Abstract

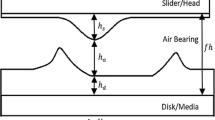

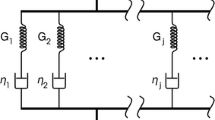

The high-temperature laser heating during heat-assisted magnetic recording (HAMR) causes the media lubricant to deform and transfer to the head via evaporation/condensation. The ability of the lubricant to withstand this writing process and sufficiently recover post-writing is critical for robust read/write performance. Moreover, the media-to-head lubricant transfer causes a continuous deposition of contaminants originating from the media at the head near field transducer, challenging the reliability of HAMR drives. Most previous studies on the effects of laser exposure on lubricant depletion have assumed the lubricant to be a viscous fluid and have modeled its behavior using traditional lubrication theory. However, Perfluoropolyether lubricants are viscoelastic fluids and are expected to exhibit a combination of viscous and elastic behavior at the timescale of HAMR. In this paper, we introduce a modification to the traditional Reynolds lubrication equation using the linear Maxwell constitutive equation and a slip boundary condition. We study the deformation and recovery of the lubricant due to laser heating under the influence of thermocapillary stress and disjoining pressure. Subsequently, we use this modified lubrication equation to develop a model that predicts the media-to-head lubricant transfer during HAMR. This model simultaneously determines the deformation and evaporation of the viscoelastic lubricant film on the disk, the diffusion of the vapor phase lubricant in the air bearing, and the evolution of the condensed lubricant film on the head. We investigate the effect of viscoelasticity, lubricant type (Zdol vs Ztetraol), molecular weight, slip, and disjoining pressure on the lubricant transfer process.

Similar content being viewed by others

References

Marchon, B., Guo, X.C., Pathem, B.K., Rose, F., Dai, Q., Feliss, N., Schreck, E., Reiner, J., Mosendz, O., Takano, K., Do, H., Burns, J., Saito, Y.: Head-disk interface materials issues in heat-assisted magnetic recording. IEEE Trans. Magn. (2014). https://doi.org/10.1109/TMAG.2013.2283068

Wu, L.: Modelling and simulation of the lubricant depletion process induced by laser heating in heat-assisted magnetic recording system. Nanotechnology (2007). https://doi.org/10.1088/0957-4484/18/21/215702

Dahl, J.B., Bogy, D.B.: Lubricant flow and evaporation model for heat-assisted magnetic recording including functional end-group effects and thin film viscosity. Tribol. Lett. (2013). https://doi.org/10.1007/s11249-013-0190-2

Marchon, B., Saito, Y.: Lubricant thermodiffusion in heat assisted magnetic recording. IEEE Trans. Magn. (2012). https://doi.org/10.1109/TMAG.2012.2194138

Dahl, J.B., Bogy, D.B.: Simulation of lubricant recovery after heat-assisted magnetic recording writing. Tribol. Lett. (2013). https://doi.org/10.1007/s11249-013-0203-1

Kono, R.-N., Izumisawa, S., Jhon, M.S., Kim, C.A., Choi, H.J.: Rheology of perfluoropolyether lubricants. IEEE Trans. Magn. (2001). https://doi.org/10.1109/20.950980

Choi, H.J., Lim, S., Izumisawa, S., Jhon, M.S.: Viscoelasticity and solution viscosity of perfluoropolyether lubricants. Tribol. Int. (2005). https://doi.org/10.1016/j.triboint.2005.01.024

Karis, T.: Lubricants for the disk drive industry. In: Rudnick, L. (ed.) Lubricant Additives: Chemistry and Applications, Chap. 22, pp. 523–584. CRC Press, Boca Raton, FL (2009)

Tanner, R.I.: Engineering Rheology. Clarendon Press, Oxford (2000)

Sarabi, S., Bogy, D.B.: Effect of viscoelasticity on lubricant behavior under heat-assisted magnetic recording conditions. Tribol. Lett. (2018). https://doi.org/10.1007/s11249-017-0979-5

Mate, C.M., Marchon, B., Murthy, A., Kim, S.-H.: Lubricant-induced spacing increases at slider-disk interfaces in disk drives. Tribol. Lett. (2010). https://doi.org/10.1007/s11249-009-9555-y

Kiely, J.D., Jones, P.M., Yang, Y., Brand, J.L., Anaya-Dufresne, M., Fletcher, P.C., Zavaliche, F., Toivola, Y., Duda, J.C., Johnson, M.T.: Write-induced head contamination in heat-assisted magnetic recording. IEEE Trans. Magn. (2017). https://doi.org/10.1109/TMAG.2016.2618842

Xiong, S., Wang, N., Smith, R., Li, D., Schreck, E., Dai, Q.: Material transfer inside head disk interface for heat assisted magnetic recording. Tribol. Lett. (2017). https://doi.org/10.1007/s11249-017-0860-6

Yang, Y., Li, X., Stirniman, M., Yan, X., Huang, F., Zavaliche, F., Wang, H., Huang, J., Tang, H., Jones, P.M., Kiely, J.D., Brand, J.L.: Head-disk lubricant transfer and deposition during heat-assisted magnetic recording write operations. IEEE Trans. Magn. (2015). https://doi.org/10.1109/TMAG.2015.2434826

Aoyama, J., Furukawa, M., Nishida, S., Tasaka, K., Matsuda, K., Kuroki, K., Ikeda, M.: A head cleaning procedure for heat-assisted magnetic recording. IEEE Trans. Magn. (2017). https://doi.org/10.1109/TMAG.2017.2706981

Kiely, J., Jones, P., Hoehn, J.: Materials challenges for the heat-assisted magnetic recording head-disk interface. MRS Bull. (2018). https://doi.org/10.1557/mrs.2018.4

Tani, H., Uesaraie, Y., Lu, R., Koganezawa, S., Tagawa, N.: Smear growth on head slider surface from siloxane outgas on heat assisted magnetic recording. Microsyst. Technol. (2018). https://doi.org/10.1007/s00542-018-3839-9

Dai, X., Li, H., Shen, S., Wu, S.: Study of perfluoropolyether lubricant consumption and recovery in heat assisted magnetic recording using molecular dynamics simulation method. IEEE Trans. Magn. (2017). https://doi.org/10.1109/TMAG.2016.2637872

Dai, X., Zhang, J., Shen, S., Li, H., Zhai, T., Wu, S., Liu, S., Du, H.: Study of formation and development of lubricant bridge in head—disk interface using molecular dynamic method. IEEE Trans. Magn. (2017). https://doi.org/10.1109/TMAG.2016.2626459

Seo, Y., Pan, D., Ovcharenko, A., Yang, M., Talke, F.: Molecular dynamics simulation of lubricant transfer at the head-disk interface. IEEE Trans. Magn. (2014). https://doi.org/10.1109/TMAG.2014.2322353

Seo, Y., Ovcharenko, A., Talke, F.: Simulation of hydrocarbon oil contamination at the head-disk interface using molecular dynamics. Tribol. Lett. (2016). https://doi.org/10.1007/s11249-016-0648-0

Mate, C.M., Marchon, B.: Shear response of molecularly thin liquid films to an applied air stress. Phys. Rev. Lett. (2000). https://doi.org/10.1103/PhysRevLett.85.3902

Scarpulla, M., Mate, C.M., Carter, M.: Air shear driven flow of thin perfluoropolyether polymer films. J. Chem. Phys. (2003). https://doi.org/10.1063/1.1536953

Sakhalkar, S.V., Bogy, D.B.: A model for lubricant transfer from media to head during heat-assisted magnetic recording (HAMR) writing. Tribol. Lett. (2017). https://doi.org/10.1007/s11249-017-0952-3

Ruths, M., Granick, S.: Tribology of confined Fomblin-Z perfluoropolyalkylethers: molecular weight dependence and comparison between unfunctionalized and telechelic chains. Tribol. Lett. (1999). https://doi.org/10.1023/A:1019137824102

Itoh, S., Fukuzawa, K., Hamamoto, Y., Zhang, H., Mitsuya, Y.: Fiber wobbling method for dynamic viscoelastic measurement of liquid lubricant confined in molecularly narrow gaps. Tribol. Lett. (2008). https://doi.org/10.1007/s11249-008-9325-2

Itoh, S., Fukuzawa, K., Hamamoto, Y., Zhang, H.: Opposing effects of confinement and confinement-induced shear-thinning on viscoelastic properties of liquid lubricant in nanometer-scale gaps. Tribol. Int. (2011). https://doi.org/10.1016/j.triboint.2010.07.007

Karis, T., Marchon, B., Flores, V., Scarpulla, M.: Lubricant spin-off from magnetic recording disks. Tribol. Lett. (2001). https://doi.org/10.1023/A:1012553415639

Marchon, B., Guo, X.C., Moser, A., Spool, A., Kroeker, R., Crimi, F.: Lubricant dynamics on a slider: the waterfall effect. J. Appl. Phys. (2009). https://doi.org/10.1063/1.3104764

Rajagopal, K.R.: On some unresolved issues in non-linear fluid dynamics. Russ. Math. Surv (2003). https://doi.org/10.1070/RM2003v058n02ABEH000612

Rauscher, M., Munch, A., Wagner, B., Blossey, R.: A thin-film equation for viscoelastic liquids of Jeffreys type. Eur. Phys. J. E (2005). https://doi.org/10.1140/epje/i2005-10016-8

Blossey, R.: Thin film rupture and polymer flow. Phys. Chem. Chem. Phys. (2008). https://doi.org/10.1039/b807728m

Wu, L.: Lubricant dynamics under sliding condition in disk drives. J. Appl. Phys. (2006). https://doi.org/10.1063/1.2220489

Mate, C.M.: Taking a fresh look at disjoining pressure of lubricants at slider-disk interfaces. IEEE Trans. Magn. (2011). https://doi.org/10.1109/TMAG.2010.2073691

LeVeque, R.: Finite Difference Methods for Ordinary and Partial Differential Equations. SIAM, Philadelphia (2007). https://doi.org/10.1137/1.9780898717839

Christensen, R.: Theory of Viscoelasticity: An Introduction. Elsevier, New York (2012)

Tichy, J.: Non-Newtonian lubrication with the convected Maxwell model. J. Tribol. (1996). https://doi.org/10.1115/1.2831307

Schowalter, W.: The behaviour of complex fluids at solid boundaries. J. Non-Newton. Fluid Mech. (1988). https://doi.org/10.1016/0377-0257(88)85048-1

Fomblin, Z.: Derivatives: Product Data Sheet. Solvay Solexis Inc., North America (2002)

Jones, P.M., Yan, X., Hohlfeld, J., Stirniman, M., Kiely, J.D., Zavaliche, F., Tang, H.H.: Laser-induced thermo-desorption of perfluoropolyether lubricant from the surface of a heat-assisted magnetic recording disk: Lubricant evaporation and diffusion. Tribol. Lett. (2015). https://doi.org/10.1007/s11249-015-0561-y

Wu, L.: A model for liquid transfer between two approaching gas bearing surfaces through coupled evaporation-condensation and migration dynamics. J. Appl. Phys. (2008). https://doi.org/10.1063/1.2951616

Lei, R.Z., Gellman, A.J., Jones, P.: Thermal stability of Fomblin Z and Fomblin Zdol thin films on amorphous hydrogenated carbon. Tribol. Lett. (2001). https://doi.org/10.1023/A:1016670303657

Zhou, W., Zeng, Y., Liu, B., Yu, S., Hua, W., Huang, X.: Evaporation of polydisperse perfluoropolyether lubricants in heat-assisted magnetic recording. Appl. Phys. Express (2011). https://doi.org/10.1143/APEX.4.095201

Zhang, Y., Polycarpou, A.: A single asperity sliding contact model for molecularly thin lubricant. Microsyst. Technol. (2017). https://doi.org/10.1007/s00542-016-2910-7

Kim, S.H., Dai, Q., Marchon, B., Flechsig, K.: Humidity effects on lubricant transfer in the head-disk interface of a hard disk drive. J. Appl. Phys. (2009). https://doi.org/10.1063/1.3061704

Ambekar, R.P., Bogy, D.B., Dai, Q., Marchon, B.: Critical clearance and lubricant instability at the head-disk interface of a disk drive. Appl. Phys. Lett. (2008). https://doi.org/10.1063/1.2837187

Acknowledgements

This work was supported by the Computer Mechanics Laboratory at University of California, Berkeley, Mechanical Engineering Department.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Sakhalkar, S.V., Bogy, D.B. Effect of Rheology and Slip on Lubricant Deformation and Disk-to-Head Transfer During Heat-Assisted Magnetic Recording (HAMR). Tribol Lett 66, 145 (2018). https://doi.org/10.1007/s11249-018-1100-4

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s11249-018-1100-4