Abstract

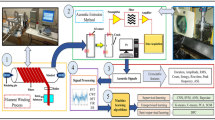

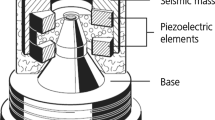

Face rub-impact of a dry gas seal was investigated using acoustic emission (AE) technology. A force applicator was designed and mounted on the seal test rig to provide controlled misalignment and thus induce rub-impact of the seal faces. Two types of AE sensor were mounted at different positions on the seal. For the PICO AE sensor mounted directly on the seal ring, the root mean square (RMS) of the original AE signal was sensitive to face rub-impact of the seal. When force was applied, the AE RMS of the PICO sensor gave a distinct periodic waveform with a period consistent with the rotational period above an initial noise signal. The magnitude and shape of the waveform changed as the applied force increased. For the R15α AE sensor mounted on the housing of the seal, no obvious changes could be found from the RMS of the original AE signal synchronously obtained during loading. Two kinds of signal processing methods were tried to eliminate noise. After band-pass filtering, the RMS of the AE signals of the R15α sensor indicated face rub-impact when the misalignment was relatively large. The empirical mode decomposition method using masking signals was found to be more effective than band-pass filtering in eliminating the noise but took much more computational time. The results indicate that the AE technology is a potentially effective tool in monitoring and investigating face rub-impact of dry gas seals.

Similar content being viewed by others

References

Wang, Y.M., Yang, H.X., Wang, J.L., et al.: Theoretical analyses and field applications of gas-film lubricated mechanical face seals with herringbone spiral grooves. Tribol. Trans. 52, 800–806 (2009)

Burgmann Inc.: Gas lubricated mechanical seals. Fodor Burgmann Dichtungswerke Gmbh & Co., Wolfrathausen (1997)

Huang, W.F., Lin, Y.B., Gao, Z., et al.: An acoustic emission study on the starting and stopping processes of a dry gas seal for pumps. Tribol. Lett. 49(2), 379–384 (2013)

Miller, B.A., Green, I.: Numerical formulation for the dynamic analysis of spiral-grooved gas face seals. J. Tribol. 123(2), 395–403 (2000)

Miller, B.A., Green, I.: Semi-analytical dynamic analysis of spiral-grooved mechanical gas face seals. J. Tribol. 125(2), 403–413 (2003)

Zou, M., Dayan, J., Green, I.: Feasibility of contact elimination of a mechanical face seal through clearance adjustment. J. Gas Turbines Power 122(3), 478–484 (2000)

Dayan, J., Zou, M., Green, I.: Contact elimination in mechanical face seals using active control. IEEE Trans. Control Syst. Technol. 10(3), 344–354 (2002)

Lee, A.S., Green, I.: Higher harmonic oscillations in a noncontacting FMR mechanical face seal test rig. J. Vib. Acoust. 116(2), 161–167 (1994)

Lingard, S., Yu, C.W., Yau, C.F.: Sliding wear studies using acoustic emission. Wear 162, 597–604 (1993)

Miettinen, J., Siekkinen, V.: Acoustic emission in monitoring sliding contact behavior. Wear 181–183, 897–900 (1995)

Mba, D., Roberts, T., Taheri, E., et al.: Application of acoustic emission technology for detecting the onset and duration of contact in liquid lubricated mechanical seals. Insight 48(8), 486–487 (2006)

Fan, Y., Gu, F., Ball, A.: Modeling acoustic emissions generated by sliding friction. Wear 268(5–6), 811–815 (2010)

Deering, R., Kaiser, J.F.: The use of a masking signal to improve empirical mode decomposition. IEEE Int. Conf. Acoust. Speech Signal Process. 4, 485–488 (2005)

Acknowledgments

This work is jointly supported by the National Basic Research Program of China (Grant No. 2012CB026003), National Key Technology R&D Program (Grant No. 2011BAF09B05), and National S&T Major Project (Grant No. ZX06901).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Huang, W., Lin, Y., Liu, Y. et al. Face Rub-Impact Monitoring of a Dry Gas Seal Using Acoustic Emission. Tribol Lett 52, 253–259 (2013). https://doi.org/10.1007/s11249-013-0210-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11249-013-0210-2