposal of MB from aqueous medium. The parameters that may impact the removal process (i.e., the sample solution pH, clay dose, stirring time, surfactant type and amount, and ionic strength) were investigated to attain the better efficiency.

2 Experimental

2.1 Materials

Dolomite was collected from the deep layer of Ain Sokhna red sea mountain (Gulf of Suez region) (29°36′0″N, 32°19′0.12″E) in the mid of October 2021. The pulverized sample used during this study was obtained through ball mailing of the bulk sample. According to Bosworth study, the Gulf of Suez area is approximately 30 million years old (Bosworth, 2015).

For solution preparation and dilution, double distilled water was employed. Analytical grade chemicals were obtained from Merck (Darmstadt, Germany) or Sigma-Aldrich (St. Louis, MO, USA) and utilized without further purification. MB stock solution (1000 mg L−1) was made by dissolving 1.0 g in double distilled water. Working solutions of various concentrations were prepared daily and utilized in the adsorption investigation as well as creation of the MB calibration curve. Acetate buffer (pH 3.0–6.0), phosphate buffer (pH 7.0–8.0), and borate buffer (pH 9.0–10.0) were used to control the pH of the solution during the adsorption process.

2.2 Instrumentation

X-ray diffractometer Philips PW 1390 (Eindhoven, Netherlands) was used to record the XRD diffractogram with Cu target and K line running at 30 kV-10 mA and 1.540 Å wavelength. Scanning electron microscope paired with energy-dispersive X-ray analysis (SEM/EDX) was proceeded on a scanning electron microscope (Quanta 250FEG, FEI, USA). Fourier-transform infrared spectrum (FT-IR) was obtained using KBr disc (4000–400 cm−1) on a Thermo-Nicolet IS10 FT-IR spectrometer (Nicolet Instrument Co, Madison, WI, USA). The concentration of MB was determined spectrophotometrically using 7300 Genway spectrophotometer (Cole-Parmer Ltd., Staffordshire, UK). Metrohm 632 digital pH meter (Metrohm Autolab, Herisau, Switzerland) was used to measure the pH.

2.3 Adsorption Experiments

The batch procedure was used for the adsorption investigations. The effect of pH was investigated by mixing 50 mg of dolomite with 100 mL of aqueous solution containing fixed amount of MB (Ci) at different pH (3.0–10.0). The contents were stirred for 90 min at ambient temperature and the supernatant was separated by filtration. The remained concentration of MB in the filtrate (Ce) was measured by spectrophotometry at 665 nm (Mohamed et al., 2019) and the adsorption capacity (qe) was calculated by Eq. (1):

where V is the initial volume of solution in liter and m is the mass of dolomite in grams.

To study the effects of other parameters on the adsorption process, the conditions were adjusted as follows: sorbent dose ranging from 0.1 to 2.5 g L−1, stirring time ranging from 10 to 180 min, surfactant concentration ranging from 0.1 to 0.5% w/v, and NaCl concentration ranging from 0.1 to 1.0 mol L−1. Each experiment was carried out in triplicate and by varying one parameter and the others are kept constant. Figure 1 presents the general schematic procedure for removal of MB.

The adsorption isotherm for aqueous solutions of MB was performed by shaking 50 mg of dolomite in bottles containing 100 mL of MB solutions at various concentrations (10–180 mg L−1).

Following the adsorption process, dolomite was filtered and washed with double distillated water to remove the excess of MB. Thereafter, the sorbent was contacted with 5.0 mL of desorbing agents: (ethanol, acetone, NH4OH or NaOH). The desorption percentage (D) can be determined using Eq. (2):

where Cd is the concentration of desorbed MB (mg L−1), Vd is the volume of the eluent (L), and V is the initial volume of the solution (L).

3 Results and Discussion

3.1 Characterization of the Studied Mineral

X-ray diffraction analysis of the studied dolomite ore powder in combination with the suggested crystal structure is shown in Fig. 2. Characteristic sharp bands attributed to the sedimentary calcium magnesium carbonate phase originally located at 23.2, 29.4, 30.1, 36, 39.5, 43.1, 44.8, 47.3, and 48.6° were perceived and assigned to their corresponding Miller indices as earlier stated in JCPDS ASTM card NOS. 5–0586 (Kaczmarek, et al., 2017; Zucchini et al., 2014).

SEM micrograph of dolomite supported by EDX, and mapping is shown in Fig. 3. Image analysis implies the homogenous crystalline structure of the dolomite. The percentage composition of each component is shown in Table 1 in combination of their assignment and attribution. EDX analysis for the studied dolomite sample detects the presence of both carbon (0.2774 keV) and oxygen (0.525 keV) in addition to other lines characterizing the presence of both calcium and magnesium in different states.

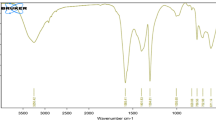

Figure 4 represents the FTIR spectral absorption data of dolomite. FTIR of pure dolomite Mg(CaCO3)2 was previously reported and assigned (Abdullah, 2021; Ji et al., 2009). The carbonate groups in the ore were characterized through the strong bands that appeared at about 2870, 2512, 1795, 1425, and 710 cm−1. Characteristic peaks were assigned to their function groups as reported in Table 2.

3.2 Factors Affecting Adsorption Process

3.2.1 Initial pH of the Solution

One of the most critical factors that strongly influence the dye adsorption process is the initial pH of the solution. MB is a cationic dye and its ionization in the solution is pH dependent. Moreover, the adsorption of the charged species is influenced by charge of the sorbent surface which is mostly affected by the solution pH. Figure 5 displays the impact of pH (3.0–10.0) on the adsorption capacity of MB onto dolomite. As is evident, the adsorption capacity increases as the solution pH increases and achieves a maximum value at pH 8.0. Below this value the adsorption capacity decreases owing to the probable competition between the positively charged dye and the hydronium ions on the active centers of the sorbent (Arabpour et al., 2021). Dolomite has an isoelectric point (pHpzc) of 6.3; therefore, its surface becomes more negative as the pH of the solution increases (Gence & Ozbay, 2006). This enhances the adsorption of the cationic dye through the electrostatic bonding (Mohamed et al., 2019). When the pH of the sample solution exceeds pHpzc, the surface of the clay becomes negatively charged, promoting the adsorption of MB. At lower pH, the surface of the clay is positively charged and thus apt to repel dye cations. Accordingly, the adsorption process is proceeded at pH 8.0 through the study.

3.2.2 Dose of the Sorbent

Another key influencing factor in the removal of pollutants from water is the relative quantity of sorbent. The effect of dolomite dose (in g L−1) on the adsorption capacity toward MB was investigated using 100 mL model containing 50 mg L−1 of MB. As presented in Fig. 6, the adsorption capacity of MB obviously increases with increasing sorbent dose from 0.1 g L−1 to 1.0 g L−1. These findings may be attributed to the increase of the available active adsorption sites on dolomite by increasing the sorbent dose. Above 1.0 g L−1 of dolomite dose, the adsorption capacity did not significantly enhance indicating that the maximum adsorption of MB by dolomite attained an optimum value at 1.0 g L−1. At equilibrium, the available adsorption sites of dolomite were almost loaded by the dye molecules; thence, any additional increase of the sorbent dose did not improve the adsorption efficiency. As a result, the sorbent dose value of 1.0 g L−1 was selected to perform the other experiments.

3.2.3 Stirring Time and Kinetic Study

The impact of stirring time on the adsorption capacity of MB by dolomite was examined by mixing 100 mg of the sorbent with 100 mL of a solution containing 20 mg L−1 of MB and pH 8.0. The containers were set in a mechanical shaker (200 rpm) for 180 min. At predefined periods, samples were taken from the supernatant to be analyzed for MB. Figure 7 shows that the adsorption capacity of dolomite toward MB enhances by increasing the contact time. The curve shows a fast adsorption rate within the first 45 min followed by a comparatively slow process, and ultimately it reaches equilibrium. The adsorption rate exceeds 80% of the maximum value after 45 min and attains equilibrium after 90 min. An increase in stirring duration beyond 90 min had no improvement effect on adsorption capacity. The initial rapid adsorption efficiency can be assigned to the considerable concentration gradient and availability of more active sites (Mortada & Abdelghany, 2020). Accordingly, 90 min shaking time was selected as the optimum equilibrium time.

3.2.4 Presence of Surfactant

Generally, the surfactant acts as an emulsifier and can promote the adsorption process by decreasing the interaction between solid particles and hence the available active sites are maximal (Yegya Raman et al., 2016). Therefore, we investigated the effect of Triton X-114 and sodium dodecyl sulfate (SDS) as non-ionic and anionic surfactants, respectively. The results in Fig. 8 display that the addition of Triton X-114 and SDS increases the adsorption capacity from 7.8 mg g−1 to 11.5 mg g−1 and 15.1 mg g−1, respectively. There was no significant impact of the concentration of the surfactant on the adsorption process. As expected, the anionic surfactant (SDS) improved the adsorption capacity compared to the non-ionic one. The anionic surfactant molecules can arrange themselves around the sorbent particles forming micelles. The hydrophobic tails of the surfactant interact with the hydrophobic regions on the sorbent surface. On the other hand, the hydrophilic heads direct themselves outward. As a result, the presence of SDS can consolidate the adsorption of MB by dolomite increasing the negative charges on the surface. According to these results, SDS was added at concentration of 0.1% (w/v) during the adsorption experiments.

3.2.5 Ionic Strength

Dye-containing wastewater generally has a high salt concentration, and the ionic strength effect is of great significance in studying the adsorption of dyes to adsorbents (Benaïssa, 2010). The impact of ionic strength of the solution on the adsorption of MB by dolomite was investigated using different amount of NaCl (0.1–1.0 mol L−1). The findings indicated that the ionic strength had no considerable strength on the adsorption capacity in the studied concentration range (Fig. 9).

3.2.6 Adsorption Isotherm

In the current work, Langmuir and Freundlich models were used to explore the equilibrium features of MB adsorption. Based on the Langmuir equation (Mohamed et al., 2019), the adsorption of MB will only take place at certain homogeneous sites on the surface of dolomite, and the energy level distribution is constant. The Langmuir isotherm is mathematically expressed as:

The model can be utilized to determine the maximum adsorption capacity (qmax) and the Langmuir constant (KL) by plotting Ce against Ce/qe. The results that were summarized in Fig. 10 and Table 3 show that qmax was decreased by increasing the temperature indicating an exothermic process. The estimated qmax values were 22.2, 20.4, 16.1, and 14.2 mg g−1 at 25, 35, 45, and 55 °C, respectively. Table 4 shows comparison between dolomite and other sorbents with respect to the adsorption capacity of MB.

The favorability of the adsorption process can be assessed by calculating the Langmuir isotherm equilibrium parameter (RL) as follows:

Based on the value of RL, the isotherm is defined as favorable based on RL values, if (0 < RL < 1) favorable, (RL > 1) unfavorable, linear (RL = 1), or irreversible (RL = 0). The estimated RL values at 25, 35, 45, and 55 °C were 0.51, 0.19, 0.34, and 0.29, respectively, suggesting that the adsorption is favorable.

The Freundlich equation for heterogeneous surface energy systems is given by Eq. 5

where KF and n are Freundlich constants that were identified from the ln qe versus ln Ce plot. The sorption capacity and intensity of the system are related to the parameters KF and 1/n. The value of 1/n indicates the favorability of the sorption process (Foo & Hameed, 2012). The linear relation between log (Ce) versus log (qe) shows high fitting of the adsorption results with a high determination coefficient (R2 = 0.999) for both using Triton X-100 and without using Triton X-100 (Table 5). The degree of non-linearity between the dissolved ion concentrations and the adsorption was related to the heterogeneity factor (1/n). From the slope of the linear plotting, the heterogeneity factor 1/n value was (0.359) when using Triton X-100 (less than unity) which reflected the chemical adsorption of dye and refers to a heterogeneous surface with minimum interactions between the adsorbed ions; on the other hand, 1/n value was 2.16 when Triton X-100 was not used (more than unity) which refers to a heterogeneous surface with maximum interactions between the adsorbed ions. Thus, the adsorption of methylene blue represented well by multi-layer adsorption rather than by monolayer adsorption when using Triton X-100.

3.3 Desorption of Methylene Blue from Dolomite

Desorption of MB from dolomite was studied using different agents. The sorbent after the adsorption process was separated and rinsed three times by double distilled water and stirred with 5.0 mL of the eluent for 15 min. MB is acidic dye so desorbing agents employed in this work were basic eluents as acetone, ethanol, NH4OH, and NaOH. Moreover, the use of acids may cause dissolution of the sorbent. The effectiveness of the solvent was evaluated by the desorption percentage of the dye (Eq. 2). The results clearly show that the desorption percentages of MB were 14.6 ± 3.3, 26.6 ± 5.2, 46.5 ± 4.2, and 96.5 ± 2.6% for acetone, ethanol, NH4OH (0.5–1.0 mol L−1), and NaOH (0.5–1.0 mol L−1). The use of higher concentrations of NH4OH or NaOH did not significantly improve the efficiency of the desorption. The poor desorption of acetone, ethanol, and NH4OH is owing to the strong interactions between the active sites of dolomite and MB. Results from the reusability study are shown in Table 6. As obviously presented, the adsorption capacity progressively reduces and reaches 67.7% of the initial value after the fourth cycle indicating that dolomite can be effectively employed as an adsorbent for MB under the prescribed condition for 3 cycles. Therefore, the use of strong basic eluent NaOH as desorbing agent allows the reusability of the sorbent for three times without significant reduction in the adsorption capacity.

4 Conclusion

Dolomite has high ability to remove MB from aqueous media with high efficiency under the optimum conditions. The maximum adsorption of MB occurred at pH 8.0, 90 min shaking time, at ambient temperature and in the presence of 0.1% SDS. Adsorption of MB onto dolomite occurred with a maximum adsorption capacity of 22.2 mg g−1 at 25 °C which reflects higher adsorption capacity toward MB when compared with various adsorbents. The same amount of dolomite can be used for adsorption MB several times after elution with NaOH with nearly the same adsorption efficiency. Our findings suggest that the raw can be effectively utilized for the adsorption of MB from aqueous solutions.

Data Availability

The datasets used or analyzed during the current study are available from the corresponding author on reasonable request.

References

Abdel Ghafar, H. H., Radwan, E. K., & El-Wakeel, S. T. (2020). Removal of hazardous contaminants from water by natural and zwitterionic surfactant-modified clay. ACS omega, 5(12), 6834–6845.

Abdelrahman, E. A., Hegazey, R., & El-Azabawy, R. E. (2019). Efficient removal of methylene blue dye from aqueous media using Fe/Si, Cr/Si, Ni/Si, and Zn/Si amorphous novel adsorbents. Journal of Materials Research and Technology, 8(6), 5301–5313.

Abdullah, S.F.A., et al. (2021) Effect of Thermal Treatment on Natural Dolomite. Journal of Physics: Conference Series, 2080, Article ID: 012009.

Alkaram, U. F., Mukhlis, A. A., & Al-Dujaili, A. H. (2009). The removal of phenol from aqueous solutions by adsorption using surfactant-modified bentonite and kaolinite. Journal of Hazardous Materials, 169(1–3), 324–332.

Amrhar, O., Nassali, H., & Elyoubi, M. (2015). Adsorption of a cationic dye, methylene blue, onto moroccan illitic clay. J. Mater. Environ. Sci, 6(11), 3054.

Anirudhan, T., & Ramachandran, M. (2015). Adsorptive removal of basic dyes from aqueous solutions by surfactant modified bentonite clay (organoclay): Kinetic and competitive adsorption isotherm. Process Safety and Environmental Protection, 95, 215–225.

Annadurai, G., Juang, R.-S., & Lee, D.-J. (2002). Use of cellulose-based wastes for adsorption of dyes from aqueous solutions. Journal of Hazardous Materials, 92(3), 263–274.

Anoop Krishnan, K., et al. (2015). Kinetic and isotherm modeling of methylene blue adsorption onto kaolinite clay at the solid-liquid interface. Separation Science and Technology, 50(8), 1147–1157.

Arabpour, A., Dan, S., & Hashemipour, H. (2021). Preparation and optimization of novel graphene oxide and adsorption isotherm study of methylene blue. Arabian Journal of Chemistry, 14(3), 103003.

Ayad, M. M., & El-Nasr, A. A. (2010). Adsorption of cationic dye (methylene blue) from water using polyaniline nanotubes base. The Journal of Physical Chemistry C, 114(34), 14377–14383.

Benaïssa, H. (2010). Influence of ionic strength on methylene blue removal by sorption from synthetic aqueous solution using almond peel as a sorbent material: Experimental and modelling studies. Journal of Taibah University for Science, 4, 31–38.

Bergaoui, M., et al. (2018). Novel insights into the adsorption mechanism of methylene blue onto organo-bentonite: Adsorption isotherms modeling and molecular simulation. Journal of Molecular Liquids, 272, 697–707.

Bosworth, W. (2015). Geological Evolution of the Red Sea: Historical Background, Review, and Synthesis. In: Rasul, N., Stewart, I. (eds) The Red Sea. Springer Earth System Sciences. Springer, Berlin, Heidelberg, pp 45–78.

Bulc, T. G., & Ojstršek, A. (2008). The use of constructed wetland for dye-rich textile wastewater treatment. Journal of Hazardous Materials, 155(1–2), 76–82.

Dev, V. V., et al. (2022). Modelling a multi-stage batch reactor for the immobilization of Fe (III) ions using humic acid and 2-mercaptobenzoxazole fabricated organo-clay. Journal of Cleaner Production, 356, 131619.

Diwan, V., et al. (2020). Adsorptive extraction of uranium (VI) from aqueous phase by dolomite. Groundwater for Sustainable Development, 11, 100424.

El-Mekkawi, D. M., Ibrahim, F. A., & Selim, M. M. (2016). Removal of methylene blue from water using zeolites prepared from Egyptian kaolins collected from different sources. Journal of Environmental Chemical Engineering, 4(2), 1417–1422.

El-Sharkaway E. A., et al. (2020). Removal of methylene blue from aqueous solutions using polyaniline/graphene oxide or polyaniline/reduced graphene oxide composites. Environmental technology, 41(22), 2854–2862.

Fadillah, G., et al. (2019). Electrochemical removal of methylene blue using alginate-modified graphene adsorbents. Chemical Engineering Journal, 378, 122140.

Foo, K., & Hameed, B. (2012). Preparation, characterization and evaluation of adsorptive properties of orange peel based activated carbon via microwave induced K2CO3 activation. Bioresource Technology, 104, 679–686.

Franca, A. S., Oliveira, L. S., & Ferreira, M. E. (2009). Kinetics and equilibrium studies of methylene blue adsorption by spent coffee grounds. Desalination, 249(1), 267–272.

Gao, Y., et al. (2013). Phosphate removal from aqueous solution by an effective clay composite material. Journal of Solution Chemistry, 42(4), 691–704.

Gemici, B. T., Ozel, H. U., & Ozel, H. B. (2021). Removal of methylene blue onto forest wastes: Adsorption isotherms, kinetics and thermodynamic analysis. Environmental Technology & Innovation, 22, 101501.

Gence, N., & Ozbay, N. (2006). pH dependence of electrokinetic behavior of dolomite and magnesite in aqueous electrolyte solutions. Applied Surface Science, 252(23), 8057–8061.

Ghosh, D., & Bhattacharyya, K. G. (2002). Adsorption of methylene blue on kaolinite. Applied Clay Science, 20(6), 295–300.

Ghosh, I., et al. (2021). Removal of methylene blue from aqueous solution using Lathyrus sativus husk: Adsorption study, MPR and ANN modelling. Process Safety and Environmental Protection, 149, 345–361.

Hafdi, H., et al. (2020). Design of a new low cost natural phosphate doped by nickel oxide nanoparticles for capacitive adsorption of reactive red 141 azo dye. Environmental Research, 184, 109322.

Ji, J., et al. (2009). Rapid identification of dolomite using a Fourier Transform Infrared Spectrophotometer (FTIR): A fast method for identifying Heinrich events in IODP Site U1308. Marine Geology, 258(1–4), 60–68.

Jin, X., et al. (2008). Adsorption of methylene blue and orange II onto unmodified and surfactant-modified zeolite. Journal of Colloid and Interface Science, 328(2), 243–247.

Kabra, A. N., et al. (2012). Phytoremediation of textile effluent and mixture of structurally different dyes by Glandularia pulchella (Sweet) Tronc. Chemosphere, 87(3), 265–272.

Kaczmarek, S.E., et al (2017) Dolomite, very-high magnesium calcite, and microbes: Implications for the microbial model of dolomitization. SEPM Special Publications, 109, 7–20.

Karuppusamy, I., et al. (2021). Ultrasound-assisted synthesis of mixed calcium magnesium oxide (CaMgO2) nanoflakes for photocatalytic degradation of methylene blue. Journal of Colloid and Interface Science, 584, 770–778.

Kavitha, D., & Namasivayam, C. (2007). Experimental and kinetic studies on methylene blue adsorption by coir pith carbon. Bioresource Technology, 98(1), 14–21.

Kishor, R., et al (2021) Efficient degradation and detoxification of methylene blue dye by a newly isolated ligninolytic enzyme producing bacterium Bacillus Albus MW407057. Colloids and Surfaces B: Biointerfaces, 206, 111947.

Mohamed, E. A., et al. (2019). Enhancing adsorption capacity of Egyptian diatomaceous earth by thermo-chemical purification: Methylene blue uptake. Journal of Colloid and Interface Science, 534, 408–419.

Mohammadi, M., et al. (2015). Adsorption of cadmium (II) and nickel (II) on dolomite powder. Desalination and Water Treatment, 53(1), 149–157.

Mortada, W. I., & Abdelghany, A. M. (2020). Preconcentration of lead in blood and urine samples among bladder cancer patients using mesoporous strontium titanate nanoparticles. Biological Trace Element Research, 193(1), 100–110.

Mortada, W. I., et al. (2023). Effective and low-cost adsorption procedure for removing chemical oxygen demand from wastewater using chemically activated carbon derived from rice husk. Separations, 10(1), 43.

Mouni, L., et al. (2018). Removal of Methylene Blue from aqueous solutions by adsorption on Kaolin: Kinetic and equilibrium studies. Applied Clay Science, 153, 38–45.

Oukil, S., Bali, F., & Halliche, D. (2020). Adsorption and kinetic studies of methylene blue on modified HUSY zeolite and an amorphous mixture of γ-alumina and silica. Separation Science and Technology, 55(15), 2642–2658.

Oz, M., et al. (2011). Cellular and molecular actions of methylene blue in the nervous system. Medicinal Research Reviews, 31(1), 93–117.

Sadik, C., et al. (2016). Review on the elaboration and characterization of ceramics refractories based on magnesite and dolomite. Journal of Asian Ceramic Societies, 4(3), 219–233.

Sanati, A., & Malayeri, M. (2021). CTAB adsorption onto dolomite in the presence of ionic liquid and deep eutectic solvent: Experimental and theoretical studies. Journal of Molecular Liquids, 325, 115176.

Santoso, E., et al. (2020). Review on recent advances of carbon based adsorbent for methylene blue removal from waste water. Materials Today Chemistry, 16, 100233.

Seera, S. D. K., et al. (2021). Synthesis and characterization of xylan-gelatin cross-linked reusable hydrogel for the adsorption of methylene blue. Carbohydrate Polymers, 256, 117520.

Shirazi, E. K., et al. (2019). Simultaneous removal of a cationic and an anionic textile dye from water by a mixed sorbent of vermicompost and Persian charred dolomite. Chemosphere, 234, 618–629.

Shirazi, E. K., et al. (2020). Removal of textile dyes from single and binary component systems by Persian bentonite and a mixed adsorbent of bentonite/charred dolomite. Colloids and Surfaces a: Physicochemical and Engineering Aspects, 598, 124807.

Su, Y., & Nan, G. (2016). Using methylene blue as a marker to find and remove tiny metallic foreign bodies embedded in the soft tissues of children: A randomised controlled trial. International Journal of Surgery, 29, 43–48.

Subramaniam, R., & Ponnusamy, S. K. (2015). Novel adsorbent from agricultural waste (cashew NUT shell) for methylene blue dye removal: Optimization by response surface methodology. Water Resources and Industry, 11, 64–70.

Sun, W., et al. (2020). Effect of Tween 80 on flotation separation of magnesite and dolomite using NaOL as the collector. Journal of Molecular Liquids, 315, 113712.

Tao, L., et al. (2021). New insight into absorption characteristics of CO2 on the surface of calcite, dolomite, and magnesite. Applied Surface Science, 540, 148320.

Tuli, F., et al. (2020). Removal of methylene blue from water by low-cost activated carbon prepared from tea waste: A study of adsorption isotherm and kinetics. Environmental Nanotechnology, Monitoring & Management, 14, 100354.

Valdés, H., Tardón, R., & Zaror, C. (2009). Methylene blue removal from contaminated waters using O3, natural zeolite, and O3/zeolite. Water Science and Technology, 60(6), 1419–1424.

Warren, J. (2000). Dolomite: Occurrence, evolution and economically important associations. Earth-Science Reviews, 52(1–3), 1–81.

Wongrueng, A., et al. (2016). Kinetic adsorption of fluoride from an aqueous solution onto a dolomite sorbent. Engineering Journal, 20(3), 1–9.

Xue, G., et al. (2013). The removal of p-nitrophenol from aqueous solutions by adsorption using gemini surfactants modified montmorillonites. Chemical Engineering Journal, 218, 223–231.

Yegya Raman, A. K., et al. (2016). Emulsion stability of surfactant and solid stabilized water-in-oil emulsions after hydrate formation and dissociation. Colloids and Surfaces a: Physicochemical and Engineering Aspects, 506, 607–621.

Ziane, S., et al. (2018). Single and binary adsorption of reactive black 5 and Congo red on modified dolomite: Performance and mechanism. Journal of Molecular Liquids, 249, 1245–1253.

Zucchini, A., et al. (2014). The effect of cation ordering and temperature on the high-pressure behaviour of dolomite. Physics and Chemistry of Minerals, 41(10), 783–793.

Funding

Open access funding provided by The Science, Technology & Innovation Funding Authority (STDF) in cooperation with The Egyptian Knowledge Bank (EKB).

Author information

Authors and Affiliations

Contributions

All authors contributed to the study conception and design. Material preparation, data collection and analysis were performed by Wael Mortada, Amr Abdelghany, and Kareem Nabieh. The first draft of the manuscript was written by Wael Mortada and Amr Abdelghany and all authors commented on previous versions of the manuscript. All authors read and approved the final manuscript.

Corresponding author

Ethics declarations

Competing Interests

The authors declare no competing interests.

Ethics Approval

Not applicable.

Consent to Participate

Not applicable.

Consent for Publication

Not applicable.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Mortada, W.I., Nabieh, K.A. & Abdelghany, A.M. Efficient and Low-Cost Surfactant-Assisted Solid Phase Extraction Procedure For Removal Of Methylene Blue Using Natural Dolomite. Water Air Soil Pollut 234, 363 (2023). https://doi.org/10.1007/s11270-023-06363-z

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s11270-023-06363-z