Abstract

Polymeric solid lubricants lay down their own wear debris onto hard metallic counterfaces to form a protective transfer film which reduces friction and wear effectively without lubrication. Adhesive shear strength at the hidden interface between the film and substrate determines the film persistence and correlates with system wear qualitatively. Previous studies showed that an ultralow wear (k ~ 10− 7 mm3/Nm) alumina-PTFE solid lubricant forms an extremely adherent and complete transfer film, and strong chemical bonds between wear debris and counterface perpetuate the film–substrate adhesion very early in the sliding. In this paper, we aimed to test the permanence of such adhesion by removing pre-developed transfer films using sliding rubber contact and measuring the topographical evolution of the interface throughout the course of a standard wear test using the well-studied alumina-PTFE system. The results unexpectedly showed continuous wear of the counterface across the wear track, and counterface wear rate decreased proportionally from 3 × 10− 7 to 3 × 10− 8 mm3/Nm with increased film area fraction and sliding distance. A proposed rule-of-mixtures wear model coincided closely with the experimental results and strongly suggested a coupled mechanism of adhesive and fatigue wear of the counterface. The upper limit of the interfacial counterface fatigue wear rate was predicted to be 3 × 10− 8 mm3/Nm.

Similar content being viewed by others

References

Archard, J.F., Hirst, W.: The wear of metals under unlubricated conditions. Proc. R. Soc. Lond. Ser. A 236, 397–410 (1956)

Nak-Ho, S., Suh, N.P.: Effect of fiber orientation on friction and wear of fiber reinforced polymeric composites. Wear 53, 129–141 (1979)

Bahadur, S., Gong, D.: The action of fillers in the modification of the tribological behavior of polymers. Wear 158, 41–59 (1992)

Blanchet, T.A.: A model for polymer composite wear behavior including preferential load support and surface accumulation of filler particulars. Tribol. Trans. 38, 821–828 (1995)

McElwain, S.E., Blanchet, T.A., Schadler, L.S., Sawyer, W.G.: Effect of particle size on the wear resistance of alumina-filled PTFE micro- and nanocomposites. Tribol. Trans. 51, 247–253 (2008)

Li, F., Hu, K., Li, J., Zhao, B.-Y.: The friction and wear characteristics of nanometer ZnO filled polytetrafluoroethylene. Wear 249, 877–882 (2001)

Chen, W.X., Li, F., Han, G., Xia, J.B., Wang, L.Y., Tu, J.P., et al.: Tribological behavior of carbon-nanotube-filled PTFE composites. Tribol. Lett. 15, 275–278 (2003)

Sawyer, W.G., Freudenberg, K.D., Bhimaraj, P., Schadler, L.S.: A study on the friction and wear behavior of PTFE filled with alumina nanoparticles. Wear 254, 573–580 (2003)

Burris, D.L., Sawyer, W.G.: Improved wear resistance in alumina-PTFE nanocomposites with irregular shaped nanoparticles. Wear 260, 915–918 (2006)

Burris, D.L., Zhao, S., Duncan, R., Lowitz, J., Perry, S.S., Schadler, L.S., et al.: A route to wear resistant PTFE via trace loadings of functionalized nanofillers. Wear 267, 653–660 (2009)

Kandanur, S.S., Rafiee, M.A., Yavari, F., Schrameyer, M., Yu, Z.-Z., Blanchet, T.A., et al.: Suppression of wear in graphene polymer composites. Carbon 50, 3178–3183 (2012)

Kandanur, S.S., Schrameyer, M.A., Jung, K.F., Makowiec, M.E., Bhargava, S., Blanchet, T.A.: Effect of activated carbon and various other nanoparticle fillers on PTFE wear. Tribol. Trans. 57, 821–830 (2014)

Blanchet, T.A., Kandanur, S.S., Schadler, L.S.: Coupled effect of filler content and countersurface roughness on PTFE nanocomposite wear resistance. Tribol. Lett. 40, 11–21 (2009)

Burris, D.L., Sawyer, W.G.: Tribological sensitivity of PTFE/alumina nanocomposites to a range of traditional surface finishes. Tribol. Trans. 48, 147–153 (2005)

Krick, B.A., Pitenis, A.A., Harris, K.L., Junk, C.P., Sawyer, W.G., Brown, S.C., et al.: Ultralow wear fluoropolymer composites: nanoscale functionality from microscale fillers. Tribol. Int. 95, 245–255 (2016)

Bahadur, S., Tabor, D.: The wear of filled polytetrafluoroethylene. Wear 98, 1–13 (1984)

Briscoe, B.: Wear of polymers: an essay on fundamental aspects. Tribol. Int. 14, 231–243 (1981)

Bahadur, S., Gong, D., Anderegg, J.W.: The role of copper compounds as fillers in transfer film formation and wear of nylon. Wear 154, 207–223 (1992)

Schwartz, C.J., Bahadur, S.: Studies on the tribological behavior and transfer film–counterface bond strength for polyphenylene sulfide filled with nanoscale alumina particles. Wear 237, 261–273 (2000)

Ye, J., Khare, H.S., Burris, D.L.: Transfer film evolution and its role in promoting ultra-low wear of a PTFE nanocomposite. Wear 297, 1095–1102 (2013)

Ye, J., Moore, A.C., Burris, D.L.: Transfer film tenacity: a case study using ultra-low-wear alumina–PTFE. Tribol. Lett. 59, 1–11 (2015)

Harris, K.L., Pitenis, A.A., Sawyer, W.G., Krick, B.A., Blackman, G.S., Kasprzak, D.J., et al. PTFE tribology and the role of mechanochemistry in the development of protective surface films. Macromolecules 48(11), 3739–3745 (2015)

Ye, J., Khare, H.S., Burris, D.L.: Quantitative characterization of solid lubricant transfer film quality. Wear 316, 133–143 (2014)

Ye, J., Burris, D.L., Xie, T.A.: Review of transfer films and their role in ultra-low-wear sliding of polymers. Lubricants 4, 4 (2016)

Krick, B.A., Ewin, J.J., Blackman, G.S., Junk, C.P., Sawyer, G.W.: Environmental dependence of ultra-low wear behavior of polytetrafluoroethylene (PTFE) and alumina composites suggests tribochemical mechanisms. Tribol. Int. 51, 42–46 (2012)

Krick, B.A., Ewin, J.J., McCumiskey, E.J.: Tribofilm formation and run-in behavior in ultra-low-wearing polytetrafluoroethylene (PTFE) and alumina nanocomposites. Tribol. Trans. 57, 1058–1065 (2014)

Pitenis, A.A., Ewin, J.J., Harris, K.L., Sawyer, W.G., Krick, B.A..: In vacuo tribological behavior of polytetrafluoroethylene (PTFE) and alumina nanocomposites: the importance of water for ultralow wear. Tribol. Lett. 1–9 (2014)

Pitenis, A.A., Harris, K.L., Junk, C.P., Blackman, G.S., Sawyer, W.G., Krick, B.A.: Ultralow wear PTFE and alumina composites: it is all about tribochemistry. Tribol. Lett. 57(1), 4 (2015)

Harris, K.L., Curry, J.F., Pitenis, A.A., Rowe, K.G., Sidebottom, M.A., Sawyer, W.G., et al.: Wear debris mobility, aligned surface roughness, and the low wear behavior of filled polytetrafluoroethylene. Tribol. Lett. 60, 1–8 (2015)

Urueña, J.M., Pitenis, A.A., Harris, K.L., Sawyer, W.G.: Evolution and wear of fluoropolymer transfer films. Tribol. Lett. 57(1), 9 (2015)

Ye, J., Zhang, H., Liu, X., Liu, K.: Low wear steel counterface texture design: a case study using micro-pits texture and alumina–PTFE nanocomposite. Tribol. Lett. 65, 165 (2017)

Ye, J., Tao, B., Sun, W., Haidar, D.R., Alam, K.I., Liu, K., et al.: The competing effects of counterface peaks and valleys on the wear and transfer of ultra-low wear alumina–PTFE. Tribol. Lett. 66, 12 (2018)

Sawyer, W.G., Argibay, N., Burris, D.L., Krick, B.A.: Mechanistic studies in friction and wear of bulk materials. Annu. Rev. Mater. Res. 44, 395–427 (2014)

Burris, D.L., Sawyer, W.G.: Measurement uncertainties in wear rates. Tribol. Lett. 36, 81–87 (2009)

Schmitz, T.L., Action, J.E., Ziegert, J.C., Sawyer, W.G.: The difficulty of measuring low friction: uncertainty analysis for friction coefficient measurements. J. Tribol. 127, 673 (2005)

Makinson, K.R., Tabor, D.: Friction and transfer of polytetrafluoroethylene. Nature 201, 464–466 (1964)

Blanchet, T.A., Kennedy, F.E.: Sliding wear mechanism of polytetrafluoroethylene (PTFE) and PTFE composites. Wear 153, 229–243 (1992)

Haidar, D.R., Ye, J., Moore, A.C., Burris, D.L.: Assessing quantitative metrics of transfer film quality as indicators of polymer wear performance. Wear 380–381, 78–85 (2017)

Bhimaraj, P., Burris, D., Sawyer, W.G., Toney, C.G., Siegel, R.W., Schadler, L.S.: Tribological investigation of the effects of particle size, loading and crystallinity on poly (ethylene) terephthalate nanocomposites. Wear 264, 632–637 (2008)

Blanchet, T.A., Kennedy, F.E., Jayne, D.T.: XPS analysis of the effect of fillers on PTFE transfer film development in sliding contacts. Tribol. Trans. 36, 535–544 (1993)

Rabinowicz, E.: Friction and wear of materials. Wiley, New York (1995)

Greenwood, J.A., Tabor, D. Deformation properties of friction junctions. Proc. Phys. Soc. Sect. B 68:609: (1955)

Suh, P.: N. The delamination theory of wear. Wear 25, 111–124 (1973)

Suh, N.P.: An overview of the delamination theory of wear. Wear 44, 1–16 (1977)

McCook, N.L., Burris, D.L., Kim, N.H., Sawyer, W.G.: Cumulative damage modeling of solid lubricant coatings that experience wear and interfacial fatigue. Wear 262, 1490–1495 (2007)

Rabinowicz, E., Shooter, K.V. The transfer of metal to plastics during sliding. Proc. Phys. Soc. Sect. B 65, 671 (1952)

Acknowledgements

The authors gratefully acknowledge financial support from the National Natural Science Foundation of China (51505117 and 11472096), the Natural Science Foundation of Anhui Province (1608085QE98) and the Fundamental Research Funds for the Central Universities.

Author information

Authors and Affiliations

Corresponding author

Appendix

Appendix

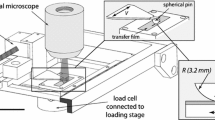

1.1 Microtribometry

Illustration of the microtribometry method used in this study to remove transfer film and expose the film–substrate interface was shown in Fig. 11. The tribometer is nominally identical to that reported in a previous publication [21], and a detailed uncertainty analysis of transfer film wear measurement can be found in Ref. [21]. Briefly, experiments were conducted on a linear reciprocating microtribometer located under an optical microscope objective which monitored the contact area in situ. The counterface sample with pre-developed transfer films was aligned and mounted to a linear reciprocating stage. A 6-mm-diameter fluoroelastomer rubber ball was superglued to the end of a steel cantilever directly mounted to a three-channel load cell. A micrometer loading stage was used to manually press the rubber ball against the reciprocating counterface. Tests were run on a 10-mm track with a mean contact pressure of 2.65 MPa and sliding speed of 10 mm/s.

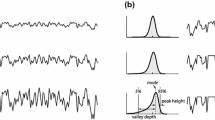

Before the test, a zero-cycle image of the transfer film was captured as a reference. Based on the image appearance, a pixel intensity thresholding technique was used to discriminate between transfer film-covered and uncovered regions with carefully selected cutoff criteria. In areas where pixel value distinction between film and free-space was less obvious, manual conversion was necessary to supplement the automated process. The converted binary image denoted film-covered and uncovered regions using black and white pixels and film area fraction was calculated as the percentage of the black pixels. In 2015, Ye et al. [21] found the extremely persistent transfer film in the native wear test lost its persistence when slid against countersamples with surface energies higher than 38 mJ/m2. Microtribometry experiments were interrupted frequently and transfer film images at the same location were captured and converted after each test interruption. In the example test in Fig. 11, a quarter of the original transfer film was removed after only 10 cycles of sliding. After 100 cycles, a majority of the transfer film was removed and film area fraction decreased to 16%. After 200 cycles, less than 1% film residue was discernable. Tests were stopped in all cases when no further change was observable with increased sliding cycles and film area fractions all decreased to less than 1%. For the particular film in Fig. 11 (200 k cycles of pre-development), the test was stopped at 200 cycles. Interestingly, up to a thousand cycles was needed for complete film removal of earlier stage transfer films. To test the abrasiveness of rubber against steel and possible back transfer of rubber, the same rubber ball was slid on a clean counterface for 1000 cycles under identical sliding conditions. The average surface height change is measured to be − 0.02 ± 0.08 µm suggesting no statistically significant steel abrasion or rubber transfer. The negative height change likely reflects the removal of surface contaminants by the sliding rubber contact.

The microtribometry test described here is unique as it enables removal of transfer film without damaging the steel substrate underneath. This preserves the topography of the transfer film–substrate interface allowing subsequent analyses. The key to this method is the use of rubber as the countersample material which has strong enough adhesion with transfer film and low enough hardness and modulus to cause any abrasion of the steel substrate. In practice, the process is not unlike the erasion of pencil marks using a rubber eraser. More details about this method could be found in Ref. [21].

Rights and permissions

About this article

Cite this article

Ye, J., Sun, W., Zhang, Y. et al. Measuring Evolution of Transfer Film–Substrate Interface Using Low Wear Alumina PTFE. Tribol Lett 66, 100 (2018). https://doi.org/10.1007/s11249-018-1054-6

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s11249-018-1054-6