Abstract

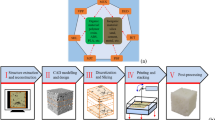

Stereolithographic 3D printing is of paramount interest for researchers studying porous media because it is possible to use resins with a wide range of physical and chemical properties. Currently, these properties can be designed and adjusted to model the interaction of solids with fluids occupying the pore space, which is not feasible with natural materials. This ability enables replicating the pore network geometry of natural rocks as well as tuning the wettability of pore network surfaces. This study presents analysis of uncured liquid resins and porous rock models 3D-printed in those resins to establish the accuracy of the stereolithographic 3D printer in repeatedly printing the same pore network, as well as the fidelity of transport properties (e.g., porosity, pore sizes, wettability) to the model design. Viscosity of uncured resins was measured to predict the physical properties of the resulting cured models. A digital model of Fontainebleau sandstone was 3D-printed at three magnifications (15-, 23-, and 30-fold) from the original tomographic volume of 1 mm3 and in six resins (black, gray, clear, white, green, and yellow). The models were validated using the following techniques: helium pycnometry (for porosity); mercury porosimetry (for pore-throat size); and drop shape analyzer (for contact angles). Validation tests showed that green resin had the highest accuracy in replicating the rock’s pore network. White, yellow, and gray resins produced models with moderate accuracy with respect to their transport properties. Black and clear resins had the lowest accuracy and would need further analysis of their physical and chemical properties to be useful in reservoir rock replication.

Similar content being viewed by others

References

Alzahid, Y.A., Mostaghimi, P., Gerami, A., Singh, A., Privat, K., Amirian, T., Armstrong, R.T.: Functionalisation of polydimethylsiloxane (PDMS)-microfluidic devices coated with rock minerals. Sci. Rep. (2018). https://doi.org/10.1038/s41598-018-33495-8

Andrä, H., Combaret, N., Dvorkin, J., Glatt, E., Han, J., Kabel, M., Keehm, Y., Krzikalla, F., Lee, M., Madonna, C., Marsh, M., Mukerji, T., Saenger, E.H., Sain, R.: Digital rock physics benchmarks—part II: computing effective properties. Comput. Geosci. (2013). https://doi.org/10.1016/j.cageo.2012.09.008

ASTM-D7334-08: Standard Practice for Surface Wettability of Coatings, Substrates and Pigments by Advancing Contact Angle Measurement (2013)

Ayub, K.V., Santos, G.C., Rizkalla, A.S., Bohay, R., Pegoraro, L.F., Rubo, J.H., Santos, M.J.M.C.: Effect of Preheating on microhardness and viscosity of 4 resin composites. J. Can. Dent. Assoc. 80, e12 (2014)

Baba, E.M., Cansoy, C.E., Zayim, E.O.: Optical and wettability properties of polymers with varying surface energies. Appl. Surf. Sci. (2015). https://doi.org/10.1016/j.apsusc.2015.02.150

Bacher, M., Schwen, A., Koestel, J.: Three-dimensional printing of macropore networks of an undisturbed soil sample. Vadose Zone J. (2014). https://doi.org/10.2136/vzj2014.08.0111

Blunt, M.J., Bijeljic, B., Dong, H., Gharbi, O., Iglauer, S., Mostaghimi, P., Paluszny, A., Pentland, C.: Pore-scale imaging and modeling. Adv. Water Resour. (2013). https://doi.org/10.1016/j.advwatres.2012.03.003

Dvorkin, J., Armbruster, M., Baldwin, C., Fang, Q., Derzhi, N., Gomez, C., Nur, B., Nur, A.: The future of rock physics: computational methods vs. lab testing. Pet. Geol. 26, 63–68 (2008)

Encinas, N., Pantoja, M., Abenojar, J., Martinez, M.A.: Control of wettability of polymers by surface roughness modification. J. Adhes. Sci. Tech. (2010). https://doi.org/10.1163/016942410X511042

Gerami, A., Mostaghimi, P., Armstrong, R.T., Zamani, A., Warkiani, M.E.: A microfluidic framework for studying relative permeability in coal. Int. J. Coal Geol. (2016). https://doi.org/10.1016/j.coal.2016.04.002

Gunda, N.S.K., Bera, B., Karadimitriou, N.K., Mitra, S.K., Hassanizadeh, S.M.: Reservoir-on-a-Chip (ROC): A new paradigm in reservoir engineering. Lab on a Chip (2011). https://doi.org/10.1039/C1LC20556K

Hasiuk, F., Ishutov, S., Pacyga, A.: Validating 3D-printed porous proxies by tomography and porosimetry. Rapid Prototyp. J. (2018). https://doi.org/10.1108/RPJ-06-2017-0121

Ishutov, S., Hasiuk, F.: 3D printing Berea sandstone: testing a new tool for petrophysical analysis of reservoirs. Petrophysics 58, 592–602 (2018)

Ishutov, S., Hasiuk, F.J., Fullmer, S.M., Buono, A., Gray, J.N., Harding, C.: Resurrection of a reservoir sandstone from tomographic images using 3-D Printing. Am. Assoc. Pet. Geol. Bull. (2017). https://doi.org/10.1306/11111616038

Ishutov, S., Hasiuk, F., Agar, S.M., Jobe, D.: Using resin-based 3D printing to build accurate proxies of porous sedimentary rocks. Groundwater (2018a). https://doi.org/10.1111/gwat.12601

Ishutov, S., Jobe, T.D., Zhang, S., Gonzalez, M.A., Agar, S.M., Hasiuk, F., Watson, F., Geiger, S., Mackay, E., Chalaturnyk, R.: 3D printing for geoscience: fundamental research, education, and applications for the petroleum industry. Am. Assoc. Pet. Geol. Bull. (2018b). https://doi.org/10.1306/0329171621117056

Ju, Y., Zheng, Z., Xie, H., Lu, J., Wang, L., He, K.: Experimental visualisation methods for three-dimensional stress fields of porous solids. Exp. Tech. (2017). https://doi.org/10.1007/s40799-017-0178-1

Lindquist, W.B., Venkatarangan, A., Dunsmuir, J., Wong, T.: Pore and throat size distributions measured from synchrotron X-ray tomographic images of Fontainebleau sandstones. J. Geophys. Res. (2000). https://doi.org/10.1029/2000JB900208

Manzano, J.S., Weinstein, Z.B., Sadow, A.D., Slowing, I.I.: Direct 3D printing of catalytically active structures. Am. Chem. Soc. Catal. (2017). https://doi.org/10.1021/acscatal.7b02111

Matsumura, S., Kobayashi, T., Mizutani, T., Bathurst, R.: Manufacture of bonded granular soil using X-ray CT scanning and 3D printing. Geotech. Test. J. (2017). https://doi.org/10.1520/GTJ20160273

Munro, B., Becker, S., Uth, M.F., Preußer, N., Herwig, H.: Fabrication and characterization of deformable porous matrices with controlled pore characteristics. Transp. Porous Med. (2015). https://doi.org/10.1007/s11242-014-0426-0

Naka, K.: Monomers, oligomers, polymers, and macromolecules (overview). In: Kobayashi, S., Müllen, K. (eds.) Encyclopedia of Polymeric Nanomaterials. Springer, Berlin, Heidelberg (2014)

Ogawa, T., Hasegawa, A.: Effect of curing environment on mechanical properties and polymerizing behaviour of methyl-methacrylate autopolymerizing resin. J. Oral Rehabil. (2005). https://doi.org/10.1111/j.1365-2842.2004.01406.x

Song, W., de Haas, T.W., Fadaei, H., Sinton, D.: Chip-off-the-old-rock: the study of reservoir-relevant geological processes with real-rock micromodels. Lab on a Chip (2014). https://doi.org/10.1039/C4LC00608A

Xu, W., Ok, J.T., Xiao, F., Neeves, K.B., Yin, X.: Effect of pore geometry and interfacial tension on water-oil displacement efficiency in oil-wet microfluidic porous media analogs. Phys. Fluids (2014). https://doi.org/10.1063/1.4894071

Zarikos, I.M., Hassanizadeh, S.M., van Oosterhout, L.M., van Oordt, W.: Manufacturing a Micro-model with integrated fibre optic pressure sensors. Transp. Porous Med. (2018). https://doi.org/10.1007/s11242-018-1000-y

Zhou, T., Zhu, J.B., Ju, Y., Xie, H.P.: Volumetric fracturing behavior of 3D printed artificial rocks containing single and double 3D internal flaws under static uniaxial compression. Eng. Frac. Mech. (2019). https://doi.org/10.1016/j.engfracmech.2018.11.030

Zhou, T., Zhu, J.B.: Identification of a suitable 3D printing material for mimicking brittle and hard rocks and its brittleness enhancements. Rock Mech. Rock Eng. (2017). https://doi.org/10.1007/s00603-017-1335-7

Zhu, J.B., Zhou, T., Liao, Z.Y., Sun, L., Li, X.B., Chen, R.: Replication of internal defects and investigation of mechanical and fracture behaviour of rock using 3D printing and 3D numerical methods in combination with X-ray computerized tomography. Internat. J. Rock Mech. Min. Sci. (2018). https://doi.org/10.1016/j.ijrmms.2018.04.022

Acknowledgements

My appreciation is to Dr. Franek Hasiuk from Kansas Geological Survey (Lawrence, Kansas, USA) for thoughtful discussions and help with mercury porosimetry analysis. I thank Mashud Alam from the Department of Apparel, Events, and Hospitality Management (Iowa State University, Ames, USA), for assistance in contact angle measurement of resin samples used in this study. I would also like to thank Dr. Jacqueline Reber for training on the Rheosys Merlin II rheometer (Structure Lab, Iowa State University).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Ishutov, S. Establishing Framework for 3D Printing Porous Rock Models in Curable Resins. Transp Porous Med 129, 431–448 (2019). https://doi.org/10.1007/s11242-019-01297-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11242-019-01297-9