Abstract

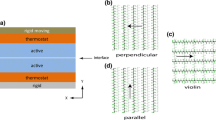

Polytetrafluoroethylene (PTFE) has been widely applied in industrial engineering applications. Its tribological behaviors are extensively studied using the experimental method. However, the friction and wear mechanisms of PTFE still need to be investigated from a microscopic point of view. In this study, we established a two-layer PTFE frictional model to simulate the frictional behaviors of PTFE using molecular dynamics (MD) simulation and verified it by experiments. To directly compare the MD simulation results to the experimental results, the motion form, range of the external load, relative velocity, and environmental temperature matched each other as closely as possible. We found that the increment of normal force is faster than that of the friction force with an increase in the external load applied to the upper layer, resulting in an apparent decrease in the friction coefficient and an increase in wear depth. The smaller PTFE fragments correspond to a higher contact temperature for a fixed external load. The higher contact temperature induced a higher mobility increasing the friction force, thereby enhancing the friction coefficient. However, the influence of PTFE fragments on the friction coefficient is unremarkable compared to the external load.

Similar content being viewed by others

References

Gong, D., Xue, Q., Wang, H.: Study of the wear of filled polytetrafluoroethylene. Wear 134, 283–295 (1989)

Blanchet, T.A., Kennedy, F.E.: Sliding wear mechanism of poly-tetrafluoroethylene (PTFE) and PTFE composites. Wear 152, 229–243 (1992)

Qiu, M., Yang, Z., Lu, J., Li, Y., Zhou, D.: Influence of step load on tribological properties of self-lubricating radial spherical plain bearings with PTFE fabric liner. Tribol. Int. (2017). https://doi.org/10.1016/j.triboint.2017.02.047

Xiong, D., Qin, Y., Li, J., Wan, Y., Tyagi, R.: Tribological properties of PTFE/laser surface textured stainless steel under starved oil lubrication. Tribol. Int. (2015). https://doi.org/10.1016/j.triboint.2014.07.017

Fragassa, C.: Investigations into the degradation of PTFE surface properties by accelerated aging tests. Tribol. Ind. 38(2), 241–248 (2016)

Frankland, S.J.V., Harik, V.M., Odegard, G.M., Brenner, D.W., Gates, T.S.: The stress-strain behavior of polymer–nanotube composites from molecular dynamics simulation. Compos. Sci. Technol. 63(11), 1655–1661 (2003)

Dong, Y., Li, Q., Martini, A.: Molecular dynamics simulation of atomic friction: a review and guide. J. Vac. Sci. Technol. A 31, 030801 (2013)

Ewen, J.P., Heyes, D.M., Dini, D.: Advances in nonequilibrium molecular dynamics simulations of lubricants and additives. Friction (2017). https://doi.org/10.1007/s40544-018-0207-9

Ye, J., Moore, A.C., Burris, D.L.: Transfer film tenacity: a case study using ultra-low-wear alumina–PTFE. Tribol. Lett. 59, 50 (2015)

Urueña, J.M., Pitenis, A.A., Harris, K.L., Sawyer, W.G.: Evolution and wear of fluoropolymer transfer films. Tribol. Lett. 57, 9 (2015)

Onodera, T., Nunoshige, J., Kawasaki, K., Adachi, K., Kurihara, K., Kubo, M.: Structure and function of transfer film formed from PTFE/PEEK polymer blend. J. Phys. Chem. C 121, 14589–14596 (2017)

Harris, K.L., Pitenis, A.A., Sawyer, W.G., Krick, B.A., Blackman, G.S., Kasprzak, D.J., Junk, C.P.: PTFE tribology and the role of mechanochemistry in the development of protective surface films. Macromolecules 48, 3739–3745 (2015)

Mclaren, K.G., Tabor, D.: The friction and deformation properties of irradiated polytetrafluoroethylene (PTFE). Wear 8, 3–7 (1965)

Jang, I., Burris, D.L., Dickrell, P.L.: Sliding orientation effects on the tribological properties of polytetrafluoroethylene. J. Appl. Phys. (2007). https://doi.org/10.1063/1.2821743

Chiu, P.Y., Barry, P.R., Perry, S.S., Sawyer, W.G., Phillpot, S.R., Sinnott, S.B.: Influence of the molecular level structure of polyethylene and polytetrafluoroethylene on their tribological response. Tribol. Lett. 42, 193–201 (2011)

Barry, P.R., Jang, I., Perry, S.S., Sawyer, W.G., Sinnott, S.B., Phillpot, S.R.: Effect of simulation conditions on friction in polytetrafluoroethylene (PTFE). J. Comput. Aided Mater. Des. 14(1), 239–246 (2007)

Barry, P.R., Chiu, P.Y., Perry, S.S., Sawyer, W.G., Sinnott, S.B., Phillpot, S.R.: Effect of temperature on the friction and wear of PTFE by atomic-level simulation. Tribol. Lett. 58, 50 (2015)

Barry, P.R., Chiu, P.Y., Perry, S.S., Sawyer, W.G., Phillpot, S.R., Sinnott, S.B.: The effect of normal load on polytetrafluoroethylene tribology. J. Phys. Condens. Matter 21, 144201 (2009)

Heo, S.J., Jang, I., Barry, P.R., Phillpot, S.R., Perry, S.S., Sawyer, W.G., Sinnott, S.B.: Effect of the sliding orientation on the tribological properties of polyethylene in molecular dynamics simulations. J. Appl. Phys. (2008). https://doi.org/10.1063/1.2900884

Sun, H.: Ab initio calculations and force field development for computer simulation of polysilanes. Macromolecules 28, 701–712 (1995)

Sun, H., Mumby, S.J., Maple, J.R., Hagler, A.T.: An ab initio CFF93 all-atom force field for polycarbonates. J. Am. Chem. Soc. 116, 2978–2987 (1994)

Zuo, Z., Yang, Y., Qi, X., Su, W., Yang, X.: Analysis of the chemical composition of the PTFE transfer film. Wear (2014). https://doi.org/10.1016/j.wear.2014.08.019

Plimpton, S.: Fast parallel algorithms for short-range molecular dynamics. J. Comput. Phys. 117, 1–19 (1995). http://lammps.sandia.gov. Accessed 16 Feb 2017

Schneider, T., Stoll, E.: Molecular-dynamics study of a three-dimensional one-component model for distortive phase-transitions. Phys. Rev. B 17(3), 1302–1322 (1978)

Gao, Y., Ruestes, C.J., Urbassek, H.M.: Nanoindentation and nanoscratching of iron: atomistic simulation of dislocation generation and reactions. Comput. Mater. Sci. (2014). https://doi.org/10.1016/j.commatsci.2014.04.027

Harrison, J.A., White, C.T., Colton, R.J., Brenner, D.W.: Molecular-dynamics simulations of atomic-scale friction of diamond surfaces. Phys. Rev. B 46(15), 9700–9708 (1992)

Yuan, X.-D., Yang, X.-J.: A study on friction and wear properties of PTFE coatings under vacuum conditions. Wear 269, 291–297 (2010)

Biswas, S.K., Vijayan, K.: Friction and wear of PTFE—a review. Wear 158(1–2), 193–211 (1992)

Acknowledgements

This project was supported by the National Natural Science Foundation of China (Grant No. 51605418), Natural Science Foundation of Hebei Province (Grant No. E2016203206), and Doctoral Fund of Yanshan University (Grant No. B927).

Author information

Authors and Affiliations

Corresponding author

Appendix

Appendix

PCFF parameters shown in Table 1 were used for simulating PTFE in this study.

Rights and permissions

About this article

Cite this article

Pan, D., Fan, B., Qi, X. et al. Investigation of PTFE Tribological Properties Using Molecular Dynamics Simulation. Tribol Lett 67, 28 (2019). https://doi.org/10.1007/s11249-019-1141-3

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s11249-019-1141-3