Abstract

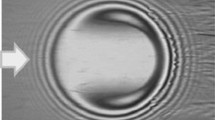

The authors showed in previous experiments with high viscosity polymeric lubricants that a non-classical elastohydrodynamic (EHL) film, which featured an inlet dimple, could be generated under pure sliding conditions. The phenomenon was tentatively attributed to boundary slippage. In this paper, much greater sliding is introduced in the experiments to gain further insight into film formation under boundary slippage. By putting all of the results on a load versus entrainment speed chart, it is found that the required conditions for the formation of the inlet dimple fall into an open triangular region in the chart. The existence of the inlet dimple can be maintained for a larger speed range with a higher load. The minimum speed required (the lower speed bound for the dimple existence) decreases only marginally with an increase in load but the speed of the disappearance of the dimple (the upper speed bound) increases with an increasing load. Interferograms show that with an increase in the slide-roll ratio, i.e., expanded boundary slippage, a bump occurs before the exit constriction, which indicates an obvious drop in film thickness, and the location of the minimum film thickness in the whole EHL contact moves from the outlet constriction to the center of the bump. The observed inlet dimple and bump have already been described in the previous numerical results that consider boundary slippage, and provide more justification for the boundary slippage postulation in the experimental films.

Similar content being viewed by others

Abbreviations

- b :

-

Radius of the Hertzian contact, m

- E′:

-

Reduced elastic modulus, Pa

- G :

-

Dimensionless material parameter, G = α E′

- H :

-

Dimensionless film thickness, H = h/R

- H cen :

-

Dimensionless central film thickness, H cen = h cen/R

- H min :

-

Dimensionless minimum film thickness, H min = h min/R

- h :

-

Film thickness, m

- h cen, h min :

-

The central and minimum film thickness, m

- p H :

-

The maximum Hertzian pressure, Pa

- S :

-

Slide-roll ratio, \( S = {{\left( {u_{\hbox{d}} - u_{\hbox{b}} } \right)} \mathord{\left/ {\vphantom {{\left( {u_{\hbox{d}} - u_{\hbox{b}} } \right)} {u_{\hbox{e}} }}} \right. \kern-\nulldelimiterspace} {u_{\hbox{e}} }} \)

- U e :

-

Dimensionless entrainment speed, \( U_{\hbox{e}} = {{u_{\hbox{e}} \eta _0 } \mathord{\left/ {\vphantom {{u_{\hbox{e}} \eta _0 } {\left( {E'R} \right)}}} \right. \kern-\nulldelimiterspace} {\left( {E'R} \right)}} \)

- u d, u b :

-

Speed of the surfaces of the disc and the ball, m/s

- u e :

-

Entrainment speed, \( u_{\hbox{e}} = {{\left( {u_{\hbox{d}} + u_{\hbox{b}} } \right)} \mathord{\left/ {\vphantom {{\left( {u_{\hbox{d}} + u_{\hbox{b}} } \right)} 2}} \right. \kern-\nulldelimiterspace} 2} \), m/s

- W :

-

Dimensionless load, \( W = {w \mathord{\left/ {\vphantom {w {\left( {E'R^2 } \right)}}} \right. \kern-\nulldelimiterspace} {\left( {E'R^2 } \right)}} \)

- w :

-

Load, N

- X :

-

Dimensionless coordinate along the central entrainment direction, X = x/b

- Y :

-

Dimensionless coordinate cross the central entrainment direction, Y = y/b

- x :

-

Coordinate along the central entrainment direction, m

- α:

-

Pressure-viscosity coefficient, Pa−1

- η0 :

-

Ambient viscosity of the lubricant, Pa s

References

Dowson, D., Higginson, G.R.: Elastohydrodynamic Lubrication. SI Edition. Pergamon Press, Oxford (1977)

Gohar, R., Cameron, A.: Nature 200, 458–459 (1983)

Foord, C.A., Wedeven, L.D., Westlake, F.J., Cameron, A.: Optical Elastohydrodynamics. Proc. Instn. Mech. Engrs. 184(1), 487–505 (1969–1970)

Chiu, Y.P., Sibley, L.B.: Contact shape and non-Newtonian effects in elastohydrodynamic point contacts. ASLE Lubrication Eng. 28, 48–60 (1972)

Bair, S., Winer, W.O.: The high-pressure, high shear stress rheology of liquid lubricants. J. Tribology 114, 1–13 (1992)

Spikes, H.A.: Slip at the wall-evidence and tribological implications. In: Dowson D., et al. (eds.) Thinning Films and Tribological Interfaces, pp. 525–535. Elsevier (2003)

Lee, R.T., Hamrock, B.J.: A circular non-Newtonian fluid model: Part I – used in elastohydrodynamic lubrication. ASME J. Tribology 112, 486–496 (1990)

Shieh, J., Hamrock, B.J.: Film collapse in EHL and micro-EHL. Trans. ASME J. Tribology 113, 372–377 (1991)

Ehret, P., Dowson, D., Taylor, C.M.: On lubricant transport conditions in elastohydrodynamic conjunctions. Proc. R. Soc. Lond. A 454, 763–787 (1998)

Livonen, H., Hamrock, B.J.: A new non-Newtonian fluid model for elastohydrodynamic lubrication of rectangular contacts. Wear 143, 297–305 (1991)

Zhang, Y.B., Wen, S.: An analysis of elastohydrodynamic lubrication with limiting shear stress: part I – theory and solutions. Tribology Trans. 45, 135–144 (2002)

Stahl, J., Jacobson, B.O.: A lubricant model considering wall-slip in EHL line contacts. ASME J. Tribology 125, 523–532 (2003)

Kaneta, M., Nishikawa, H., Kameishi, K., Saka, T., Ohno, N.: Effects of elastic moduli of contact surfaces in elastohydrodynamic lubrication. ASME J. Tribology 114, 75–80 (1992)

Kaneta, M., Nishikawa, H., Kanada, T., Matsuda, K.: Abnormal phenomena appearing in EHL contacts. ASME J. Tribology 118, 886–892 (1996)

Qu, S., Yang, P., Guo, F.: Theoretical investigation on the dimple occurrence in the thermal EHL of simple sliding steel-glass circular contacts. Tribol. Int. 33, 59–65 (2000)

Guo, F., Yang, P., Qu, S.: On the theory of thermal elastohydrodynamic lubrication at high slide-roll ratios – circular glass-steel contact solution at opposite sliding. ASME J. Tribology 123, 816–821 (2001)

Yang, P., Qu, S., Kaneta, M., Nishikawa, H.: Formation of steady dimples in point TEHL contacts. ASME J. Tribology 123, 42–49 (2001)

Guo, F., Wong, P.L.: An anomalous elastohydrodynamic lubrication film: inlet dimple. ASME J. Tribology 127, 425–434 (2005)

Guo, F., Wong P.L.: Variations of an EHL film under boundary slippage. Proc. IUTAM Symposium on Elastohydrodynamics and Micro-elastohydrodynamics, 285–296 (2004)

Guo, F., Wong, P.L.: Experimental observation of a wedge-dimple elastohydrodynamic lubricating film. Tribology Int. 37, 119–127 (2004)

Guo, F., Wong, P.L.: A multiple-beam intensity-based approach for thin lubricant film measurement in non-conformal contacts. Proc. Instn. Mech. Engrs. J. Engg. Tribol. 216, 281–291 (2002)

Choo, J.H., Spikes, H.A., Ratoi, M., Glovnea, R.P., Forrest, A.K.: Friction reduction in low-load hydrodynamic lubrication with a hydrophobic surface. Tribology Int. 40, 154–159 (2007)

Acknowledgments

The work described in this paper was supported by the Research Grants Council of the Hong Kong Special Administrative Region, China (Project No. CityU 121405) and the National Natural Science Foundation of China (Project No. 50475165 -05-2-P-4).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Fu, Z., Guo, F. & Wong, P.L. Non-classical Elastohydrodynamic Lubricating Film Shape Under Large Slide-roll Ratios. Tribol Lett 27, 211–219 (2007). https://doi.org/10.1007/s11249-007-9227-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11249-007-9227-8