Abstract

The widespread digitization and dynamic development of the technologies of the fourth industrial revolution, leading to the dehumanization of industry, have increased the interest of the scientific community in aspects of industrial humanization, sustainability and resilience. Hence, the aim of the article is to identify areas related to humanization and sustainability of the concept of Industry 4.0. A bibliometric analysis of Web of Science using Vosviewer tools, Excell and content analysis of selected papers were applied. The most important results include the determination of the dynamics of the increase in the number of publications in the segment of Industry 4.0 and Industry 5.0. The article indicates the weaknesses of the concept of Industry 4.0, especially in the area of the role of man in smart factories and sustainable development. Thus, the framework of the concept of Industry 5.0 was identified. In addition, the bibliometric analysis carried out allowed the identification of an important stream of employee skill development.

Similar content being viewed by others

Introduction

Difficulties in defining the Industry 4.0 concept have existed since its inception in 2011, finally accepted that Industry 4.0 is a set of technologies capable of creating cyber-physical systems inside companies and in supply chains (Kagermann et al., 2015). The assumptions of the Industry 4.0 concept formulated in the publications of Prof. K. Schwab (2017, 2018) have not yet been fully realized, because technological investments require high financial resources. Until 2020, the German industry has invested a total of euros 40 billion in Industry 4.0 every year. The annual investments in the European industrial sector are as high as euros 140 billion (Geissbauer et al., 2016). There is a great potential for companies' digital transformation, but the global progress results are still small. In some industries, change is progressing faster than in others. Based on the indicators used by the EU to monitor the level of digitization (DESI), it can be concluded that the biggest challenge for companies is still the integration of digital technology with the digitization of services. There is still a lot to do in the way of transformation of companies to Industry 4.0. The critical elements are high investments and the pace of implementing technological changes in companies from various industries. Companies realise the development visions of Industry 4.0 and work on changes for "Vision 2030". An opportunity for accelerating technological development is the 5G network and government programs supporting digital technologies and policies for digitalization of societies and economies, such as, e.g. RFCs, PR7, EUREKA, SPIRE.

Industry 4.0 builds cyber-physical production systems to integrate information technology and operational technology in enterprises and supply chains. The evolution of industrialization from Industry 4.0 to Industry 5.0 is dictated primarily by the need to expose man's role in cyber-physical systems. Technologies used to build Industry 4.0 cannot impose their choices on people but offer them to them. The first mentions of the role of operators in Industry 4.0 appeared in the publications of Romero et al. (2016). It was emphasized that symbiosis between humans and new technologies is needed. The authors proposed to introduce the human factor into cyber-physical systems. The new system design is called Human Cyber-Physical System (H CPS). The humanization of the built technological environment for Industry 4.0 was one of the first factors in the evolution of Industry 4.0 towards Industry 5.0. Nowadays, apart from the human factor, the authors noted research gaps in sustainability, responsibility, safety, and others in the Industry 4.0 concept (Longo et al., 2020).

Saniuk et al. (2020) attempted to systematize the barriers of Industry 4.0 in the following categories: social and market, concerning particular groups of stakeholders of changes. Other authors (scientists, researchers) also participated in discussing social and environmental problems (gaps) of Industry 4.0. Ranghino (2019) undertook a discussion about environmental risks. Bonilla et al. (2020) wrote about the impact of Industry 4.0 technology on the environment and sustainability, creating optimistic and pessimistic scenarios. The sustainability aspect of Industry 4.0 was also a topic of publication: Gajdzik et al. (2020), Luthra and Mangla (2018), Lopes et al. (2018), Pagoropoulos et al. (2017) and others. Gajdzik et al. (2020) discussed the place and role of sustainability in the concept of Industry 4.0. Luthra and Mangla (2018) presented a topic about sustainability in the supply chain, and Lopes et al. (2018) about Industry 4.0 and the circular economy. A similar topis was analyzed by Pagoropoulos et al. (2017) but in the influence of digital technologies on the circular economy. At the same time, Terlau and Hirsch (2015) discussed sustainable consumption in the development of industries and economies. Sustainable Manufacturing in Industry 4.0 topic was presented by Stock and Seliger (2016). Thus, the issues of discussion were many. Their goal was to seek consensus among the various communities (scientific, political, business) on the need to incorporate social and environmental priorities in industrialization better. According to European Commission (EC), the power of Industry 5.0 is a societal goal beyond jobs and growth to become a resilient provider of prosperity by making production respect the boundaries of our planet and placing the well-being of the industry worker at the centre of the production process (Document EC, 2021).

The authors of this publication, joining the discussion about the evolution of Industry 4.0 towards Industry 5.0, analyzed the research gaps of Industry 4.0 based on a review of the topics of publications in the WoS scientific database, which served to initiate a discussion about the new directions of industrial development, defined, according to the time chronology of industrialization—Industry 5.0.

The article aims to identify areas related to humanization and sustainable development of the concept of Industry 4.0. In addition, the article identifies the weaknesses of the Industry 4.0 concept, especially in the role of human resources in smart factories and sustainability, which are reported by scientists and researchers in numerous scientific studies.

The bibliometric analysis methodology was used, which is the most suitable for studying the evolution of areas of scientific research conducted in the field of transformation of the Industry 4.0 concept into the Industry 5.0 concept. As one of the quantitative methods, the bibliometric analysis allowed determining the state and development trends of the literature in the subject of the evolution of the Industry 4.0 to Industry 5.0 concept. According to M. Norton, bibliometric analysis is a method of evaluating research results and a comprehensive view of current scientific achievements. It is based on the use and quantification of quantitative data in scientific papers and quantitative indicators of various databases. It is a measure of texts and information (Norton, 2001).

The article consists of the following sections: Introduction, Industry 4.0 towards Industry 5.0, Material and methods, Results and discussion, Conclusions. In the Industry 4.0 towards Industry 5.0 section, the authors presented the Industry 4.0 concept and the need to humanize the industry, paying attention to the aspects of sustainable development and resilience. Furthermore, the authors presented an outline and origins of the Industry 5.0 concept. Based on selected publications, the authors paid attention to the directions of the conducted research in this area. In Material and methods section, the authors presented the research methodology, selecting bibliometric analysis segments and the justification for choosing the Web of Science (WoS) database. The Web of Science ™ Core Collection database was used for research purposes because it is the most widely used database and citation database. This database is also considered the most consistent. Vosviewer and Excell software were used. The Results and discussion section describes the research results obtained based on bibliometric analysis and the analysis of the content of selected publications in the Industry 5.0 area. The article ends with a Conclusion section containing the conclusions, limitations of the conducted research and directions of future work.

Industry 4.0 towards Industry 5.0

Industry 4.0 means the integration of intelligent machines and systems and making changes in production processes to increase production efficiency. Industry 4.0 is about resilient technology, new ways of working, and the role of people in the industry (Luthra & Mangla, 2018). The changes occurring in Industry 4.0 include a wide range of innovations at the level of plants and factories belonging to various industries and services and the functioning of entire societies. Industry 4.0 is essentially a trend toward automation and data sharing in manufacturing technologies and processes that include Cyber-Physical Systems (CPS), the Internet of Things (IoT), Cloud Computing, Cognitive Computing, and Artificial Intelligence (Lee et al., 2015).

In the media and literature, the perception of Industry 4.0 in terms of technological changes that should be implemented in manufacturing companies is dominant. Still, this industrial revolution, its trends and effects are visible in all macro and micro areas of the market. The proposed technological changes, which have taken on strategic importance in the thinking and actions of many market participants, penetrating all links in the value chain and how they are connected, have changed the scope of competition and how consumer needs are met (Saniuk et al., 2020).

From a sustainability perspective, Industry 4.0 can be defined as a step towards more sustainable industrial value creation, arguing that industrial value creation must be focused on sustainability. In Industry 4.0, there is a lot of focus on sustainability aspects—consumers, business models, economy. By providing detailed information about each point of production, processes, resources, and energy consumption can be optimized across the value network. The new technological solutions promoted by Industry 4.0 are expected to increase production efficiency and the environmental performance of products throughout their life cycle. This also means increasing demand for smart products and smart manufacturing technologies (Stock & Seliger, 2016).

The currently observed rapid increase in the implementation of Industry 4.0 technologies and the orientation of enterprises towards the dehumanization of production systems cause many concerns for workers, society, and even governments. In Industry 4.0, the work environment is determined by integrated, advanced and resilient manufacturing technologies, equipped with sensors tracking the work of machines and communication systems enabling data reporting and advanced simulations. The role of current workers is very rarely mentioned. Numerous scientific studies (Romero et al., 2015) draw attention to the need to include the crucial role of humans in the assumptions of future industrial development. Above that, it is believed that limiting resilience in technology is not enough. Resilience should encompass the entire value chain, business processes, and even business models. Therefore, in 2019, a discussion began about the concept of Industry 5.0. This concept involves returning the human factor to industry, i.e., increasing cooperation between people and intelligent production systems and combining the best of two worlds—the speed and accuracy guaranteed by automation with humans' cognitive skills and critical thinking (Longo et al., 2020).

The concept of Industry 5.0 was considered from 2 to 9 July 2020 amongst participants from research and technology organisations organised by Directorate "Prosperity" of DG Research and Innovation European Commission EC. In the EC document, one can find assumptions to the concept of "Industry 5.0". The essence of this document is critical directions of change to make the industry more sustainable and human-centred (Breque et al., 2021).

Industry 5.0 focuses on the interaction between humans and machines (Özdemir & Hekim, 2018). Nowadays, humans work alongside machines and are connected to smart factories through intelligent devices (Demir et al., 2019). The world of technology, mass customization and advanced production is undergoing a rapid transformation. Robots are becoming even more important as they can now be connected to the human mind via the brain-machine interface and advances in artificial intelligence (Welfare et al., 2019). Nowadays, robots are intertwined with the human brain and work as a collaborator, not a competitor (Nahavandi, 2019). The fifth industrial revolution will likely push for more advanced human–machine interfaces using artificial intelligence (AI) algorithms. This will mean better integration, enabling faster, better automation combined with the power of human brains (Aslam et al., 2020). It also means that robots won't be taking control of manufacturing plants anytime soon, as was so feared in the Industry 4.0 era (Javaid & Haleem, 2020). The transition from I 4.0 to I 5.0 means combining the best of the human and machine worlds—it will likely also mean increased productivity (Di Nardo et al., 2020; Nelles et al., 2016). Vollmer said that Industry 5.0 is the future and emerging trend: interaction and collaboration between man and machine (Longo et al., 2020).

In an Accenture survey, as many as 85% of 500 manufacturing company executives said it would be standard for workers and robots to work together "side by side" on production lines as early as 2020 (Østergaard, 2022). In the process of human–machine integration, the trend of talent management is accentuated. According to Forbes: 34% of HR leaders invest in workforce learning and retraining as part of their strategy to prepare for the future of work. And 5.0 will free HR teams from much of the day-to-day administration (Eschbach, 2021). This will give them time to refine and meet talent requirements, focusing on organizational growth and productivity. Industry 5.0 will bring unprecedented challenges in human–machine interaction (HMI) as it will bring machines very close to everyone's daily lives. It is predicted that Industry 5.0 will create many jobs in HMI and human computational factors (HCF). Industry 5.0 will create new jobs in intelligent systems, AI and robotics, programming, maintenance, training, planning, repurposing, and the invention of a new breed of manufacturing robots (Martynov et al., 2019). The goal of Industry 5.0 is a higher standard of living and creativity with high-quality custom-made products to lead to sustainable production and consumption. Many companies in recent years have started sustainable manufacturing programs. In addition, companies continue to implement social responsibility projects. Environmental awareness among people is increasing. Customers are beginning to choose products created by companies participating in the green economy (Elfar et al., 2021).

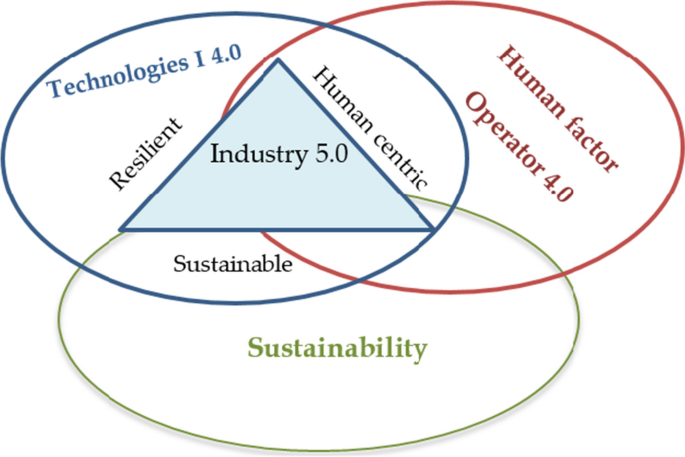

Based on a literature review and a forecast analysis, the essence of Industry 5.0 focuses on three determinants of development: human-centric, sustainable and resilient development (Romero et al., 2016; Felsberger & Reiner, 2020). The adjective "resilient" has been used by EC. The popularity of the adjective "resilient" is growing. It is considered valuable to describe the features of the Industry 5.0 concept, especially in the effects of the COVID-19 pandemic on economies, societies, and industries. Underlying the development of the new concept are social and environmental needs. Sustainability emphasises that business focused solely on profit is increasingly challenging to sustain in a globalized and highly volatile (unpredictable) environment. For an industry to become a provider of true prosperity, it must include social, environmental and societal aspects. The symbiosis of the three segments: technological, social and ecological constitute the essence of Industry 5.0. Industry 4.0 put technology at the center, while the next one is to be focused on production workers who perceived progressive automation as a threat to their jobs. Industry 5.0 recognizes the power of technology for industrial (business) development but combines the achievement of business goals with social goals in the workplace (e.g., emphasis on workplace safety with the use of next-generation technologies or human–machine relationships) and outside the workplace (social and environmental responsibility) (Gorodetsky et al., 2019). The center of the production process is constituted by cyber-physical systems entwined with social and ecological frameworks, the preservation of which (respect, appreciation, compliance) by Industry 4.0 technologies leads to economic growth and places the human being at the center of cooperation. Industry 4.0 is a concept for integrating automation and IT, exchanging data, and creating cyber-physical systems and new ways of manufacturing. It also concerns changes in value chains and the possibilities for personalizing products. All of this is part of the megatrend that is digital transformation. Digitalization has been recognized as the foundation for the development of Industry 4.0 (Kagermann, 2015). Industry 4.0 sought a strong collaboration between information and communication technologies (ICT) and operational technologies (OT). The symbiosis of IC and OT technologies was to be achieved in Industry 4.0. Industry 5.0 does not deny the need to digitize societies, economies and industries (Doyle-KEnt & Kopacek, 2019).

Digitalization in Industry 5.0 should be comprehensive to organize processes in the enterprise and supply chains. Industry 5.0 emerged from the megatrend that is Industry 4.0. The emerging picture of the Industry 5.0 paradigm is the penetration of artificial intelligence into people's daily lives. There are voices among researchers that probably a more precise term instead of Industry 5.0 is "Society 5.0" (Super Smart Society) (Elim & Zhai, 2020). Unlike the concept of Industry 4.0, Society 5.0 is not limited to the manufacturing sector but solves social problems through the integration of physical and virtual space. Society 5.0 is a society in which advanced technologies are actively used in people's lives, in industry, health care and other spheres not for the sake of progress but the benefit and convenience of every person (John et al., 2020).

Materials and methods

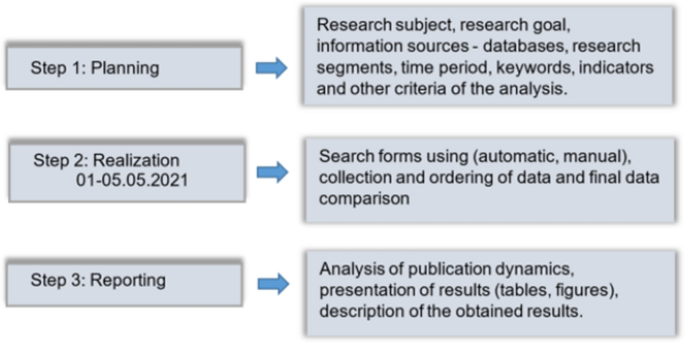

The bibliometric analysis methodology was used, which is the most suitable for studying the evolution of areas of scientific research conducted in the field of transformation of the Industry 4.0 concept into the Industry 5.0 concept. As one of the quantitative methods, the bibliometric analysis allowed determining the state and development trends of the literature in the subject of the evolution of the Industry 4.0 to Industry 5.0 concept. In the analysis, the authors focused on the number of publications in segments according to characteristics (research criteria): citation rates, types of publications, research areas as units of measurement. The analysis results were presented in the forms: figures, tables and descriptions. Furthermore, the bibliometric analysis has made it possible to identify the internal logic of the evolution of Industry 4.0 to Industry 5.0. The advantage of the bibliometric measurement carried out is its objectivity. In the article, the Systematic Literature Network Analysis (SLNA), introduced by Colicchia and Strozzi (2012), was adopted as the bibliometric analysis method. This analysis combines a systematic literature review (SLR) and analysis with the visualization of the bibliographic network. This approach identifies critical trends and issues that influence knowledge development in a given field more scientifically and objectively than descriptive reviews.

In the methodology of the bibliometric analysis adopted in the study, the following stages were carried out: planning, implementation, reporting. The methodology of the bibliometric analysis is presented in the Fig. 1.

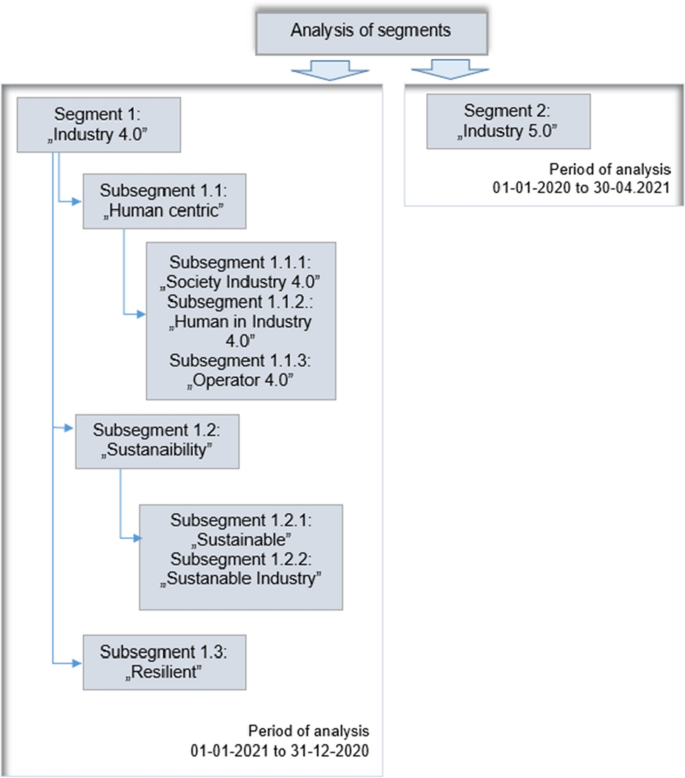

The search for scientific publications was carried out using the Core collection Web of Science (WoS), a database provided by Clarivate Analytics, on 01–05 May 2021. The phrases used to search the database were organized into segments, and topics and research periods contained the mentioned phrases. The selection of phrases was based on available studies about Industry 5.0 (and presented in the literature section of this publication). The following two main segments of the bibliometric analysis were determined:

-

1.

Segment 1: „Industry 4.0” (8085 publications).

-

2.

Segment 2: „Industry 5.0” (22 publications).

The segments: "Industry 4.0" and "Industry 5.0" were crucial to realize the research area: Evolution of Industry 4.0 to Industry 5.0. In addition to the key segments, the content of scientific publications in the sub-segments of industrialization was analyzed (according to the EU document):

-

1.

Sub-segment: "Human-centric" (36 publications) and related: Society Industry 4.0 (418 publications), Human in Industry 4.0 (1193 publications), Operator 4.0 (1040); these areas are a reference to the humanization of industries;

-

2.

Sub-segment: "Sustainability" and its related meanings such as Sustainable, Sustainable Industry 4.0; these areas represent the essence of the development of industries (as conceptualized by the policies of each country) (1286 publications);

-

3.

Sub-segment: "Resilient", which is highlighted in the EC (Research and Innovation) document as flexible and adaptable technologies in Industry 5.0 (78 publications).

These sub-segments complement the research area: Evolution of Industry 4.0 to Industry 5.0 and provided phrases to complete the bibliometric analysis for segments 1 and 2. The following periods of bibliometric analysis were established for each key segment:

-

1.

From 01-01-2011 to 31-12-2020 for the segment: Industry 4.0". The analysis began in 2011, as this is when the name "Industry 4.0" was first used in Germany;

-

2.

From 01-01-2020 to 30-04-2021 for the segment: "Industry 5.0". The analysis began in 2020 when the name "Industry 5.0" was first used by the European Commission.

The designated time frame is a closed period, which made it easier for the authors to make comparisons of segment sizes (number of publications).

The procedure for bibliometric analysis was as follows: Selected database: Web of Science (Core Collection);

-

1.

Basic search: Topic (title, abstract, keywords author; Keywords Plus);

-

2.

Data collection: 01/05-05-2021;

-

3.

Timespan: used periods: from 01-01-2011 to 31-12-2020 (for “Industry 4.0”) and 01-01-2020 to 30-04-2021 (for “Industry 5.0”);

-

4.

Result limitation: English language;

-

5.

Used: Vosviewer, Excel, content analysis of selected works, keyword grouping (Fig. 6), Venn diagrams which were used to present the configuration of the segments (research fields) obtained from the bibliometric analysis). The size of the boxes reflects the strength of the researchers' interest in the given subject area. In addition, the arrangement of the fields is logical—the top fields are above the keywords, the subordinate fields are below (Figs. 13, 14, 15, 16);

-

6.

Results: number of publications, publication years, citation, document types, research areas.

Figure 2 shows the analyzed segments (research fields/nomenclature used interchangeably in the publication: segment or research field) along with the established analysis periods.

Web of Science is an interdisciplinary (multidisciplinary) research platform that captures the content of over 12,000 high-profile journals and over 160,000 conferences from around the world. It allows researchers to search multiple databases simultaneously from a single interface—via the Web of Science ™ Core Collection. This database collects many bibliometric indicators and includes literature from most disciplines. It covers many other databases and tools necessary to establish bibliometric indicators, parametric evaluation and creating a bibliography. It is also the most widely used database and citation database for research purposes. Its decisive advantage is its transparency and order. The Web of Science database is one of the most consistent databases of scientific publications. Compared to e.g. the Scopus database, Web of Science has a search ability “shorter range of year”. Considered area of research and high dynamics of changes has a significant impact on the analysis results. However, a severe disadvantage of the Scopus database is the quality of the data, which is not "clean" like that of WoS, as some publications are not identified (Zhao & Strotmann, 2015). Therefore, the authors decided to use the WoS database.

Results and discussion

According to the methodology adopted, the research results and discussion will be presented according to the following order: first, general data on the number of publications in the field of Industry 4.0 and Industry 5.0 will be presented, followed by results on Industry 4.0 (in particular human-centric, sustainability and resilience), and finally results from the field of Industry 5.0.

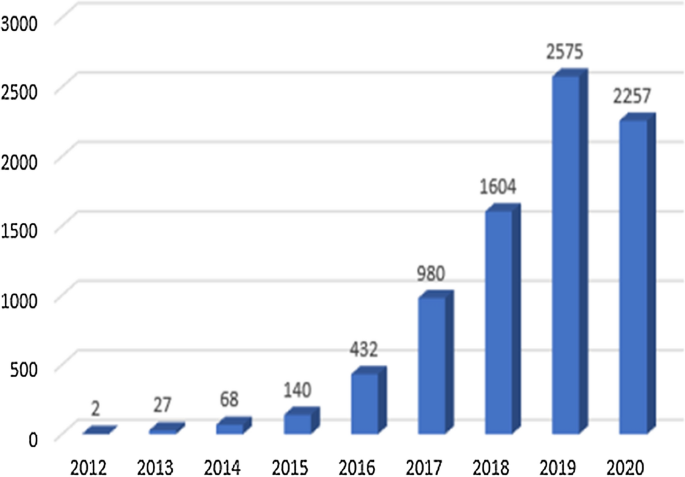

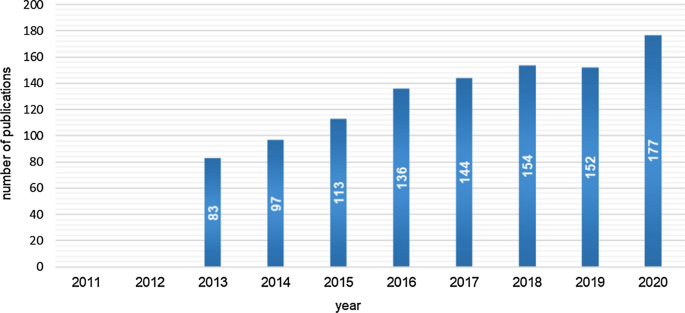

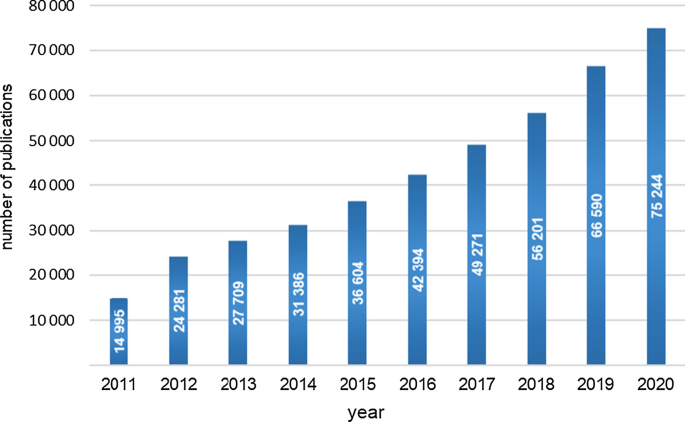

Figure 3 shows the number of publications for Industry 4.0 by year. As shown in the figure, the trend of publications for "Industry 4.0" was upward until 2019. In 2019, there were 2573 more publications for Industry 4.0 than in 2012 (only two publications were reported then). The first two publications in the database were by Bettenhausen (2012), Hofmann et al. (2011). The first publication referred to ICT trends that preceded the development of the Industry 4.0 concept, the second to the use of mobile devices in Industry 4.0. There was a decrease in the number of publications in 2020 compared to the previous year (318 fewer publications). Academic interest in Industry 4.0 topics will peak in 2019.

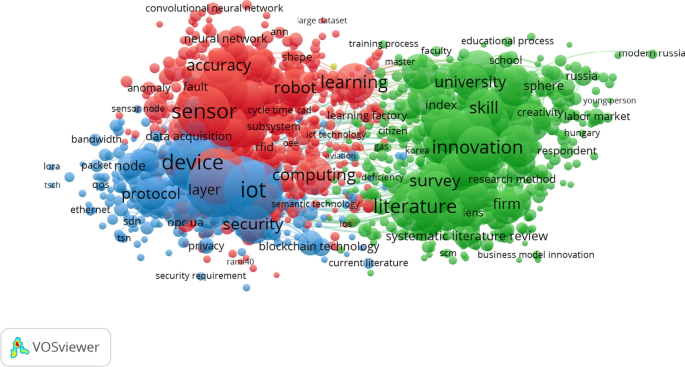

Based on the retrieved articles, a semantic map was created that shows the areas of interest for Industry 4.0 researchers (Fig. 4). Verification of the term network shown in Fig. 4 reveals potential relationships grouped into themes. For publications identified in the "Industry 4.0" area, the terms fall into three clusters, whereas many as two of them are oriented around technology. It is difficult to find themes related to "human", "Sustainability", or "resilient". The red cluster is oriented around sensing and includes the robot, learning, accuracy, neural network and shape. The device consists of, e.g., IoT, security, protocol, layer, the node in the blue cluster. The third cluster, green, includes concepts related to innovation (literature, university, school, firm, business model.

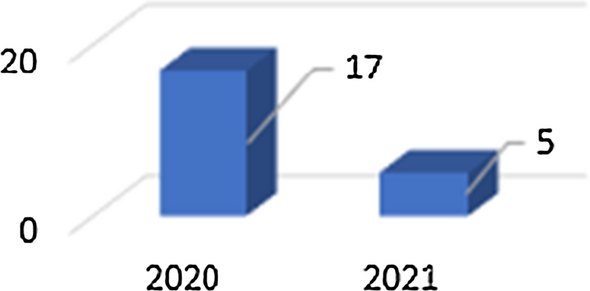

In 2020, the first publications on Industry 5.0 appeared (Fig. 5). At the end of April 2021, the number of articles containing "Industry 5.0" was 22. There were 17 publications in 2020 and 5 in 2021 (between January and April).

Table 1 summarizes the results of the research area analysis: Industry 5.0 in the database: WoS. During the study period, 22 papers were found (17 papers from 2020 and 5 papers from 2021); 14 of them were available in open access. The total citations of these papers were 53, the Average Citations per Item was 2.41, and the h-index was 5. Most papers were classified as articles (18), 3 papers were early access, 3 proceedings paper, and one editorial material. All papers are written in English. Most papers (6) are from the US, Italy (5) and China (2). The papers were indexed in the following research areas: Engineering (7), Business economics (6), Computer Science (6), Chemistry (3), Materials Science (3), Environmental Sciences Ecology (2), Science technology other topics (2), Instrumentation instruments (1), Metallurgy, metallurgical engineering (1), Physics (1), Social sciences other topics (1), Telecommunication (1).

Table 2 summarizes the results of the research field analysis: Industry 5.0 with the highest number of citations. The ten papers with the highest number of citations are outlined in the table. Next to each paper, the total number of citations, the average number of citations per year, number of citations in 2020 and 2021 were marked. The publication of Bednar and Welch (11) received the most citations. The topic of the publication was sociotechnical determinants of smart work. The authors of this work used the following keywords: smart working, social-technical approaches, open system, emergence, Industry 4.0 and Industry 5.0. The essence of the publication is "smart working", according to the assumptions of Industry 5.0, in which technological and social systems work in harmony, and a person is an active participant in cyber-physical systems. Analyzing the number of citations of the works collected in the table, it can be noted that Industry 5.0 is a young concept, which is still relatively unknown among researchers.

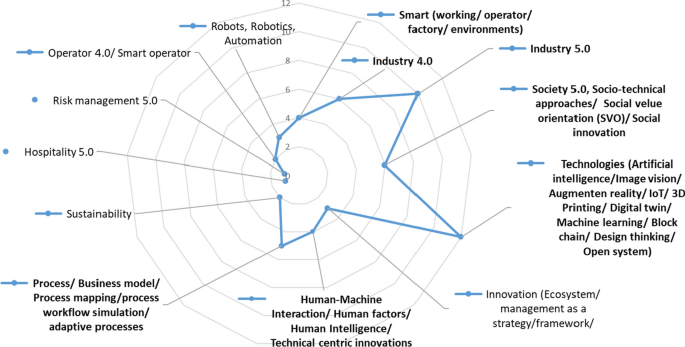

The research areas Industry 5.0 were analysed in terms of keywords of individual articles (Fig. 6). The result is a map of keywords developed based on open access publications—14 publications listed in the WoS database were used, indexed during the data collection period 01-05-05-2021. The identified keywords were combined into groups for increased readability. Based on their experience, the authors intuitively combined the keywords reported in the authors' publications into aggregated groups representing individual keywords.

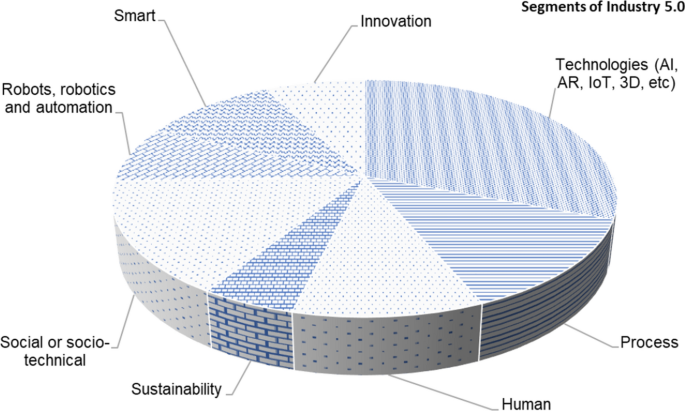

Based on content analysis of publications in area of Industry 5.0, it has been established that the socio-technical and human segments are among the segments relevant to this concept. The segments were developed based on the subject area indicated by the publication's authors in their methodology. A detailed analysis is shown in Fig. 7. Scientists (researchers) have emphasized the phenomenon of 'smart'. Some pointed to the fourth industrial revolution (Industry 4.0), in which 'smart factories' use robotics to achieve high productivity. Others saw progress toward Industry 5.0, in which technological and social systems work in harmony to deliver personalized products to the masses. Keywords connected with segments: 'innovation', 'technologies' and 'process' also fit into the framework of the new concept. The process approach has been a determinant of how companies operate in the marketplace for many years. Industry 4.0 technologies are also used to develop Industry 5.0. They are still focused on process optimization and innovation, assuming that socio-technical conditions are the best way to support smart technologies in companies (Bednar & Welch, 2020).

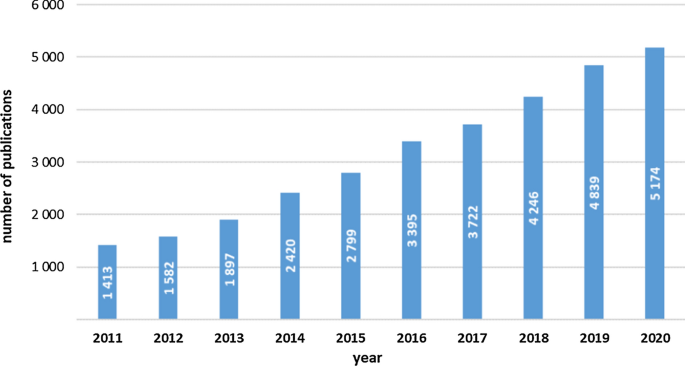

The stage of the analysis was the "human" segment. Within this segment, 1,182 publications were recorded (Fig. 8). More than 100 publications per year were recorded starting in 2015. In the first two years after the emergence of the Industry 4.0 concept, there weren't publications in the database using the "human-centric" keywords. Due to the small number of publications, this segment was classified (at the current stage of development) as niche but pretending to be a key area of research.

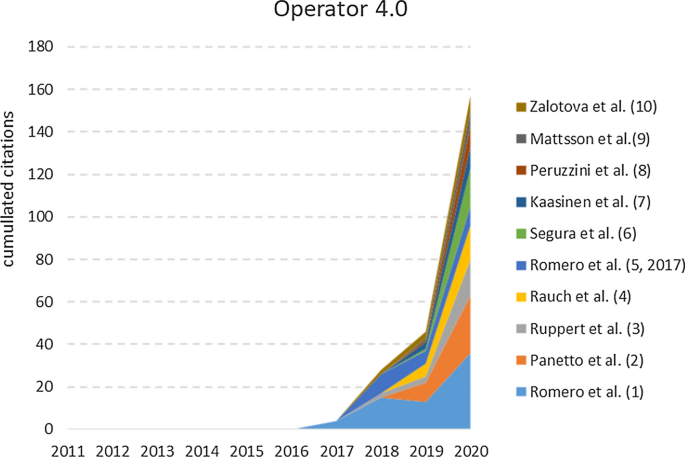

In the research field: "Human-centric" several subsegments can be distinguished, and so: "Society Industry" was formed by 5 publications, "Human in Industry 4.0" was built by 2 publications and "Operator 4.0" had as many as 35 publications with the sum of the times cited: 367 and average citations 10.49 by h-index: 11). The highest citation index was obtained by Romero et al. (2016) (presented in the first row in Table 3).

The progress of the analysis for “Operator 4.0” using cumulative values based on selected articles is shown in Fig. 9.

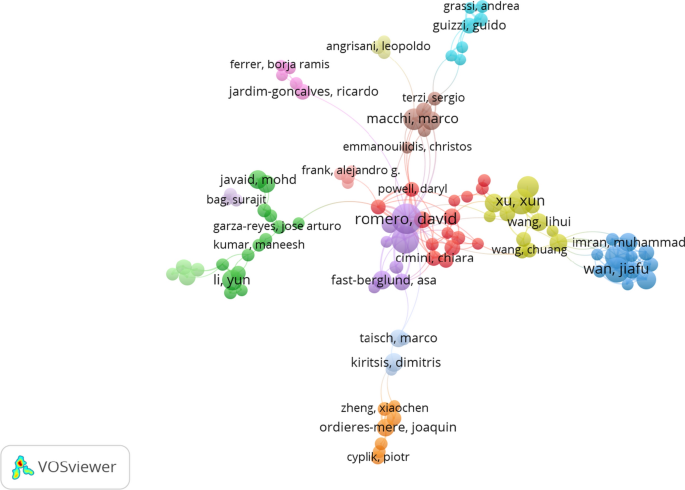

Based on analysis, citation accrual of the publication Romero et al. (2016) by other authors was found (Fig. 10). From the publication (Romero et al. 2016), the citation links of this publication by other authors (total 78 publications in the WoS database) were established. Author Romero David's citation map gives an overview of the structure of interest in "Operator 4.0" regarding the number of citations. On the map, you can identify clusters of related authors citing works from the area of "Operator 4.0". Each cluster is characterized by a different color and contains a network of links between the authors who mention the author with the most citation. This author is marked on the map in the bigger font (quoted at least five times). The circle size indicates the number of citations of a given author. The author Romero David received the most citations. The number of authors' collaborations means 11 separate clusters following David Romero.

Repeated keywords that belonged to the "Human-centric" segment were analyzed. In the research area: "Human-centric" includes a broad new topic: "Operator 4.0". The list of analyzed keywords is presented in Table 4. The authors listed all keywords in the research field: "Human-centric" by using keywords in particular publications. The analysis results will be used to develop sets of studies presented using Venn diagrams (later in the article).

The next level (field) of analysis was "Sustainability". The list of analyzed publications from the research area we considered niche and named: "Sustainable Industry 4.0" is summarized in Table 5. In both Industry 3.0 and Industry 4.0, sustainability was the paradigm of business management. In the new (next) development concept—Industry 5.0—sustainability remains the strategic direction of the business. The analyzed area "Sustainability" was enriched (expanded) with the adjective "sustainable". The adjective "sustainable" was found in publications more often than the noun "sustainability". Indications increase for both "Sustainability" and "Sustainable". The results of the searched publications are presented in Fig. 11. The adjective "sustainable" is combined with the words: production and manufacturing, product, process, development, economy, and Industry 4.0. Additionally, the sub-segment "Sustainable Industry 4.0" was introduced into the analysis, which we classified as niche because the number of publications was low (only 9 publications, including 2 in 2018 and 7 in 2020).

The last area (field) analyzed was "Resilient". The results found are presented in Fig. 11. In 2020 there were 5174 publications in the WOS database using the search phrase "Resilient". This resulted in an increase of 3761 publications in the year under review compared to the number of publications in 2011. "Resilient" means resilience, resilience, flexibility. The adjective describes many aspects of business, enterprises, and most importantly, equipment, machinery and technology. Based on the number of results obtained, it was classified as a significant area (field) of research in the era of industrialization. Every two years, one can notice a significant increase in publications with the adjective "resilient" in the subject or keywords. Concerning Industry 5.0, the adjective "resilient" has been used by EC (cited document from January 2021 several times already). The popularity of the adjective "resilient" is growing. It is considered valuable to describe the features of the new concept of industrial development Industry 5.0 especially in the context of the effects of the COVID-19 pandemic for economies, societies and industries (Fig. 12).

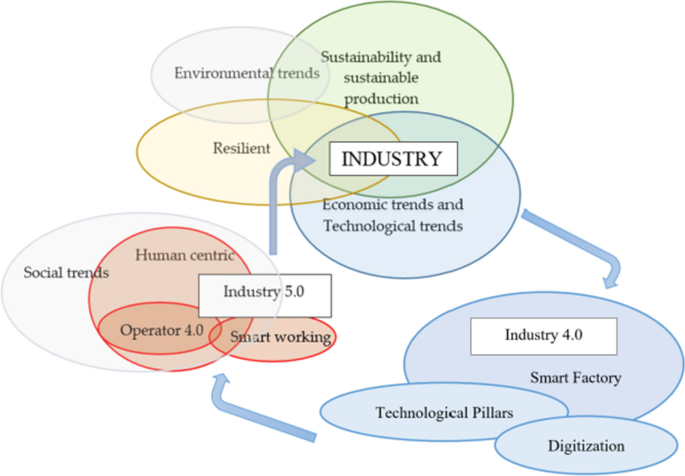

Venn diagrams (Fig. 13) were used to present the configuration of segments (research fields) obtained based on bibliometric. The proposed arrangements of links began with establishing the key area, which in the opinion of the researched, confirmed by the results of the searched publications, are technological and economic trends. These trends were placed in the center of other sets. Above this area, a more significant and relevant collection was added, "Sustainability", along with many aspects of sustainable production. For many years, sustainability has been the paradigm for industry development regardless of its numerology levels. The next segment/subsegments (research field): "Resilient" is related to trend directions and sustainability. The next segments (determined by bibliometric analysis) are arranged below the already linked extensive collections, creating niche (for now) but new research fields for Industry 5.0. Also highlighted are the areas related to Industry 4.0, which are Smart Factory, Digitalization and Technological Pillars of the Fourth Industrial Revolution.

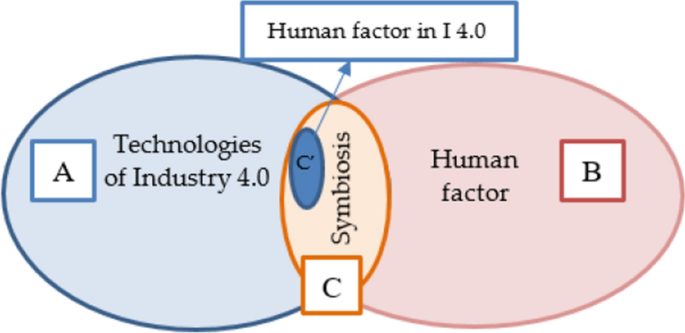

The placement of the human factor in the technology of Industry 4.0 is the beginning of the transformation to Industry 5.0. Set C' (Fig. 14a) is formed, based on bibliometric analysis, by publications obtained for the keywords "Human factor in Industry 4.0" and "Human-centered" in the topics of these papers:

-

1.

Di Nardo, M.; Forino, D., Murino, T. The evolution of man–machine interaction: the role of human in industry 4.0 paradigm. Times cited: 6 (from Web of Science Core Collection);

-

2.

Nelles, Jochen; Kuz, Sinem; Mertens, Alexander; et al. Human-centered design of assistance systems for production planning and control. Times cited: 2 (from Web of Science Core Collection).

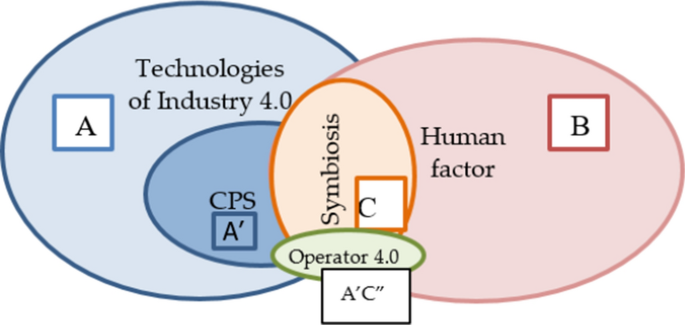

Based on the bibliometric analysis, a strong impact of the collection: "Operator 4.0" on the development of the concept of Industry 5.0. The "Operator 4.0" collection is rapidly growing, piercing the research area "Human factor in Industry 4.0". Using Venn diagrams, we presented another range of relationships (Fig. 15).

In this new relationship between the technological environment of Industry 4.0 and the human factor, the concept of Industry 5.0 is built (Fig. 16). The humanistic approach dictated the development of this concept to the technological propaganda of Industry 4.0. Authors: Gajdzik et al. analyzed the popularity of the sustainability concept in Industry 4.0 and concluded that sustainable Industry 4.0 is a niche topic of researchers (scientists). Currently, the industry is investing in the technologies of the fourth industrial revolution, but the diversity of technologies results in the segmentation of the implemented changes (Gajdzik et al., 2021). During the COVID-19 crisis period, evolution is described using the adjective "resilient". The triad of relationships: human-centric, resilient and sustainability formed the basis of the EC document (January 2021). Therefore, the following scheme of the Industry 5.0 concept can be proposed, which the authors consider is the general framework of Industry 5.0.

Based on the bibliometric analysis detailing the essence of Industry 5.0 was found. The new concept is based on technologies popularized in Industry 4.0, which led to the creation of cyber-physical systems, but the human factor is more strongly exposed. The Industry 4.0 concept that revealed technological aspects (hard) is changing into Industry 5.0. The new concept manifests a strong symbiosis between man and technology, i.e. "soft" areas. The evolution of Industry 4.0 to Industry 5.0 begins, changing the areas of research of scientists from "technology" to "human" or from "hard" to "soft". New conditions for the functioning of employees, described by the adjective "smart" or "intelligent", are emerging, e.g. smart workplace, smart worker, smart engineer, smart operator 4.0, intelligent workspace; intelligent space.

Along with focusing attention (of scientists and researchers) on people, the fifth industrial revolution puts a premium on human resources development. New occupations, skills, and functions of people in manufacturing are emerging, such as Chief Robotics Officer (CRO). This C-suite position will require an expert specialising in human–machine connectivity and responsible for all matters related to technology, from making decisions about which machines or equipment to add to the factory floor to refining strategies for optimizing the production line. Modern technology operators, because of the breadth of technological solutions employed, are multi-taskers. They are assigned various roles concerning machines and equipment, such as equipment teacher, solution mentor, process controller, robot assistant, machine programmer, mobile robot manager, cyber-physical systems analyst, collaborative operator, equipment liaison, artificial intelligence operator, virtual operator. The scope of each role is based on the tasks received and the type of technology supported (Ruppert et al., 2018 after Romero et al., 2015, 2016). The roles assigned to operators may also be determined by the modes of operation of the equipment, e.g., startup, operation, maintenance, cleaning, memorization (Poreda, ASTOR works). Multitasking enriches work and facilitates job rotation. Specialization of technology operators may result from the specifics of the monitored devices and the costs of their purchase and operation. The scope of specialization may focus on operating a selected group of machines, e.g., due to the specificity of data generated by the equipment.

The discussion concludes that the key technologies of Industry 4.0 have contributed to the debate on the role of the human factor in the next generation technology space. Two key sets—set A: "Industry 4.0 technologies" and set B: "Human factor" collided at the beginning of the second decade of the current century. In the cyber-physical systems being created (formulated), a place for humans is now being sought. Business is moving towards a symbiosis of technology and man. In Industry 5.0, human is positioned at the center of technological change.

Conclusion

The currently observed dynamic increase in the implementation of Industry 4.0 technologies and the orientation of companies towards the dehumanization of production systems have resulted in many concerns of employees, society and even governments. In Industry 4.0, the work environment is determined by integrated and advanced production technologies, equipped with a set of sensors to track the work of machines and communication systems to report data and perform advanced simulations. The role of existing employees is very rarely mentioned. Hence, the article identifies the weaknesses of the Industry 4.0 concept, especially in the aspect of man's role in smart factories and defines the framework of the Industry 5.0 concept.

Numerous scientific studies emphasize the need to include sustainability and the key role of human beings in the assumptions for the development of the industry of the future. At the basis of the development of a new concept are social and environmental needs, and the base of the evolution is the sustainability of the economy. The essence of Industry 5.0 is concentrated around three areas of development: human-centric, sustainable and resilient. Industry 4.0 was mainly focused on applying technologies to eliminate a human being from the production process, entrusting him only with supervisory and control functions, which resulted in a perception of progressing automation and digitalization as a serious threat by production workers. The symbiosis of three segments: technological, social and ecological, constitutes the essence of Industry 5.0. Industry 5.0 acknowledges the power of technology for the development of industry (business). Still, the achievement of business objectives is combined with social objectives in workplaces (e.g., human–machine relations) and outside workplaces (social and ecological responsibility).

This paper analyzes a collection of scientific studies that emphasize the need for human symbiosis with new technologies. The authors of the analyzed studies proposed the introduction of the human factor into cyber-physical systems. The new system construction is called Human Cyber-Physical System (H CPS). The humanization of the built technological environment for Industry 4.0 was one of the first factors in Industry 4.0 towards Industry 5.0. In addition to the human factor, Industry 4.0 noted research gaps in sustainability, accountability, and safety. In Industry 5.0, system designers must design CPPS using a "human-centred" rather than a "technology-centred" approach. Concerns about the effects of the development of artificial intelligence raise ethical concerns about the possible making of complex decisions beyond human control. There is the need to examine human values and ethical considerations a priori so that they are not treated as costs but as design requirements in newly developed cyber-physical systems.

In addition, the bibliometric analysis carried out allowed us to identify a significant strand of employee skill development. By design, the fifth industrial revolution puts a premium on workforce development. New skills, qualifications and even professions are emerging, such as Chief Robotics Officer (CRO), device teacher, solution mentor, process controller, robot assistant, machine programmer, mobile robot manager, cyber-physical systems analyst, collaborative operator, device linker, artificial intelligence operator, virtual operator. It means the need to focus attention on an appropriate system of education and training of workers.

The authors of the article postulate further research in the field of development of the Industry 5.0 concept, analysis of the human role in the processes of industry digitalization and development of the economy 4.0 and the Society 5.0 in the context of sustainable development. The lack of conducted research on social, ecological and economic effects of the Industry 4.0 concept implementation can cause some dissatisfaction. Scenarios for how Society 5.0 will function in the future are still lacking.

References

Aslam, F., Aimin, W., Li, M., & Ur Rehman, K. (2020). Innovation in the era of IoT and industry 5.0: absolute innovation management (AIM) framework. Information, 11(2), 124.

Bednar, P. M., & Welch, C. (2020). Socio-technical perspectives on smart working: Creating meaningful and sustainable systems. Information Systems Frontiers, 22, 281–298. https://doi.org/10.1007/s10796-019-09921-1

Bettenhausen, K. D. (2012). Industry 4.0: GMA wants to develop current ICT Trends specifically for the Automation. ATP Edition, 6, 8–8.

Bonilla, S. H., Silva, H. R. O., Terra, M., da Silva, R., Gonçalves, F., & Sacomano, J. B. (2020). Industry 4.0 and sustainability implications: A scenario-based analysis of the impacts and challenges. Sustainability, 10, 3740. https://doi.org/10.3390/su10103740

Breque M., De Nul L., & Petridis A., Industry 5.0. Towards a sustainable, human-centric and resilient European industry. Retrieved November 26, 2021, from https://op.europa.eu/en/publication-detail/-/publication/468a892a-5097-11eb-b59f-01aa75ed71a1/

Colicchia, C., & Strozzi, F. (2012). Supply chain risk management: A new methodology for a systematic literature review. Supply Chain Management: An International Journal, 17(4), 403–418. https://doi.org/10.1108/13598541211246558

Demir, K. A., Döven, G., & Sezen, B. (2019). Industry 5.0 and human-robot co-working. Procedia Computer Science, 158, 688–695.

Di Nardo, M., Forino, D., & Murino, T. (2020). The evolution of man-machine interaction: the role of human in industry 4.0 paradigm. Production and Manufacturing Research-an Open Access Journal, 8(1), 34–20.

Doyle-Kent, M., & Kopacek, P. (2019, August). Industry 5.0: Is the manufacturing industry on the cusp of a new revolution?. In Proceedings of the International Symposium for Production Research 2019 (pp. 432–441). Springer.

ElFar, O. A., Chang, C. K., Leong, H. Y., Peter, A. P., Chew, K. W., & Show, P. L. (2021). Prospects of Industry 5.0 in algae: Customization of production and new advance technology for clean bioenergy generation. Energy Conversion and Management: X, 10, 100048.

Elim, H. I., & Zhai, G. (2020). Control system of multitasking interactions between society 5.0 and industry 5.0: A conceptual introduction & its applications. Journal of Physics: Conference Series, 1463(1), 012035.

Eschbach, A. Psst. (2021). These 9 sets of matching family pajamas are on sale for cyber monday. Retrieved May 28, 2021, from https://www.forbes.com/sites/forbes-personal-shopper/2021/11/29/matching-family-pajamas/?sh=b8665353ba84.

Felsberger, A., & Reiner, G. (2020). Sustainable Industry 40 in production and operations management: A systematic literature review. Sustainability, 12, 7982.

Gajdzik, B., Grabowska, S., & Saniuk, S. (2021). A theoretical framework for Industry 4.0 and its implementation with selected practical schedules. Energies, 2021(14), 940. https://doi.org/10.3390/en14040940

Gajdzik, B., Grabowska, S., Saniuk, S., & Wieczorek, T. (2020). Sustainable development and Industry 4.0: A bibliometric analysis identifying key scientific problems of the sustainable Industry 4.0. Energies, 13, 4254. https://doi.org/10.3390/en13164254

Geissbauer, R., Vedso, J., Schrauf, S. (2016). Industry 4.0: Building the digital enterprise. PwC, 1–36.

Gorodetsky, V., Larukchin, V., & Skobelev, P. (2019, October). Conceptual model of digital platform for enterprises of industry 5.0. In International symposium on intelligent and distributed computing (pp. 35–40). Springer.

Hofmann, D., Margull, R., Dittrich, P.-G. (2011). Smartphone Green Vision at Dawn of Industry 4.0. Conference: 7th international conference on MEMS, NANO and smart systems (ICMENS 2011) Location: Kuala Lumpur, MALAYSIA Date: NOV 04–06, 2011. Sponsor(s): Int Assoc Comp Sci & Informat Technol; Singapore Inst Elect.

Industry 5.0 Towards a sustainable, human centric and resilient European industry, p. 14. European Commission, Brussels, Manuscript completed in January 2021. Retrieved May 10, 2021, from https://op.europa.eu/en/publication-detail/-/publication/aed3280d-70fe-11eb-9ac9-01aa75ed71a1/language-en/format-PDF/source-search

Javaid, M., & Haleem, A. (2020). Critical components of Industry 5.0 towards a successful adoption in the field of manufacturing. Journal of Industrial Integration and Management, 5(03), 327–348.

John, K. K., Adarsh, S. N., & Pattali, V. (2020). Workers to super workers: A brief discussion on important technologies for industry 5.0 manufacturing systems. In AIP conference proceedings (Vol. 2311, No. 1, p. 070025). AIP Publishing LLC.

Kagermann, H. (2015). Change through digitization—value creation in the age of Industry 40. In H. Albach, H. Meffert, A. Pinkwart, & R. Reichwald (Eds.), Management of permanent change. Springer.

Lee, J., Bagheri, B., & Kao, H. (2015). Research letters: A cyber-physical systems architecture for Industry 4.0-based manufacturing systems. Manufacturing Letters, 3, 18–23.

Longo, F., Padovano, A., & Umbrello, S. (2020). Value-oriented and ethical technology engineering in Industry 5.0: A human-centric perspective for the design of the factory of the future. Applied Sciences, 10, 4182.

Lopes de Sousa Jabbour, A. B., Jabbour, C. J. C., Godinho Filho, M., & Roubaud, D. (2018). Industry 4.0 and the circular economy: a proposed research agenda and original roadmap for sustainable operations. Annals of Operations Research, 270(1), 273–286.

Luthra, S., & Mangla, S. K. (2018). Evaluating challenges to Industry 4.0 initiatives for supply chain sustainability in emerging economies. Process Safety and Environment Protection, 117, 168–179.

Martynov, V. V., Shavaleeva, D. N., & Zaytseva, A. A. (2019, September). Information technology as the basis for transformation into a digital society and Industry 5.0. In 2019 International conference" Quality Management, Transport and Information Security, Information Technologies" (IT&QM&IS) (pp. 539–543). IEEE.

Nahavandi, N. (2019). Industry 5.0—A Human-Centric Solution. Sustainability, 11, 4371. https://doi.org/10.3390/su11164371

Nelles, J., Kuz, S., & Mertens, A. (2016). Human-centered design of assistance systems for production planning and control. In Conference: IEEE International Conference on Industrial Technology (ICET) Location: Taipei, TAIWAN Date: MAR 14–17, 2016. Institute of Electrical and Electronics Engineers; IEEE Industrial Electronics Society; National Taiwan University, Int Ctr Excellence Intelligent Robot & Automat Res. Proceedings of the IEEE international conference on industrial technology (ICIT) (pp. 21–2099).

Norton, M. (2001). Introductory concepts in information science, New Jersey

Özdemir, V., & Hekim, N. (2018). Birth of industry 5.0: Making sense of big data with artificial intelligence, “the internet of things” and next-generation technology policy. Omics: A Journal of Integrative Biology, 22(1), 65–76.

Østergaard, E. Industry 5.0—Return of the human touch. Retrieved February 15, 2022, from https://www.universal-robots.com/blog/industry-50-return-of-the-human-touch/

Pagoropoulos, A., Pigosso, D. C. A., & McAloone, T. C. (2017). The emergent role of digital technologies in the circular. Procedia CIRP, 64, 19–24.

Piątek, Z. (2018). Industry 5.0? Na kolejną rewolucję jest raczej zbyt wcześnie. Gospodarka. Retrieved May 5, 2021, from https://automatykab2b.pl/magazyn

Psst, E. A. (2021). These 9 sets of matching family pajamas are on sale for cyber Monday. Retrieved February 15, 2022, from https://www.forbes.com/sites/forbes-personal-shopper/2021/11/29/matching-family-pajamas/?sh=b8665353ba84

Ranghino, F. (2019). Industry 4.0 and environmental sustainability: good or bad news? Ambienta Sustainability Lens, 1–8.

Romero, D., Noran, O., Stahre, J., Bernus, P., & Fast-Berglund, A. (2015). Towards a human-centred reference architecture for next generation balanced automation systems: Human-automation symbiosis. In IFIP international conference on advances in production management systems (pp. 556–566). Cham: Springer.

Romero, D., Bernus, P., Noran, O., Stahre, J., & Fast-Berglund, Å. (2016). The operator 4.0: Human cyber-physical systems & adaptive automation towards human-automation symbiosis work systems. In IFIP international conference on advances in production management systems (pp. 677–686). Cham: Springer.

Ruppert, T., Jaskó, Sz., Holczinger, T., & Abonyi, J. (2018). Enabling technologies for Operator 4.0: A survey. Apply Science, 8, 1650. https://doi.org/10.3390/app8091650

Saniuk, S., Grabowska, S., & Gajdzik, B. (2020). Social expectations and market changes in the context of developing the Industry 4.0 concept. Sustainability, 12, 1362. https://doi.org/10.3390/su12041362

Scanlon, S. (2018). Now prepare for the 5th Industrial Revolution. Retrieved March 20, 2021, from https://gadget.co.za/now-prepare-for-the5th-industrial-revolution/

Schwab, K. (2017). The fourth industrial revolution. Retrieved May 28, 2021, from https://jmss.vic.edu.au/wp-content/uploads/2021/06/The_Fourth_Industrial_Revolution.pdf

Schwab, K. (2018). Czwarta rewolucja przemysłowa; Wydawnictwo Studio EMKA: Warszawa, Poland.

Shelzer, R. (2017). What is Industry 5.0—And how will it affect manufacturers. https://gesrepair.com/industry-5-0-will-affect-manufacturers/

Stock, T., & Seliger, G. (2016). Opportunities of sustainable manufacturing in Industry 4.0. Procedia CIRP, 40.

Terlau, W., & Hirsch, D. (2015). Sustainable consumption and the attitude-behaviour-gap phenomenon-causes and measurements towards a sustainable development. International Journal on Food System Dynamics, 6(3), 159–174.

The Next Industrial Revolution: Industry 5.0 and Discussions on Industry 4.0. Retrieved May 23, 2021, from https://www.researchgate.net/publication/336653504_The_Next_Industrial_Revolution_Industry_50_and_Discussions_on_Industry_40

Welfare, K. S., Hallowell, M. R., Shah, J. A., Riek, L. D. (2019, March). Consider the human work experience when integrating robotics in the workplace. In 2019 14th ACM/IEEE international conference on human-robot interaction (HRI) (pp. 75–84). IEEE.

Zhao, D., & Strotmann, A. (2015). Analysis and visualization of citation networks. Synthesis Lectures on Information Concepts, Retrieval, and Services, 7(1), 1–207. https://doi.org/10.2200/S00624ED1V01Y201501ICR039

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Grabowska, S., Saniuk, S. & Gajdzik, B. Industry 5.0: improving humanization and sustainability of Industry 4.0. Scientometrics 127, 3117–3144 (2022). https://doi.org/10.1007/s11192-022-04370-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11192-022-04370-1