Bench studies were conducted to evaluate the effect of design parameters of tipped cone drill bits on their wear rate in drilling. Investigation results were used to construct mathematical models that desribe the effect of these parameters on the wear properties of the cutting surfaces of drilling tool teeth, which are treated after different cladding schemes. An increase in the clad area across the tooth width is shown to be the optimum relit-surfacing scheme.

Similar content being viewed by others

Notes

Tungsten carbide-based cladding powder.

References

N. A. Zhidovtsev, V. Ya. Kershenbaum, and É. S. Ginzburg, Durability of Cone Drill Bits [in Russian], Nedra, Moscow (1992).

K. A. Krylov and O. A. Strel’tsova, Enhancement of Durability and Performance of Drill Bits [in Russian], Nedra, Moscow (1983).

N. N. Zakirov, “Contact strength of drill bit cladding,” Buren. Neft’, No. 7-8, 46–47 (2003).

V. M. Shatt, Powder Metallurgy. Sintered Composite Materials [in Russian], Metallurgiya, Moscow (1983).

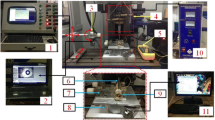

O. M. Semegen, “Device for studying impact-abrasive wear parameters for hard-faced drilling tools,” Rozvid. Rozrob. Naft. Gaz. Rodov., No. 2 (43), 152–158 (2012).

O. M. Semegen, Z. M. Odosii, P. I. Voitenko, and M. M. Semegen, Bench for Abrasive Wear Testing of Hard-Faced Drilling Tools [in Ukrainian], Patent of Ukraine No. 101775, MPK G01N 3/56 (2006.01), Valid since April 25, 2013.

O. M. Semegen, “Effect of the clad teeth surface shape of tipped cone drill bits on the energy intensity of rock breakage,” Nauk. Visn. Ivano-Frank. Nats. Tekhn. Univer. Naft. Gaz., No. 3 (34), 134–139 (2013).

I. I. Plyaskin, Optimization of Designs in Mechanical Engineering [in Russian], Mashinostroenie, Moscow (1982).

A. A. Spiridonov, Experimental Design in Process Studies [in Russian], Mashinostroenie, Moscow (1981).

Author information

Authors and Affiliations

Additional information

Translated from Problemy Prochnosti, No. 4, pp. 162 – 171, July – August, 2014.

Rights and permissions

About this article

Cite this article

Semegen, O.M., Odosii, Z.M. & Kustov, V.V. Studies and Simulation of the Effect of Design Parameters on the Wear Properties of Tipped Cone Drill Bits. Strength Mater 46, 575–582 (2014). https://doi.org/10.1007/s11223-014-9585-z

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11223-014-9585-z