Abstract

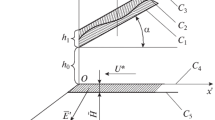

Externally pressurized grooved gas thrust bearings for shaft systems were studied both numerically and experimentally. Three thrust bearings composed of a symmetric pair of rings facing a shaft collar were tested. The rings, with inner and outer diameters of 52 and 110 mm, respectively, are equipped with a polar array of eight holes, with a 0.35-mm diameter, distributed on a 65-mm-diameter circumference. The influence of a circumferential groove situated in correspondence with the supply holes is discussed. In particular, two thrust bearings have a rectangular cross-sectional groove of 0.7-mm width and 10- and 20-μm depth. A numerical model based on Reynolds' equation is used to study thrust-bearing performance in relation to geometry (diameter of supply holes, clearance, and groove dimensions). A test rig is used to monitor thrust-bearing axial load capacity and stiffness, and evaluate damping and stability at different supply pressure rates. Experimental and numerical results are compared and discussed.

Similar content being viewed by others

Abbreviations

- b :

-

Theoretical pressure critical ratio = 0.528

- c :

-

Damping coefficient

- c d :

-

Discharge coefficient

- C S :

-

Conductance of supply port

- d S :

-

Supply port diameter

- f d :

-

Frequency of damped system

- f h :

-

Air hammer frequency

- f n :

-

Natural frequency

- F :

-

Axial force acting on shaft (including shaft weight for vertical position)

- G :

-

Air mass flow rate

- h :

-

Clearance

- h 0 :

-

Clearance in center position

- h g :

-

Groove depth

- K :

-

Stiffness

- k T :

-

Temperature coefficient\( = \sqrt {293/T^{0} } \)

- m :

-

Shaft mass

- N :

-

Number of ports on each bearing ring

- P :

-

Absolute pressure

- P a :

-

Ambient pressure

- P C :

-

Supply port downstream pressure

- P S :

-

Absolute supply pressure

- q :

-

Inlet mass flow rate per unit area

- r :

-

Radial coordinate

- R 0 :

-

Gas constant = 287.6 m2/s2 K

- r 0 :

-

Supply ports circumference radius

- r e :

-

Thrust-bearing outer radius

- r i :

-

Thrust-bearing inner radius

- Re :

-

Reynolds number

- r g :

-

Groove radius

- S :

-

Port cross-section

- t :

-

Time

- T 0 :

-

Absolute temperature in normal condition

- w g :

-

Groove width

- z :

-

Axial coordinate

- δ:

-

Logarithmic decrement

- ε:

-

Eccentricity ratio = z/h 0

- μ:

-

Air viscosity

- ρST :

-

Air density in standard condition

- θ:

-

Angular coordinate

- ω:

-

Rotational frequency

- \( \omega_{n} = \sqrt {{\frac{k}{m}}} \) :

-

Natural angular frequency

- \( \omega_{d} = \omega_{n} \sqrt {1 - \zeta^{2} } \) :

-

Angular frequency of damped system

- \( \zeta = {\frac{c}{{2\sqrt {km} }}} \) :

-

Damping factor

References

Blondeel, E., Snoeys, R., Devrieze, L.: Dynamic stability of externally pressurized gas bearings. J. Lubr. Technol. 102, 511–519 (1980)

Al-Bender, F., Van Brussel, H.: Tilt characteristics of circular centrally fed aerostatic bearings. Tribol. Int. 25–3, 189–197 (1992)

Huges, S.J., Hogg, S.I., Jones, T.V.: Analysis of a gas lubricated hydrodynamic thrust bearing. J. Tribol. 118–7, 449–456 (1996)

Bang, K.G., Lee, D.G.: Thrust bearing design for high-speed composite air spindles. Compos. Struct. 57, 149–160 (2002)

Li, H., Ding, H.: Influences of the geometrical parameters of aerostatic thrust bearing with pocketed orifice-type restrictor on its performance. Tribol. Int. 40, 1120–1126 (2007)

Yoshimoto, S., Tamamoto, M., Toda, K.: Numerical calculations of pressure distribution in the bearing clearance of circular aerostatic thrust bearings with a single air supply inlet. Trans. ASME 129–4, 384–390 (2007)

Nakamura, T., Yoshimoto, S.: Static tilt characteristics of aerostatic rectangular double compound restrictors. Tribol. Int. 2, 145–152 (1996)

Yoshimoto, S., Tamura, J., Nakamura, T.: Dynamic tilt characteristics of aerostatic rectangular double-pad thrust bearings with compound restrictors. Tribol. Int. 32, 731–738 (1999)

Chen, M.F., Lin, Y.T.: Static behavior and dynamic stability analysis of grooved rectangular aerostatic thrust bearings by modified resistance network method. Tribol. Int. 35, 329–338 (2002)

Bonneau, D., Huitric, J., Tournerie, B.: Finite element analysis of grooved gas thrust bearings and grooved gas face seals. J. Tribol. 115, 348–354 (1993)

Belforte, G., Raparelli, T., Viktorov, V., Trivella, A., Colombo, F.: An experimental study of high-speed rotor supported by air bearings: test rig and first experimental results. Tribol. Int. 39, 839–845 (2006)

Belforte, G., Colombo, F., Raparelli, T., Trivella, A., Viktorov, V.: Study of a high speed electrospindle with air bearings. In: European Conference on Tribology ECOTRIB 2007, Ljubliana, vol. 2, pp. 969–982, 12–15 June 2007

Belforte, G., Colombo, F., Raparelli, T., Trivella, A., Viktorov, V.: Study of a gas thrust bearing with supply grooves. In: Proceedings of the 7th JFPS International Symposium on Fluid Power, Toyama, pp. 515–519, 15–18 September 2008

Grassam, N.S., Powell, J.W.: Gas lubricated bearings, pp. 135–139. Butterworths, London (1964)

ISO 6358:1989. Pneumatic fluid power—determination of flow-rate characteristics

Belforte, G., Raparelli, T., Viktorov, V., Trivella, A.: Discharge coefficients of port-type restrictor for aerostatic bearings. Tribol. Int. 40, 512–521 (2007)

Acknowledgments

This research work was conducted by LAQ-IBIS with the support of PRIN06 “Study and development of gas bearings for ultra-high-speed electrospindle” and FIRB Project “Enabling technologies for multitasking high-precision machining of microparts.”

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Belforte, G., Colombo, F., Raparelli, T. et al. Performance of Externally Pressurized Grooved Thrust Bearings. Tribol Lett 37, 553–562 (2010). https://doi.org/10.1007/s11249-009-9550-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11249-009-9550-3