Abstract

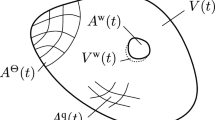

Sinuous flow is a recently discovered mode of unsteady plastic flow in the cutting of metal involving large plastic strains, extensive material folding, and consequences ranging from paradoxically large cutting forces to poor surface finish. Here we use full-scale simulations to show how sinuous flow, and the concomitant redundant plastic deformation in cutting, are caused by microstructure-related inhomogeneity. The computations are carried out in a Lagrangian continuum mechanics framework using a simple, but effective, pseudograin model to represent metal as a polycrystalline aggregate. Our simulations successfully capture all experimentally observed aspects of sinuous flow in metals, including highly undulating, non-laminar streaklines of flow in the chip, folds, and mushroom-like features, and severely deformed high aspect ratio grains. The simulations also shed light on the mechanism of sinuous flow, and the effect of deformation geometry, explaining why it is suppressed at high rake angles. We find that folding and sinuous flow can occur even at low friction, for grain sizes as small as 25–50 microns, and at very low-cutting speeds. Our study clearly points at the critical importance of incorporating microstructure in cutting simulations of pure metals.

Similar content being viewed by others

Notes

‘Laminar’ is used here to describe flows in which the streaklines of flow are nearly parallel to each other, with no kinks or vortices. A streakline is the locus of all material points that passed through a given spatial location at some earlier time.

References

Shaw, M.C.: Metal Cutting Principles. Oxford University Press, Oxford (2005)

Challen, J., Oxley, P.: An explanation of the different regimes of friction and wear using asperity deformation models. Wear 53, 229–243 (1979)

Ernst, H.: Machining of Metals. American Society for Metals, Ohio (1938)

Merchant, M.E.: Mechanics of the metal cutting process. I. Orthogonal cutting and a type 2 chip. J. Appl. Phys. 16, 267–275 (1945)

Field, M., Merchant, M.E.: Mechanics of formation of the discontinuous chip in metal cutting. Trans. Am. Soc. Mech. Eng. 71, 421 (1949)

Nakayama, K.: The formation of saw-toothed chip in metal cutting. Proc. Int. Conf. on Prod. Eng. 1, 572–577 (1974)

Viswanathan, K., Udupa, A., Yeung, H., Sagapuram, D., Mann, J.B., Saei, M., Chandrasekar, S.: On the stability of plastic flow in cutting of metals. CIRP Ann. Manuf. Technol. 66, 69–72 (2017)

Usui, E., Gujral, A., Shaw, M.C.: An experimental study of the action of CCl4 in cutting and other processes involving plastic flow. Int. J. Mach. Tool D. R. 1, 187–197 (1961)

Williams, J.E., Smart, E.F., Milner, D.R.: Metallurgy of machining. Pt. 1. Basic considerations and the cutting of pure metals. Metallurgia 81, 3–10 (1970)

Cook, N., Finnie, I., Shaw, M.: Discontinuous chip formation. Trans. ASME 76, 153 (1954)

Komanduri, R., Brown, R.: On the mechanics of chip segmentation in machining. J. Eng. Ind. 103, 33–51 (1981)

Semiatin, S., Rao, S.: Shear localization during metal cutting. Mat. Sci. Eng. 61, 185–192 (1983)

Molinari, A., Soldani, X., Miguélez, M.: Adiabatic shear banding and scaling laws in chip formation with application to cutting of Ti-6Al-4V. J. Mech. Phys. Solids 61, 2331–2359 (2013)

Yeung, H., Viswanathan, K., Compton, W.D., Chandrasekar, S.: Sinuous flow in metals. Proc. Nat. Acad. Sci. USA 112, 9828–9832 (2015)

Trent, E.M., Wright, P.K.: Metal Cutting. Butterworth-Heinemann, Oxford (2000)

Udupa, A., Viswanathan, K., Ho, Y., Chandrasekar, S.: The cutting of metals via plastic buckling. Proc. R. Soc. A 473, 20160863 (2017)

Ramalingam, S., Doyle, E., Turley, D.: On chip curl in orthogonal machining. J. Eng. Ind. 102, 177–183 (1980)

Komanduri, R., Von Turkovich B.F.: New observations on the mechanism of chip formation when machining titanium alloys. Wear 69, 179–188 (1981)

Sundaram, N.K., Guo, Y., Chandrasekar, S.: Mesoscale folding, instability, and disruption of laminar flow in metal surfaces. Phys. Rev. Lett. 109, 106001 (2012)

Vandana, A.S., Sundaram, N.K.: Interaction of a sliding wedge with a metallic substrate containing a single inhomogeneity. Trib. Lett. 65, 124 (2017)

Sundaram, N.K., Mahato, A., Guo, Y., Viswanathan, K., Chandrasekar, S.: Folding in metal polycrystals: Microstructural origins and mechanics. Acta Mater. 140C, 67–78 (2017)

Strenkowski, J.S., Carroll, J.T.: A finite element model of orthogonal metal cutting. J. Eng. Ind. 107, 349–354 (1985)

Marusich, T., Ortiz, M.: Modelling and simulation of high-speed machining. Int. J. Numer. Meth. Eng. 38, 3675–3694 (1995)

Chuzhoy, L., DeVor, R., Kapoor, S., Bammann, D.: Microstructure-level modeling of ductile iron machining. J. Manuf. Sci. Eng. 124, 162–169 (2002)

Chuzhoy, L., DeVor, R., Kapoor, S.: Machining simulation of ductile iron and its constituents, Part 2: Numerical simulation and experimental validation of machining. J. Manuf. Sci. Eng. 125, 192–201 (2003)

Simoneau, E., Ng, Elbestawi, M.: Surface defects during microcutting. Int. J. Mach. Tool. Manuf. 46, 1378–1387 (2006)

Ashby, M.: The deformation of plastically non-homogeneous materials. Philos. Mag. 21, 399–424 (1970)

Harren, S., Asaro, R.: Nonuniform deformations in polycrystals and aspects of the validity of the Taylor model. J. Mech. Phys. Solids 37, 191–232 (1989)

Huang, J.M., Black, J.T.: An evaluation of chip separation criteria for the FEM simulation of machining. J. Manuf. Sci. E 118, 545–554 (1996)

Subbiah, S., Melkote, S.N.: Evidence of ductile tearing ahead of the cutting tool and modeling the energy consumed in material separation in micro-cutting. J. Eng. Mater. Technol. 129, 321–331 (2007)

Johnson, G.R., Cook, W.H.: A constitutive model and data for metals subjected to large strains, high strain rates and high temperatures. In: Proceedings of the 7th International Symposium on Ballistics 21, 541–547 (1983)

Armstrong, P.E., Hockett, J.E., Sherby, O.: Large strain multidirectional deformation of 1100 aluminum at 300 K. J. Mech. Phys. Solids 30, 37–58 (1982)

Lindholm, U.S.: Some experiments with the split Hopkinson pressure bar. J. Mech. Phys. Solids 12, 317–335 (1964)

Vachhani, S.J., Kalidindi, S.R.: Grain-scale measurement of slip resistances in aluminum polycrystals using spherical nanoindentation. Acta Mater. 90, 27–36 (2015)

Lemaitre, J.: A continuous damage mechanics model for ductile fracture. J. Eng. Mater. 107, 83–89 (1985)

Atkins, A.G.: Modelling metal cutting using modern ductile fracture mechanics: quantitative explanations for some longstanding problems. Int. J. Mech. Sci. 45, 373–396 (2003)

Dassault-Systemes: Abaqus Analysis User Manual. Dassault Systemes Simulia Corporation, Providence (2012)

Chung, W.J., Cho, J.W., Belytschko, T.: On the dynamic effects of explicit FEM in sheet metal forming analysis. Eng. Comput. 15, 750–776 (1998)

Melkote, S.N., Grzesik, W., Outeiro, J., Rech, J., Schulze, V., Attia, H., Arrazola, P.-J., MSaoubi, R., Saldana, C.: Advances in material and friction data for modelling of metal machining. CIRP Ann. 66, 731–754 (2017)

Okushima, K., Hitomi, K.: On the Cutting Mechanism for Soft Metals. Mem. Fac. Eng. 19, 135–166 (1957)

A.Molinari and Moufki, A.: The Merchant’s model of orthogonal cutting revisited: A new insight into the modeling of chip formation. Int. J. Mech. Sci. 50, 124–131 (2008)

Childs, T.H.C.: Friction modelling in metal cutting. Wear 260, 310–318 (2006)

Hill, R.: The mechanics of machining: A new approach. J. Mech. Phys. Solids 3, 47–53 (1954)

Dewhurst, P.: On the non-uniqueness of the machining process. Proc. R. Soc. A 360, 587–610 (1978)

Hansen, N., Jensen, D.J.: Development of microstructure in FCC metals during cold work. Philos. Trans. R. Soc. A 357, 1447–1469 (1999)

Roters, F., Eisenlohr, P., Hantcherli, L., Tjahjanto, D.D., Bieler, T.R., Raabe, D.: Overview of constitutive laws, kinematics, homogenization and multiscale methods in crystal plasticity finite-element modeling: Theory, experiments, applications. Acta Mater. 58, 1152–1211 (2010)

Madhavan, V., Chandrasekar, S., Farris, T.: Machining as a wedge indentation. J. Appl. Mech. 67, 128–139 (2000)

Beckmann, N., Romero, P., Linsler, D., Dienwiebel, M., Stolz, U., Moseler, M., Gumbsch, P.: Origins of folding instabilities on polycrystalline metal surfaces. Phys. Rev. Appl. 2, 064004 (2014)

Li, Szlufarska, I.: How grain size controls friction and wear in nanocrystalline metals. Phys. Rev. B 92, 075418 (2015)

Guo, Y., M’Saoubi, R., Chandrasekar, S.: Control of deformation levels on machined surfaces. CIRP Ann. 60, 137–140 (2011)

Komanduri, R., Schroeder, T., Hazra, J., Von Turkovich, B., Flom, D.: On the catastrophic shear instability in high-speed machining of an AISI 4340 steel. J. Eng. Ind. 104, 121–131 (1982)

Davies, M.A., Burns, T.J., Evans, C.J.: On the dynamics of chip formation in machining hard metals. CIRP Ann. 46, 25–30 (1997)

Mann, J., Guo, Y., Saldana, C., Compton, W., Chandrasekar, S.: Enhancing material removal processes using modulation-assisted machining. Tribol. Int. 44, 1225–1235 (2011)

Author information

Authors and Affiliations

Corresponding author

Electronic supplementary material

Links to the electronic supplementary material are given below.

Rights and permissions

About this article

Cite this article

Vandana, A.S., Sundaram, N.K. Simulation of Sinuous Flow in Metal Cutting. Tribol Lett 66, 94 (2018). https://doi.org/10.1007/s11249-018-1047-5

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s11249-018-1047-5