Abstract

Although size effects in hardness have been extensively reported and analyzed for the static (indentation) case, much less attention has been given to these effects in non-static (scratch) hardness measurements. In the present work, size effects in the indentation and scratch hardness response of the Ni–Co system are evaluated by performing tests at several penetration depths, from the micro to the nanometer range. It is shown that, for all the range of compositions, the hardness response of these materials is strongly affected by the depth of penetration of the indenter: when the depth decreases, both the indentation and scratch hardness increase several times. This result denotes that, when studying the wear behavior of materials, special care must be taken concerning the scale one is dealing with, since the tribo-mechanical response of the material may change significantly from the micrometric to the nanometric contact scale.

Similar content being viewed by others

References

Colaço, R.: Surface damage mechanisms from nano and microcontacts to wear of materials. In: Meyer, E., Gnecco, E. (eds.) Fundamentals of Friction and Wear on the Nanoscale, pp. 453–480. Springer-Verlag (2007)

ASM handbook, vol. 18, Friction, Lubrication and Wear Technology. ASM International, Metals Parks, OH (1992)

Williams, J.A.: Analytical models of scratch hardness. Tribol. Int. 29, 675–694 (1996). doi:10.1016/0301-679X(96)00014-X

Fleck, N.A., Muller, G.M., Ashby, M.F., Hutchinson, J.W.: Strain gradient plasticity – theory and experiment. Acta Metall. Mater. 42, 475–487 (1994). doi:10.1016/0956-7151(94)90502-9

Ma, Q., Clarke, D.R.: Size dependent hardness of silver single-crystals. J. Mater. Res. 10, 853–863 (1995). doi:10.1557/JMR.1995.0853

McElhaney, K.W., Vlassak, J.J., Nix, W.D.: Determination of indenter tip geometry and indentation contact area for depth-sensing indentation experiments. J. Mater. Res. 13, 1300–1306 (1998). doi:10.1557/JMR.1998.0185

Liu, Y., Ngan, A.H.W.: Depth dependence of hardness in copper single crystals measured by nanoindentation. Scr. Mater. 44, 237–241 (2001). doi:10.1016/S1359-6462(00)00598-4

Misra, A., Finnie, I.: On the size effect in abrasive and erosive wear. Wear 65, 359–373 (1981). doi:10.1016/0043-1648(81)90062-4

Chaudhuri, D., Xie, D., Lakshmanan, A.N.: The influence of stacking fault energy on the wear resistance of nickel base alloys. Wear 209, 140–152 (1997). doi:10.1016/S0043-1648(97)00010-0

Carvalho, P.A., Braz, N., Pontinha, M.M., Ferreira, M.G.S., Steen, W.M., Vilar, R., et al.: Automated workstation for variable composition laser cladding – its use for rapid alloy scanning. Surf. Coat. Technol. 72, 62–70 (1995). doi:10.1016/0257-8972(94)02333-L

Graça, S., Colaço, R., Vilar, R.: Indentation size effect in nickel and cobalt laser clad coatings. Surf. Coat. Technol. 202, 538–548 (2007). doi:10.1016/j.surfcoat.2007.06.031

Graça, S., Colaço, R., Vilar, R.: Using atomic force microscopy to retrieve nanomechanical surface properties of materials. Mater. Sci. Forum 514–516, 1598–1602 (2006)

Tabor, D.: The Hardness of Metals. Oxford University Press, Oxford (2000)

Antunes, J.M., Cavaleiro, A., Menezes, L.F., Simões, M.I., Fernandes, J.V.: Ultra-microhardness testing procedure with Vickers indenter. Surf. Coat. Technol. 149, 27–35 (2002). doi:10.1016/S0257-8972(01)01413-X

Metals Handbook, vol. 8, 8th edn. ASM, Metals Park, OH (1973)

Gane, N., Skinner, J.: Friction and scratch deformation of metals on a microscale. Wear 24, 207–217 (1973). doi:10.1016/0043-1648(73)90233-0

Thompson, A.W.: Order in Ni 25 percent Co. Scr. Metall. 8, 1167–1170 (1974). doi:10.1016/0036-9748(74)90489-X

Taylor, A.: Latice parameters of binary nickel cobalt alloys. J. Inst. Met. 77, 585–594 (1950)

Garlipp, W., Cilense, M., Beatrice, C.R.S.: Evidence of short-range order in Ni-Co (25at-percent-Co) alloy by electrical-resistivity. Scr. Metall. Mater. 29, 1035–1037 (1993). doi:10.1016/0956-716X(93)90173-P

Cable, J.W., Wollan, E.O., Koehler, W.C.: Distribution of magnetic moments in Pd-3D and Ni-3D alloys. Phys. Rev. 138, A755 (1965). doi:10.1103/PhysRev.138.A755

Ma, Z., Long, S., Pan, Y., Zhou, Y.: Indentation depth dependence of the mechanical strength of Ni films. J. Appl. Phys. 103, 043512 (2008). doi:10.1063/1.2885090

Mathieu, H.J., Datta, M., Landolt, D.: Thickness of natural oxide-films determined by AES and XPS with and without sputtering. J. Vac. Sci. Technol. A 3, 331–335 (1985). doi:10.1116/1.573260

Thouless, M.D.: An analysis of spalling in the microscratch tests. Eng. Fract. Mech. 61, 75–81 (1998). doi:10.1016/S0013-7944(98)00049-6

Degiampietro, K., Colaco, R.: Nanoabrasive wear induced by an AFM diamond tip on stainless steel. Wear 263, 1579–1584 (2007). doi:10.1016/j.wear.2006.10.020

Acknowledgments

The authors thank Prof. Albano Cavaleiro for his help in performing ultramicrohardness experiments and FCT for the financial support of this research (Project Nanonico, POCTI/CTM/59376/2004). S. Graça also acknowledges FCT for the PhD grant SFRH/BD/17758/2004.

Author information

Authors and Affiliations

Corresponding author

Appendix: Geometrical Characterization of Nanoindentation and Nanoscratch Hardness Tests

Appendix: Geometrical Characterization of Nanoindentation and Nanoscratch Hardness Tests

The Veeco DNISP diamond AFM tip used in this work is an equilateral triangular base pyramid (Fig. A1a) with tip apex angle of ~93° (Fig. A1b). Assuming that the tip is infinitely sharp (Fig. A2), the angle between the back face and the axis of the pyramid (β) is ~47.5°, while the angle between the front edge and the axis of the pyramid (α) is ~45.5°. By using simple trigonometric relations, the following equations can be obtained:

SEM micrographs of Veeco DNISP probe viewed from bottom (a) and side (b). The side view shows that the top part of the diamond mounted on the cantilever is pyramidal, with the axis of the pyramid perpendicular to the cantilever, whereas the bottom part, where most of the glue is located, has irregular geometry

with a, b, w, and h, defined in Fig. A2. Combining Eqs. A1–A3, the area function of the tip, A p(h), can be obtained:

Replacing the apex semi-angles α and β by the values retrieved from the SEM micrograph of Fig. A1b, an approximated value of the area function of the DNISP tip can be obtained:

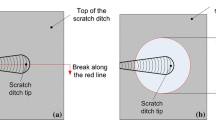

A 2-D scheme of the DNISP tip scratching the surface of a material can be seen in Fig. A3. During the scratching process it is assumed that the perimeter of the contact is located at the surface mean line and, consequently, pile-up or sink-in effects do not contribute to the contact area. In this case w corresponds exactly to the width of the groove. Moreover, the contact between indenter and material only occurs at the two frontal faces of the pyramid (dark areas at the bottom part of Fig. A3). By introducing the values of a and b (given by Eqs. A1 and A2, respectively) in Eq. A3, and solving this equation in relation to h, the following relation is obtained:

From Fig. A3 results:

Combining Eqs. A1, A6, and A7, c can be written as function of w:

The projected area of contact between indenter and material during the scratch test, A s, is then given by:

and, finally, the scratch hardness (H s) can be determined:

with

Replacing the apex semi-angles α and β by the values retrieved from the SEM micrograph of Fig. A1b leads to η = 4.786 for the DNISP tip.

The depth of the nanoindentations, h i, can be estimated by combining Eqs. 1 and A5:

where H i is the indentation hardness measured from the AFM images of nanoindentations. The depth of the nanoscratches can be determined by combining Eqs. A6, A10, and A11 and replacing the apex semi-angles α and β by the values retrieved from the SEM micrograph of Fig. A1b:

where H s is the scratch hardness measured from the AFM images of nanoscratches.

Rights and permissions

About this article

Cite this article

Graça, S., Colaço, R. & Vilar, R. Micro-to-Nano Indentation and Scratch Hardness in the Ni–Co System: Depth Dependence and Implications for Tribological Behavior. Tribol Lett 31, 177–185 (2008). https://doi.org/10.1007/s11249-008-9350-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11249-008-9350-1